How Platform Machine Vision Systems Work

Imagine a world where machines can "see" and make decisions just like humans. A platform machine vision system makes this possible by enabling machines to process and analyze images. This technology allows you to automate complex tasks like identifying defects, tracking objects, or even diagnosing diseases. Its impact on industries is undeniable.

- The industrial machine vision market was valued at approximately USD 10 billion in 2023.

- It is expected to grow to USD 24.5 billion by 2032, with a 10.5% annual growth rate.

This rapid growth reflects the increasing demand for automation and precision across various sectors. By replacing manual processes, a machine vision system can save billions spent on labor costs while improving efficiency.

Key Takeaways

- Machine vision systems help find defects and check product quality. They make work faster and more accurate in many industries.

- Using machine vision can save money. It lowers labor costs and reduces waste by spotting problems early.

- These systems improve quality checks by giving steady results. Only good products are sent to the market.

- Machine vision tools can grow and change to fit needs. They work well for small businesses and big companies in areas like factories and healthcare.

- Adding machine vision to current workflows can make work smoother and boost productivity.

Overview of Platform Machine Vision Systems

Definition and Purpose

A platform machine vision system combines artificial intelligence, machine learning, and advanced imaging technologies to help machines "see" and interpret visual data. These systems analyze images to extract meaningful information, enabling automation in tasks like quality control, defect detection, and object tracking.

| Definition | Purpose |

|---|---|

| Computer vision is a field of artificial intelligence that uses machine learning and neural networks to derive meaningful information from visual inputs. | It enables systems to detect defects and issues at a scale that surpasses human capabilities, making it relevant for various industries. |

| Machine learning uses algorithmic models that allow computers to teach themselves about visual data. | This self-learning capability enhances the efficiency and accuracy of inspections in production processes. |

| Convolutional neural networks (CNNs) break images down into pixels to make predictions about what they are seeing. | CNNs are essential for understanding single images, which is crucial for quality control in manufacturing. |

These systems are not just tools; they are transformative technologies that redefine how industries operate.

Key Differences from Traditional Vision Systems

Platform machine vision systems stand apart from traditional vision systems in several ways. Traditional systems rely on pre-programmed algorithms, which limit their flexibility and accuracy. In contrast, platform machine vision systems use AI and machine learning to adapt and improve over time.

| Metric | AI-Powered Machine Vision Systems | Traditional Vision Systems |

|---|---|---|

| Accuracy | Higher due to learning from data | Limited by programmed algorithms |

| Flexibility | Adapts to environmental changes | Struggles with variations |

| Automation | Enables large-scale automation | Manual processes required |

| Efficiency | Operates continuously, 24/7 | Dependent on human workers |

| Real-Time Decision Making | Instantly detects and reacts | Slower response times |

By leveraging AI, these systems can handle complex tasks and environmental changes, making them indispensable in modern industries.

Importance in Automation and Industry

The importance of platform machine vision systems in automation cannot be overstated. They enable industries to achieve higher efficiency, accuracy, and scalability. For example:

- The machine vision market is projected to grow at a CAGR of 14.09% from 2025 to 2033, reaching USD 203.38 billion by 2033.

- Key trends include the integration of AI, compact system designs, and the rise of smart factories.

These systems excel in tasks like quality inspection, where they outperform human capabilities. Their ability to analyze images in real-time ensures consistent results, reducing errors and downtime. As industries continue to embrace automation, the demand for machine vision systems will only grow.

Key Components of a Platform Machine Vision System

Lighting for Image Capture

Lighting plays a crucial role in ensuring the clarity and accuracy of captured images. Without proper lighting, even the most advanced machine vision system struggles to deliver reliable results. You need to select lighting configurations based on environmental factors and the specific requirements of your application.

| Environmental Factor | Impact on Lighting | Suggested Solution |

|---|---|---|

| Temperature | Reduced lifespan | Thermal management |

| Humidity | Corrosion | IP-rated fixtures |

| Dust | Diminished output | Regular cleaning |

| Vibrations | Component damage | Vibration-resistant fixtures |

Bright field illumination enhances surface details, while dark field illumination emphasizes edges and detects imperfections. For high-speed applications, LED pulsing and strobing synchronize with the camera's frame rate, reducing motion blur and improving image clarity. These techniques are essential for production lines where objects move quickly.

