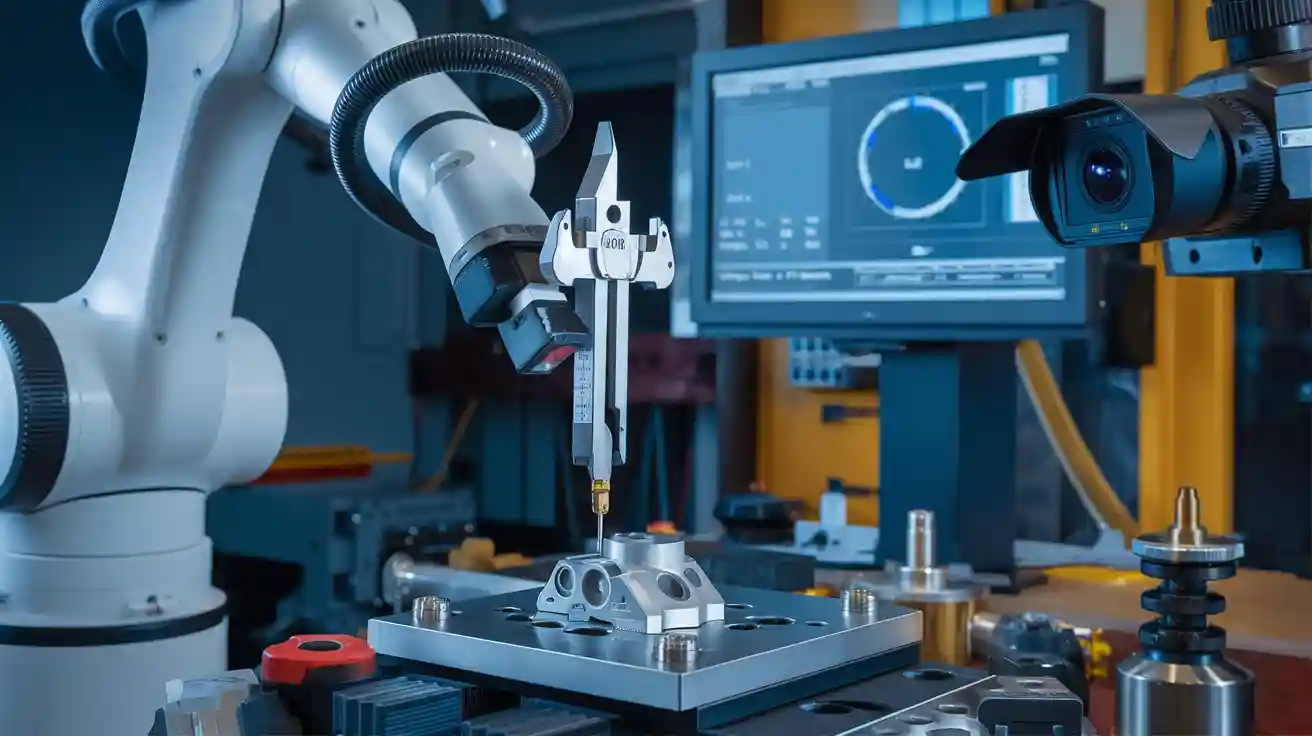

A Beginner’s Guide to Dimensional Measurement in Machine Vision

Dimensional Measurement machine vision system utilizes advanced technology to measure object size, shape, and geometry with precision. This ensures products meet strict quality control standards. For example, these systems have shown improved accuracy, reducing errors from 0.0305 to 0.0108. By minimizing measurement errors, industries avoid inefficiencies that disrupt production and increase costs.

Key Takeaways

- Machine vision systems help check quality by being accurate. They also lower mistakes, making products better.

- Non-contact methods check items quickly and exactly. They don’t harm delicate materials, so they work well in many industries.

- Picking the right system depends on what you need it for. Think about how detailed and exact the measurements must be.

Understanding Dimensional Measurement Machine Vision Systems

What is dimensional measurement in machine vision?

Dimensional measurement in machine vision refers to the process of using advanced imaging technologies to measure the size, shape, and geometry of objects. These systems rely on cameras, sensors, and software to capture precise data about an object’s dimensions without physical contact. Unlike traditional measurement tools like calipers or micrometers, these systems can analyze objects quickly and with high accuracy.

