A Beginner's Guide to Vision System Calibration Software

Calibration software for a machine vision system plays a crucial role in aligning the digital images captured by cameras with real-world measurements. By using calibration software, a machine vision system can ensure accurate interpretation of objects and their dimensions. Without proper calibration, the system may experience image distortions, leading to incorrect object detection or measurement errors.

You might ask why calibration software for a machine vision system is so essential. The answer lies in the precision it provides. For example:

- Calibrated systems can maintain accuracy within 1% over 10,000 cycles.

- When properly calibrated, robotic vision systems can achieve up to 99.9% object detection accuracy in controlled environments.

With these impressive results, calibration software becomes indispensable for ensuring consistent and reliable performance in any machine vision system.

Key Takeaways

- Calibration software helps machines see images correctly. It fixes errors and matches sizes to real-world measurements.

- Recalibrating often keeps the system working well. Check it every 6 to 12 months, or sooner for busy systems.

- Pick the right calibration type for your needs. Simple calibration is easier, but advanced calibration fixes tricky errors for better accuracy.

- Use good-quality equipment for better results. Cameras, lenses, and sensors that fit well give dependable outcomes.

- Use calibration tools to make work easier. Automation saves time, cuts costs, and follows industry rules.

Basics of Machine Vision System Calibration

How machine vision systems create digital images

Machine vision systems rely on advanced technology to convert real-world objects into digital images. This process involves several key steps:

- Image acquisition: A digital camera or sensor captures a representation of an object.

- Image processing: The captured image undergoes enhancement to optimize its quality.

- Image analysis: Features within the image are analyzed to extract useful information, such as dimensions or patterns.

- Results processing: The extracted data is sent to automated systems for further action, such as sorting or quality control.

The type of sensor used plays a significant role in image creation. For example:

- Global shutter sensors capture all pixels simultaneously, making them ideal for high-speed applications.

- Rolling shutter sensors capture images line by line, which can cause distortions if the object moves quickly.

Additionally, factors like quantum efficiency and adherence to the EMVA 1288 standard ensure sensors perform optimally. These standards help you compare sensor performance across different models, making it easier to choose the right one for your needs.

The importance of calibration in correcting distortions

Calibration is essential for ensuring the accuracy of machine vision systems. Without it, images may suffer from distortions, such as curved lines appearing straight or objects being misaligned. Proper calibration corrects these issues, allowing the system to interpret images with precision.

For example, a proposed calibration method reduced the root-mean-square deviation of distorted straight lines from 23–65 pixels to approximately 1 pixel. This improvement highlights how calibration enhances image accuracy, making it indispensable for applications requiring high precision.

By calibrating your system, you can also address challenges like lens distortion, misaligned sensors, or environmental factors that affect image quality. This ensures your machine vision system performs reliably, even in demanding conditions.

Real-world applications of calibrated systems

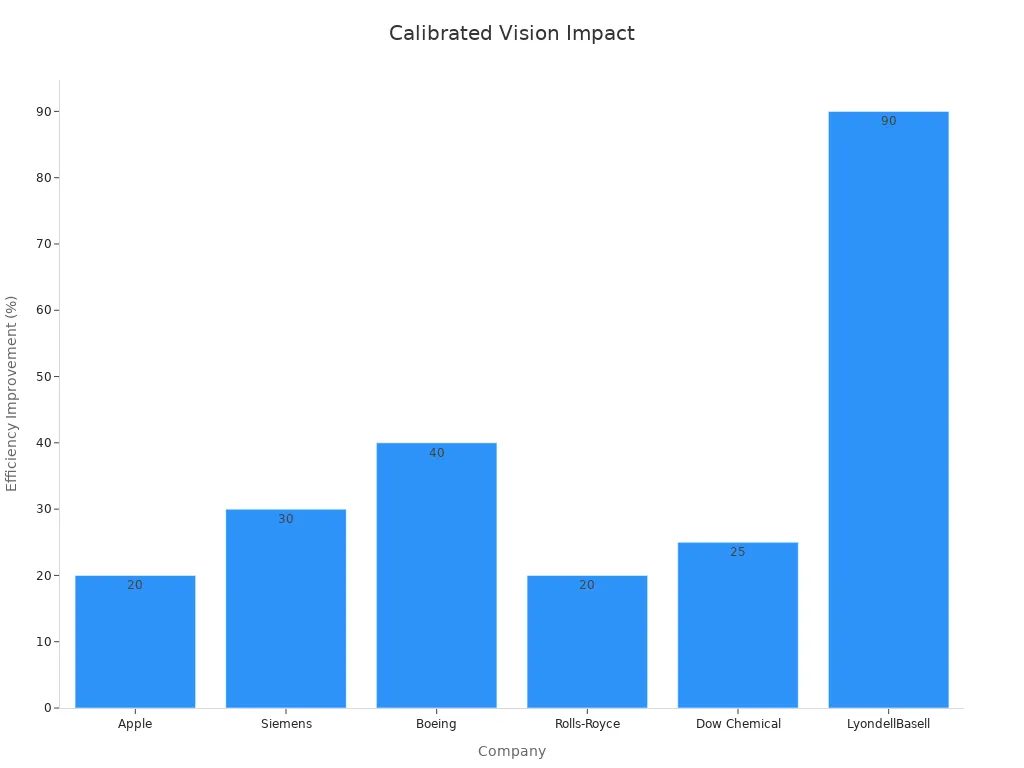

Calibrated machine vision systems play a critical role in various industries. They improve efficiency, reduce waste, and enhance accuracy. Here are some examples:

