How Computer Vision Differs from Machine Vision

Computer vision uses artificial intelligence to interpret and analyze visual data, enabling machines to "see" and understand their surroundings. It powers technologies like image recognition, object detection, and facial recognition. This field has seen remarkable growth, with AI adoption in computer vision increasing by 270% over four years. Industries like manufacturing, retail, and healthcare leverage it for insights and efficiency, contributing to a projected market value of $89 billion by 2032.

Machine vision focuses on hardware-based systems designed for real-time processing in controlled environments. It excels in industrial automation, performing tasks like defect detection and quality control. For instance, average runtimes for machine vision tasks, such as tracking (8 milliseconds) and registration (0.2 milliseconds), highlight its speed and precision.

While computer vision emphasizes AI-driven image analysis, machine vision prioritizes practical applications in industries requiring reliability and speed. Choosing the right Computer Vision(CV) machine vision system depends on your specific needs and goals.

Key Takeaways

- Computer vision uses AI to study pictures. It helps machines understand images like people do. It is used in things like face recognition and finding objects.

- Machine vision uses special tools to work fast in set environments. It is great for spotting mistakes and checking quality in factories.

- To pick one, think about what you need. Computer vision is good for tricky tasks. Machine vision is better for quick and exact work in steady places.

- Jobs like healthcare, factories, and stores use these tools a lot. They make work faster and more accurate in many ways.

- Knowing what each system does well helps you choose wisely. This can lead to better machines and more work done.

Understanding Computer Vision

Definition and Purpose

Computer vision is a subset of artificial intelligence that enables machines to process and interpret digital images similarly to how humans see and understand visuals. This system aims to perform visual tasks with greater efficiency and accuracy than humans. Over the years, its capabilities have evolved significantly. In the 1970s, computer vision handled basic tasks, but today, it achieves up to 99% accuracy in complex operations. Key factors driving this growth include the explosion of visual data, affordable computing power, and advancements in deep learning algorithms.

