Breaking Down Flaw Detection with Machine Vision Systems

Imagine a system that never gets tired, misses no detail, and ensures every product meets the highest standards. Machine vision systems play this role by automating flaw detection with unmatched precision. Industries like manufacturing, automotive, and electronics rely on these systems to identify defects that human inspectors might overlook. For example, machine learning algorithms can detect even the smallest flaws, improving quality assurance while reducing costs. Automation also eliminates human error, boosting efficiency and consistency. By integrating a Flaw Identification machine vision system, you can achieve faster, more reliable inspections and elevate your production standards.

Key Takeaways

- Machine vision systems find flaws automatically, making quality checks faster and better.

- They can spot different problems like surface scratches or weak spots in many industries.

- Using machine vision saves time during inspections and makes products better, keeping customers happy.

- Buying machine vision systems can save money by cutting waste and lowering worker costs.

- These systems can handle large production needs while keeping quality steady.

Understanding Flaw Detection in Machine Vision

What is Flaw Detection?

Flaw detection refers to the process of identifying imperfections or irregularities in products or materials. These flaws can range from visible surface defects to microscopic issues that are hard to detect with the naked eye. Machine vision systems play a crucial role in automating this process. By using advanced imaging technologies and algorithms, these systems analyze products in real-time to ensure they meet quality standards. This automation not only improves accuracy but also reduces the time required for inspection.

Types of Flaws Detected

Machine vision systems can identify a wide variety of defects across industries. For example:

- Surface Defects: Scratches, dents, or discoloration on materials.

- Structural Issues: Cracks or weak points in components.

- Assembly Errors: Misaligned parts or missing components.

In car manufacturing, these systems inspect paint quality, welds, and assembly with precision. In electronics, they detect cracks or missing parts, reducing human error. The aviation industry relies on these systems to identify structural flaws that could compromise safety. The table below highlights the benefits of flaw detection in different applications:

| Application Area | Benefits of Flaw Detection in Machine Vision |

|---|---|

| Car Manufacturing | Faster and more accurate than manual inspection; checks paint, weld quality, and assembly. |

| Electronics | Automatically detects and classifies issues like cracks and missing components; reduces human error. |

| Aviation | Detects structural issues like cracks that can affect safety; ensures high quality standards. |

| General Manufacturing | Provides consistent results and real-time monitoring; allows for immediate corrective actions. |

