AI-Based Visual Inspection for Quality Assurance in 2025

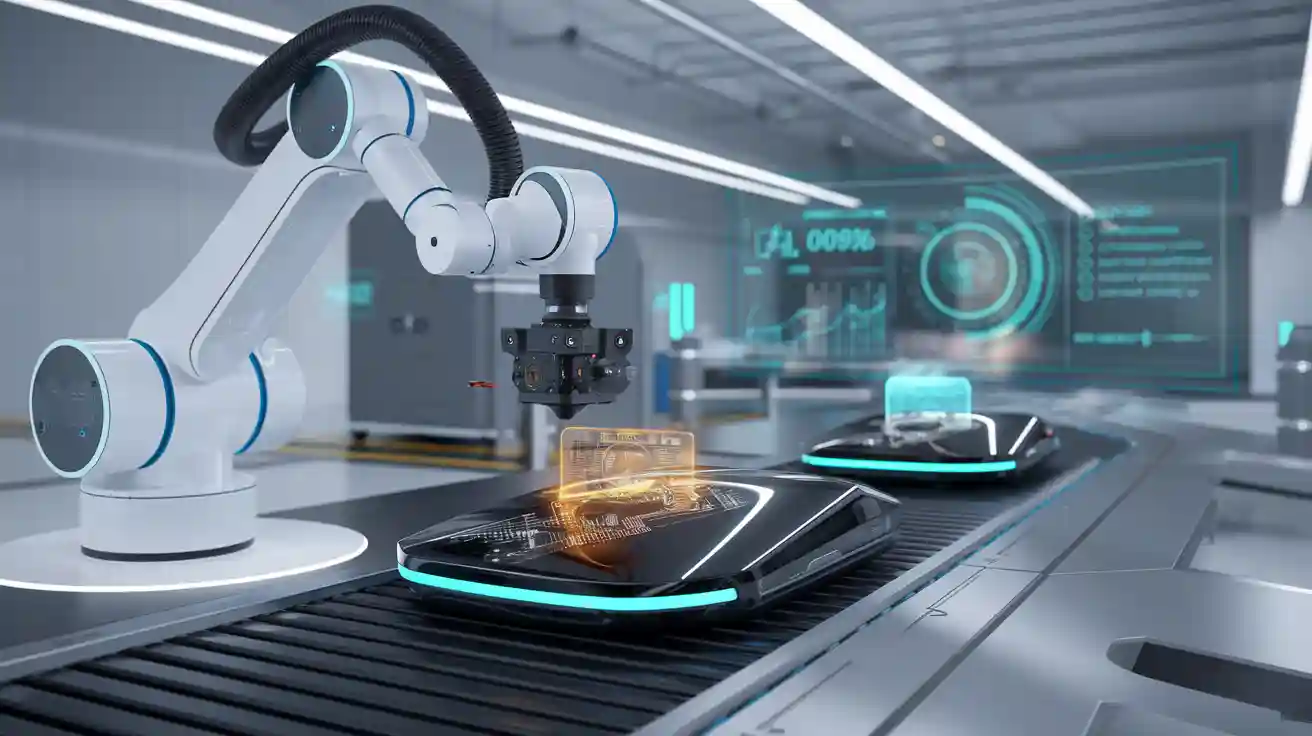

AI-based visual inspection machine vision systems are reshaping how industries approach quality assurance. These systems leverage advanced algorithms to detect defects and ensure precision. AI achieves superhuman results, reducing escape rates and uncovering issues that traditional methods often miss. By analyzing multi-modal datasets, it accelerates root cause analysis, making quality control faster and more reliable.

The transformative impact of AI-powered visual inspection is undeniable. The global market reached $4.13 billion in 2024 and is expected to grow significantly, adding $12 billion in revenue by 2033. With accuracy levels reaching up to nine decimal places, industries like automotive and healthcare are adopting these systems rapidly. By 2025, AI will redefine inspection processes, ensuring higher standards across sectors.

Key Takeaways

- AI-powered inspection systems find tiny flaws to improve quality checks.

- Using machines lowers worker costs and boosts work speed, saving money.

- These systems can grow and change, fitting many industries like factories or hospitals.

- Fast data and smart cameras make checks quicker and more trustworthy, fixing problems right away.

- Spending on AI inspection tools can pay off well, helping businesses save a lot of money.

