Frame Grabbers for Modern Machine Vision Systems

Frame grabbers are integral to any Frame Grabbers machine vision system, ensuring seamless communication between cameras and processing units. These devices are designed to capture and transfer high-speed image data, enabling smooth operation during inspections or analyses. Their importance lies in their ability to efficiently manage immense data rates, which is crucial for optimal performance.

For example, CoaXPress (CXP) technology currently supports a maximum data rate of 6.25 Gbit/s, with future advancements targeting speeds of 10 or even 12.5 Gbit/s. By utilizing multiple coaxial links, data rates can scale up to an impressive 25 Gbit/s. This exceptional capability allows a Frame Grabbers machine vision system to process data with unparalleled precision and speed, even in the most demanding applications.

Key Takeaways

- Frame grabbers help capture and move fast image data smoothly.

- Picking the right frame grabber means knowing your needs, like camera type, resolution, and hardware fit.

- Frame grabbers make systems faster by handling tasks like image prep, speeding up data movement and study.

- They manage many camera inputs well, keeping things in sync and avoiding slowdowns.

- Frame grabbers work with many standards, fitting with new cameras and different uses easily.

Understanding Frame Grabbers

Definition and Core Functions

A frame grabber is a device that captures image data from cameras and transfers it to a computer for processing. You can think of it as the bridge between your camera and the machine vision system. Its primary role is to convert analog images into digital formats, making them ready for analysis.

Frame grabbers simplify image acquisition by bundling multiple functions into one device. They handle synchronization in multi-camera setups, which is essential for tasks requiring precise timing. Advanced models also perform data checks to ensure reliable transfers. These features make frame grabbers indispensable for applications like quality control and robotics.

Tip: When working with multiple cameras, choose a frame grabber that supports triggering and synchronization. This ensures efficiency and accuracy in your system.

Types of Frame Grabbers

Frame grabbers come in various types, each designed for specific interfaces and applications.

- Analog Frame Grabbers: These are ideal for older cameras that output analog signals. They convert the signals into digital formats for processing.

- Digital Frame Grabbers: These work with modern cameras, offering high-speed data transfer and compatibility with advanced technologies.

- CoaXPress Frame Grabbers: Known for their high bandwidth, these are perfect for applications requiring rapid image capture, such as web inspections.

- GigE Vision Frame Grabbers: These use Ethernet interfaces, making them suitable for long-distance data transmission.

- USB Frame Grabbers: Compact and easy to use, these are great for portable systems or setups with limited space.

Each type has unique advantages, so you should select one based on your system's requirements and the interface your cameras use.

Key Components of Frame Grabbers

Modern frame grabbers consist of several key components that contribute to their performance.

- PCIe Slots: These slots enable high-speed data transfer, with bandwidths reaching up to 6.4 GB/s.

- Triggering Mechanisms: These components manage the timing of image acquisition, ensuring synchronization across multiple cameras.

- Data Buffers: Buffers temporarily store image data, preventing loss during high-speed transfers.

- Processing Units: These units perform initial data checks and formatting, ensuring reliable transfers.

- Interface Ports: Ports like CoaXPress, GigE, or USB connect the frame grabber to cameras and other system components.

The global market for frame grabbers reflects their importance. In 2023, it was valued at USD 1.65 billion, with a projected growth rate of 7.5% CAGR through 2030. Their role in web inspections, which held a 27.7% market share, highlights their significance in advanced applications.

Note: When selecting a frame grabber, ensure its components align with your system's needs. Compatibility is key to optimizing performance.

Importance of Frame Grabbers in Machine Vision Systems

High-Speed Image Capture and Data Transfer

Frame grabbers play a vital role in ensuring high-speed image capture and efficient data transfer in a machine vision system. These devices handle the immense data rates generated by modern cameras, enabling smooth and reliable performance. For instance, frame grabbers with scalable bandwidth can achieve speeds of up to 16 GBytes/sec. This capability ensures that even the most demanding applications, such as time-critical quality inspections, run without delays.

Another advantage is the ability to transmit data over long distances. Using copper or fiber optic cables, frame grabbers can maintain transmission distances exceeding 300 meters. This feature is particularly useful in large-scale industrial setups where cameras and processing units are far apart.