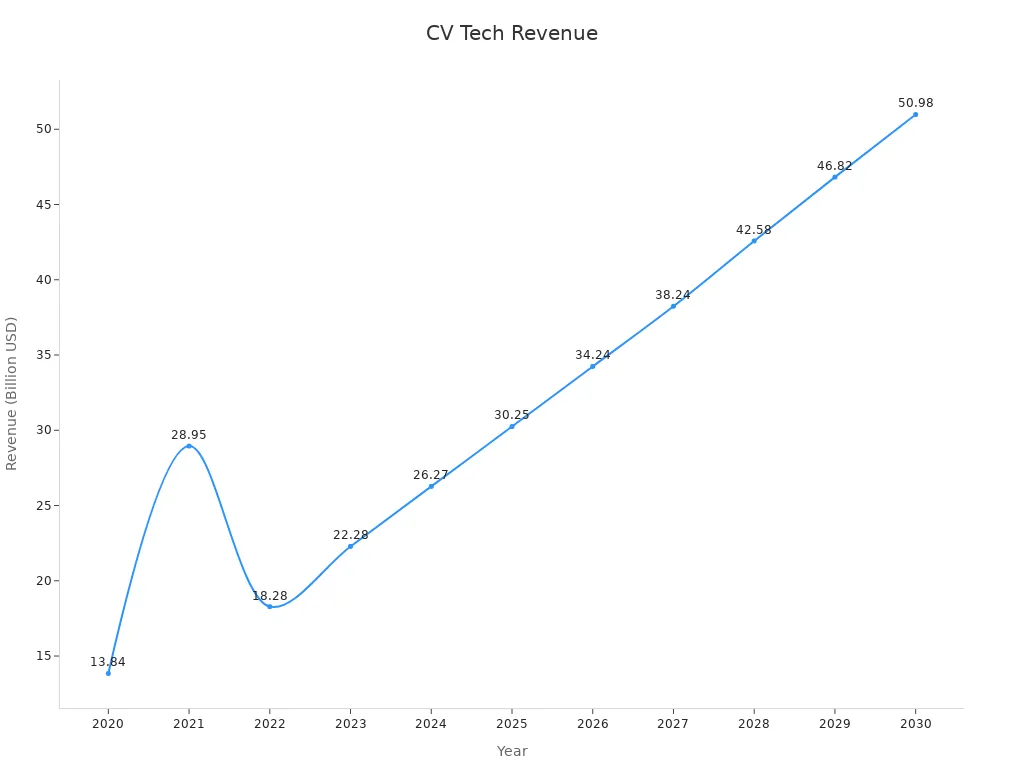

The global adoption of computer vision technologies has surged across various sectors. For example, industries like manufacturing, healthcare, and security have embraced it for tasks such as quality inspection, anomaly detection, and medical diagnostics. The following table illustrates the projected revenue growth of computer vision technologies:

| Year | Revenue (in billion USD) |

|---|---|

| 2020 | 13.84 |

| 2021 | 28.95 |

| 2022 | 18.28 |

| 2023 | 22.28 |

| 2024 | 26.27 |

| 2025 | 30.25 |

| 2026 | 34.24 |

| 2027 | 38.24 |

| 2028 | 42.58 |

| 2029 | 46.82 |

| 2030 | 50.98 |

AI-Based Computer Vision Technologies

AI-based computer vision relies on advanced techniques like deep learning and convolutional neural networks (CNNs) to enhance image processing performance. These technologies have revolutionized fields such as healthcare by automating complex tasks. For instance, CNNs can detect diabetic retinopathy in retinal images with high sensitivity and specificity. Similarly, AI systems analyze large datasets of medical images to provide accurate diagnoses, reducing variability in clinical findings.

The combination of machine learning and high-performance computing has also enabled real-time image analysis. This capability is crucial for industries like manufacturing, where quality control demands precision and speed. By automating visual inspections, AI-based computer vision ensures consistent results and minimizes human error.

Applications in Diverse Fields

The applications of computer vision span multiple industries, showcasing its versatility. In healthcare, AI-based computer vision analyzes brain MRI scans to predict Alzheimer’s disease and segments cartilage in knee MRI scans to assess osteoarthritis risk. In the automotive sector, self-driving vehicles use computer vision for real-time environmental sensing and autonomous navigation. Security systems leverage AI to enhance anomaly detection and prevent breaches through adaptive monitoring.

Manufacturing remains a key adopter, utilizing computer vision for quality inspection and defect detection. Retailers use it to analyze customer behavior, while energy companies apply it to monitor equipment and ensure safety. The following chart highlights the adoption rates of computer vision across various sectors:

From healthcare to transportation, AI-based computer vision continues to transform industries by automating processes and improving efficiency.

Exploring Machine Vision

Definition and Core Components

Machine vision refers to the use of hardware and software systems to enable machines to "see" and interpret visual data. Unlike computer vision, which relies heavily on artificial intelligence, machine vision focuses on integrating specialized hardware for tasks like image capture and analysis. Its core components include cameras, lighting systems, image processing units, and software algorithms. These components work together to perform tasks such as object detection, defect detection, and visual inspection with high precision.

For example, stereo vision uses two cameras to calculate depth with an accuracy of up to 0.1 mm, making it ideal for precise object placement. Structured light projects patterns onto surfaces to measure distortions, which is useful for industrial inspections. Time-of-flight sensors measure the time light takes to travel, creating 3D maps for dynamic object tracking. These technologies form the backbone of machine vision solutions, enabling reliable performance in industrial applications.

| Dimensional Measurement Technique | Description | Key Applications |

|---|---|---|

| Stereo Vision | Uses two cameras to calculate depth | Precise object placement |

| Structured Light | Projects patterns to measure distortions | Industrial inspection |

| Time-of-Flight Sensors | Measures light travel time to create 3D maps | Dynamic object tracking |

Hardware-Centric Design and Real-Time Processing

Machine vision systems prioritize hardware-centric designs to achieve real-time processing. High-speed cameras and processors ensure rapid image capture and analysis, making them suitable for environments where speed and accuracy are critical. For instance, machine vision systems can process tasks like tracking and registration in milliseconds, ensuring seamless operations on production lines.