Importance of Flaw Detection in Quality Assurance

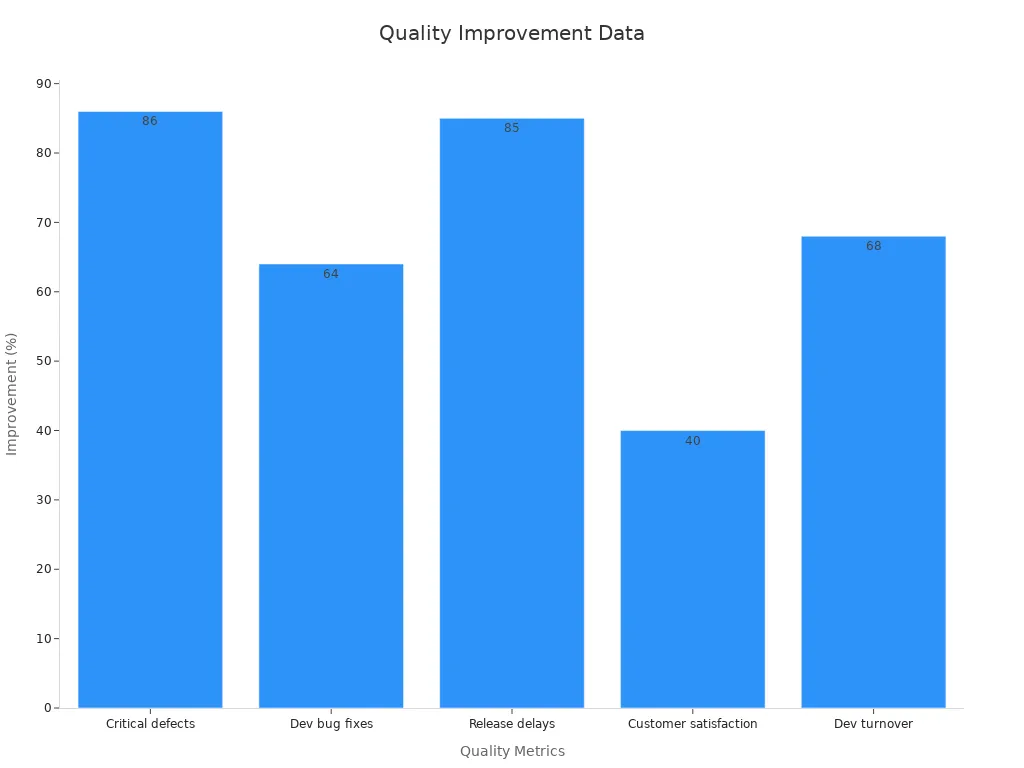

Flaw detection is essential for maintaining high-quality standards. It ensures that defective products are identified and removed before reaching customers. This process not only protects your brand reputation but also reduces costs associated with returns and repairs. Research shows that implementing machine vision systems for defect detection can lead to significant improvements in quality metrics. For instance, critical defects per release can drop by 86%, while customer satisfaction can increase by 40%. The chart below illustrates these improvements:

By adopting machine vision systems, you can achieve faster inspections, consistent results, and scalable solutions for high-volume production. These systems not only enhance quality control but also pave the way for innovation in industries like manufacturing and electronics.

How Flaw Identification Machine Vision Systems Work

Types of Machine Vision Systems

Machine vision systems come in various types, each tailored to specific applications. You can categorize these systems based on their functionality and design. For instance:

- 2D Vision Systems: These systems analyze flat images to detect surface defects like scratches or discoloration. They are ideal for gauging dimensions and inspecting printed labels.

- 3D Vision Systems: These systems capture depth information, making them suitable for detecting structural flaws or assembly errors. They excel in applications requiring precise measurements.

- Line Scan Systems: These systems inspect continuous materials, such as textiles or metal sheets, by scanning one line at a time. They are perfect for identifying defects in high-speed manufacturing processes.

- Smart Cameras: These compact systems integrate cameras and image analysis software, offering a cost-effective solution for automated detection tasks.

Each type of system plays a vital role in flaw identification, ensuring high accuracy and efficiency during inspection processes.

Technologies Used in Defect Detection

Modern machine vision systems rely on advanced technologies to achieve precise defect detection. These technologies include:

- Cameras: High-resolution cameras capture detailed images of products, enabling accurate analysis. The importance of lighting cannot be overstated, as proper illumination enhances image clarity and ensures reliable detection.

- Computer Vision Algorithms: These algorithms process captured images to identify flaws. Techniques like edge detection and pattern recognition help pinpoint surface defects and structural issues.

- AI and Machine Learning: AI models, such as convolutional neural networks (CNNs), analyze images to detect defects. Pre-trained models like ResNet and MobileNet offer robust performance, while real-time models like YOLOv8 excel in speed.

- Prognostics and Health Management (PHM): PHM systems analyze past operations and environmental conditions to predict defects, paving the way for Zero-Defect Manufacturing (ZDM).

- Intelligent Sensors: These sensors collect data on production characteristics, enabling real-time monitoring and analysis.

By integrating these technologies, you can achieve automated detection with unparalleled accuracy and consistency.

Real-time vs. Pre-trained Models

Choosing between real-time and pre-trained models depends on your specific needs. Real-time models, such as Faster R-CNN and YOLOv8, prioritize speed, making them ideal for applications requiring immediate defect detection. These models excel in scenarios where quick decisions are critical, such as high-speed manufacturing lines.

Pre-trained models, on the other hand, focus on accuracy and efficiency. Models like ResNet and MobileNet are trained on vast datasets, enabling them to identify defects with high precision. They are particularly useful for applications requiring detailed analysis, such as detecting micro-level flaws in electronics.

Recent studies highlight the differences between these models. For example:

- Pre-trained models demonstrate improved accuracy across various tasks, including gauging and surface defect detection.

