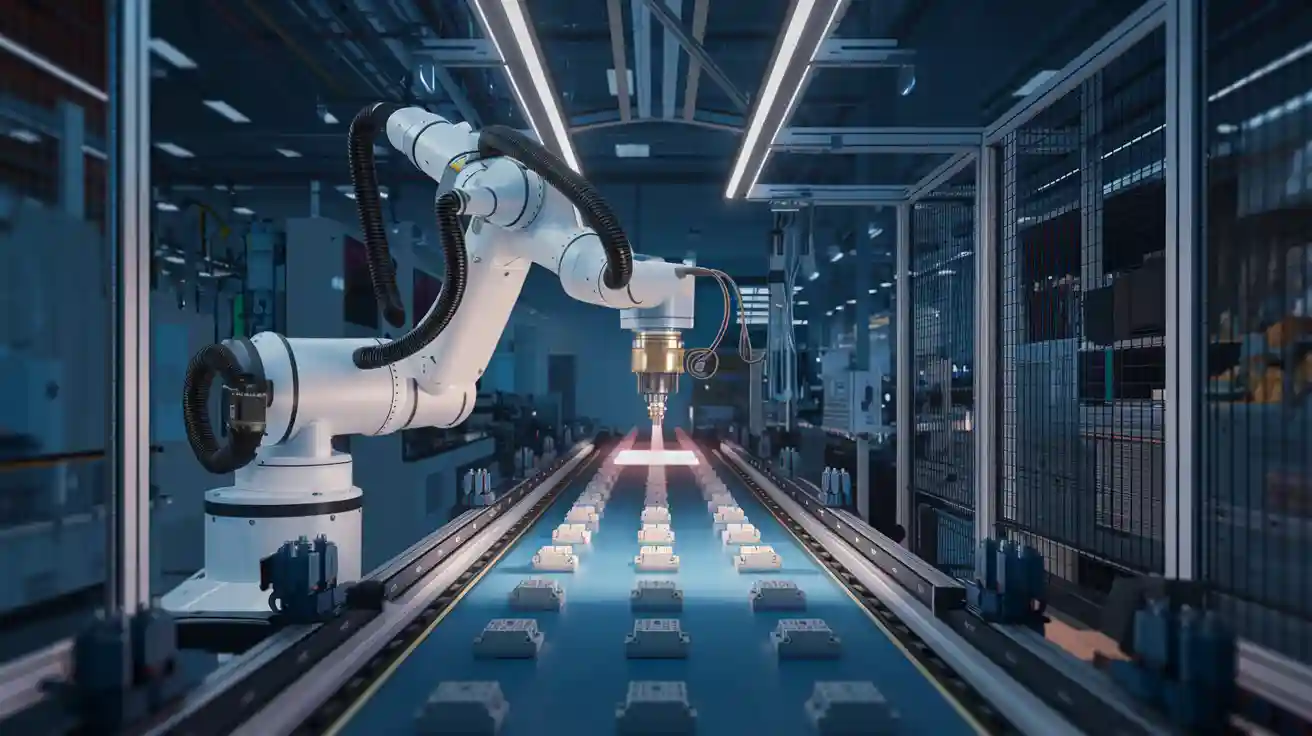

What Is Illumination Machine Vision System?

An illumination machine vision system combines advanced lighting technologies with optical components to help machines "see" objects more clearly. You use this system to enhance image quality and ensure accurate detection in automated processes. It adjusts light intensity, direction, and uniformity to highlight specific features, making it easier for cameras and sensors to capture precise data.

The adoption of these systems continues to rise in industries. For example:

- Quality assurance and inspection will dominate the market in 2024.

- The market size is projected to grow from USD 14,571.29 Million in 2024 to over USD 28,615.08 Million by 2032.

- A CAGR of 9.8% is expected from 2025 to 2032, showing steady growth in machine vision applications.

By leveraging illumination, you empower machines to perform tasks with greater accuracy and efficiency.

Key Takeaways

- Illumination machine vision systems use light to improve image quality. This helps machines see and study objects more clearly.

- Good lighting, like soft or backlighting, makes things easier to see. It also reduces shadows, creating clear images for jobs like checking products or diagnosing problems.

- Picking the right lights, lenses, and sensors is very important. It helps machine vision work better in industries like factories and healthcare.

- Using covers and light spreaders creates even lighting. This is needed for clear pictures and accurate data.

- Buying these systems can make work faster, more accurate, and safer. They are useful for tasks like checking products or medical scans.