| Industry | Company | Energy Reduction | Waste Reduction | Efficiency Improvement |

|---|---|---|---|---|

| Electronics | Apple | 35% | N/A | 20% |

| Electronics | Siemens | N/A | 50% | 30% |

| Aerospace | Boeing | 25% | N/A | 40% |

| Aerospace | Rolls-Royce | N/A | N/A | 20% |

| Chemical | Dow Chemical | N/A | 40% | 25% |

| Chemical | LyondellBasell | 35% | N/A | 90% |

One case study highlights the calibration of an omnidirectional vision system for a robotics sorting system. After calibration, the measurement error for obstacle distances dropped to less than 0.5% for synthetic data and less than 1.6% for real data. Additionally, the calibration process reduced computation time by 12%.

These examples demonstrate how calibration not only improves accuracy but also enhances operational outcomes across industries. By investing in proper calibration, you can achieve similar benefits in your applications.

Types of Calibration Methods

Linear calibration: Overview and benefits

Linear calibration is one of the simplest methods used in machine vision systems. It assumes that the relationship between the camera's input and output is linear. This method works well when the system operates in controlled environments with minimal distortions. You can use linear calibration to correct basic alignment issues or scale errors in your system.

One of its key benefits is its ease of implementation. Linear calibration requires fewer data points, making it faster to set up. It also consumes less computational power, which is ideal for systems with limited processing capabilities. For example, if you are working with a conveyor belt system where objects move in a straight line, linear calibration can provide reliable results without unnecessary complexity.

Non-linear calibration: Overview and benefits

Non-linear calibration addresses more complex distortions that linear methods cannot handle. It accounts for factors like lens distortion, curved surfaces, or irregular object shapes. This method uses advanced mathematical models to map the relationship between the camera and the real-world scene.

Non-linear calibration is particularly useful in applications where precision is critical. For instance, in robotics, it helps ensure that a robotic arm can accurately pick up objects, even if they are positioned at odd angles. Although this method requires more data and processing power, it delivers higher accuracy. You can rely on non-linear calibration when working with wide-angle lenses or systems that operate in dynamic environments.

Key differences between linear and non-linear methods

The main difference between these two methods lies in their complexity and application. Linear calibration is straightforward and works best in simple setups. Non-linear calibration, on the other hand, handles intricate distortions and delivers greater precision.

A study comparing eight calibration methods revealed that many methods, including linear ones, show significant variations in intrinsic parameters when the camera is slightly displaced. Non-linear methods, while more stable, require more computational resources. This highlights the importance of choosing the right method based on your system's needs.

By understanding these differences, you can select the calibration method that best suits your application. Whether you prioritize simplicity or precision, the right choice will enhance your system's performance.

Factors Influencing Calibration Accuracy

Hardware considerations in machine vision systems

The hardware you choose for your machine vision system significantly impacts calibration accuracy. Cameras, lenses, and sensors must work together seamlessly to produce reliable results. For instance, studies comparing marker-based motion capture systems revealed that calibration procedures could achieve a mean error of just 0.5 degrees in dynamic setups. However, angular displacement differences between systems ranged from 0.1 to 2.0 degrees, highlighting the importance of selecting compatible hardware.

To improve repeatability, you should ensure that your system uses high-quality components. A poorly aligned lens or a low-resolution camera can introduce systematic biases, such as errors ranging from -0.54 to 0.19 degrees. By investing in robust hardware, you can enhance both repeatability and accuracy in your calibration process.

Environmental conditions affecting calibration

Environmental factors, such as temperature, lighting, and vibrations, can disrupt calibration accuracy. For example, fluctuating temperatures may cause materials to expand or contract, altering the alignment of your system. Similarly, inconsistent lighting can create shadows or glare, making it harder for the system to interpret images correctly.

Research shows that incorporating differentials in calibration models can improve accuracy by aligning data more effectively. Using auxiliary data, such as sensor outputs, can also help compute correction coefficients, ensuring your system adapts to environmental changes. By controlling these variables, you can maintain repeatability and achieve consistent results.

Imaging parameters and their impact on accuracy

Imaging parameters, such as resolution, frame rate, and exposure time, play a crucial role in calibration. Higher resolution improves the system's ability to detect fine details, while an optimized frame rate ensures smooth image capture. However, improper settings can lead to errors.