- Real-time models offer faster inference times, making them suitable for applications where speed is crucial.

The choice between these models ultimately depends on your priorities—whether you value speed or detailed analysis.

Applications of Machine Vision Systems in Flaw Detection

Manufacturing: Improving Efficiency and Reducing Costs

In manufacturing, machine vision systems have revolutionized the way you identify flaws and maintain quality. These systems inspect products at speeds and levels of precision that manual methods cannot match. For instance, they can process hundreds or even thousands of items per minute, ensuring that every product meets your quality standards. This capability not only reduces defective products but also minimizes downtime caused by rework.

Machine vision systems also enhance accountability in the manufacturing process. By providing detailed traceability reports, they allow you to track defects back to their source. This insight helps you streamline production processes and improve overall yield. Additionally, robotic systems equipped with visual intelligence adapt to changing conditions on the production line, further boosting efficiency.

"Visionify's Automated Visual Inspection system has completely transformed our quality control process. We're now able to inspect 100% of our products with a level of consistency and accuracy that was impossible with manual inspection. The reduction in customer complaints and warranty claims alone justified the investment, but we've also seen significant improvements in production throughput and cost efficiency."

The financial impact of these systems is equally impressive. A case study revealed annual savings of $1.2 million from reduced warranty claims, $480,000 from lower waste-related costs, and $320,000 from reduced labor expenses. With a return on investment (ROI) of 325% within the first year, the payback period was just 3.7 months.

| Advantages Over Manual Inspection | Description |

|---|---|

| Superior Detection Capability | Higher optical resolution for detecting minute defects |

| Increased Speed and Throughput | Inspection times measured in seconds rather than minutes |

| Objective and Consistent Results | Elimination of subjective judgments |

| Data-Driven Insights | Comprehensive defect statistics |

By integrating machine vision systems into your manufacturing process, you can achieve faster inspections, reduce costs, and maintain consistent quality.