For example, parameters such as field of view, working distance, and resolution play a critical role in defining how these systems operate. The table below highlights some of these measurable parameters:

| Parameter | Description |

|---|---|

| Field Of View | The viewable area of the object, influenced by the camera’s sensor and lens focal length. |

| Working Distance | The distance from the lens to the object, which varies based on application constraints. |

| Resolution | The detail reproduction capability of the imaging system, determined by pixel size and count. |

| Depth Of Field | The maximum object depth that can be kept in focus, important for applications like barcode reading. |

| Sensor Size | The active area size of the camera sensor, affecting the choice of lens and magnification. |

| Primary Magnification | The ratio of sensor size to the field of view, crucial for selecting the appropriate lens. |

These parameters ensure that dimensional measurement machine vision systems can adapt to various industrial applications, from inspecting tiny electronic components to analyzing large automotive parts.

Why is it essential for quality control and defect detection?

Dimensional measurement machine vision systems are vital for maintaining quality control and detecting defects in production processes. They enhance precision, speed, and consistency, which are critical for industries aiming to meet high-quality standards.

Here are some quantifiable benefits of these systems in quality control and defect detection:

| Benefit | Description |

|---|---|

| Accuracy | Enhances precision in measurements, reducing defective products and maintaining consistent quality. |

| Speed | Inspects multiple dimensions simultaneously, significantly reducing quality control time. |

| Cost Reduction | Lowers labor costs and minimizes material waste, especially in sectors like automotive. |

| Automation | Replaces manual inspection, eliminating human error and achieving consistent results. |

| Data Storage | Allows for compliance and future analysis through detailed 3D models. |

For instance, manufacturing companies use these systems to inspect products thoroughly with multiple camera sensors. Automated defect detection through image-processing technologies reduces the need for manual labor and ensures consistent results. By analyzing images and 3D scans, these systems can identify anomalies and prevent defective products from reaching customers.

Key principles of machine vision systems for dimensional measurement

To understand how these systems work, you need to know their key principles. Machine vision systems for dimensional measurement rely on non-contact imaging methods, which allow them to measure objects without touching them. This ensures that delicate or fast-moving objects can be inspected without damage or interruption.

The principles include:

- Image Acquisition: Cameras capture high-resolution images of the object. The field of view and resolution determine the level of detail captured.

- Image Processing: Software analyzes the images to extract dimensional data. Techniques like edge detection and pattern recognition help identify features and measure dimensions.

- Data Interpretation: The system compares the measured dimensions against predefined specifications to detect defects or confirm compliance.

The adoption of these systems is growing rapidly. The industrial measurement machine vision system market was valued at USD 2.5 billion in 2024 and is projected to reach USD 4.8 billion by 2033, reflecting a compound annual growth rate (CAGR) of 7.8% from 2026 to 2033. This growth highlights their increasing importance in industries like automotive, aerospace, and electronics.

Tip: If you’re considering implementing these systems, focus on selecting the right combination of cameras, sensors, and software to meet your specific needs.

How Dimensional Measurement Machine Vision Systems Work

Non-contact measurement methods and their advantages

Non-contact measurement methods play a pivotal role in machine vision systems. These methods rely on technologies like optical imaging, radar, and lasers to measure objects without physical contact. This approach ensures that delicate or fast-moving items remain undisturbed during inspection.

One of the key advantages of non-contact measurement methods is their ability to deliver rapid and precise results. For instance, impulse-radio ultrawideband (IR-UWB) radar provides high-precision measurements for applications like gauging anthropometric data. It eliminates exposure risks and privacy concerns, making it ideal for healthcare and industrial settings. Additionally, these methods allow for real-time inspection of large-scale objects, enhancing efficiency in automated inspection processes.

Non-contact techniques also reduce the risk of damage to sensitive materials. Unlike traditional tools, they avoid wear and tear caused by repeated physical contact. This makes them indispensable for industries requiring dimensional accuracy, such as electronics and aerospace.

Note: Non-contact measurement methods are particularly effective for defect detection in high-speed production lines, ensuring consistent quality without slowing operations.