Tip: Choose lighting equipment with built-in thermal management systems to maintain performance in extreme conditions. Lights with appropriate IP ratings prevent moisture ingress, ensuring durability in challenging environments.

Lenses for Focusing and Directing Light

Lenses are the eyes of a machine vision system. They focus and direct light onto the image sensor, ensuring the captured image is sharp and detailed. The choice of lens depends on factors like focal length, aperture size, and the working distance between the lens and the object.

- Focal Length: Determines the field of view and magnification. Short focal lengths capture wider areas, while longer focal lengths zoom in on specific details.

- Aperture Size: Controls the amount of light entering the lens. Larger apertures allow more light, improving image brightness in low-light conditions.

- Working Distance: Impacts the lens's ability to focus on objects. Adjustable lenses accommodate varying distances, making them versatile for different applications.

High-quality lenses minimize distortions and aberrations, ensuring the image remains true to the original scene. For tasks requiring extreme precision, you should consider telecentric lenses. These lenses maintain consistent magnification across the field of view, making them ideal for measuring and inspecting objects.

Cameras for Capturing Visual Data

Cameras are the heart of a platform machine vision system. They capture visual data and convert it into digital signals for processing. The camera's performance depends on its image sensor, resolution, and frame rate.

- Image Sensor: The sensor resolution determines the level of detail in the captured image. Higher resolutions allow for better defect detection and analysis.

- Frame Rate: High frame rates are essential for capturing fast-moving objects without motion blur. This feature is critical in industries like manufacturing and logistics.

- Connectivity: Cameras with reliable cabling and interface peripherals ensure seamless data transfer to the computing platform.

Modern cameras often include features like automatic exposure control and color correction, enhancing the quality of captured images. For applications requiring extreme precision, you should opt for cameras with advanced image sensors capable of capturing minute details.

Note: Mechanical failures or misalignments can lead to downtime and performance losses. Regular maintenance ensures the camera operates efficiently and reliably.

Cabling and interface peripherals for connectivity

Cabling and interface peripherals form the backbone of a platform machine vision system, ensuring seamless communication between components. Without reliable connectivity, even the most advanced cameras and software cannot function effectively.

To achieve efficient data transfer, you should consider the following technical standards and performance metrics:

- Gigabit Ethernet: This standard supports multi-point distribution and allows cable lengths of up to 100 meters. It provides scalable networking for large systems.

- Cat 6a Cables: These cables offer data rates of up to 10 Gbps and maintain noise immunity. Shielded options help reduce electromagnetic interference (EMI) and radio frequency interference (RFI).

- Precision Time Protocol (PTP): Standardized under IEEE 1588, PTP synchronizes devices within microseconds. This improves the precision of operations in time-sensitive applications.

- GigE Vision and GenICam Standards: These ensure interoperability between hardware and software, simplifying system integration and enhancing user experience.

| Metric | Performance Benefit | Example Use Case |

|---|---|---|

| Data Rates | Up to 10 Gbps with Cat 6a cables | High-speed image transfer |

| Cable Length | 100 meters for standard Ethernet cables | Large-scale manufacturing setups |

| Frequency | Up to 500 MHz for Cat 6a cables | High-speed data transmission |

Tip: Use shielded cables in environments with high EMI or RFI to maintain signal integrity and prevent data loss.

By selecting the right cabling and interface peripherals, you can ensure your machine vision system operates reliably and efficiently, even in demanding industrial environments.

Computing platforms for image processing

The computing platform is the brain of a machine vision system. It processes the raw data captured by the camera and transforms it into actionable insights. The choice of computing platform depends on the complexity of your application and the volume of data your system needs to handle.

Modern computing platforms often include:

- Central Processing Units (CPUs): Ideal for general-purpose processing tasks. CPUs handle basic image processing and system control.

- Graphics Processing Units (GPUs): These excel at parallel processing, making them perfect for tasks like deep learning and real-time image analysis.

- Field-Programmable Gate Arrays (FPGAs): FPGAs offer customizable hardware acceleration, enabling ultra-fast processing for specific applications.

- Edge Computing Devices: These devices process data locally, reducing latency and bandwidth usage. They are particularly useful in applications requiring real-time decision-making.