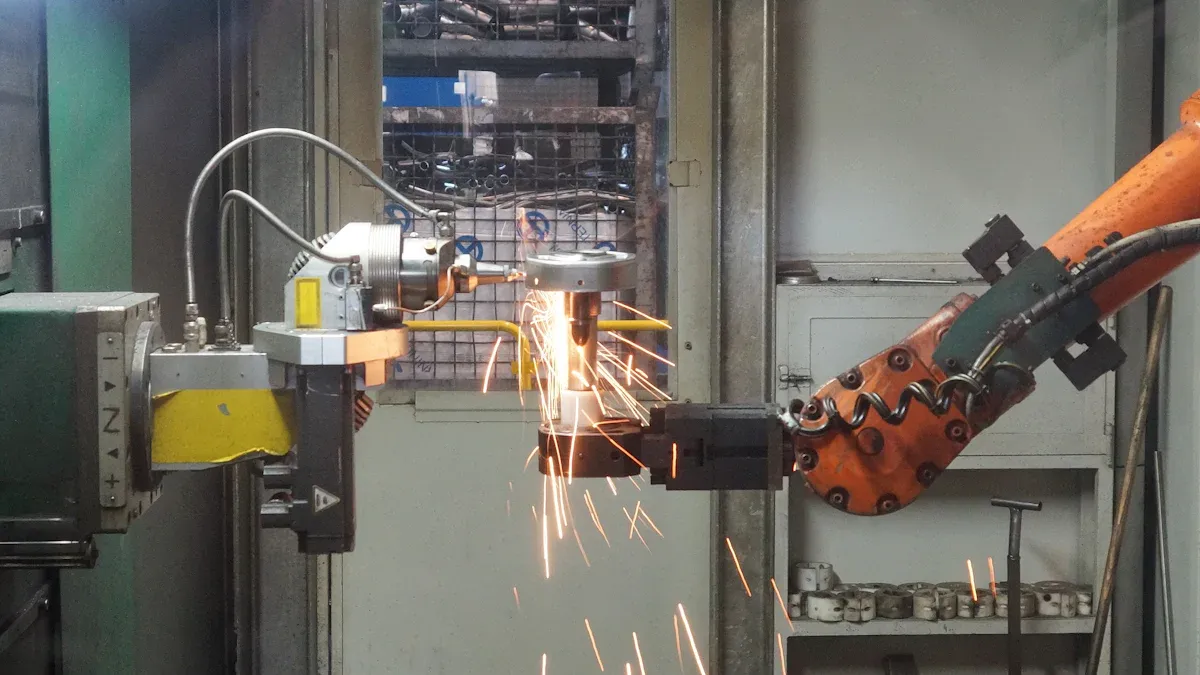

Automotive: Enhancing Safety and Reliability

In the automotive industry, safety and reliability are paramount. Machine vision systems play a critical role in ensuring that every component meets stringent quality standards. These systems inspect parts for defects such as cracks, misalignments, and surface imperfections. They also verify the accuracy of welds and the uniformity of paint finishes, ensuring that vehicles are both safe and visually appealing.

One of the most significant advantages of these systems is their ability to operate in real-time. For example, gaze detection systems in vehicles monitor driver behavior to enhance safety. These systems achieve remarkable accuracy, with a mean absolute error of just 7.4° for azimuth and 8.7° for elevation. They can classify open and closed eyes with an AUC of 0.9998, making them highly reliable for real-time applications.

- Machine vision systems detect and classify multiple types of defects, improving speed and accuracy in quality assurance.

- They reduce defective products, leading to fewer rejections and less downtime for rework.

- Although initial investments are high, long-term savings from reduced labor costs and minimized recalls lower the total cost of ownership.

By adopting these technologies, you can enhance vehicle safety, reduce production costs, and improve customer satisfaction.

Electronics: Detecting Micro-level Defects

The electronics industry demands precision at a microscopic level. Machine vision systems excel in detecting flaws that are invisible to the human eye. These systems inspect components for defects such as cracks, soldering issues, and missing parts. By automating this process, you can ensure that every product meets the highest quality standards.

Lighting plays a crucial role in these inspections. Proper illumination enhances image clarity, allowing the system to identify even the smallest defects. Advanced algorithms, such as convolutional neural networks (CNNs), analyze these images to detect flaws with unparalleled accuracy.

| Industry | Application Description | Numerical Impact |

|---|---|---|

| Electronics | Automated systems detect micro-level defects in circuit boards and components. | Reduces defective products by 99%, improving overall quality and reducing waste. |

Machine vision systems also provide data-driven insights that help you optimize your production processes. By identifying patterns in defect occurrences, these systems enable you to address root causes and prevent future issues. This proactive approach not only improves product quality but also reduces waste and enhances sustainability.

"Visionify's brick quality detection system has transformed our quality control process. We're now able to inspect every single brick with a level of accuracy and consistency that was impossible before. The system's ability to distinguish between critical defects and minor imperfections that don't affect performance has been particularly valuable, significantly reducing waste while ensuring only quality products reach our customers."

By leveraging machine vision systems, you can achieve unparalleled precision in flaw detection, ensuring that your electronic products meet the highest standards of quality and reliability.

Benefits of Using Machine Vision Systems for Defect Detection

Enhanced Accuracy and Consistency

Machine vision systems bring unmatched precision to flaw detection. These systems achieve over 99% accuracy in identifying defects, ensuring that even the smallest flaws are detected. Object detection accuracy reaches 98.5%, significantly reducing false positives and enhancing operational consistency. Unlike human inspectors, machine vision systems operate continuously without fatigue, maintaining consistent precision throughout the inspection process.