Moreover, frame grabbers support low-latency triggering, which allows precise control of cameras and image data transmission over a single cable. This reduces complexity and enhances system efficiency. The GenICam standard further simplifies integration by normalizing interactions between software, drivers, and cameras.

| Feature | Description |

|---|---|

| Scalable Bandwidth | Up to 16 GBytes/sec |

| Transmission Distance | Copper or fiber optic cables allow for distances beyond 300+ meters |

| Low-latency Triggering | Camera control and image data transmission on the same cable |

| Power Supply | Frame grabber provides power to the camera over the same cable |

| GenICam Standard | Normalizes interaction between software, driver, and camera |

| Image Pre-processing | Offloads operations to frame grabber, improving system performance |

| GPIOs | Available in formats like LVDS, TTL, and OPTO for device connections |

| Direct Memory Access | Transfers images to host memory with minimal intervention |

| Autonomous Capture | Mechanism inside FPGA reduces host interruptions during high-speed imaging |

By offloading image pre-processing tasks to the frame grabber, you can significantly improve the overall performance of your machine vision system. This ensures that your system remains efficient and reliable, even under heavy workloads.

Relieving Processing Load on Vision Controllers

In a frame grabbers machine vision system, the vision controller often handles multiple tasks, including image processing, analysis, and decision-making. Without a frame grabber, this workload can overwhelm the controller, leading to slower performance and potential errors.

Frame grabbers alleviate this issue by taking on some of the processing tasks. For example, they can perform initial data checks, format conversions, and even image pre-processing. This reduces the burden on the vision controller, allowing it to focus on more critical tasks.

Direct Memory Access (DMA) is another feature that enhances efficiency. With DMA, frame grabbers transfer image data directly to the host memory, minimizing the need for processor intervention. This not only speeds up data transfer but also ensures that the vision controller operates at peak performance.

By integrating a frame grabber into your system, you can achieve faster processing speeds and improved accuracy, which are essential for applications like inspections and robotics.

Managing Multiple Camera Inputs

Modern machine vision systems often require multiple cameras to capture images from different angles or locations. Managing these inputs can be challenging, especially when dealing with high-resolution cameras and fast capture rates. Frame grabbers simplify this process by synchronizing and managing multiple camera inputs efficiently.

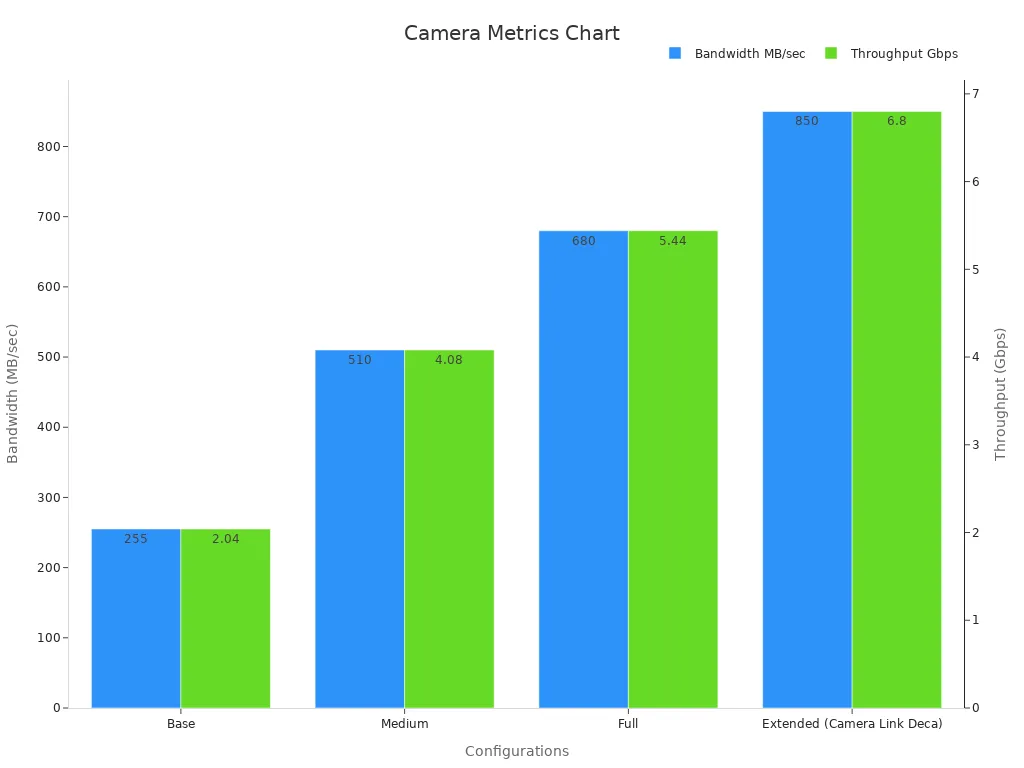

For instance, a frame grabber can handle configurations ranging from base to extended setups, with bandwidths reaching up to 6.8 Gbps. This ensures that all cameras operate seamlessly without data bottlenecks.

| Configuration | Bandwidth (MB/sec) | Throughput (Gbps) |

|---|---|---|

| Base | 255 | 2.04 |

| Medium | 510 | 4.08 |

| Full | 680 | 5.44 |

| Extended (Camera Link Deca) | 850 | 6.8 |

Additionally, frame grabbers support high capture rates across multiple cameras. For example, a system using JAI cameras can achieve a capture rate of 200 Hz across nine cameras, even when set to HD resolution (1920 x 1080). This level of performance is crucial for applications requiring real-time data, such as robotics and automation.

