The Role of AI in Machine Vision Model Training

Artificial intelligence (AI) plays a crucial role in advancing the model training machine vision system. It empowers these systems to automate complex tasks, improving their ability to identify patterns and detect objects with remarkable precision. You can rely on AI to make these systems faster and more efficient in decision-making processes. Through advanced machine vision technology, AI has transformed how machines learn and adapt to visual data. This shift has made vision-based applications more reliable and accessible across industries.

Key Takeaways

- AI labels data automatically, saving time and avoiding mistakes in vision systems.

- Smart algorithms find patterns better, helping with tasks like checking products and medical scans.

- AI speeds up training, making models faster to build and use in real-time.

- Transfer learning uses already-trained models, making training quicker and better with less data.

- Edge learning handles data nearby, improving quick decisions and keeping data safe.

How AI Transforms Model Training in Machine Vision Systems

Automating Data Labeling and Annotation

AI has revolutionized the way you handle data labeling and annotation in machine vision systems. Traditionally, labeling large datasets required significant manual effort. You had to assign labels to thousands of images, which was both time-consuming and prone to human error. AI simplifies this process by automating the labeling of images, ensuring consistency and accuracy.

For example, in a case study involving a toilet paper manufacturer, AI-powered vision inspection systems were implemented to detect defects. Quality engineers collaborated to label images accurately, which was critical for training the AI model. The system identified a 22% failure rate on one production line, uncovering a maintenance issue that had gone unnoticed. This demonstrates how AI not only automates data preparation but also enhances the overall efficiency of the model training process.

Enhancing Pattern Recognition and Object Detection

AI algorithms excel at recognizing patterns and detecting objects in visual data. By leveraging advanced learning techniques, these algorithms can identify intricate details that might escape the human eye. This capability is particularly valuable in applications like quality control, autonomous vehicles, and medical imaging.

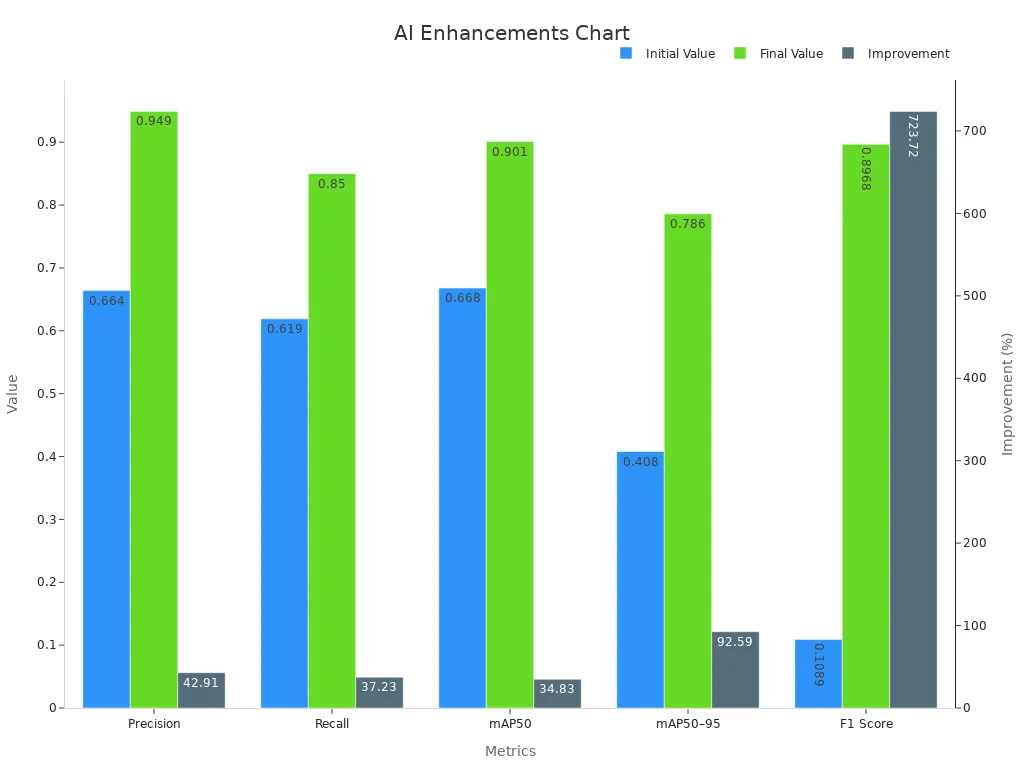

Quantitative metrics highlight the improvements AI brings to pattern recognition and object detection. For instance, a comparison of initial and final values in a machine vision system shows significant enhancements:

| Metric | Initial Value | Final Value | Improvement (%) |

|---|---|---|---|

| Precision | 0.664 | 0.949 | 42.91 |

| Recall | 0.619 | 0.850 | 37.23 |

| mAP50 | 0.668 | 0.901 | 34.83 |

| mAP50–95 | 0.408 | 0.786 | 92.59 |

| F1 Score | 0.1089 | 0.8968 | 723.72 |

These metrics demonstrate how AI-driven learning models significantly improve the precision and reliability of machine vision systems.

Optimizing Training Time with AI Algorithms

AI algorithms optimize the training process by reducing the time required to develop accurate models. Traditional methods often involved lengthy iterations and manual adjustments. With AI, you can leverage techniques like deep learning and transfer learning to accelerate the process. These methods allow pre-trained models to adapt to new datasets quickly, saving both time and computational resources.

For instance, edge learning enables on-device training, reducing the need for extensive cloud-based computations. This approach not only speeds up the training process but also minimizes latency, making it ideal for real-time applications. By optimizing training time, AI ensures that machine vision systems can be deployed faster and more efficiently.

Key AI Technologies in Model Training for Machine Vision Systems

Deep Learning and Neural Networks

Deep learning has become a cornerstone of machine vision model training. It allows you to uncover complex patterns in data that traditional methods often miss. Unlike older techniques, deep learning eliminates the need for manual feature engineering by automatically extracting relevant features from images. This makes it especially effective for handling large datasets and solving intricate problems.

For example, convolutional neural networks (CNNs) have revolutionized image recognition and classification. These networks learn directly from data, enabling them to identify objects and patterns with remarkable accuracy. Advanced models like ResNet-50 and YOLO have further enhanced the capabilities of machine vision systems. ResNet-50 allows for deeper neural networks, improving the complexity and precision of image classification tasks. YOLO, on the other hand, excels in real-time object detection, making it ideal for applications requiring speed and efficiency.

Deep learning also employs advanced training techniques like autoencoders and backpropagation. These methods minimize errors during training and improve prediction accuracy. By using non-linear functions, deep learning algorithms capture intricate patterns in visual data, ensuring superior performance in tasks like industrial image analysis and medical imaging.

Edge Learning for On-Device Model Training

Edge learning brings machine vision training closer to the source of data collection. Instead of relying on cloud-based systems, you can train models directly on devices equipped with an image acquisition system. This approach reduces latency and enhances real-time decision-making, making it ideal for applications like autonomous vehicles and smart manufacturing.

One of the key advantages of edge learning is its ability to optimize resource usage. By processing data locally, you minimize the need for extensive computational power and bandwidth. This not only speeds up the training process but also ensures data privacy and security. For instance, in industrial image analysis, edge learning enables machines to analyze images on-site, providing immediate feedback and reducing downtime.

Edge learning also supports incremental learning, where models continuously improve as they process new data. This adaptability makes it a powerful tool for dynamic environments where conditions change frequently. By leveraging edge learning, you can achieve faster and more efficient training while maintaining high levels of accuracy.

Transfer Learning for Faster and Efficient Training

Transfer learning has emerged as a game-changer in machine vision model training. Instead of starting from scratch, you can use pre-trained models to accelerate the training process. This approach saves time and computational resources while improving efficiency.

For example, researchers have used transfer learning to fine-tune pre-trained models like ResNet and VGG16 for specific tasks. In medical imaging, a pre-trained ResNet model significantly reduced training time while improving accuracy in classifying X-ray images. Similarly, during the COVID-19 pandemic, a fine-tuned VGG16 model enabled rapid and reliable diagnostics with limited training data.

