The Role of Guidance Machine Vision in Robotics

A guidance machine vision system allows robots to "see" their environment through advanced imaging and processing technologies. By equipping robots with this capability, you enable them to perform tasks with unmatched precision and adaptability. This system plays a transformative role in modern manufacturing by enhancing efficiency while reducing errors.

- Machine vision technology detects quality issues in real-time, minimizing defects and rework.

- It improves safety by reducing accidents and monitoring compliance with safety protocols.

- Companies report over 99% accuracy in defect detection, ensuring consistent product quality.

These advancements make guidance machine vision systems essential for optimizing industrial processes and achieving higher productivity.

Key Takeaways

- Guidance machine vision helps robots see and understand their surroundings. This improves accuracy and flexibility in tasks.

- Machine vision finds defects quickly, reducing mistakes and making better products. This keeps customers happier.

- Using advanced imaging tools, like 3D vision, makes inspections more accurate and factories work better.

- Robots with vision make jobs like assembly and sorting easier. This speeds up production and lowers worker costs.

- Picking the right vision system means checking cameras, ensuring they fit, and planning for future growth.

Understanding the Guidance Machine Vision System

What is a Guidance Machine Vision System?

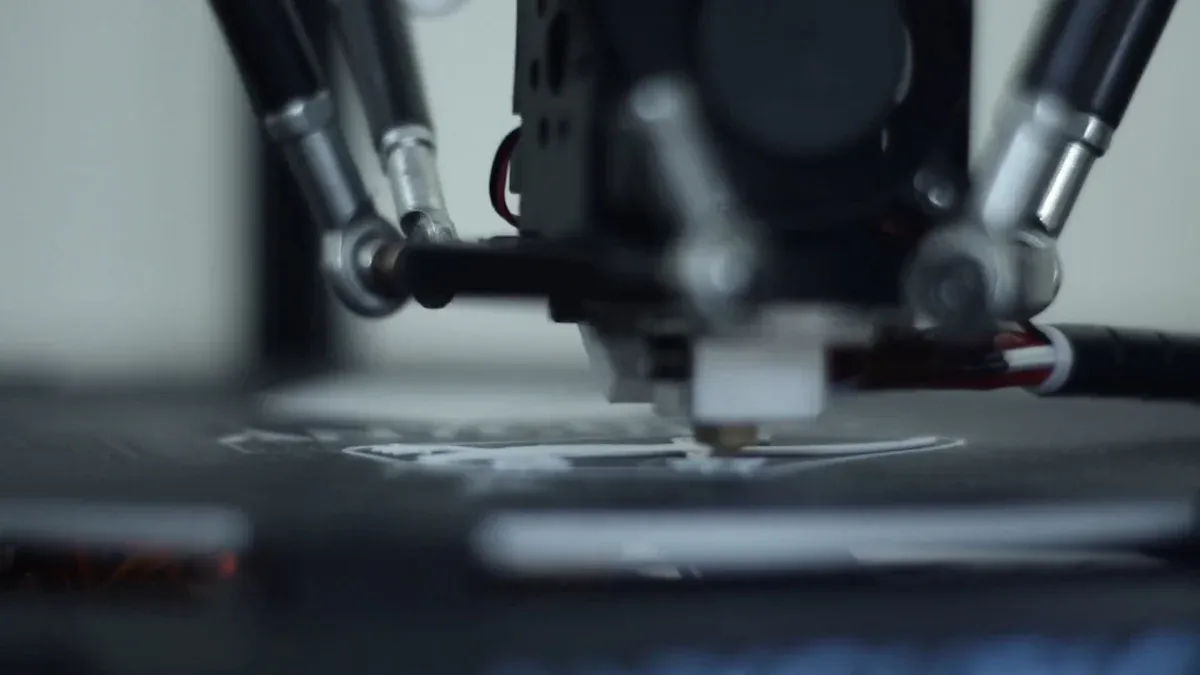

A guidance machine vision system allows robots to interpret their surroundings using advanced imaging technologies. This system combines cameras, sensors, and software to help robots perform tasks with precision. It identifies objects, measures dimensions, and determines positions in real-time. By doing so, it enables robots to adapt to dynamic environments and execute complex operations.

The core functions of this system include locating objects, reporting their orientation, and aligning them for specific tasks. For example, in manufacturing, it ensures parts are positioned correctly for assembly. These capabilities make the system essential for automation and robotics, especially in industries requiring high accuracy.

| Core Function | Description |

|---|---|

| Locating | Identifies the position of parts in 2D or 3D space. |

| Reporting | Communicates the orientation of parts to a machine controller. |

| Applications | Used in automation and robotics for alignment and geometric pattern matching. |

Core Components of a Machine Vision System

A machine vision system consists of several key components that work together to guide robots effectively. These include:

- Cameras: 2D cameras capture flat images, while 3D profilers analyze depth and dimensions. For instance, 3D vision technologies like laser triangulation are critical for inspecting complex assemblies, such as electric vehicle batteries.