The integration of diverse hardware, such as CPUs, GPUs, and TPUs, enhances the system's ability to handle complex workloads. Innovations like SparseCore in TPUv4 demonstrate how continuous optimization improves performance under dynamic conditions. These advancements allow machine vision to excel in tasks like detecting defects and performing high-precision inspections.

| Evidence Type | Description |

|---|---|

| Performance Metrics | Data from Google’s TPU fleet showcases real-world performance metrics. |

| Hardware Diversity | Integration of CPUs, GPUs, and TPUs maximizes efficiency in real-time tasks. |

| Optimization Challenges | New hardware features like SparseCore improve performance under workloads. |

Applications in Industrial Automation

Machine vision plays a vital role in industrial automation by enhancing efficiency, quality, and safety. It automates tasks like defect detection, quality control, and material handling, reducing human intervention in hazardous environments. For example, pharmaceutical companies use machine vision to detect defects and ensure compliance with regulatory standards. Manufacturing industries rely on it to maintain high-quality standards and optimize production processes.

The following table highlights the performance metrics that validate the effectiveness of machine vision in industrial applications:

| Performance Metric | Description |

|---|---|

| Increased Speed and Efficiency | Faster production cycles leading to increased output without compromising quality. |

| Enhanced Quality Control | Detects defects and inconsistencies that may go unnoticed by human inspectors. |

| Cost Savings | Reduces errors and waste, optimizing resource utilization and lowering operational costs. |

| Improved Worker Safety | Reduces human intervention in hazardous tasks, enhancing workplace safety. |

| Better Data Collection and Analysis | Provides real-time insights for process optimization and predictive maintenance. |

Machine vision solutions also enable real-time monitoring, allowing you to make quick, informed decisions. By automating inspections and leveraging deep learning techniques, these systems reduce waste and improve overall operational efficiency. Their ability to integrate with robotics further enhances assembly line productivity, making them indispensable in modern industrial applications.

Comparing Computer Vision and Machine Vision

Differences in Technology and Approach

When comparing computer vision and machine vision, you will notice distinct differences in their technologies and approaches. Machine vision relies heavily on hardware systems designed for real-time processing. It uses high-speed cameras, lighting systems, and processors to capture and analyze images instantly. This makes it ideal for industrial environments where speed and precision are critical. On the other hand, computer vision focuses on software-driven solutions powered by artificial intelligence. It processes visual data using deep learning algorithms to interpret and analyze images.

The table below highlights the key differences between these two systems:

| Aspect | Machine Vision | Computer Vision |

|---|---|---|

| Data Processing | Processes vast amounts of data in real-time | Processes predetermined datasets prepared by professionals |

| Application | Utilizes computer vision technologies for enhanced processes | Primarily focuses on deep learning training for model accuracy |

| AI Implementation | Uses AI inferencing with trained preset models | Aims to develop accurate dataset models for training |

Machine vision excels in environments where tasks need to be completed quickly and consistently. In contrast, computer vision thrives in scenarios requiring complex image analysis and decision-making.

Deployment Scenarios and Use Cases

You will find that the deployment scenarios for machine vision and computer vision differ significantly. Machine vision is commonly used in controlled environments like factories and production lines. It performs tasks such as defect detection, quality control, and material handling. For example, a machine vision system can inspect thousands of products per hour, ensuring consistent quality without human intervention.

Computer vision, however, is more versatile. It can operate in dynamic environments and handle unstructured data. For instance, in healthcare, computer vision analyzes medical images to detect diseases. In retail, it tracks customer behavior to optimize store layouts. Self-driving cars also rely on computer vision to navigate roads and avoid obstacles.

If you need a system for industrial automation, machine vision is the better choice. But if your goal is to analyze complex visual data, computer vision offers the flexibility you need.

Real-World Examples of Each System

To better understand these technologies, let’s look at some real-world examples. Machine vision is widely used in the automotive industry. It inspects car parts for defects and ensures proper assembly. Pharmaceutical companies use it to verify the accuracy of labels and packaging. These systems operate in milliseconds, making them indispensable for high-speed production lines.