Transfer learning also excels in industrial applications. In aluminum production, a transfer learning pipeline enhanced product quality predictions, demonstrating better accuracy and control. By leveraging knowledge from well-trained models, you can achieve superior performance in tasks like image relevancy ranking and automotive quality prediction.

This method is particularly effective when you have limited training data. By building on existing knowledge, transfer learning allows you to develop robust models quickly, making it an invaluable tool for machine vision systems.

Practical Benefits of AI in Machine Vision Model Training

Improved Accuracy and Reliability in Vision Tasks

AI significantly improves the accuracy and reliability of machine vision systems. By automating the analysis of visual data, AI reduces human biases and ensures consistent results. For example, AI algorithms applied to LiDAR data enhance the precision of object detection, minimizing the risk of misinterpretation. This capability is crucial in industries like autonomous vehicles and quality control, where even minor errors can have significant consequences.

AI also excels in identifying acceptable and unacceptable anomalies in images. Technologies like deep learning and edge learning simplify automation, making vision tasks more dependable. Real-time monitoring further enhances reliability, especially in dynamic environments where conditions change rapidly. These advancements ensure that machine vision systems deliver consistent and accurate results, even in challenging scenarios.

Scalability for Large-Scale Industrial Applications

AI enables machine vision systems to scale efficiently for industrial applications. By automating repetitive tasks, AI boosts productivity and reduces the need for manual intervention. According to industry reports, AI can increase productivity by up to 50% compared to human inspection. It also improves defect detection rates by up to 90%, ensuring higher product quality.

| Statistic Description | Value |

|---|---|

| Predicted boost in production by AI by 2035 | 40% |

| Increase in productivity compared to human inspection | Up to 50% |

| Improvement in defect detection rates | Up to 90% |

| Cost savings from predictive maintenance | Up to 40% |

| Reduction in downtime due to predictive maintenance | 50% |

| Increase in equipment lifetime | 20% to 40% |

These statistics highlight how AI-driven machine vision systems can handle large-scale operations without compromising efficiency or quality. By integrating AI, you can achieve scalability while maintaining high standards in production and inspection processes.

Cost and Time Efficiency in Model Development

AI reduces the cost and time required for model training and development. Traditional methods often involve extensive manual effort and high operational costs. AI automates repetitive tasks, saving time and reducing labor expenses. For instance, AI-powered systems require fewer hardware components, lowering the total cost of ownership.

| Feature | Firmware Machine Vision Systems | Traditional Systems |

|---|---|---|

| Total Cost of Ownership | Lower due to compact design | Higher due to external components |

| Initial Investment | Reduced hardware requirements | Requires additional hardware |

| Maintenance Expenses | Lower | Higher due to complexity |

| Speed | Faster processing, real-time detection | Slower due to external processing |

| Flexibility | Less flexible | More customizable |

AI also improves efficiency by enabling faster processing and real-time detection. This capability is particularly valuable in industries like manufacturing and healthcare, where quick decision-making is essential. By leveraging AI, you can develop machine vision models more cost-effectively and deploy them faster, ensuring a competitive edge in the market.

Overcoming Challenges in AI-Powered Machine Vision Systems

Addressing Data Privacy and Security Concerns

AI-powered machine vision systems face significant challenges in maintaining data privacy and security. You must ensure that sensitive data remains protected during the learning process. However, these systems often process large volumes of data, increasing the risk of breaches. Common issues include data leakage, overcollection, and bias. For example:

- Data leakage compromises the confidentiality of sensitive information.

- Overcollection infringes on privacy rights by gathering unnecessary data.

- Bias in training datasets leads to unfair decision-making.

To mitigate these risks, organizations like Microsoft and AWS have implemented responsible AI programs. Microsoft's Responsible AI Program emphasizes ethical principles, ensuring user data rights are respected. Similarly, AWS provides tools to promote fairness and privacy in AI systems. These initiatives demonstrate how you can adopt strategies to safeguard data integrity while advancing machine vision technologies.