Experimental results demonstrate that advanced calibration methods can reduce reprojection errors by 42.7% and computation time by over 80%. These improvements highlight the importance of fine-tuning imaging parameters to enhance accuracy. By adjusting these settings, you can achieve better repeatability and accuracy in your machine vision system.

Practical Strategies for Calibration

Real-time calibration techniques for dynamic systems

Real-time calibration is essential for systems operating in dynamic environments. These systems, such as robotic arms or autonomous vehicles, require continuous adjustments to maintain accuracy. Real-time calibration ensures that your machine vision system adapts to changes in motion, lighting, or object positioning without interrupting operations.

Several studies have evaluated the performance of real-time calibration techniques. For instance:

- Research comparing six hand-eye calibration algorithms revealed that their accuracy depends on factors like rotation noise and motion.

- The method developed by Park and Martin achieved the best computation time and second-best accuracy.

- Daniilidis and Bayro-Corrochano's methods provided the highest accuracy in relative pose error.

These findings highlight the importance of selecting the right algorithm for your system. You can improve performance by choosing methods tailored to your specific conditions. For example, if your system experiences frequent rotational motion, opt for an algorithm that excels under such conditions.

To implement real-time calibration effectively, consider using advanced sensors and software tools. These tools can process data quickly, enabling your system to adjust in milliseconds. This approach minimizes errors and ensures consistent performance, even in fast-paced environments.

Periodic validation and recalibration processes

Periodic validation and recalibration are critical for maintaining the long-term accuracy of your machine vision system. Over time, factors like hardware wear, environmental changes, or software updates can affect calibration. Regular checks help you identify and correct these issues before they impact performance.

A well-structured recalibration process involves several steps:

- Schedule routine checks: Set intervals based on your system's usage and environment.

- Use reference objects: Validate accuracy by comparing measurements against known standards.

- Document results: Keep records of calibration data to track trends and identify recurring issues.

By following these steps, you can ensure your system remains reliable. For example, in an inspection line, periodic recalibration can prevent errors in detecting defects, improving overall quality control.

Recalibration also helps you comply with industry standards. Many sectors, such as aerospace or pharmaceuticals, require strict adherence to calibration schedules. By staying proactive, you can meet these requirements and avoid costly penalties.

Using calibration software tools and APIs effectively

Calibration software tools and APIs simplify the calibration process, making it more efficient and accurate. These tools automate tasks like data collection, analysis, and reporting, allowing you to focus on strategic improvements.

Using calibration software offers several benefits:

- It streamlines workflows by automating repetitive tasks.

- It improves efficiency by optimizing calibration intervals.

- It reduces costs by eliminating paper documentation and manual processes.

- It ensures compliance with industry standards by tracking calibration schedules.

For example, software tools can notify you when recalibration is due, helping you avoid missed deadlines. APIs, on the other hand, allow you to integrate calibration functions into your existing systems. This integration enables real-time tracking of key performance indicators, enhancing your system's overall performance.

To maximize these benefits, choose software tailored to your needs. Look for features like user-friendly interfaces, compatibility with your hardware, and robust data analysis capabilities. By leveraging these tools, you can enhance the quality and reliability of your machine vision system.

Calibration is the backbone of any reliable machine vision system. It ensures your system delivers accurate results, even in challenging conditions. Without proper calibration, you risk errors that could disrupt operations or reduce efficiency.

🛠️ Tip: Tailor your calibration software to your specific needs. Custom solutions often provide better accuracy and save time during implementation.

By prioritizing accurate calibration, you can improve long-term reliability and maintain consistent performance. Start investing in the right tools today to unlock the full potential of your machine vision system.

FAQ

What is the purpose of calibration software in machine vision systems?

Calibration software ensures your machine vision system interprets images accurately. It corrects distortions, aligns measurements with real-world dimensions, and improves precision. This process enhances the system's reliability and performance, especially in applications requiring high accuracy, such as robotics or quality control.

How often should you recalibrate your machine vision system?

You should recalibrate periodically based on your system's usage and environment. For most setups, recalibration every 6 to 12 months works well. However, dynamic systems or those in harsh conditions may require more frequent checks to maintain accuracy.

Can you use calibration software with any camera?

Most calibration software supports a wide range of cameras, but compatibility depends on the software and hardware. Check the software's specifications to ensure it works with your camera model. Using compatible tools ensures better results and smoother integration.

What are the signs that your system needs recalibration?

Look for signs like measurement errors, misaligned images, or inconsistent results. If your system struggles with accuracy or fails to meet performance standards, it likely needs recalibration. Regular validation helps you catch these issues early.

Is it difficult to learn how to use calibration software?

Most calibration software is user-friendly and designed for easy learning. Many tools include tutorials, guides, and support resources. With some practice, you can quickly master the basics and start improving your system's accuracy.

See Also

Essential Tips for Equipment Placement in Vision Systems

Understanding Machine Vision for Enhanced Industrial Automation

Fundamentals of Camera Resolution in Vision Systems