Understanding AI-Based Visual Inspection Machine Vision Systems

AI-based visual inspection machine vision systems are revolutionizing how industries ensure product quality. These systems combine artificial intelligence with advanced imaging technologies to detect defects, improve efficiency, and maintain high standards. To understand their impact, you need to explore their core components, processes, and the role of machine vision systems.

Core Components of AI-Based Visual Inspection

Every AI-based visual inspection machine vision system relies on three essential components to function effectively:

| Component | Description |

|---|---|

| Feeding system | Spreads items evenly and moves them at a constant speed for the optical system to capture frames. |

| Optical system | Includes a lighting source and a sensor (digital camera) to capture images for analysis. |

| Separation system | Removes defective items and categorizes products based on quality. |

The feeding system ensures smooth and consistent movement of items, allowing the optical system to capture high-quality images. The optical system, equipped with advanced lighting and cameras, provides the visual data needed for analysis. Finally, the separation system automates defect detection and sorting, ensuring only high-quality products move forward.

How AI Visual Inspection Works: Key Processes

AI visual inspection involves several key processes that enable precise defect detection automation. First, the system captures images of products using its optical system. These images undergo analysis through computer vision AI algorithms, which identify defects, irregularities, or deviations from quality standards. The system then categorizes products based on their quality and triggers corrective actions if necessary.

This process offers several advantages:

- Enhanced accuracy and reduced human error. AI ensures 100% inspection coverage, scanning every side of a product.

- Cost efficiency and long-term savings. Automation reduces labor costs and minimizes rework expenses.

- Scalability without compromising speed or quality. AI systems handle increased production volumes while maintaining precision.

- Proactive risk mitigation. Real-time alerts allow you to address issues immediately, preventing larger problems.

By combining these processes, AI-powered visual inspection delivers unmatched efficiency and reliability.

Role of Machine Vision Systems in AI-Powered Inspection

Machine vision systems play a critical role in enabling AI-powered visual inspection. These systems process hundreds of units per minute, acquiring and analyzing images in less than 20 milliseconds. This speed ensures real-time inspection capabilities, which are essential for industries with high production demands.

The benefits of machine vision systems include:

- Over 99% accuracy in identifying defects.

- Object detection accuracy of 98.5%, reducing false positives.

- Inspection accuracy improvements of 94%, with inspection time reduced by 40%.

- Significant reductions in material waste and false positives, leading to measurable ROI within six months.

Machine vision systems combine speed, precision, and reliability, making them indispensable for modern inspection processes. By integrating these systems, you can achieve higher product quality and customer satisfaction.

Benefits of AI-Based Visual Inspection for Quality Assurance

Enhanced Accuracy and Defect Detection Rates

AI-powered visual inspection systems deliver unparalleled accuracy in defect detection. These systems use advanced algorithms and AI image processing to identify even the smallest irregularities that human inspectors might overlook. By automating defect detection, you can achieve consistent and objective results, eliminating the variability caused by human error. For example, AI defect detection systems can scan every product with precision, ensuring no defect goes unnoticed.

Industries worldwide have already experienced significant improvements in inspection accuracy. For instance, Siemens reported a 30% increase in inspection accuracy, while Foxconn achieved an 80% improvement in defect detection rates. In the automotive sector, a parts manufacturer in Japan reached a 95% defect detection rate, reducing labor costs by 30%. These results demonstrate how AI-based visual inspection systems enhance quality assurance across diverse applications.

| Industry | Improvement Description |

|---|---|

| Packaging Manufacturer (US) | 50% reduction in inspection time, 10% reduction in labor costs |

| Semiconductor Manufacturer (Taiwan) | 10% reduction in scrap rates, 50% increase in throughput |

| Automobile Parts Manufacturer (Japan) | 30% reduction in labor costs, 95% defect detection rate |

| BMW Dingolfing Plant (Germany) | Reduced accidents and injuries, increased efficiency through safety monitoring |

| Foxconn | 30% reduction in inspection time, 80% improvement in accuracy |

| GE | 25% reduction in inspection time, 30% reduction in manufacturing costs |

| Siemens | 30% increase in inspection accuracy, 50% reduction in inspection time |

These examples highlight how AI visual inspection systems improve accuracy and efficiency, making them indispensable for modern quality assurance.

Efficiency Gains and Cost Reduction

AI-powered visual inspection systems offer significant efficiency improvements and cost savings. By automating quality inspection processes, you can reduce labor costs and increase productivity. AI models trained with minimal images ensure precise defect detection, minimizing costly reviews and rework. Additionally, near-zero false positives reduce unnecessary inspections, saving time and resources.