By using a frame grabber, you can ensure that your machine vision system handles multiple camera inputs effectively. This not only improves system performance but also enhances the accuracy and reliability of your vision applications.

Enhancing System Performance with Frame Grabbers

Faster Image Processing and Analysis

Frame grabbers significantly enhance the speed of image processing systems. By offloading tasks like data formatting and pre-processing, they reduce the workload on your main processing unit. This allows your system to analyze images faster and more efficiently. For example, frame grabbers equipped with Direct Memory Access (DMA) technology transfer image data directly to the host memory. This minimizes delays and ensures smooth operation, even in high-speed applications.

Additionally, frame grabbers support real-time image acquisition. This feature is crucial for industries like manufacturing, where rapid inspections are necessary to maintain production quality. With faster processing, you can achieve higher throughput without compromising accuracy.

Improved Accuracy and Reliability

Using frame grabbers in your system improves both accuracy and reliability. These devices ensure precise synchronization between cameras and processing units, which is essential for capturing high-quality images. Advanced models also include error-checking mechanisms to prevent data loss during transmission.

Real-world applications highlight their effectiveness. Marexi Marine Technology's TUNASCAN® system, for instance, achieves near-perfect accuracy in scanning and classifying tuna by species, size, and quality. This level of precision demonstrates how frame grabbers can enhance the reliability of image processing systems in demanding environments.

Tip: To maximize accuracy, choose a frame grabber that supports advanced triggering and synchronization features.

Compatibility with Advanced Camera Technologies

Frame grabbers are designed to work seamlessly with modern camera technologies. They support various industry standards like Camera Link, GigE Vision, USB3 Vision, and CoaXPress. These standards ensure compatibility between components from different suppliers, making it easier to build a versatile and efficient system.

For example, selecting the right camera interface is critical for optimal performance. Frame grabbers that adhere to these standards facilitate interoperability, allowing you to integrate advanced cameras into your system without compatibility issues. This flexibility is particularly valuable in industrial applications, where diverse imaging requirements often exist.

By ensuring compatibility with advanced technologies, frame grabbers future-proof your system and enable you to adopt new innovations as they emerge.

Practical Tips for Selecting and Using Frame Grabbers

Factors to Consider When Choosing a Frame Grabber

Choosing the right frame grabber is essential for building an efficient machine vision solution. Start by understanding your application’s requirements. Consider the type of sensor in your cameras, as it directly impacts image quality. Select a lens with the correct focal length to match your needs. Lighting also plays a crucial role; prioritize light sources with long lifetimes, such as red LEDs, and explore techniques like backlighting for better image clarity.

Evaluate your camera’s specifications carefully. Ensure the resolution and frame rate meet your application’s demands. Compatibility with existing hardware and software is equally important. If scalability matters, choose a frame grabber that supports future upgrades to advanced camera technologies.

| Factor | Details |

|---|---|

| Lighting | Use durable light sources like red LEDs and experiment with lighting techniques. |

| Optics | Match the lens and camera to your resolution and field-of-view requirements. |

| Image Acquisition Hardware | Select based on application type and processing speed needs. |

Ensuring Compatibility with System Components

Compatibility ensures your machine vision solution operates smoothly. Verify that your frame grabber works with your cameras and vision software. Industry standards like Camera Link and GigE Vision simplify this process. These standards allow seamless integration between components from different manufacturers.

Driver software is another critical factor. Use drivers that connect to various camera types to avoid compatibility issues. If your system requires multiple cameras, ensure the frame grabber supports synchronization and triggering. This feature guarantees efficient data capture and transfer.

Tip: Always check compatibility with existing hardware and software before purchasing a frame grabber. This step prevents costly errors during installation.

Optimizing Performance in Machine Vision Systems

To optimize performance, focus on reducing bottlenecks in your system. Frame grabbers equipped with Direct Memory Access (DMA) technology speed up data transfer by minimizing processor intervention. This feature ensures fast and reliable solutions for high-speed applications.

Pre-processing tasks like data formatting can be offloaded to the frame grabber. This reduces the workload on your main processing unit, allowing faster image analysis. For systems with multiple cameras, synchronization features improve efficiency and accuracy.