Core Components of an Illumination Machine Vision System

Light Sources (e.g., LED, halogen lamps)

Light sources form the backbone of any illumination machine vision system. You rely on them to provide consistent and controlled lighting for capturing high-quality images. LEDs and halogen lamps are commonly used due to their reliability and adaptability. LEDs, for instance, offer high efficacy, producing more lumens per watt compared to traditional lamps. They also have a longer rated life, maintaining 70% brightness over extended periods.

When selecting a light source, you consider several technical specifications:

- Wattage: Determines the energy required to operate the light.

- Lumens: Measures the total light output.

- Color Temperature (CCT): Indicates the color of the emitted light, ranging from warm to cool tones.

- Color Rendering Index (CRI): Reflects how accurately colors appear under the light.

- Center Beam Candle Power (CBCP): Shows the intensity of light at the center of the beam.

| Specification | Value |

|---|---|

| Optical Power Drift per °C (Typical) | 0.1% |

| Lamp Electrical Power | 150 W |

| Lamp Lifespan (Average) | 1000 Hours |

| Output Power (SLS301) | >1.6 W |

| Output Power (SLS302) | >10 W |

Integrated lights, such as LEDs, are preferred for their ability to deliver uniform illumination across the field, ensuring accurate image capture.

Optics (e.g., lenses, filters)

Optics play a critical role in shaping and directing light within the system. You use lenses to focus light on specific areas and filters to block unwanted wavelengths. High-quality optics ensure that the light interacts with objects in the field precisely, enhancing image clarity.

Modern systems employ advanced technologies like the OptiSpheric® system to test optical components. This system provides measurements with up to 0.03% accuracy, ensuring reliability. It also allows quick testing of lenses, reducing measurement time to just a few seconds. This speed and accuracy make it ideal for applications requiring high throughput.

Filters, on the other hand, help you control the wavelength of light. For example, you might use a bandpass filter to isolate specific colors or a polarizing filter to reduce glare. These tools ensure that the light reaching the sensors is optimized for the task at hand.

Sensors (e.g., cameras, photodetectors)

Sensors are the eyes of the machine vision system. Cameras and photodetectors capture the light reflected or emitted by objects, converting it into digital data for analysis. You choose sensors based on their quantum efficiency, which measures their ability to detect light. Higher quantum efficiency means better performance in low-light conditions.

Standardized metrics like EMVA 1288 help you compare sensor models across vendors. These metrics ensure that you select sensors with the best accuracy and reliability for your application. Cameras often excel in capturing detailed images, while photodetectors specialize in measuring light intensity.

By integrating sensors with advanced optics and light sources, you create a system capable of capturing precise data across various fields, from manufacturing to healthcare.

Diffusors and Housings

Diffusors and housings are essential components of an illumination machine vision system. They work together to control and shape the light, ensuring it meets the specific requirements of your application. Without these elements, achieving consistent and uniform lighting would be challenging.

Diffusors: Enhancing Light Uniformity

A diffusor scatters light to reduce glare and shadows. It ensures that the light spreads evenly across the object being inspected. This uniformity is crucial when you need to capture fine details or inspect surfaces for defects.

Tip: Use diffusors when working with shiny or reflective objects. They help minimize unwanted reflections, making it easier to analyze the object.

Here are some common types of diffusors you might encounter:

- Frosted Glass Diffusors: These are ideal for softening light and reducing harsh shadows.

- Acrylic Diffusors: Lightweight and durable, they work well in industrial environments.

- Polycarbonate Diffusors: These offer high impact resistance and are suitable for rugged applications.

When selecting a diffusor, consider its material and thickness. Thicker diffusors provide better light scattering but may reduce brightness.

Housings: Protecting and Directing Light

Housings serve two primary purposes. They protect the light source from environmental factors like dust and moisture. They also direct the light toward the target area, ensuring precision.

You can choose from various housing designs based on your needs:

- Spotlight Housings: Focus light on a small area for detailed inspections.

- Floodlight Housings: Spread light over a wide area for general illumination.

- Adjustable Housings: Allow you to change the light's angle and direction easily.

Note: Proper housing not only improves performance but also extends the lifespan of your light source by shielding it from damage.

Combining Diffusors and Housings

When you pair diffusors with housings, you gain greater control over the lighting conditions. For example, a frosted glass diffusor inside a spotlight housing can create a focused yet soft beam of light. This combination is perfect for applications requiring both precision and uniformity.

| Component | Function | Example Use Case |

|---|---|---|

| Diffusor | Scatters light for uniformity | Inspecting reflective surfaces |

| Housing | Protects and directs the light | Harsh industrial environments |

By understanding how diffusors and housings work, you can optimize your illumination machine vision system for better performance. These components ensure that your system delivers consistent and reliable results, no matter the application.

