What You Need to Know About Computer Vision and Machine Vision

Computer vision and machine vision systems are revolutionizing industries by empowering machines to process and act on visual data. A computer vision machine vision system combines the ability to teach computers to analyze and interpret images or videos with the practical application of this technology in industrial environments. These systems are driving advancements in automation and AI by improving accuracy and efficiency. For instance, machine vision systems can identify defects that are undetectable to the human eye, while computer vision streamlines repetitive tasks in sectors like logistics and manufacturing. The computer vision machine vision system market is experiencing significant growth, with forecasts predicting it will reach $48.6 billion by 2032.

Key Takeaways

Computer vision helps machines understand pictures, like how people see. It is used in things like face recognition and self-driving cars.

Machine vision focuses on factory work, making tasks faster and more exact. It checks products quickly, helping factories work better.

Using computer vision with machine vision makes work more accurate. This teamwork allows better checking and faster results, saving money.

Fields like healthcare, stores, and factories gain a lot from these tools. They help find health problems, manage stock, and check product quality.

The use of computer and machine vision is growing fast. Learning about these tools can help you use them well.

Understanding Computer Vision

Definition and Core Concepts

Computer vision enables machines to interpret and analyze visual data, such as images or videos, by mimicking human vision. At its core, it treats images as grids of numbers, where each pixel holds a numerical value. These values allow computers to perform operations like adjusting brightness or detecting patterns. For example, multiplying pixel values can enhance image clarity, while algorithms identify objects or faces within an image. This foundational concept powers many modern applications, from facial recognition to autonomous vehicles.

Applications Across Industries

Computer vision is transforming industries by automating processes and improving decision-making. Here are some key applications:

Retail and E-commerce: Systems track inventory, analyze customer behavior, and enable virtual try-ons.

Healthcare: AI-powered tools analyze medical images, aiding in early disease detection.

Manufacturing: Machines inspect products for defects and monitor equipment for maintenance.

Transportation: Autonomous vehicles use computer vision for navigation and obstacle detection.

Agriculture: Drones equipped with computer vision assess crop health and optimize farming practices.

The global market for computer vision is projected to reach $82.1 billion by 2032, growing at a CAGR of 18.7%. Companies like Google, Intel, and Microsoft are leading this technological revolution.

Industry | Applications | Key Players |

|---|---|---|

Retail and E-Commerce | Inventory management, virtual try-ons | Google, Amazon Web Services |

Healthcare | Diagnostic imaging, surgery | Microsoft, Texas Instruments |

Manufacturing | Quality control, automation | KEYENCE CORPORATION, Cognex Corp. |

Transportation | Autonomous driving, logistics | Intel, Mobileye |

Examples of Computer Vision in Practice

Computer vision is already making a significant impact in real-world scenarios:

Healthcare: AI algorithms analyze X-rays and MRIs, improving early disease detection and patient outcomes.

Autonomous Vehicles: Cars use computer vision to recognize road signs, detect obstacles, and enhance safety.

Retail: Stores monitor customer behavior and optimize inventory, reducing theft and increasing satisfaction.

Agriculture: Drones equipped with cameras monitor crops, leading to higher yields and better resource management.

These examples highlight how computer vision machine vision systems are driving innovation across sectors, improving efficiency and accuracy in ways that were previously unimaginable.

Exploring Machine Vision Systems

Definition and Core Concepts

Machine vision systems allow machines to "see" and interpret visual data in industrial environments. These systems use cameras, sensors, and software to capture and analyze images. Unlike computer vision, which focuses on broader applications, machine vision is tailored for industrial automation. It emphasizes speed, precision, and reliability. For example, a machine vision system can inspect thousands of products per hour, ensuring quality standards are met.

Machine vision systems often rely on smart cameras and deep learning algorithms. These tools enable real-time decision-making, such as identifying defective items on a production line. The software processes visual data to detect patterns, measure dimensions, and classify objects. This capability makes machine vision essential for industries that demand high accuracy and efficiency.