- Lighting: Proper illumination ensures accurate image capture, even in challenging conditions.

- Sensors: High-resolution optical sensors detect patterns and details in the environment.

- Processing Units: Advanced processors analyze visual data and make decisions in real-time.

- Software: AI-powered algorithms interpret data, enabling robots to recognize objects and adapt to changes.

The Zivid 2+ camera exemplifies the integration of these components. It delivers high-quality 3D color images, even in poor lighting, making it ideal for robotic applications.

- Increased use of 3D vision technologies enhances inspection accuracy.

- 2D images often fall short for tasks requiring depth analysis.

- Technologies like structured light and stereo vision improve precision in assembly tasks.

How Robot Guidance Works with Machine Vision

Robot guidance relies on machine vision to navigate and perform tasks. The system uses cameras and sensors to capture visual data, which is then processed to identify objects and their positions. This information guides the robot's movements, ensuring accuracy and efficiency.

For example, machine vision systems analyze patterns and recognize details, enabling robots to adapt to their surroundings. Techniques like Simultaneous Localization and Mapping (SLAM) allow robots to navigate autonomously. Optical flow analysis helps detect movement, enabling real-time obstacle avoidance.

In industrial settings, factors like camera distance, processing speed, and lighting conditions play a crucial role in ensuring accurate robot guidance. By addressing these factors, you can optimize the system's performance and achieve better results.

| Metric Type | Description |

|---|---|

| Productivity and Efficiency | Comparison of parts produced per unit of time before and after system implementation. |

| Reject Rate | Measurement of the number of defective parts produced. |

| Error Rate | Assessment of the frequency of errors occurring during operation. |

| Occupational Safety | Evaluation of the reduction in accidents or injuries, particularly with collaborative robots. |

| Real-time Data Analysis | Collection of data on system effectiveness, accuracy, and error rates. |

| System Utilization | Data on how often the system is used, including maintenance history and availability. |

By leveraging these metrics, you can evaluate the effectiveness of your guidance machine vision system and make informed decisions for improvement.

Applications of Vision-Guided Robots

Inspection and Quality Control

Vision-guided robots have revolutionized inspection processes in manufacturing. These systems excel at detecting defects, ensuring that only high-quality products reach the market. By using advanced imaging technologies, they can identify surface imperfections, dimensional inaccuracies, and other anomalies in real-time. This capability minimizes waste and reduces the risk of defective products being shipped to customers.

For example, integrating AI with machine vision systems enhances defect detection accuracy. AI analyzes process parameters and identifies anomalies instantly, providing operators with actionable insights. This ensures consistent quality and streamlines the inspection process. Manufacturers report that vision-guided robots achieve a defect detection accuracy of up to 98.7%, significantly reducing warranty claims and improving customer satisfaction.

| Manufacturer | Application Description |

|---|---|

| ABB | Integrates with Cognex solutions for quality assurance on the factory floor. |

| KUKA | Offers a flexible 2D vision solution for locating, inspecting, and reading codes on parts. |

| Mitsubishi | Combines MELFA robots with Cognex vision systems for high-speed handling and assembly. |

| Universal Robots | Provides URCap solution for guiding users and calibrating robots with Cognex vision systems. |

| Yaskawa | Uses MotoSight 2D for guidance, error proofing, and inspection in various applications like machine tending. |

Vision-guided robots also simplify the setup process. Features like auto-calibration allow you to configure the system quickly, reducing labor and training time. Their robustness ensures reliable operation even in challenging environments, making them indispensable for appearance inspection and quality control tasks.

Precision Assembly and Pick-and-Place Tasks

In assembly lines, precision is critical. Vision-guided robots excel in tasks requiring high accuracy, such as assembling intricate components or performing pick-and-place operations. These robots use advanced imaging to locate parts, measure dimensions, and align components with exceptional precision.

Performance reports highlight the stark difference between operations with and without machine vision. Robots equipped with vision systems automate component sorting, detect defects in real-time, and ensure adherence to specifications. This results in faster production speeds and fewer errors compared to manual processes.

| Aspect | With Machine Vision | Without Machine Vision |

|---|---|---|

| Component Sorting | Automated identification and categorization of parts | Manual sorting, prone to errors |

| Defect Detection | Real-time detection of defects | Potentially missed defects |

| Specification Accuracy | Enhanced accuracy in meeting specifications | Variability in adherence to specifications |

| Overall Efficiency | Increased production speed and reduced errors | Slower processes with higher error rates |

By automating these tasks, vision-guided robots improve production efficiency and reduce costs. Their ability to adapt to different parts and configurations makes them ideal for industries like electronics, automotive, and aerospace.