For example, GPUs can process high-resolution images at lightning speed, making them indispensable in industries like healthcare and manufacturing. Meanwhile, edge computing devices allow you to analyze images directly at the source, minimizing delays and improving system responsiveness.

Note: Regularly update your computing platform's firmware and drivers to ensure compatibility with the latest cameras and software.

By investing in the right computing platform, you can unlock the full potential of your machine vision system, enabling faster and more accurate image processing.

Software for analysis and decision-making

Software is the decision-making engine of a platform machine vision system. It analyzes the processed image data and generates actionable outputs. Advanced software solutions leverage artificial intelligence and machine learning to enhance accuracy and efficiency.

Key features of modern machine vision software include:

- Deep Learning Algorithms: These algorithms, such as Convolutional Neural Networks (CNNs), excel at tasks like image segmentation, object detection, and classification. For instance, CNNs can identify defects in manufacturing or detect tumors in medical imaging.

- Real-Time Analysis: Software with real-time capabilities enables immediate decision-making, which is critical in applications like automated quality control.

- User-Friendly Interfaces: Intuitive interfaces allow you to configure and monitor the system easily, even without extensive technical expertise.

- Interoperability: Compliance with standards like GenICam ensures seamless integration with various hardware components.

| Algorithm Type | Application | Benefit |

|---|---|---|

| Convolutional Neural Networks (CNNs) | Image segmentation and object detection | Enhanced accuracy in defect detection |

| Machine Learning Models | Pattern recognition and anomaly detection | Improved efficiency in inspections |

Deep learning algorithms have revolutionized image analysis. They automatically extract meaningful features from images, reducing the need for manual intervention. In healthcare, these algorithms assist in diagnosing diseases by analyzing medical images with precision.

Tip: Choose software that supports updates and scalability to future-proof your machine vision system.

With the right software, you can transform raw image data into valuable insights, driving automation and improving decision-making across industries.

How Components Work Together in a Machine Vision System

Image capture and data acquisition

The first step in a platform machine vision system is capturing and acquiring image data. This process begins with the camera and its image sensor, which work together to convert light into digital signals. The quality of the captured image depends on factors like lighting, lens selection, and the camera's resolution. A well-lit environment ensures the camera captures clear and detailed images, while high-quality lenses minimize distortions.

In industrial applications, this stage significantly improves efficiency. For example, in tire manufacturing, inspection times have been reduced from six minutes to just one minute. The accuracy of inspections has also increased from 60% to 95%, demonstrating the importance of precise image capture.

| Industry Application | Improvement Description | Metrics Achieved |

|---|---|---|

| Tire Manufacturing | Reduced inspection times | From 6 to 1 minute |

| Industrial Manufacturing | Improved inspection accuracy | From 60% to 95% |

| Tire Manufacturing | Reduced out-of-tolerance events | By 35% |

| Tire Manufacturing | Reduced start-up time | From 5 to 1 minute |

| Tire Manufacturing | Improved uniformity of tire treads | By 50% |

Tip: Ensure your camera's image sensor matches the resolution and frame rate requirements of your application. This alignment guarantees optimal performance during image capture.

Data transfer and processing

Once the image is captured, the system transfers the data to the computing platform for processing. This step involves moving large volumes of data quickly and efficiently. Technologies like Gigabit Ethernet and RoCE (RDMA over Converged Ethernet) enhance data transfer by reducing latency and bypassing the CPU. These methods ensure real-time performance, which is critical for applications like automated quality control.

Processing begins as soon as the data reaches the computing platform. Simpler algorithms perform basic tasks like edge detection, while more complex methods handle advanced image processing tasks such as pattern recognition. Benchmarks show that simpler algorithms execute faster, making them suitable for time-sensitive applications. However, complex algorithms require more processing power, which may increase execution times.

Note: Choose a computing platform that balances processing speed and complexity. This ensures your machine vision system can handle real-time applications without delays.