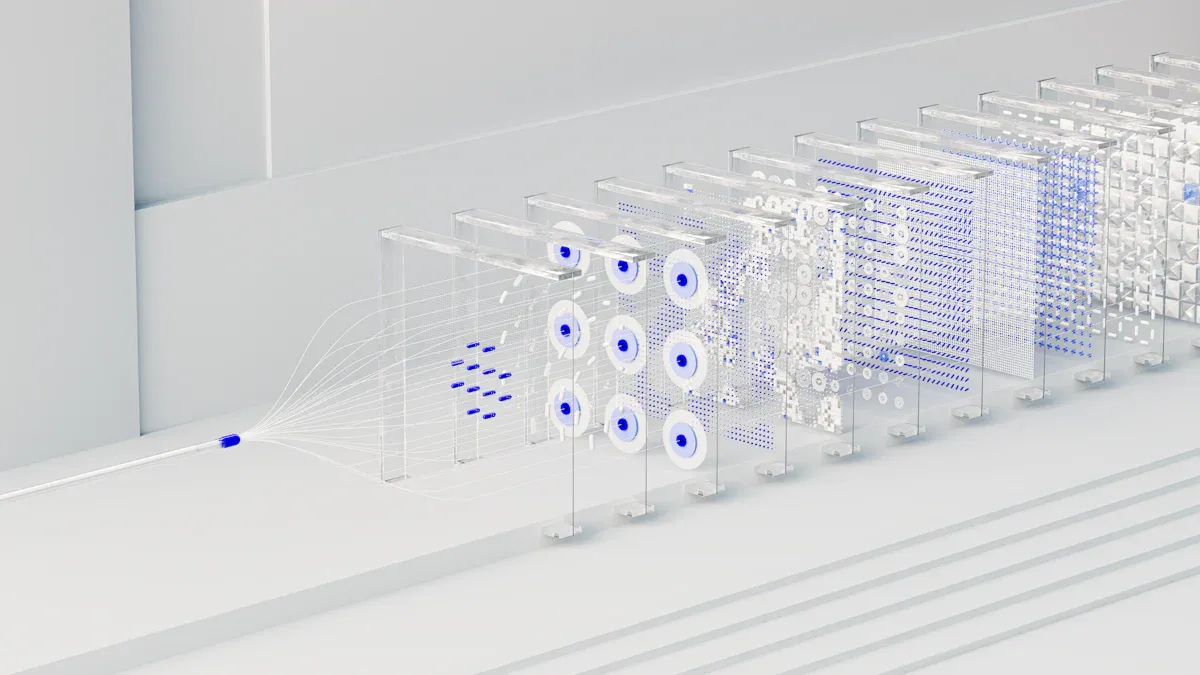

Differences between 1D, 2D, and 3D systems

Dimensional measurement systems come in three primary types: 1D, 2D, and 3D. Each system offers unique capabilities tailored to specific applications.

| Dimensional System | Measurement Range | Accuracy |

|---|---|---|

| 1D LiDAR | Up to 20m | ±3mm |

| 2D LiDAR | 10 to 80 meters | Not specified |

| 3D LiDAR | Not specified | Not specified |

1D systems focus on linear measurements, making them suitable for gauging distances or heights. They are commonly used in applications like conveyor belt monitoring. 2D systems expand this capability by capturing width and height dimensions, enabling more detailed analysis of flat objects. These systems excel in tasks like measuring printed circuit boards or inspecting labels.

3D vision systems take dimensional measurement to the next level. They create detailed models of objects by capturing depth information. This allows for precise gauging of complex geometries, such as automotive parts or medical devices. The ability to analyze objects in three dimensions enhances defect detection and ensures dimensional accuracy in intricate designs.

Tip: When choosing between 1D, 2D, and 3D systems, consider the complexity of your application and the level of detail required for real-time inspection.

Role of cameras, sensors, and software in dimensional measurement

Cameras, sensors, and software form the backbone of machine vision systems. Each component contributes to the system’s ability to achieve high accuracy and efficiency in measuring and gauging objects.

Cameras capture high-resolution images, providing the raw data needed for analysis. Sensors enhance this process by detecting specific features, such as edges or contours. For example, edge location standard deviation (σ) helps locate object boundaries with precision, while object visibility metrics ensure small or low-contrast objects are detectable.

Software processes the captured data, transforming it into actionable insights. Techniques like pattern recognition and noise reduction improve defect detection and dimensional accuracy. Advanced algorithms also enable automated inspection, reducing human error and increasing consistency.

| Indicator | Description |

|---|---|

| Noise Power Spectrum (NPS) | Provides important information for calculating additional figures of merit. |

| Noise Equivalent Quanta (NEQ) | A frequency-dependent SNR, important in medical imaging. |

| Ideal observer Signal-to-Noise Ratio (SNRi) | Measures detectability of small objects. |

| Edge location standard deviation (σ) | Describes how well the edges of the object can be located. |

| Object visibility | Relates to the detectability of small/low contrast objects, associated with SNRi. |

Callout: To maximize the performance of your machine vision system, ensure proper integration of cameras, sensors, and software. Balanced integration enhances measurement precision and supports real-time inspection.