Continuous operations enabled by AI systems boost throughput without compromising quality. For example, Foxconn reduced inspection time by 30%, while GE achieved a 25% reduction in inspection time and a 30% decrease in manufacturing costs. These efficiency improvements allow you to meet growing demand while maintaining high standards.

Other benefits include:

- High accuracy with no human error, ensuring consistent results.

- Labor savings through reduced personnel requirements.

- Increased productivity by eliminating downtime and bottlenecks.

By adopting AI-powered visual inspection, you can streamline operations, lower costs, and enhance overall efficiency.

Scalability Across Diverse Industries

AI-based visual inspection systems are highly scalable, making them suitable for various industries. From manufacturing to healthcare, these systems adapt to different environments and production scales. The global market for AI visual inspection systems is projected to grow from $1.2 billion in 2023 to $4.5 billion by 2032, with a compound annual growth rate (CAGR) of 15.8%. This growth reflects the increasing adoption of AI-powered solutions across sectors.

AI systems can enhance productivity by up to 50% and improve defect detection rates by up to 90%. For example, a semiconductor manufacturer in Taiwan increased throughput by 50%, while a packaging company in the US reduced inspection time by 50%. By 2035, AI is expected to boost production by 40%, according to a PWC analysis.

Key advantages of scalability include:

- Seamless integration into existing workflows.

- Flexibility to handle varying production volumes.

- Consistent performance across different industries.

With AI-based visual inspection, you can future-proof your operations and stay competitive in a rapidly evolving market.

Challenges in AI-Based Visual Inspection Implementation

Implementing AI-based visual inspection systems comes with its own set of challenges. While these systems promise significant benefits, you must address several hurdles to ensure successful deployment.

Data Requirements and Model Training

AI systems rely heavily on high-quality data for effective defect detection automation. To train a reliable model, you need a comprehensive dataset of labeled images that represent both defective and non-defective products. Data augmentation techniques can help enhance the dataset's variety, making the model more robust. However, ensuring the dataset's validity, compliance, and representativeness is critical to avoid biased or inaccurate results.

| Metric | Description |

|---|---|

| Validity | Ensures data credibility by checking for invalid values that can distort analytics. |

| Compliance | Ensures AI systems adhere to relevant rules and regulations for ethical use. |

| Representativeness | Ensures datasets reflect real-world concerns to avoid biased AI systems. |

Once you collect the data, you must train the model using techniques like cross-validation and evaluate its performance using metrics such as accuracy, precision, recall, and F1-score. This process requires specialized skills, which can be a barrier for many organizations.

Integration with Legacy Systems

Integrating AI-based visual inspection into existing workflows can be complex. Many manufacturers rely on legacy systems that were not designed to accommodate modern AI technologies. This mismatch often leads to compatibility issues, requiring significant time and resources to resolve. You may need to upgrade hardware, reconfigure software, or even redesign workflows to ensure seamless integration.

Tip: Start with a pilot project to test the integration process before scaling up. This approach helps identify potential issues early and minimizes disruptions.

Cost and ROI Considerations

The initial investment for AI-based visual inspection systems can be substantial. For example, the first-year cost, including hardware, software, and integration, often exceeds $460,000. Ongoing costs, such as maintenance and updates, add another $60,000 annually. However, the potential savings are equally significant. Many industries report annual benefits of $300,000 or more from reduced scrap and labor costs, leading to a payback period of about two years.

In the automotive sector, BMW reduced inspection time by 30% and defect rates by 25%, achieving measurable cost savings. Similarly, food processing companies have seen a 90% reduction in inspection time and a 50% decrease in product waste. These examples highlight the long-term financial benefits of adopting AI-powered quality inspection automation.

While the upfront costs may seem daunting, the return on investment often justifies the expense. Careful planning and a phased implementation strategy can help you maximize the value of your investment.

Future Trends in AI Visual Inspection by 2025

Advancements in Deep Learning and Real-Time Analytics

Deep learning continues to drive innovation in ai-powered visual inspection. Convolutional neural networks (CNNs) have improved defect detection rates significantly. For example, models trained with augmented datasets identified 65% of previously unseen good units, showcasing their ability to adapt to new scenarios. AI algorithms now offer greater customization, allowing you to tailor visual inspection systems to meet specific industry needs.

Real-time analytics enhances inspection processes by reducing latency and enabling immediate decision-making. Multimodal sensing technologies, which combine data from various sources, improve defect detection across diverse environments. These advancements ensure that ai-based visual inspection machine vision systems remain accurate and efficient, even in challenging conditions.