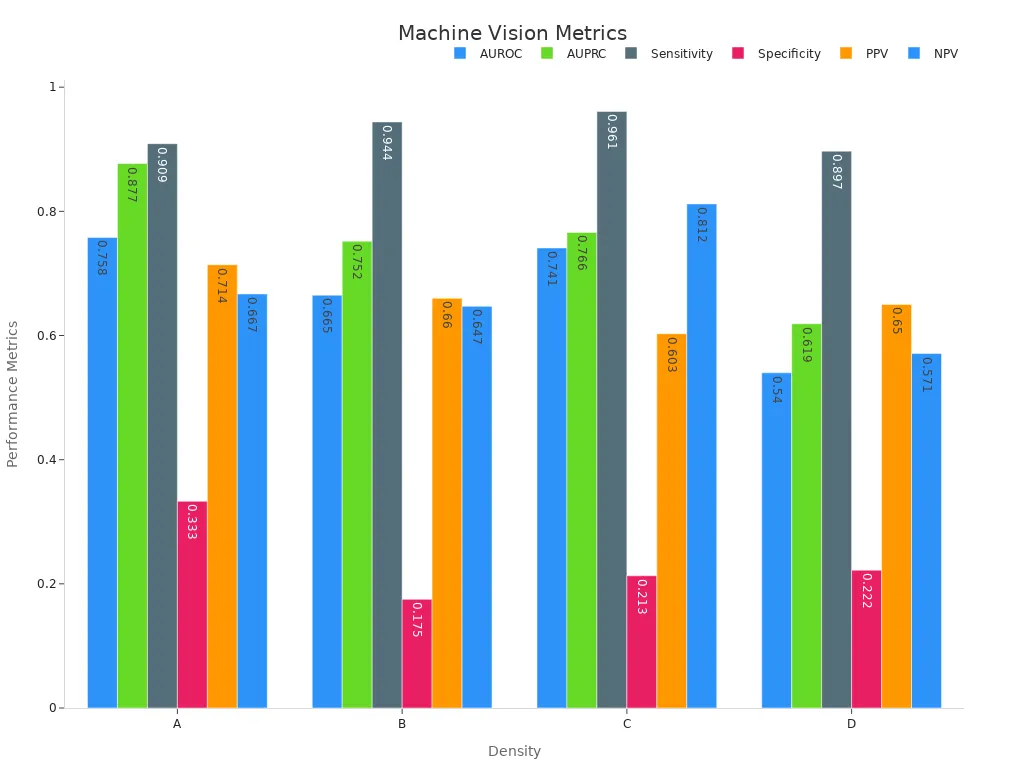

Image analysis and interpretation

The final stage involves analyzing and interpreting the processed image data. Advanced software uses deep learning algorithms like Convolutional Neural Networks (CNNs) to identify patterns, detect anomalies, and classify objects. These algorithms excel at tasks like defect detection and medical diagnostics, where precision is crucial.

Studies reveal impressive accuracy rates during this stage. For instance, a system analyzing 485 document images achieved an Intersection over Union (IoU) of 0.97 or higher in 54.84% of observations. When the IoU threshold was set at 0.9, 91.34% of documents exceeded this benchmark. These results highlight the reliability of modern machine vision systems in interpreting image data.

| Density | AUROC | AUPRC | Sensitivity | Specificity | PPV | NPV |

|---|---|---|---|---|---|---|

| A | 0.758 | 0.877 | 0.909 | 0.333 | 0.714 | 0.667 |

| B | 0.665 | 0.752 | 0.944 | 0.175 | 0.66 | 0.647 |

| C | 0.741 | 0.766 | 0.961 | 0.213 | 0.603 | 0.812 |

| D | 0.54 | 0.619 | 0.897 | 0.222 | 0.65 | 0.571 |

Tip: Regularly update your software to leverage the latest advancements in image analysis. This ensures your system remains accurate and efficient.

System feedback and integration

System feedback and integration play a crucial role in ensuring the seamless operation of a platform machine vision system. Feedback mechanisms allow the system to monitor its performance and make adjustments in real time. Integration ensures that the system works harmoniously with other equipment and processes in your workflow.