Applications in Industrial Automation

Machine vision plays a critical role in automating industrial processes. It enhances production efficiency and reduces labor costs. Here are some key benefits:

Benefit | Description |

|---|---|

Production Efficiency | Detects defects in real-time, ensuring products meet quality standards. |

Labor Cost Reduction | Automates manual inspection tasks, freeing workers for more complex activities. |

Real-time Monitoring | Provides immediate insights into production performance, enabling quick issue resolution. |

Data Analysis and Optimization | Extracts insights from visual data to optimize manufacturing operations and reduce inefficiencies. |

Safety and Compliance | Monitors environments to ensure safety standards and regulatory compliance are met. |

The food and beverage industry is a prime example. Machine vision ensures compliance with safety regulations by inspecting packaging and labeling. This segment is projected to grow at a 12% CAGR from 2024 to 2029. Similarly, the U.S. market is expected to expand at over 12% CAGR from 2025 to 2030, driven by advancements in technology and automation.

Examples of Machine Vision Systems in Action

Machine vision systems have transformed industrial operations. They reduce quality assurance labor costs by approximately 50%. Vision-guided robots handle up to 10,000 parts per hour in high-speed environments. Deep learning-based systems improve classification accuracy by 20% compared to traditional methods.

Incorporating 3D machine vision with automation systems enhances data capture and production speed. For instance, these systems automate quality control, ensuring products meet client requirements. They also optimize resource management, reducing waste and increasing profitability. By improving safety and throughput, machine vision minimizes human intervention in critical steps, making industrial processes more efficient and reliable.

The integration of machine vision with computer vision machine vision systems demonstrates how these technologies complement each other. Together, they drive innovation and efficiency across industries.