Managing Computational and Hardware Limitations

Computational and hardware limitations often hinder the efficiency of machine vision systems. You need to optimize resources to handle complex learning tasks effectively. A recent study in Science critiques existing AI benchmarks, highlighting the need for granular evaluation methods. Aggregate metrics can obscure critical performance details, leading to biases and safety concerns.

| Aspect | Description |

|---|---|

| ML System Benchmarks | Evaluates computational infrastructure for AI workloads, focusing on performance metrics. |

| Metrics | Includes throughput, latency, and resource utilization for objective comparisons. |

| Insights | Guides infrastructure selection and system optimization based on workload efficiency. |

By understanding these benchmarks, you can select hardware architectures that enhance AI performance. Incremental improvements in hardware and software can help overcome these limitations, ensuring machine vision systems operate efficiently.

Adapting to Emerging Trends in AI and Machine Vision

Emerging trends in AI and machine vision are reshaping how you approach training and deployment. Generative AI is becoming mainstream, enabling synthetic data creation for tasks like object detection and facial recognition.

Over the next 12 months, synthetic data will minimize privacy risks and reduce training costs, making AI integration more practical.

Event-based imaging and AI-driven tools are also setting new benchmarks for efficiency and precision. These innovations improve quality assurance and process optimization, ensuring machine vision systems stay ahead of evolving demands. By adapting to these trends, you can leverage cutting-edge technologies to enhance learning and vision capabilities.

AI has become a transformative force in machine vision model training, driving advancements in automation, accuracy, and scalability. By leveraging technologies like deep learning, edge learning, and transfer learning, you can achieve faster and more efficient model development. These innovations ensure that machine vision systems remain reliable and adaptable across various industries.

| Key Takeaways | Description |

|---|---|

| Increased Accuracy Percentage | Drives model reliability, ensuring better performance in real-world tasks. |

| Reduced Training Times | Facilitates rapid experimentation, leading to quicker iterations and improvements. |

| Greater Scalability and Energy Efficiency | Enhances deployability of models in practical applications. |

| Tangible Cost Savings | Lowers operational costs and reduces error rates, making CNN models more viable. |

To maintain effectiveness, you should monitor performance metrics like distribution shifts and feature drift. Automated retraining processes help models adapt to changing data, ensuring their relevance and reliability. As AI evolves, its role in machine vision will continue to foster innovation and efficiency, shaping the future of visual data analysis.

FAQ

What is the role of AI in machine vision model training?

AI automates tasks like data labeling, pattern recognition, and object detection. It reduces manual effort and improves accuracy. By using advanced algorithms, AI helps you train models faster and more efficiently, making machine vision systems reliable for real-world applications.

How does transfer learning benefit machine vision systems?

Transfer learning allows you to use pre-trained models for new tasks. This saves time and resources by eliminating the need to train from scratch. It’s especially useful when you have limited data, enabling faster deployment and improved performance in specialized applications.

Can edge learning improve real-time decision-making?

Yes, edge learning processes data directly on devices instead of relying on cloud systems. This reduces latency and enhances real-time decision-making. It’s ideal for applications like autonomous vehicles and industrial automation, where immediate responses are critical.

What are the challenges of using AI in machine vision?

AI-powered systems face challenges like data privacy concerns, computational limitations, and adapting to emerging trends. You must address these issues by implementing ethical AI practices, optimizing hardware, and staying updated with the latest advancements in AI and machine vision.

How does AI improve scalability in industrial applications?

AI automates repetitive tasks, allowing machine vision systems to handle large-scale operations efficiently. It boosts productivity, reduces downtime, and ensures consistent quality. This scalability makes AI-driven systems suitable for industries like manufacturing, healthcare, and logistics.

See Also

Understanding How Machine Vision Guides Robotics Development

An Overview of Computer Vision Models and Systems

The Impact of Deep Learning on Machine Vision Technology

Investigating the Use of Synthetic Data in Machine Vision

Key Insights on Transfer Learning for Machine Vision Applications