How Feedback Enhances Performance

Feedback loops enable the system to identify and correct errors during operation. For example, if a defect is detected on a production line, the system can immediately signal the machinery to halt or redirect the faulty product. This prevents defective items from advancing further in the process. Real-time feedback also allows you to optimize production settings, such as adjusting lighting or camera angles, to maintain consistent image quality.

| Metric/Case Study | Description |

|---|---|

| Enhanced Accuracy | Vision systems can detect even the smallest defects that human inspectors might miss, significantly improving product quality. |

| Increased Efficiency | Automating the inspection process reduces the time needed for quality control, allowing for faster production cycles and minimizing downtime. |

| Consistency | Unlike human inspectors, vision systems provide consistent results, ensuring that every product is evaluated with the same level of scrutiny. |

| Real-Time Feedback | Many vision systems offer real-time data analysis, allowing for immediate corrective actions if defects are detected, thus preventing faulty products from reaching customers. |

| Cost Savings | While the initial investment in vision inspection technology can be significant, the long-term savings from reduced waste, rework, and improved quality often justify the cost. |

| Applications | Vision systems are used in various industries such as electronics manufacturing, food and beverage, automotive, pharmaceuticals, and textiles, showcasing their transformative impact. |

Tip: Use systems with real-time feedback capabilities to minimize downtime and improve overall efficiency.

Integration with Existing Systems

Integration ensures that your machine vision system communicates effectively with other devices and software in your production environment. For instance, the system can send inspection results directly to a programmable logic controller (PLC), which then adjusts the machinery based on the data. This level of integration streamlines operations and reduces the need for manual intervention.

Modern machine vision systems often support industry-standard protocols like OPC UA and MQTT. These protocols enable seamless data exchange between devices, ensuring compatibility across different platforms. Additionally, cloud-based integration allows you to store and analyze data remotely, providing insights into long-term trends and performance metrics.

Note: Ensure your system supports the communication protocols used in your facility to avoid compatibility issues.

By combining robust feedback mechanisms with effective integration, you can maximize the performance and reliability of your machine vision system. This approach not only enhances accuracy and efficiency but also ensures that your operations remain scalable and adaptable to future needs.

Practical Applications of Platform Machine Vision Systems

Manufacturing: Quality control and defect detection

Machine vision systems revolutionize quality control in manufacturing by delivering fast, accurate, and consistent inspections. These systems capture high-resolution images to detect defects, ensuring products meet stringent quality standards. For example:

- In the food and beverage industry, machine vision ensures product safety by identifying contaminants and verifying packaging integrity.

- Automotive manufacturers use these systems to inspect intricate components, reducing defects and enhancing safety.

- In paper and pulp production, high-speed cameras monitor quality and detect imperfections in real time.

These systems also excel in assembly verification, ensuring all components are correctly aligned. They identify issues like discoloration, cracks, and scratches, improving defect detection speed and consistency. By automating these tasks, you can maintain high production rates without sacrificing accuracy.

| Aspect | Description |

|---|---|

| Accuracy and Precision | High-resolution images ensure products meet quality standards. |

| Speed and Efficiency | Automated inspections maintain rapid production rates. |

| Real-time Data Processing | Instant defect detection enables immediate corrective actions. |

Tip: Implement machine vision to reduce costly recalls and regulatory issues while improving operational efficiency.

Healthcare: Medical imaging and diagnostics

In healthcare, machine vision systems play a critical role in medical imaging and diagnostics. These systems analyze images from modalities like MRI and CT to detect abnormalities with remarkable precision. For instance, diagnostic tools use pattern recognition to identify tumors or other anomalies, enhancing accuracy and aiding early detection.

Machine vision also supports treatment planning by analyzing historical data to optimize approaches. Clinical decision support systems compare cases to improve diagnostic reliability. Additionally, quality assurance mechanisms ensure consistent imaging standards across healthcare facilities.

Detection efficiencies in healthcare applications range from 65% to 100%, depending on the methodology and imaging modality. This variability highlights the adaptability of machine vision systems to different medical needs.

Note: Regular updates to diagnostic software can further improve accuracy and expand the system's capabilities.

Logistics: Sorting and tracking packages

Logistics operations benefit immensely from machine vision systems, particularly in sorting and tracking packages. These systems use cameras and AI to identify, classify, and route parcels with exceptional accuracy. For example, a U.S.-based logistics company achieved a sorting accuracy of 99.1% by implementing machine vision.

Vision-enabled robotic sorters increase parcel processing efficiency by 45%, optimizing the sorting process and reducing delays. These systems also track worker productivity and automatically count packages, streamlining operations.