How Illumination Impacts Machine Vision Performance

Role of Lighting in Image Quality

Lighting plays a vital role in determining the quality of images captured by machine vision systems. When you use good lighting, it enhances the visibility of object features, making it easier for the system to detect and analyze them. Poor lighting, on the other hand, can lead to blurry or inconsistent images, reducing the accuracy of the system.

A study on a novel LED flash system for agricultural robots highlights how tailored lighting solutions can address challenges like motion blur and lighting variability. This research shows that optimizing the lighting setup improves image clarity, even in outdoor environments where conditions are unpredictable. By carefully analyzing how light interacts with objects in the field, you can ensure that the system captures high-quality images consistently.

Good lighting also minimizes shadows and glare, which can obscure important details. For example, in industrial applications, a well-designed lighting setup ensures that defects on a product's surface are clearly visible. This level of precision is critical for tasks like quality control and inspection.

Examples of Lighting Techniques

To achieve optimal results, you can use various illumination techniques tailored to specific applications. Each technique serves a unique purpose, helping you highlight certain features or reduce unwanted effects like reflections. Here are some common techniques:

- Bright Field Lighting: This technique directs light onto the object from the same angle as the camera. It works well for inspecting surface details, such as scratches or dents.

- Dark Field Lighting: Light is projected at a low angle, emphasizing edges and textures. You might use this technique to detect cracks or other fine details.

- Diffuse Lighting: A diffusor spreads light evenly across the field, reducing shadows and glare. This technique is ideal for inspecting shiny or reflective objects.

- Structured Lighting: Patterns of light, such as grids or stripes, are projected onto the object. This method helps you measure dimensions or detect surface irregularities.

By selecting the right illumination techniques, you can optimize the performance of your machine vision system for any task.

Backlighting for Object Silhouettes

Backlighting is a powerful technique that involves placing the light source behind the object. This setup creates a high-contrast silhouette, making it easier to analyze the object's shape and size. You often use backlighting in applications where the outline of an object is more important than its surface details.

For instance, in the food industry, backlighting helps you inspect the shape of fruits or vegetables to ensure they meet quality standards. Similarly, in manufacturing, this technique allows you to measure the dimensions of components with high precision. The simplicity of backlighting makes it a reliable choice for tasks that require clear and consistent results.

When setting up backlighting, you should ensure that the light source provides uniform illumination across the field. This prevents uneven silhouettes, which can lead to errors in analysis. A well-designed backlighting setup enhances the accuracy and reliability of your machine vision system.

Diffuse Lighting for Uniform Illumination

Diffuse lighting ensures even illumination across the entire field, eliminating harsh shadows and glare. You use this technique when inspecting objects with reflective surfaces or intricate details. By scattering the light, a diffusor creates a soft and uniform glow that enhances visibility.

For example, imagine inspecting a shiny metal part for scratches. Without diffuse lighting, reflections might obscure the surface, making it difficult to spot defects. With this technique, the light spreads evenly, revealing every detail clearly.

Benefits of Diffuse Lighting

- Improved Image Quality: Uniform illumination reduces inconsistencies, ensuring accurate image capture.

- Enhanced Detail Visibility: Diffuse lighting highlights subtle features, such as fine textures or small imperfections.

- Reduced Glare: By scattering the light, this technique minimizes reflections that can interfere with analysis.

Tip: Use diffuse lighting when working with objects that have glossy or uneven surfaces. It helps you achieve consistent results in challenging conditions.

Applications of Diffuse Lighting

You often rely on diffuse lighting in industries like manufacturing and healthcare. In manufacturing, it helps you inspect products for defects without interference from reflections. In healthcare, it ensures clear imaging of biological samples, aiding in accurate diagnostics.

To set up diffuse lighting, choose a high-quality diffusor and position it to cover the entire field. This ensures that the light reaches every part of the object evenly, enhancing the performance of your machine vision system.

Bright Field Lighting for Surface Details

Bright field lighting focuses light directly onto the object from the same angle as the camera. This technique is ideal for inspecting surface details, such as scratches, dents, or other imperfections. You use it when you need to highlight features that are visible under direct illumination.

How Bright Field Lighting Works

The light source illuminates the object, and the camera captures the reflected light. This setup creates high contrast between the object's surface and its surroundings, making it easier to analyze. For example, when inspecting a painted surface, bright field lighting reveals inconsistencies like uneven coatings or tiny cracks.

Advantages of Bright Field Lighting

- Precision: Direct illumination ensures that surface details stand out clearly.

- Versatility: You can use this technique for a wide range of applications, from quality control to defect detection.

- Ease of Setup: Bright field lighting requires minimal adjustments, making it simple to implement.