Computer vision, on the other hand, powers applications like facial recognition and autonomous vehicles. For example, Tesla’s self-driving cars use computer vision to identify road signs, pedestrians, and other vehicles. In agriculture, computer vision analyzes drone images to monitor crop health. These examples show how computer vision adapts to diverse fields, offering solutions beyond industrial automation.

By understanding these examples, you can see how each system serves unique purposes. Machine vision focuses on efficiency and reliability in controlled settings. Computer vision, with its AI-driven approach, excels in dynamic and complex environments.

Choosing the Right Computer Vision(CV) Machine Vision System

Factors to Consider

When deciding between a computer vision(cv) machine vision system, you need to evaluate several factors to ensure the best fit for your application. These factors include performance, cost, and the specific requirements of your industry.

- Accuracy and Speed: Machine vision systems excel in real-time processing, making them ideal for tasks requiring speed and precision. For example, simpler methods in machine vision can execute tasks in just 100 milliseconds, while more complex algorithms may take longer.

- Application Environment: Machine vision works best in controlled environments like factories, where lighting and conditions remain consistent. Computer vision, however, adapts to dynamic and unstructured settings, such as outdoor environments or healthcare facilities.

- Integration Needs: Machine vision systems often integrate seamlessly with industrial equipment like PLCs (Programmable Logic Controllers). This integration ensures smooth operations in manufacturing.

- Cost and ROI: Evaluate the return on investment by comparing the system's performance with its cost. Use criteria like accuracy, processing speed, and real-time capability to determine the best option.

| Factor | Description |

|---|---|

| Accuracy | Measures the correctness of the system in identifying defects and sorting products. |

| Processing Speed | Indicates how quickly the system can process images and make decisions. |

| Execution Times | Time taken to execute algorithms, crucial for real-time applications. |

| Real-time Capability | Ability to handle tasks in real-time, essential for industrial applications. |

| Integration with PLCs | Discusses trade-offs between performance, simplicity, and robustness in industrial environments. |

When to Opt for Computer Vision

You should choose computer vision when your application requires advanced image analysis and decision-making. This system thrives in scenarios where artificial intelligence plays a critical role.

For example, in healthcare, computer vision analyzes medical images to detect diseases like cancer or Alzheimer’s. It also powers self-driving cars, enabling them to recognize road signs, pedestrians, and other vehicles. These applications highlight the system's ability to handle complex tasks in dynamic environments.

Performance benchmarks further demonstrate the advantages of computer vision. Models like AlexNet and ResNet have significantly improved error rates in image recognition tasks, showcasing the system's scalability and efficiency. If your project involves unstructured data or requires high levels of customization, computer vision is the better choice.

When to Opt for Machine Vision

Machine vision is the right choice for industrial applications that demand speed, precision, and reliability. This system excels in controlled environments, such as manufacturing plants, where it automates tasks like defect detection and quality control.

The machine vision market is growing rapidly, with projections showing an increase from USD 14.1 billion in 2024 to USD 26.7 billion by 2033. This growth reflects the rising demand for automation and safety in industries like manufacturing, healthcare, and agriculture.

