Image Processing Machine Vision Systems Explained

An image processing machine vision system enables machines to "see" and interpret visual data. You can use these systems to automate tasks that require inspection, measurement, or identification. Their ability to enhance quality control ensures consistent product standards. For example, 93% of manufacturers emphasize the importance of reliable inspections for maintaining quality. Machine vision systems also improve efficiency by reducing errors and speeding up processes. Industries like manufacturing, healthcare, and agriculture rely on these systems to meet modern demands for precision and productivity.

Key Takeaways

- Machine vision systems help machines understand pictures automatically. They improve quality checks and reduce mistakes in factories and hospitals.

- These systems give instant feedback, so problems can be fixed quickly. This stops delays and makes work faster and better.

- They are great at finding defects, with over 99% accuracy. This reduces waste and makes products better.

- Good lighting and clear cameras are very important. They help capture and study images properly.

- Using machine vision with robots increases work speed. It lowers labor costs, keeps work safe, and stays accurate.

What Are Image Processing Machine Vision Systems?

Definition and Purpose

An image processing machine vision system is a technology that allows machines to interpret visual data with precision and speed. These systems capture images, process them, and make decisions based on predefined criteria. Unlike traditional methods that rely on human inspection, machine vision systems use advanced algorithms to analyze images, ensuring consistent and objective results.

You’ll find these systems particularly useful in industrial image processing, where accuracy and efficiency are critical. For instance, high-resolution cameras can detect even the smallest defects in products, reducing waste and improving quality. Machine vision systems also excel in tasks like measuring dimensions, identifying objects, and guiding robotic movements. Their ability to perform these tasks with minimal human intervention makes them indispensable in modern industries.

Note: The advancement of computer technology has significantly expanded the applications of machine vision systems, from food processing to automotive manufacturing.

Key Features of Machine Vision Systems

Machine vision systems come equipped with several features that make them highly effective in industrial settings. Here are some of the key attributes:

- High Accuracy: These systems capture and process image information with exceptional precision, ensuring reliable results.

- Real-Time Processing: They analyze images and make decisions almost instantly, which increases production speed.

- Flexibility: Machine vision systems can handle diverse tasks, such as surface inspection, component positioning, and defect detection.

- Automation: By replacing human inspectors, these systems reduce labor costs and improve occupational safety.

- Integration with Robotics: Cameras guide robots in tasks like pick-and-place operations, enhancing efficiency in industries like automotive and electronics.

In industries like food and pharmaceuticals, machine vision systems play a crucial role. For example, they inspect food products for foreign objects or check tablets for defects, ensuring high-quality standards. These advanced vision systems not only improve productivity but also enhance safety by taking over high-risk inspections.

Machine Vision vs. Computer Vision

While machine vision and computer vision share similarities, they serve different purposes, especially in industrial applications. The table below highlights their key differences:

| Feature | Machine Vision | Computer Vision |

|---|---|---|

| Definition | A subset of computer vision focused on specific applications in manufacturing and quality assurance. | Encompasses a broader range of image analysis tasks. |

| Application | Tailored for industrial use, such as inspection and decision-making in production lines. | Can be used for various theoretical and practical applications. |

| Image Processing | Involves image processing based on a set of rules and parameters. | Focuses on capturing and automating image analysis. |

| Decision Making | Outputs specific decisions (e.g., pass or fail) based on detected defects. | Can operate independently without a larger machine system. |

| Data Focus | Concentrates on specific parts or critical qualities of an object. | Aims to extract as much data as possible about an object. |

You’ll notice that machine vision systems are purpose-built for industrial image processing tasks. They focus on specific objectives, such as identifying defects or measuring dimensions, and provide actionable outputs. In contrast, computer vision has a broader scope, often used in fields like autonomous vehicles and facial recognition.

By understanding these distinctions, you can better appreciate how machine vision systems contribute to industrial automation and quality control. Their specialized design makes them a cornerstone of modern manufacturing processes.

How Do Image Processing Machine Vision Systems Work?