Benefits and Applications of Dimensional Measurement in Machine Vision

Advantages of machine vision systems for quality control

Machine vision systems offer significant advantages for quality control. These systems improve precision, ensuring products meet exact specifications during dimensional inspection. They also enhance efficiency by automating labor-intensive processes, reducing the need for manual intervention.

A study by Lu et al. (2000) highlights several quantifiable benefits of machine vision systems in quality testing:

| Advantage | Source |

|---|---|

| Improved consistency | Lu et al. (2000) |

| Efficiency | Lu et al. (2000) |

| Cost-effectiveness | Lu et al. (2000) |

| Automation of labor-intensive processes | Gunasekaran (2001) |

| Non-destructive inspection | Tao et al. (1995a); Zayas et al. (1996) |

| Creation of permanent records | Tarbell and Reid (1991) |

| Quick and objective data generation | Li et al. (1997a); Li et al. (1997b) |

| Reduction of tedious human involvement | Ni et al. (1997b) |

These systems also enable continuous inspection, allowing real-time detection of defects and anomalies. By generating permanent records, they support compliance with industry standards and facilitate future analysis.

Tip: Implementing machine vision systems can streamline your quality testing processes, saving time and reducing costs.

Applications in manufacturing, electronics, and medical industries

Dimensional measurement plays a vital role across various industries. In manufacturing, it ensures high precision during final inspection, verifying that components meet design specifications. Electronics industries use these systems for object detection and counting, ensuring accurate assembly of intricate parts like circuit boards.

In the medical field, dimensional inspection ensures the integrity of drug packaging. For example, dimensional analysis helps select and qualify container components, such as rubber stoppers and glass vials. This guarantees proper fit and compliance with FDA standards, which emphasize dimensional drawings and performance criteria for packaging approval. Poorly fitting components can compromise container closure integrity, affecting product safety.

Note: Dimensional measurement systems are indispensable for industries requiring real-time precision and compliance with strict regulations.

Use cases in automotive, aerospace, and logistics

Automotive and aerospace industries rely heavily on 3D dimensional measurement systems for object recognition and defect detection. These systems analyze complex geometries, ensuring parts like engine components and turbine blades meet exact specifications. Real-time inspection during production prevents costly errors and enhances safety.

In logistics, dimensional measurement systems optimize object detection and counting processes. They ensure accurate sizing and sorting of packages, improving efficiency in warehouse operations. By automating these tasks, you can reduce human error and achieve faster throughput.

Callout: Whether you’re in automotive, aerospace, or logistics, dimensional measurement systems can transform your operations with high precision and real-time insights.

Dimensional measurement machine vision systems have revolutionized modern industries. They enhance quality control, boost efficiency, and ensure precise defect detection. For example, studies highlight their effectiveness in industrial applications:

| Study Title | Findings |

|---|---|

| Industrial robot product inspection system based on 3D vision guidance | Demonstrates effectiveness in dimensional measurements and quality control. |

| A machine vision based automated quality control system for product dimensional analysis | Supplies quantitative data on performance in industrial applications. |

| Experimental comparison of optical inline 3D measurement and inspection systems | Provides quantitative insights into accuracy and reliability for dimensional inspections. |

These systems also support lean manufacturing by reducing waste and improving operational efficiency. You can explore these technologies to optimize your processes and achieve consistent results.

Tip: Start by identifying your specific needs and selecting a system that aligns with your industry requirements.

FAQ

What industries benefit the most from dimensional measurement machine vision systems?

Industries like automotive, aerospace, electronics, and medical manufacturing benefit greatly. These systems ensure precision, improve quality control, and enhance efficiency in production processes.

How do I choose the right dimensional measurement system for my needs?

Focus on your application’s complexity and required precision. Consider factors like object size, speed, and whether you need 1D, 2D, or 3D measurements.

Tip: Consult with experts or vendors to match your requirements with the system’s capabilities.

Are dimensional measurement systems difficult to integrate into existing workflows?

No, most systems are designed for seamless integration. They work with existing automation setups and require minimal adjustments to your current processes.

Note: Proper training and setup ensure smooth implementation and optimal performance.

See Also

Grasping Dimensional Measurement Within Machine Vision Technology

An Introduction to Metrology in Machine Vision Systems

Fundamentals of Camera Resolution in Machine Vision Systems