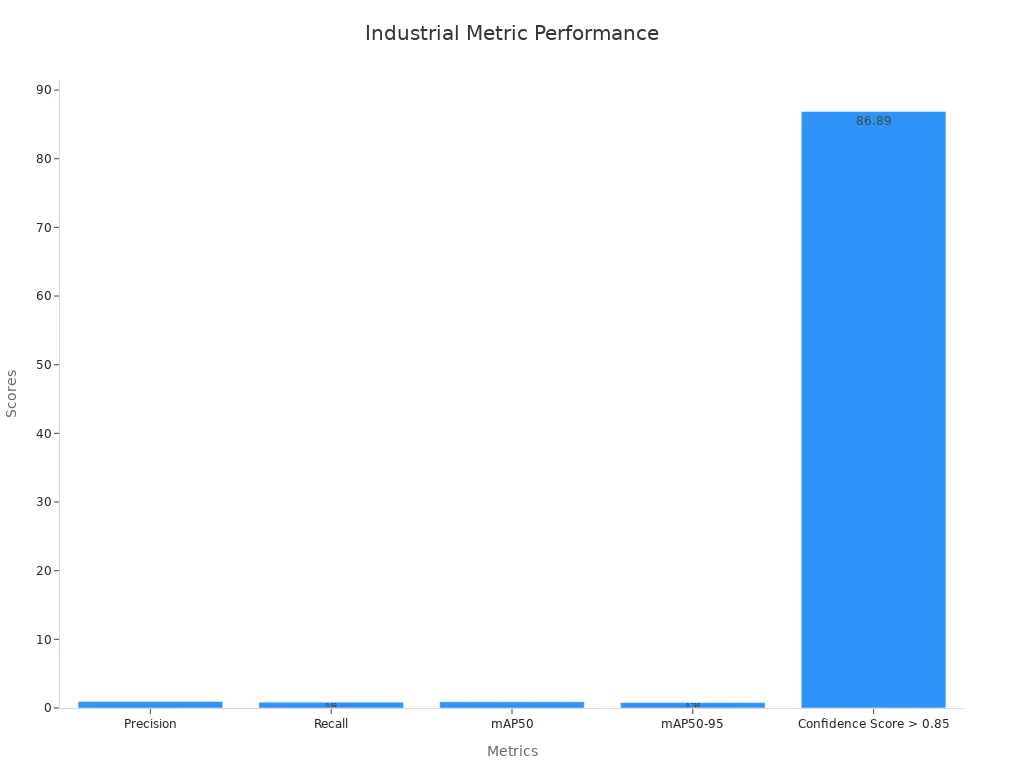

Key performance metrics also highlight the system's strengths. For instance, machine vision achieves a precision score of 0.949 and a recall score of 0.850, making it highly effective for real-time applications. The chart below illustrates these metrics:

If your goal is to enhance efficiency and reduce errors in a production line, a machine vision system will deliver the results you need. Its ability to integrate with robotics and other industrial equipment makes it indispensable for modern automation.

Computer vision and machine vision serve distinct purposes. Computer vision uses AI to analyze complex visual data, offering flexibility and adaptability in dynamic environments. Machine vision, on the other hand, excels in controlled settings with predefined rules, ensuring precision and speed.

When choosing a system, consider your goals. If you aim to streamline processes or achieve productivity targets, computer vision’s adaptability and transfer learning capabilities provide a competitive edge. For tasks in stable environments, machine vision delivers reliable results. By aligning your needs with these strengths, you can unlock new opportunities and improve efficiency.

FAQ

What is the main difference between computer vision and machine vision?

Computer vision focuses on analyzing visual data using AI, while machine vision emphasizes hardware for real-time processing in controlled environments. You can think of computer vision as software-driven and machine vision as hardware-centric.

Can computer vision and machine vision work together?

Yes, they can complement each other. Machine vision systems often use AI-powered computer vision algorithms to enhance their ability to analyze visual data and improve decision-making in industrial applications.

Which industries benefit the most from AI-based computer vision?

Healthcare, automotive, and retail industries benefit significantly. For example, AI in healthcare analyzes medical images, while in retail, it tracks customer behavior. These applications showcase how AI transforms visual data into actionable insights.

How does machine vision ensure accuracy in industrial automation?

Machine vision uses high-speed cameras, precise lighting, and advanced sensors to capture and process visual data instantly. This ensures accurate defect detection, quality control, and material handling in production lines.

Is AI necessary for machine vision systems?

AI is not always necessary for machine vision. Many systems rely on pre-programmed algorithms to process visual data. However, integrating AI can enhance their capabilities, especially for complex tasks like pattern recognition or anomaly detection.

See Also

Essential Insights Into Computer Vision And Machine Vision

Understanding Computer Vision Models And Machine Vision Systems

Comparing Firmware Machine Vision With Conventional Systems