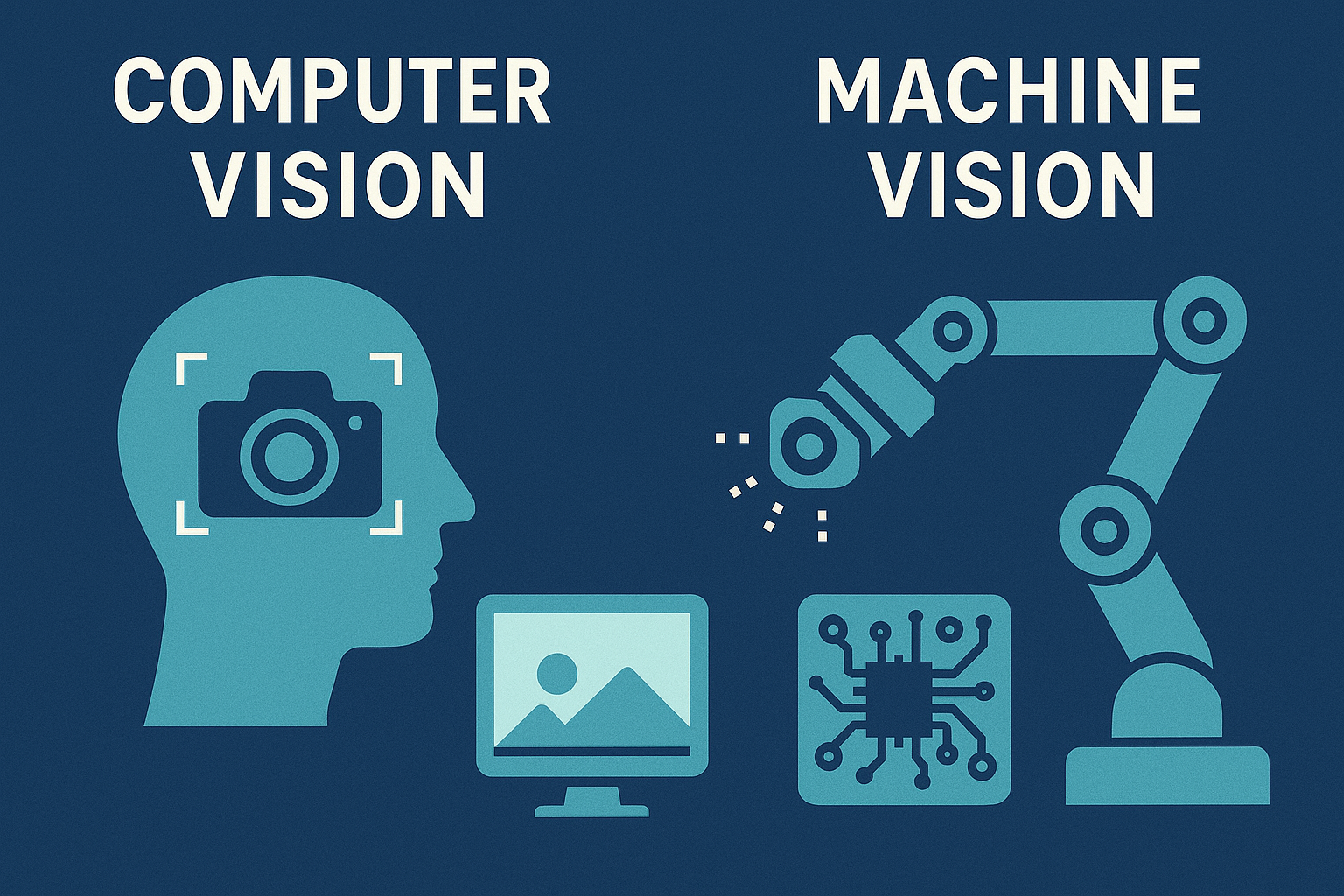

Key Differences Between Computer Vision and Machine Vision Systems

Processing Capabilities and Complexity

When comparing computer vision and machine vision systems, you’ll notice differences in how they process visual data. Computer vision focuses on analyzing images and videos. It uses algorithms to identify patterns, detect objects, and interpret visual information. This makes it highly versatile for tasks like facial recognition or medical imaging.

Machine vision, on the other hand, applies computer vision in industrial environments. It operates on predefined rules and parameters, making it more specialized. For example, a machine vision system might inspect thousands of products per hour on a production line, ensuring they meet quality standards.

Here’s a quick breakdown of their processing capabilities:

Computer vision automates image capture and analysis, focusing on extracting meaningful insights.

Machine vision enhances existing technologies with vision capabilities, often tailored for specific tasks like defect detection.

Both systems process data faster than human vision, but machine vision prioritizes speed and precision in industrial settings.

These differences highlight how each system serves unique purposes, depending on the complexity of the task and the environment in which it operates.

Real-Time vs Historical Data Analysis

Another key difference lies in how these systems handle data analysis. Machine vision excels in real-time analysis. It processes visual data instantly, making it ideal for tasks like monitoring production lines or ensuring safety in industrial environments. For example, it can detect defective items as they move through a conveyor belt, allowing immediate corrective action.

Computer vision, while capable of real-time analysis, often focuses on historical data. It uses techniques like heatmaps or anomaly detection algorithms to identify patterns over time. This makes it valuable for applications like studying customer behavior in retail or analyzing medical trends.

Analysis Type | Key Metrics/Techniques | Purpose |

|---|---|---|

Real-time Data Analysis | - Current number of people | Immediate situational awareness and safety management during events like health crises. |

Historical Data Analysis | - Statistical Anomaly detection algorithm | Identifying patterns and anomalies over time for proactive threat detection and resource allocation. |

By understanding these differences, you can choose the right system for your needs, whether it’s real-time monitoring or long-term data analysis.

Deployment Contexts and Use Cases

The deployment of computer vision and machine vision systems also varies significantly. Computer vision is versatile and finds applications in diverse fields like healthcare, retail, and transportation. For instance, it powers facial recognition in smartphones, assists in diagnosing diseases through medical imaging, and enables autonomous vehicles to navigate safely.

Machine vision, however, is more specialized. It’s primarily used in industrial automation, where precision and speed are critical. You’ll find it in factories inspecting products, guiding robotic arms, or monitoring equipment for maintenance. These systems are designed to work in controlled environments, ensuring consistent performance.

Here’s how their use cases differ:

Computer Vision: Ideal for applications requiring advanced image analysis and pattern recognition.

Machine Vision: Best suited for industrial tasks demanding high-speed, rule-based processing.

By combining these systems, industries can achieve greater efficiency and accuracy. For example, a computer vision machine vision system might analyze historical data to improve future production processes while ensuring real-time quality control on the factory floor.