Automated sorting systems not only enhance accuracy but also improve tracking efficiency, ensuring packages reach their destinations on time. This level of precision is essential in today’s fast-paced e-commerce environment.

Tip: Use machine vision to handle high volumes of packages efficiently, reducing errors and improving customer satisfaction.

Agriculture: Crop monitoring and sorting

Machine vision systems are transforming agriculture by improving crop monitoring and sorting processes. These systems analyze images to detect plant health, identify ripe fruits, and sort produce efficiently. You can use them to automate tasks that traditionally require manual labor, saving time and reducing errors.

For example, machine vision enhances accuracy in detecting plant diseases, monitoring growth, and harvesting crops. It also excels in sorting fruits and vegetables based on size, color, and quality. Manual sorting often leads to inconsistencies, but automated systems ensure uniformity and precision.

Researchers have developed advanced methodologies to improve agricultural tasks. For instance, segmenting cotton leaves using PCNN combined with an immune algorithm achieves 93.50% accuracy. Similarly, detecting overlapping leaves with the Sobel and C-V model reaches 95.72% accuracy. These results demonstrate the reliability of machine vision in agricultural applications.

| Task | Methodology | Accuracy |

|---|---|---|

| Cotton leaves segmentation | PCNN + Immune algorithm | 93.50% |

| Overlapping leaves | Sobel + C-V model | 95.72% |

By integrating machine vision, you can monitor crops more effectively and sort produce faster. High-resolution image analysis ensures that only the best-quality items reach the market. This technology not only boosts productivity but also reduces waste, making it a sustainable solution for modern farming.

Tip: Use machine vision to monitor plant health and optimize harvesting schedules. This approach ensures better yields and higher profits.

Retail: Automated checkout and inventory management

In retail, machine vision systems are revolutionizing how you manage inventory and handle customer transactions. These systems use image analysis to automate checkout processes and track stock levels in real time. You can rely on them to reduce human errors and improve operational efficiency.

Automated checkout systems equipped with cameras and AI recognize products instantly. They eliminate the need for barcode scanning, speeding up transactions and enhancing the shopping experience. For instance, smart carts with built-in cameras can identify items as you place them inside, allowing for seamless payment at the end of your shopping trip.

Inventory management also benefits from machine vision. Cameras installed in storage areas capture images of shelves and stock levels. The system analyzes these images to identify low-stock items and generate restocking alerts. This ensures that your store remains well-stocked without overordering.

Machine vision systems also help prevent theft by monitoring suspicious activities. They analyze images from security cameras to detect unusual behavior, alerting staff in real time. This adds an extra layer of security to your retail operations.

Note: Implementing machine vision in retail can reduce checkout times and improve inventory accuracy, leading to higher customer satisfaction.

Benefits of Machine Vision Systems

Enhanced efficiency and accuracy

Machine vision systems significantly improve efficiency and accuracy in industrial processes. By automating tasks like defect detection and quality inspection, these systems eliminate human error and ensure consistent results. For example, AI-based visual inspection enhances brand consistency by reducing labeling mistakes. Deep learning algorithms in camera systems continuously adjust settings, enabling real-time analysis and boosting production rates.

You can also rely on these systems to handle repetitive tasks faster than manual methods. This automation reduces downtime and improves overall productivity. In industries like manufacturing, machine vision systems have become indispensable for maintaining high standards while meeting tight deadlines.

Tip: Use high-resolution cameras and advanced software to maximize the accuracy of your inspections.

Cost savings through automation

Adopting machine vision systems leads to substantial cost savings. Automating visual inspections reduces labor expenses and minimizes waste by catching defects early. For instance, a single production line can save $352,620 weekly and $18,336,240 annually. Labor savings alone can amount to $691,200 per year.

| Savings Type | Amount |

|---|---|

| Weekly Savings per Line | $352,620 |

| Annual Savings per Line | $18,336,240 |

| Labor Savings | $691,200/year |

Calculating the return on investment (ROI) for these systems is straightforward. If your total investment is $100,000 and annual returns reach $175,000, the ROI would be 75%. This demonstrates the financial benefits of integrating machine vision into your operations.

Improved quality control

Machine vision systems excel at enhancing quality control. They eliminate human error, ensuring only products that meet your standards reach the market. These systems automate inspections, reducing time and increasing productivity. Real-time data collection allows you to analyze trends and optimize processes.