Identification and Sorting in Manufacturing

Sorting and categorizing parts is another area where vision-guided robots shine. These systems use advanced algorithms to identify objects based on size, shape, color, or other attributes. This capability ensures accurate sorting, even in high-speed production environments.

Case studies demonstrate the impact of machine vision on manufacturing. Companies report a 27% increase in production throughput and a 34% reduction in waste from false positives. These improvements translate to significant cost savings and a rapid return on investment.

| Metric | Result |

|---|---|

| Detection Accuracy for Critical Defects | 98.7% |

| Reduction in Warranty Claims | 92% |

| Increase in Production Throughput | 27% |

| Reduction in Waste from False Positives | 34% |

| Reduction in Quality Control Labor Costs | 68% |

| Annual Savings from Reduced Warranty Claims | $1.2 million |

| ROI within the First Year | 325% |

| Payback Period | 3.7 months |

Vision-guided robots also enhance flexibility. Their ability to adapt to different products and production lines ensures seamless integration into diverse manufacturing environments. This adaptability makes them a valuable asset for industries aiming to optimize their operations.

Real-World Examples of Vision-Guided Robots

Vision-guided robots are transforming industries by solving complex challenges and improving efficiency. These robots use advanced imaging systems to perform tasks that require precision and adaptability. Let’s explore some real-world examples that highlight their impact.

In logistics and warehousing, autonomous mobile robots (AMRs) equipped with vision systems have become indispensable. These robots transport components and products across fulfillment centers, even in complex environments. Their AI-enabled vision allows them to handle product variability, ensuring smooth operations in high-volume facilities. You can see their value in e-commerce warehouses, where they optimize order picking and reduce delivery times.

Underwater inspections also benefit from vision-guided robots. NMS, a commercial diving company, used Blue Atlas Robotics' Sentinus ROVs to inspect underwater pipes. These robots captured high-resolution images and created detailed 3D models of the pipes. This approach enhanced safety and efficiency, reducing the risks associated with human divers. By using vision-guided ROVs, you can achieve accurate inspections in challenging underwater conditions.

In construction, ABB Robotics collaborated with AUAR to address labor shortages and improve housing affordability. They developed robotic micro-factories that integrate vision AI for building homes. These robots ensure precise assembly and high-quality construction. If you’re in the construction industry, this technology can help you meet demand while maintaining quality standards.

These examples demonstrate how vision-guided robots adapt to diverse industries. Whether it’s streamlining warehouse operations, conducting underwater inspections, or building homes, these robots deliver measurable benefits. By adopting this technology, you can enhance productivity, reduce costs, and stay competitive in your field.

Overcoming Challenges in Guidance Machine Vision Systems

Addressing Calibration and Accuracy Issues

Calibration plays a vital role in ensuring the accuracy of guidance machine vision systems. Without proper calibration, even the most advanced systems can produce errors in object detection and positioning. You can address this challenge by implementing regular calibration routines and using high-quality reference tools. For example, calibration grids and fiducial markers help align the system's cameras and sensors with the robot's movements. This alignment ensures that the system maintains its precision over time.

Another effective approach involves leveraging 3D vision technologies. These technologies enhance accuracy by capturing depth information, which is crucial for tasks like inspection with industrial robots. By integrating 3D vision, you can minimize errors caused by variations in lighting or object orientation. Regularly monitoring system performance and recalibrating when necessary will further improve accuracy and efficiency.

Ensuring Compatibility with Robotic Platforms

Integrating machine vision systems with different robotic platforms can be challenging due to varying industry standards. To overcome this, you should select systems that adhere to widely recognized standards. These standards ensure seamless communication between the vision system and the robot, enhancing overall efficiency.

| Standard | Benefits | Limitations |

|---|---|---|

| GigE Vision | High scalability, excellent interoperability, vendor independence | Limited to Ethernet infrastructure |

| USB3 Vision | High-speed data transfer, cost-effective | Limited cable length |

| CoaXPress | High bandwidth, suitable for high-resolution applications | Lack of vendor diversity, more complex implementation requirements |

When choosing a system, consider your specific industrial needs. For example, USB3 Vision may suit applications requiring cost-effective solutions, while CoaXPress is ideal for high-resolution tasks. Ensuring compatibility during the configuration phase will save time and reduce integration issues.

Building Robust Systems for Dynamic Environments

Dynamic environments present unique challenges for guidance machine vision systems. Factors like changing lighting conditions, moving objects, and unpredictable interactions can impact system performance. To build robust systems, you should adopt advanced evaluation strategies that go beyond traditional testing methods. These strategies involve using diverse datasets that reflect real-world conditions. By doing so, you can ensure the system operates reliably in various scenarios.