Note: Ensure the light source provides consistent intensity across the field. This prevents uneven illumination, which can affect the accuracy of your analysis.

Applications of Bright Field Lighting

Bright field lighting is widely used in industries like automotive and electronics. In automotive manufacturing, it helps you inspect painted surfaces for scratches or blemishes. In electronics, it ensures that circuit boards are free from defects, such as soldering errors.

When setting up bright field lighting, position the light source and camera at the same angle. This alignment ensures that the full bright field lighting technique works effectively, capturing every surface detail with precision.

Importance of Proper Illumination in Machine Vision Applications

Improving Accuracy in Image Capture

Proper illumination ensures that your machine vision system captures images with high precision. When lighting is optimized, the system can highlight critical features of objects, making them easier to detect and analyze. For example, bright field lighting reveals surface imperfections, while diffuse lighting eliminates glare and shadows. These techniques improve the clarity of captured images, which is essential for tasks like defect detection or quality control.

The importance of lighting becomes evident when you consider how poor illumination can lead to blurry or inconsistent images. These issues reduce the accuracy of your system and compromise the reliability of automated processes. By implementing an optimal lighting solution, you enhance the system's ability to capture detailed and consistent images across various machine vision applications.

Enhancing Reliability in Data Analysis

Reliable data analysis starts with high-quality image capture. When illumination is tailored to your application, it ensures that the data extracted from images is accurate and consistent. For instance, backlighting simplifies the analysis of object shapes, while structured lighting helps measure dimensions with precision.

You can see the importance of lighting in industries like healthcare, where medical imaging relies on clear visuals for diagnostics. Similarly, in manufacturing, proper illumination ensures that defects are detected accurately, reducing the risk of faulty products reaching consumers. By prioritizing the importance of lighting, you improve the reliability of your machine vision system's data analysis capabilities.

Reducing Errors in Automated Processes

Errors in automated processes often stem from poor image quality. When lighting is inconsistent, the system struggles to identify objects or features correctly. This can lead to misclassifications, missed defects, or inaccurate measurements.

By optimizing illumination, you reduce these errors significantly. Techniques like diffuse lighting create uniform illumination, ensuring that every detail is visible. Backlighting enhances contrast, making it easier to identify shapes and edges. These methods improve the system's performance, allowing it to operate with greater accuracy and efficiency.

Proper illumination is not just about enhancing image quality; it also ensures that your automated processes run smoothly. This reduces downtime and improves overall productivity in machine vision applications.

Benefits of Illumination Machine Vision Systems in Industries

Manufacturing (e.g., quality control, defect detection)

Illumination machine vision systems play a crucial role in manufacturing by ensuring high-quality production standards. You can use these systems to detect defects, verify product dimensions, and maintain compliance with industry regulations. For example, high-resolution cameras paired with optimized lighting can identify tiny abnormalities in medical devices or car parts. This level of precision helps prevent safety risks and costly recalls.

In industries like food production, machine vision systems ensure accurate labeling and monitor ingredients for safety compliance. Similarly, in transportation, these systems enable real-time defect detection during vehicle assembly, enhancing both quality control and regulatory adherence.

| Industry | Application Description |

|---|---|

| Manufacturing | High-resolution cameras detect small abnormalities, crucial for safety in products like medical devices and car parts. |

| Food Production | Machine vision ensures correct labeling, ingredient monitoring, and compliance with safety standards. |

| Transportation | Real-time defect detection in vehicle assembly processes enhances quality control and regulatory compliance. |

| Medical Industry | Inspections ensure correct sealing and labeling of medical products, reducing medication errors significantly. |

By implementing these systems, you can improve production efficiency and reduce the risks associated with defective products.

Healthcare (e.g., medical imaging, diagnostics)

In healthcare, illumination machine vision systems enhance medical imaging and diagnostics. These systems provide clear and detailed visuals, which are essential for accurate diagnoses. For instance, they ensure that biological samples are illuminated uniformly, allowing you to detect abnormalities with precision.

Machine vision systems also play a role in inspecting medical products. They verify the sealing and labeling of items like syringes and medication packaging. This reduces the chances of errors, ensuring patient safety. Additionally, these systems help monitor compliance with strict healthcare regulations, minimizing risks for both patients and providers.

Tip: Use diffuse lighting in medical imaging to eliminate glare and shadows, ensuring clear and consistent results.

Logistics (e.g., barcode scanning, package inspection)

In logistics, illumination machine vision systems improve efficiency in barcode scanning and package inspections. Optimized lighting ensures that barcodes are readable, even when damaged or partially obscured. This reduces errors in routing and enhances overall operational accuracy.