How Computer Vision and Machine Vision Systems Work Together

Collaborative Use Cases in Industry

You might wonder how computer vision and machine vision systems collaborate in industries. These technologies often complement each other to enhance efficiency and accuracy. Here are some examples:

Predictive Maintenance: Computer vision monitors machinery for early signs of wear and tear. This helps prevent costly downtimes. Companies like Royal Dutch Shell and ExxonMobil use this approach to maintain their equipment.

Quality Inspection: Machine vision systems track production steps while computer vision detects anomalies. This ensures fewer defective items reach customers. A collaboration between Hepta Airborn and MindTitan showcases this use case.

Safety Enhancements: Computer vision integrates with security systems to detect suspicious activities. It also ensures compliance with safety protocols in industrial environments.

These collaborative use cases demonstrate how combining these technologies can solve complex challenges in industrial settings.

Benefits of Integration

When you integrate computer vision with machine vision systems, the benefits multiply. This combination allows industries to achieve higher levels of automation and precision. Some key advantages include:

Improved Accuracy: Machine vision excels at high-speed inspections, while computer vision adds advanced analysis capabilities. Together, they reduce errors significantly.

Enhanced Efficiency: By automating repetitive tasks, these systems free up human workers for more complex responsibilities. This leads to faster production cycles.

Cost Savings: Predictive maintenance and real-time monitoring minimize downtime and reduce repair costs.

Scalability: Integrated systems can adapt to different tasks, making them suitable for various industries.

For example, in manufacturing, an integrated system might inspect products for defects while analyzing historical data to improve future processes. This dual functionality boosts productivity and ensures consistent quality.

Examples of Combined Systems in Real-World Applications

Real-world examples highlight the transformative potential of combining computer vision and machine vision systems.

Automotive Industry: Autonomous vehicles rely on this integration to navigate roads safely. Machine vision handles real-time obstacle detection, while computer vision processes complex data like traffic patterns.

Healthcare: Hospitals use integrated systems to analyze medical images. Machine vision identifies abnormalities, while computer vision provides detailed insights for diagnosis.

Retail: Stores combine these technologies to monitor inventory and analyze customer behavior. This helps optimize stock levels and improve the shopping experience.

These examples show how a computer vision machine vision system can revolutionize industries by enhancing both real-time operations and long-term decision-making.

Understanding computer vision and machine vision systems is essential as these technologies continue to reshape industries. Their applications in manufacturing, healthcare, and retail demonstrate their transformative potential:

The machine vision market is projected to grow from $14.1 billion in 2024 to $26.7 billion by 2033, driven by advancements in AI and deep learning.

In healthcare, these systems enhance diagnostics and enable robotic-assisted surgeries.

Retail benefits from cashier-less checkouts and smarter inventory management.

Ongoing innovations in imaging and AI integration promise even greater efficiency and automation. By staying informed, you can better appreciate how these technologies are revolutionizing industries and shaping the future of AI.

FAQ

What is the main difference between computer vision and machine vision?

Computer vision focuses on analyzing and interpreting visual data for diverse applications like healthcare and retail. Machine vision specializes in industrial automation, emphasizing speed and precision for tasks like quality control.

Can computer vision and machine vision work together?

Yes, they often complement each other. For example, machine vision handles real-time inspections, while computer vision analyzes historical data to improve processes. Together, they enhance efficiency and accuracy in industries like manufacturing and healthcare.

How do machine vision systems improve industrial automation?

Machine vision systems automate tasks like defect detection and product sorting. They process visual data in real time, ensuring high-speed and accurate operations. This reduces labor costs and boosts production efficiency.

Are these technologies expensive to implement?

The cost depends on the complexity of the system and its application. While initial investments can be high, the long-term benefits, such as reduced errors and increased efficiency, often outweigh the costs.

What industries benefit the most from these technologies?

Industries like manufacturing, healthcare, retail, and transportation gain the most. For example, manufacturing uses machine vision for quality control, while healthcare relies on computer vision for medical imaging and diagnostics.

💡 Tip: Start small by integrating these systems into specific processes. Gradual implementation can help you manage costs and measure effectiveness.

See Also

A Detailed Overview of Machine Vision in Automation

Utilizing Machine Vision Technology in Food Manufacturing

Comparing Fixed and Motion Integrated Vision Systems

Harnessing Synthetic Data to Enhance Machine Vision Capabilities

Achieving Excellence in Visual Inspection Through AI Solutions