Many teams encounter a "prototype purgatory" where systems perform well in controlled environments but fail in real-world applications. This gap often arises from limited testing on small, curated datasets. To address this, focus on continuous testing and optimization. Incorporating AI-powered algorithms can also enhance the system's adaptability, allowing it to handle complex industrial tasks with greater efficiency.

By addressing these challenges, you can create guidance machine vision systems that deliver consistent accuracy and reliability, even in unpredictable environments.

Choosing the Right Guidance Machine Vision System

Evaluating Camera Types and Configurations

Selecting the right camera type is crucial for achieving optimal performance in your machine vision system. Cameras serve as the "eyes" of the system, capturing images that undergo image processing to guide robotic actions. You can choose between 2D and 3D cameras based on your application needs. For tasks like picking flat objects or inspecting surface defects, 2D cameras are sufficient. However, 3D cameras are essential for applications requiring depth analysis, such as assembling complex components.

Configurations also play a significant role. Factors like resolution, frame rate, and field of view determine how well the system performs in real-world conditions. For example, high-resolution cameras capture finer details, while higher frame rates are ideal for fast-moving production lines. Properly configuring these elements ensures easy configuration and enhances production efficiency.

Aligning System Capabilities with Industry Needs

Your industry’s specific requirements should guide your choice of a machine vision system. For instance, in aerospace, a vision-guided assembly cell can automate nutplate installation. This system uses 3D vision to identify 225 part styles and 28 nutplate configurations, addressing the sector's traditionally low automation levels. Such tailored solutions ensure high productivity and seamless integration into existing workflows.

To align capabilities effectively, consider the following steps:

- Define your application requirements, such as inspection or picking tasks.

- Assess environmental conditions like lighting and temperature.

- Evaluate hardware and software options for compatibility and functionality.

By focusing on these factors, you can select a system that meets your operational goals and enhances automation.

Prioritizing Scalability and Future-Proofing

Scalability ensures your system can adapt to future demands. As industries evolve, your machine vision system should accommodate new technologies and increased workloads. Deployment modes like on-premises, cloud-based, hybrid, and edge computing offer varying levels of scalability and flexibility. For example, edge computing provides real-time data processing, making it ideal for smart manufacturing and autonomous vehicles.

| Deployment Mode | Advantages | Industries Benefiting |

|---|---|---|

| On-Premises | Complete control, data security, flexibility, customization | Pharmaceuticals, sensitive data sectors |

| Cloud-Based | Reduced costs, ease of maintenance, scalability | Small and medium-sized enterprises |

| Hybrid | Balances control and scalability, optimizes operations | Various industries seeking flexibility |

| Edge Computing | Real-time data processing, reduced latency, enhances performance | Autonomous vehicles, smart manufacturing |

Future-proofing involves anticipating technological advancements. Choose systems with modular designs and software that supports updates. This approach ensures your investment remains valuable as your industry grows.

Guidance machine vision systems have revolutionized robotics by enhancing precision, efficiency, and adaptability. These systems empower you to automate complex tasks, reduce errors, and improve product quality. Industry reports highlight the growing demand for automation and quality inspection, driven by the need for safety and operational excellence. However, challenges like integrating cameras, optics, and software remain significant.

Looking ahead, advancements in AI, deep learning, and smart cameras will shape the future of robotics. The machine vision market is projected to grow from $19.59 billion in 2024 to $32.66 billion by 2029, reflecting its expanding role across industries. By adopting these technologies, you can stay ahead in an increasingly automated world.

FAQ

What is the role of vision in robotics?

Vision allows robots to interpret their surroundings. It helps them identify objects, measure dimensions, and determine positions. This capability improves precision and enables robots to perform complex tasks like inspection, assembly, and pick and place operations.

How do robots use machine vision for flexible picking?

Robots equipped with machine vision can adapt to different shapes, sizes, and orientations of objects. This flexibility allows them to handle diverse items in dynamic environments, making them ideal for tasks like sorting and packaging.

What are robot-guided tasks?

Robot-guided tasks involve robots using vision systems to navigate and perform actions. These tasks include assembling components, inspecting products, and sorting items. Vision systems ensure accuracy and adaptability in these operations.

How does deep learning with 3D machine vision enhance robotics?

Deep learning with 3D machine vision enables robots to analyze complex data and make intelligent decisions. This technology improves object recognition, depth perception, and adaptability, making robots more efficient in dynamic environments.

Why is machine vision important for pick and place tasks?

Machine vision ensures accuracy in pick and place tasks by identifying object positions and orientations. It allows robots to handle items with precision, reducing errors and increasing efficiency in manufacturing and logistics.

See Also

An In-Depth Look at Machine Vision in Automation

Essential Tips for Positioning Gear in Vision Systems

Understanding the Role of Cameras in Vision Systems