Performance metrics validate the importance of proper illumination in logistics. For example:

- Read Rate: Measures the percentage of successfully decoded barcodes, ensuring seamless data capture.

- Decodability: Assesses the ability to decode damaged barcodes, crucial for accurate routing.

- Print Contrast Signal (PCS): Quantifies the difference in reflectance between bars and spaces, indicating print quality.

| Metric | Description |

|---|---|

| Read Rate (Decode Rate) | Measures the percentage of successfully decoded barcodes, ensuring seamless data capture. |

| Decodability | Assesses the ability to decode damaged or partially obscured barcodes, crucial for accurate routing. |

| Robustness to Environmental Factors | Evaluates how well barcodes perform under varying conditions, including lighting and environmental challenges. |

| Print Contrast Signal (PCS) | Quantifies the difference in reflectance between bars and spaces, indicating print quality. |

By leveraging these systems, you can streamline operations, reduce errors, and improve productivity in logistics.

Food and Beverage (e.g., contamination detection, sorting)

Illumination machine vision systems transform food and beverage operations by improving contamination detection and sorting processes. You can use these systems to ensure product safety and quality while meeting industry standards.

Contamination Detection

Machine vision systems equipped with proper lighting help you identify contaminants in food products. These contaminants could include foreign objects like plastic, metal, or glass. By using techniques such as backlighting or diffuse lighting, you can highlight irregularities that might otherwise go unnoticed.

Tip: Use bright field lighting to detect surface contaminants like dirt or residue on fruits and vegetables. This technique enhances visibility and ensures thorough inspections.

For example, in beverage production, these systems inspect bottles for cracks or leftover residue before filling. In food packaging, they verify that containers are free from contaminants, ensuring consumer safety.

Sorting Applications

Sorting food items based on size, shape, or color becomes more efficient with illumination machine vision systems. You can use structured lighting to measure dimensions or diffuse lighting to enhance color differentiation. These techniques help you separate defective items from high-quality products.

| Sorting Criteria | Lighting Technique Used | Example Application |

|---|---|---|

| Size | Structured Lighting | Sorting fruits by diameter |

| Shape | Backlighting | Identifying irregular vegetables |

| Color | Diffuse Lighting | Separating ripe from unripe fruit |

In the food industry, these systems also sort grains or nuts by detecting discoloration or deformities. This ensures that only high-quality items reach consumers.

By integrating illumination machine vision systems into your food and beverage operations, you enhance safety, improve efficiency, and maintain product quality.

Illumination forms the backbone of machine vision systems, enabling accurate image capture and analysis. You’ve learned how components like light sources, optics, and sensors work together to optimize performance. Proper lighting techniques, such as backlighting and diffuse lighting, ensure precision in diverse applications, from manufacturing to healthcare.

Key Takeaway: By prioritizing illumination, you enhance the reliability, accuracy, and efficiency of automated processes. Whether inspecting products or diagnosing medical conditions, the right lighting transforms machine vision into a powerful tool for innovation.

FAQ

What is the main purpose of an illumination machine vision system?

The system helps machines "see" by improving image quality. It uses controlled lighting to highlight object features, making it easier for cameras and sensors to capture accurate data. This ensures better performance in automated tasks.

How do you choose the right lighting technique for your application?

You select a technique based on your needs. For surface details, use bright field lighting. For shapes, backlighting works best. Diffuse lighting reduces glare, while structured lighting highlights dimensions. Match the technique to your task.

Tip: Test different setups to find the most effective lighting for your system.

Why is uniform illumination important in machine vision?

Uniform lighting ensures consistent image quality. It eliminates shadows and glare, making object features more visible. This improves the accuracy of defect detection, measurements, and other automated processes.

Can illumination systems work in harsh environments?

Yes, many systems include durable housings to protect light sources. These housings shield against dust, moisture, and temperature changes, ensuring reliable performance even in challenging industrial settings.

What industries benefit the most from illumination machine vision systems?

Industries like manufacturing, healthcare, logistics, and food processing rely heavily on these systems. They improve quality control, enhance diagnostics, streamline operations, and ensure product safety.

Emoji Insight: 🏭 Manufacturing, 🏥 Healthcare, 📦 Logistics, and 🍎 Food Processing all gain from these systems.

See Also

Comparing Fixed And Motion Integrated Vision Systems In Machine Vision

Understanding The Fundamentals Of Camera Resolution In Machine Vision

The Role Of Deep Learning In Advancing Machine Vision Systems

An In-Depth Guide To Machine Vision In Industrial Automation

Essential Insights Into Computer Vision Versus Machine Vision