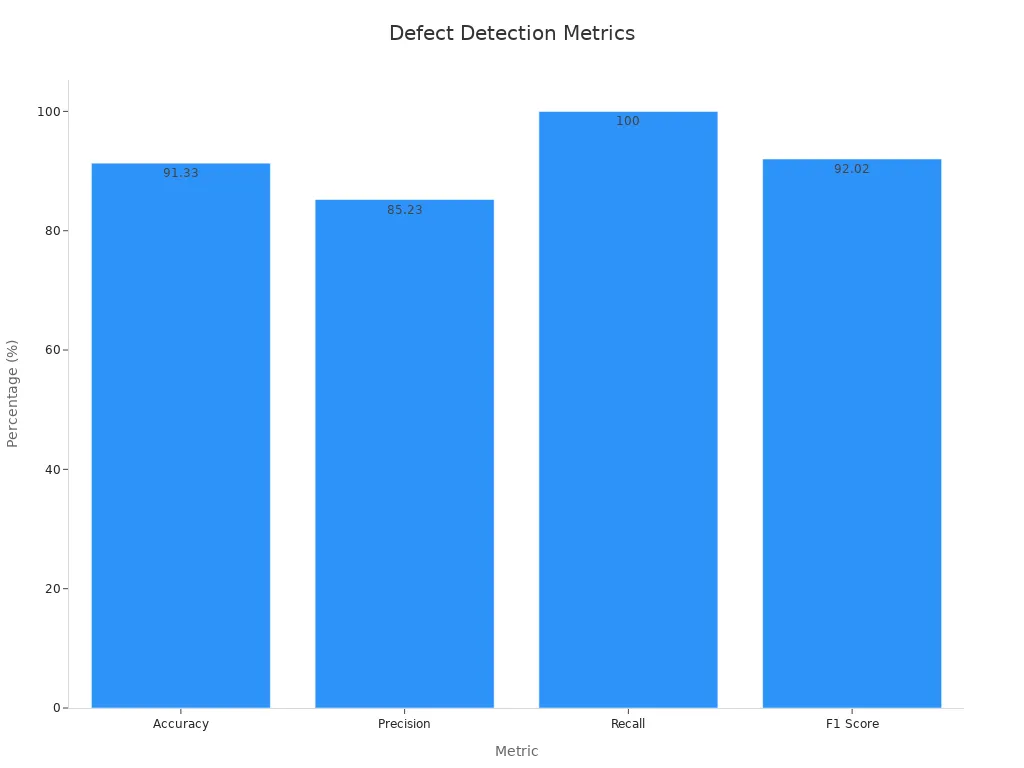

You can rely on AI-powered systems to eliminate human error, which often compromises quality. Real-time data integration with quality management systems further improves efficiency, allowing you to monitor and adjust processes instantly. A documented case study highlights the impressive metrics achieved by these systems:

| Metric | Value |

|---|---|

| Accuracy | 91.33% |

| Precision | 85.23% |

| Recall | 100% |

| F1 Score | 92.02% |

By adopting machine vision systems, you ensure consistent inspections and elevate product quality, leading to higher customer satisfaction.

Faster Inspection Processes

Speed is a critical advantage of machine vision systems. High-speed applications process hundreds of units per minute, making them ideal for manufacturing environments where efficiency matters. These systems acquire and analyze images in less than 20 milliseconds, enabling rapid flaw detection without compromising accuracy.

Continuous operation at speeds above 30 frames per second (fps) ensures that your production lines run smoothly. This capability accelerates production timelines, allowing you to meet tight deadlines and improve customer satisfaction. Faster inspections also reduce bottlenecks, ensuring that your process remains efficient and productive.

Cost-effectiveness and Waste Reduction

Machine vision systems save costs by improving quality control and reducing waste. By identifying manufacturing flaws early, these systems minimize scrap rates and control overhead expenses. High-speed and high-accuracy decision-making further contributes to waste reduction, ensuring that only flawless products reach customers.

Automated waste sorting is another benefit. Machine vision systems enhance recycling rates and reduce waste disposal costs, promoting better sustainability practices. Accurate sorting improves operational efficiency, helping you achieve environmental goals while lowering expenses.

"Machine vision systems not only reduce defects but also optimize waste management, making them a cost-effective solution for modern production lines."

By integrating these systems, you reduce waste, improve product quality, and achieve significant cost savings, making them an essential tool for any manufacturing process.

Scalability for High-volume Production

Machine vision systems excel in scaling up to meet the demands of high-volume production environments. These systems are designed to handle continuous inspection applications, ensuring every product meets quality standards without slowing down production lines. Their ability to operate at high-speed processing rates makes them indispensable for industries like automated automotive assembly, where precision and efficiency are critical.