For example, machine vision systems adapt to various inspection requirements, making them flexible and scalable. They also integrate seamlessly into existing workflows, ensuring smooth operations. By using these systems, you can maintain high-quality standards while improving efficiency.

Note: Regularly update your system's software to stay ahead of evolving quality control benchmarks.

Scalability across industries

Machine vision systems adapt to industries of all sizes, making them a versatile solution for automation. Whether you manage a small-scale operation or a large enterprise, these systems can scale to meet your needs. Their flexibility allows you to integrate them into existing workflows without disrupting operations.

Advancements in artificial intelligence (AI) have made machine vision systems more precise and efficient. In manufacturing, AI-powered systems handle complex tasks like defect detection and assembly verification. In healthcare, they analyze medical images with remarkable accuracy, aiding in diagnostics and treatment planning. These capabilities drive adoption across diverse sectors.

PC-based machine vision systems dominate the market due to their scalability. They process large volumes of data quickly, making them ideal for industries requiring high-speed operations. For example, the automotive sector leads in market share by using machine vision for safety inspections and quality control. These systems enhance vehicle perception, ensuring operational transparency and reliability.

| Evidence Description | Industry Impact |

|---|---|

| Increasing demand for automation enhances machine vision industry expansion. | Greater efficiency, accuracy, and productivity across industries. |

| Advancements in AI improve precision and efficiency in sectors like manufacturing and healthcare. | Enables handling of complex tasks, driving market expansion. |

| PC-based machine vision systems are highly scalable and can handle complex operations quickly. | Dominates the market due to higher processing power. |

| Automotive industry leads in market share, utilizing machine vision for safety and inspection. | Enhances vehicle perception and operational transparency. |

- The automotive sector is the largest market for machine vision, focusing on safety and inspection tasks.

- AI-powered systems are increasingly adopted for precision in manufacturing and healthcare.

- PC-based systems are preferred for their scalability and ability to perform complex operations.

By choosing machine vision systems, you can future-proof your operations. Their ability to scale ensures they remain relevant as your business grows, making them a valuable investment across industries.

Platform machine vision systems combine advanced components like cameras, lenses, and software to deliver precise image analysis. These systems streamline processes across industries, from manufacturing to healthcare. Their transformative potential is evident in market growth, with the global market size projected to rise from USD 13.49 billion in 2023 to nearly USD 20.68 billion by 2030, growing at a CAGR of 6.29%.

- 🌏 APAC Highlights:

- Over 38% of global sales in 2023.

- Dominance expected through 2030, led by China and Japan.

You can harness this technology to enhance efficiency, reduce costs, and solve unique challenges in your field.

FAQ

What industries benefit the most from machine vision systems?

Machine vision systems are widely used in manufacturing, healthcare, logistics, agriculture, and retail. They improve efficiency, accuracy, and quality control in these industries. For example, manufacturers use them for defect detection, while healthcare professionals rely on them for medical imaging and diagnostics.

How do machine vision systems differ from human inspection?

Machine vision systems analyze images faster and more consistently than humans. They operate 24/7 without fatigue and detect minute defects that human eyes might miss. This makes them ideal for high-speed production lines and tasks requiring precision.

Can machine vision systems work in low-light environments?

Yes, they can. Proper lighting configurations, such as LED illumination or infrared lighting, ensure clear image capture even in low-light conditions. You can also use cameras with high sensitivity to improve performance in challenging environments.

Are machine vision systems difficult to integrate into existing workflows?

Most modern systems support industry-standard protocols like OPC UA and MQTT, making integration seamless. You can connect them to existing equipment and software with minimal disruption. Many systems also offer user-friendly interfaces for easy configuration.

What is the ROI of implementing a machine vision system?

The ROI depends on your application. For example, automating quality inspections can save labor costs, reduce waste, and improve product quality. Many businesses see significant returns within the first year, making it a cost-effective investment.

Tip: Evaluate your specific needs and calculate potential savings to estimate ROI accurately.

See Also

Understanding Image Processing Within Machine Vision Systems

Comparing Firmware Machine Vision With Conventional Systems

How to Properly Position Equipment in Machine Vision