Note: Continuous improvements in AI algorithms make quality inspection automation more reliable, helping you achieve higher standards in defect detection and quality control.

Broader Industry Adoption of AI-Based Visual Inspection

The adoption of ai visual inspection technology is expanding rapidly across industries. Analysts predict strong growth in the market, driven by the need for cost-effective quality control solutions and automation. Manufacturing sectors benefit from automated optical inspection systems that streamline processes and reduce costs.

In the automotive industry, ai defect detection systems ensure the safety and functionality of vehicle parts. Healthcare applications include diagnostic tools that analyze medical images, such as radiology scans, to detect diseases early. These examples highlight how ai-powered visual inspection transforms industries by improving accuracy and efficiency.

Integration of Edge Computing and Cloud Technologies

Edge computing and cloud technologies are revolutionizing automated visual inspection systems. Edge-based solutions process visual data on-site, reducing latency and enabling real-time decision-making. For instance, smart factories use edge AI to inspect products and enhance quality control.

Cloud integration complements edge computing by providing scalable storage and advanced analytics. Intelligent Video Analytics (IVA) leverages computer vision AI techniques, such as CNNs, to analyze video streams in real-time. This combination of edge and cloud technologies ensures turnkey visual inspection systems deliver faster and more accurate results.

Unifying these technologies allows you to implement proactive problem-solving strategies, such as anomaly detection, while maintaining high inspection standards.

AI-powered visual inspection systems are transforming quality assurance across industries. These systems offer unmatched accuracy, detecting even the smallest defects while reducing human error and bias. They operate continuously, ensuring consistent inspection results and minimizing downtime. By processing large volumes of visual data quickly, they increase production rates and reduce costs associated with rework and recalls.

| Benefit/Challenge | Description |

|---|---|

| Unmatched Accuracy in Defect Detection | AI systems detect even the smallest defects, ensuring higher quality control. |

| Augmented Effectiveness | AI can process large amounts of visual data quickly, increasing production rates. |

| Expense Reduction | Reduces costs associated with rework and recalls, minimizing human error. |

| Innovation Through Industry Overlap | Applicable across various industries, fostering growth and advancement. |

| Exploitable Loopholes for Quality Advancement | AI systems provide data for analyzing defects, improving production cycles. |

| Business Practices and Legal Risk Supervision | Ensures compliance with safety regulations, reducing legal risks. |

| Reduced Human Error and Bias | AI eliminates fatigue and bias, ensuring consistent inspection accuracy. |

| 24/7 Operational Ability | AI systems operate continuously, maintaining quality without breaks. |

These systems have already demonstrated remarkable results, including a 94% reduction in defect escape rates, a 99.7% detection accuracy for critical defects, and an 85% decrease in customer complaints. Industries report annual savings of $1.8 million in quality-related costs and a return on investment of 280% within the first year.

By 2025, AI-powered visual inspection will revolutionize quality assurance, enabling businesses to achieve higher standards and greater efficiency. Adopting these systems ensures you stay competitive in a rapidly evolving market.

FAQ

What is AI-based visual inspection?

AI-based visual inspection uses artificial intelligence to analyze images or videos of products. It detects defects, irregularities, or quality issues automatically. This technology ensures higher accuracy and faster inspection compared to manual methods.

How does AI improve defect detection?

AI analyzes visual data with advanced algorithms. It identifies even the smallest defects that human inspectors might miss. This ensures consistent quality control and reduces errors in production.

Can AI-based visual inspection work with existing systems?

Yes, AI-based visual inspection can integrate with most existing systems. However, you may need to upgrade some hardware or software to ensure compatibility and optimal performance.

Is AI-based visual inspection cost-effective?

While the initial investment can be high, AI-based visual inspection reduces long-term costs. It minimizes labor expenses, prevents product recalls, and improves efficiency, offering a strong return on investment.

Which industries benefit most from AI-based visual inspection?

Industries like manufacturing, automotive, healthcare, and electronics benefit significantly. AI ensures precise quality control, faster production, and reduced waste, making it ideal for sectors with high standards.

See Also

Exploring Machine Vision Systems for Inspections in 2025

Harnessing AI Tools for Effective Visual Inspection

Enhancing Quality Control in Manufacturing with AI in 2025

Determining ROI for Automated Visual Inspection Systems in 2025

Improving Product Quality with Surface Inspection Vision Systems