Artificial intelligence plays a key role in enhancing scalability. By integrating AI, you can boost production by up to 40% by 2035. These systems also increase productivity by 50% compared to manual inspections. In complex production environments, defect detection rates improve by as much as 90%. This level of performance ensures that even as production scales, quality remains consistent.

Predictive analytics further enhances scalability. Machine vision systems continuously monitor equipment conditions, visualizing wear-and-tear patterns. Alerts generated by these systems help you anticipate equipment failures, allowing timely interventions. This proactive approach prevents costly disruptions and ensures smooth operations, even in high-demand scenarios.

The benefits of scalability extend beyond production speed. Higher productivity and lower expenses contribute to improved profitability. Enhanced product quality reduces the risk of recalls, while worker safety improves as automated systems take over repetitive and hazardous tasks. These advantages make machine vision systems a reliable solution for final inspection processes in large-scale manufacturing.

By adopting machine vision systems, you can achieve seamless scalability, ensuring your production lines remain efficient and reliable, even under high-volume demands. Their ability to adapt to growing needs makes them a cornerstone of modern manufacturing.

Machine vision systems have transformed flaw detection by delivering unmatched accuracy and efficiency. Across industries, these systems improve inspection accuracy by 94% and reduce inspection time by 40%, as shown below:

| Metric | Improvement Percentage |

|---|---|

| Inspection accuracy | 94% |

| Reduction in inspection time | 40% |

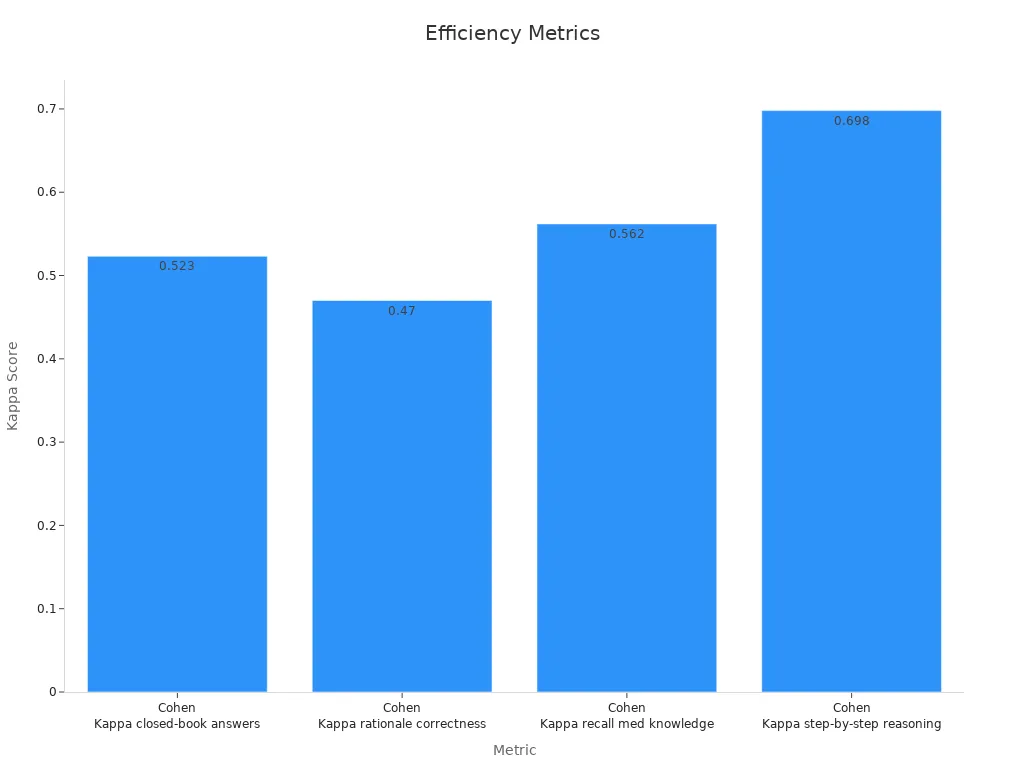

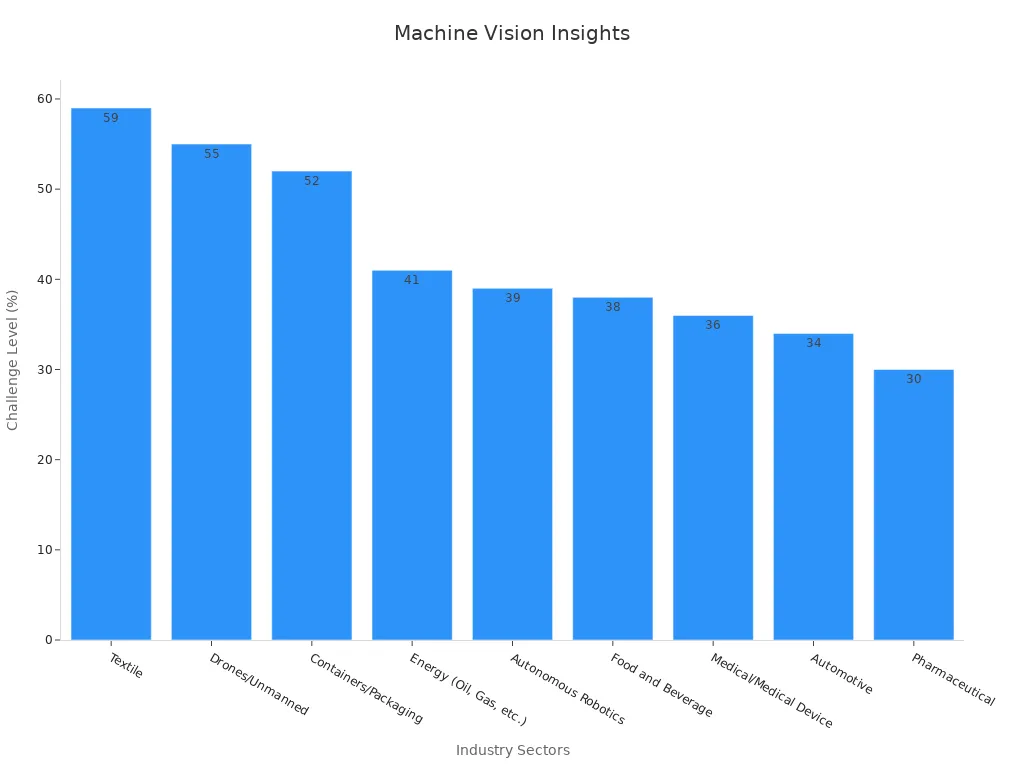

Despite challenges in adoption, industries like automotive and medical devices report significant benefits. The chart below highlights challenge levels across sectors:

By adopting these systems, you can enhance quality control, reduce costs, and scale production. Explore solutions tailored to your needs to stay ahead in today’s competitive landscape.

FAQ

What industries benefit the most from machine vision systems for flaw detection?

Industries like manufacturing, automotive, and electronics gain the most from machine vision systems. These systems improve quality control, reduce waste, and enhance efficiency. For example, they detect micro-level defects in electronics and ensure safety in automotive production.

How do machine vision systems handle different types of defects?

Machine vision systems use advanced cameras and algorithms to identify defects. They detect surface flaws, structural issues, and assembly errors. AI-powered models analyze images in real-time, ensuring accurate and consistent results across various applications.

Are machine vision systems cost-effective for small businesses?

Yes, they are. While the initial investment may seem high, these systems reduce labor costs, minimize waste, and improve product quality. Over time, the savings and efficiency gains outweigh the upfront costs, making them a smart choice for businesses of all sizes.

Can machine vision systems adapt to new production requirements?

Absolutely! Machine vision systems are highly adaptable. You can train AI models to recognize new defect types or adjust settings for different products. This flexibility ensures they remain effective as your production needs evolve.

What is the role of AI in machine vision systems?

AI enhances the accuracy and speed of machine vision systems. It powers real-time defect detection, predictive analytics, and pattern recognition. AI models like YOLOv8 and ResNet enable these systems to identify flaws with precision, even in high-speed production environments.

See Also

Exploring How Machine Vision Systems Identify Defects Effectively

A Comprehensive Guide To Thresholding In Machine Vision

An Insight Into Object Detection In Today's Vision Systems