Regular maintenance also plays a role in performance optimization. Clean your cameras and inspect cables for wear and tear. Update your frame grabber’s firmware to access new features and improve compatibility with advanced technologies.

By following these tips, you can build a machine vision solution that delivers consistent and reliable results.

Applications of Frame Grabbers in Modern Industries

Manufacturing and Quality Control

Frame grabbers play a critical role in manufacturing by ensuring precise and efficient quality control. They enable high-speed image capture and processing, which is essential for detecting defects in products. For example, in assembly lines, frame grabbers work with digital cameras to inspect items for flaws like cracks or misalignments. This ensures that only high-quality products reach the market.

In addition, frame grabbers support multi-camera setups, allowing manufacturers to monitor multiple production stages simultaneously. This capability improves efficiency and reduces downtime. By integrating frame grabbers into your system, you can achieve faster inspections and maintain consistent product quality.

Medical Imaging and Diagnostics

The healthcare industry relies heavily on frame grabbers for advanced imaging solutions. These devices enhance the clarity and speed of image processing, which is vital for accurate diagnoses. For instance, frame grabbers enable real-time imaging in procedures like endoscopy and radiology.

- The global frame grabber market was valued at approximately USD 250 million in 2023.

- It is projected to grow to around USD 420 million by 2032, driven by a 6% CAGR.

- The healthcare sector is a major contributor to this growth due to the demand for high-resolution imaging.

The increasing prevalence of chronic diseases has expanded the need for advanced imaging technologies. Frame grabbers meet this demand by supporting high-resolution digital cameras and ensuring seamless data transfer. Their role in early diagnosis and preventive care highlights their importance in modern healthcare.

Robotics and Automation

In robotics, frame grabbers enhance performance by managing complex image processing tasks. They integrate seamlessly with cameras and lighting systems to capture high-quality images. This integration is crucial for tasks like object recognition and navigation.

- Successful robotic vision systems depend on optimal lighting and camera settings.

- Frame grabbers ensure precision and speed in image processing, even in challenging environments.

- They also support real-time data transfer, which is essential for dynamic robotic operations.

By incorporating frame grabbers, you can improve the accuracy and efficiency of your robotic systems. This makes them indispensable for applications like automated assembly and warehouse management.

Frame grabbers play a pivotal role in modern machine vision systems. They enable high-speed image capture, efficient data transfer, and seamless integration with advanced camera technologies. These devices enhance system performance by reducing latency, improving accuracy, and supporting real-time processing.

| Key Contribution | Description |

|---|---|

| Speed Potential | CMOS sensors generally offer higher speed potential compared to CCD sensors. |

| Data Transmission | CCD sensors can use multiple taps to boost data transmission speed. |

| Interface Standards | Camera Link and CoaXPress require frame grabbers for higher speeds. |

| Modern Connectivity | PCIe interfaces reduce latency and improve overall performance. |

| Processing Options | GPUs and FPGAs enhance image processing capabilities. |

| Software Considerations | Selecting the right software optimizes system performance. |

By leveraging these capabilities, you can build a machine vision system that meets your unique needs. Explore tailored frame grabber solutions to unlock the full potential of your applications.

FAQ

What is the primary purpose of a frame grabber?

A frame grabber captures image data from cameras and transfers it to a computer for processing. It ensures high-speed data transfer and synchronization, making it essential for machine vision systems.

How do frame grabbers improve system performance?

Frame grabbers offload tasks like image pre-processing and data formatting from the main processor. This reduces latency, speeds up image analysis, and ensures smooth operation in high-speed applications.

Tip: Use frame grabbers with Direct Memory Access (DMA) for faster data transfer.

Can frame grabbers handle multiple cameras?

Yes, frame grabbers can manage multiple camera inputs efficiently. They synchronize cameras, prevent data bottlenecks, and support high capture rates, even in complex setups.

| Configuration | Bandwidth (MB/sec) | Throughput (Gbps) |

|---|---|---|

| Base | 255 | 2.04 |

| Medium | 510 | 4.08 |

| Full | 680 | 5.44 |

Are frame grabbers compatible with all cameras?

Frame grabbers support various industry standards like Camera Link, GigE Vision, and CoaXPress. These standards ensure compatibility with most modern cameras, making integration seamless.

What industries benefit the most from frame grabbers?

Frame grabbers are widely used in manufacturing, healthcare, and robotics. They enhance quality control, enable advanced medical imaging, and improve robotic vision systems for tasks like navigation and object recognition.

Note: Choose a frame grabber tailored to your industry’s specific needs for optimal results.

See Also

Exploring Pixel Machine Vision In Today's Applications

Grasping Object Detection Within Contemporary Machine Vision

The Influence Of Frame Rate On Vision System Efficiency