Image Acquisition

Image acquisition is the first step in any image processing machine vision system. It involves capturing visual data using cameras and sensors. The quality of this data directly impacts the system's performance. High-resolution cameras, combined with proper lighting and optics, ensure consistent image quality. For example, edge-based tools can extract information even under varying brightness conditions, making gradients in image data crucial for analysis.

The imaging system and acquisition protocol play a vital role in determining task performance. Specific parameters, such as light intensity and object reflectivity, must be optimized to ensure accuracy. The table below highlights key aspects of image acquisition:

| Aspect | Description |

|---|---|

| Imaging System | The imaging system and acquisition protocol can significantly affect task performance. |

| AI Algorithm Dependency | An AI algorithm's effectiveness may vary based on the resolution of the imaging system used. |

| Protocol Specification | Specific acquisition protocol parameters must be defined to ensure the algorithm's applicability. |

| Observer Impact | The competency of human observers can influence the performance of imaging algorithms. |

| Figure of Merit (FoM) | FoMs quantitatively describe algorithm performance, allowing for comparisons and defining success metrics. |

Proper image acquisition techniques ensure that the system captures high-quality data for further processing. This step lays the foundation for accurate image analysis and decision-making.

Image Processing and Analysis

Once the system acquires an image, it processes and analyzes the data to extract meaningful information. Machine vision systems use advanced algorithms to identify patterns, detect defects, and classify objects. These algorithms rely on pixel data, which is influenced by factors like light intensity and camera settings.

Statistical data highlights the efficiency of image processing in machine vision systems. For example, Optical Character Recognition (OCR) achieves over 99.5% accuracy, while AI-powered defect detection ranges from 95–98%. Automated visual inspection reduces defect rates by up to 80%, significantly improving quality control. The table below provides additional insights:

| Evidence Description | Accuracy/Efficiency Rate |

|---|---|

| OCR (Optical Character Recognition) | Over 99.5% |

| AI-powered defect detection | 95–98% |

| Hybrid vision systems | 30% improvement |

| Vision-guided robots | Up to 10,000 parts/hour |

| Robotic part-picking efficiency | Over 40% improvement |

| Automated visual inspection | Up to 80% defect rate reduction |

| Inspection error reduction | Over 90% compared to manual |

| Human error rate reduction | From 25% to under 2% |

| Cycle time reduction in assembly | Up to 20% |

| 3D stereo vision accuracy | Over 90% for depth estimation |

Machine vision systems excel in industrial image processing tasks, such as dimensional inspection and defect detection. By leveraging optimized algorithms, these systems enhance accuracy and efficiency, ensuring consistent results across production lines.

Decision-Making and Action

After processing and analyzing the image, the system makes decisions based on predefined criteria. These decisions guide actions, such as rejecting defective products or adjusting robotic movements. Dimensional inspection plays a key role in this stage, ensuring that products meet design specifications.

Machine vision systems provide real-time feedback, allowing manufacturers to detect issues instantly. This capability prevents production delays and reduces costly rework. Advanced algorithms identify minute defects, such as surface scratches or assembly errors, ensuring consistent quality standards.

Key aspects of decision-making and action include:

- Dimensional accuracy confirms adherence to design specifications.

- Real-time feedback enables immediate adjustments without halting production.

- Higher efficiency improves output, product quality, and lowers production costs.

By detecting flaws early in the process, machine vision systems prevent defective products from reaching later stages. This reduces waste and enhances overall productivity. Unlike human inspectors, these systems maintain uniformity across all products, ensuring reliable results every time.

Core Components of Machine Vision Systems

Cameras and Sensors

Cameras and sensors form the backbone of machine vision systems. They capture images that drive the entire process. Choosing the right camera depends on your application needs. For example, interface technologies like Camera Link, GigE, or USB 3.0 balance performance, cost, and reliability. Cameras with features such as Area of Interest (AOI) and Autofeatures enhance image processing efficiency. Compact camera housing also simplifies integration in multi-camera setups, especially in tight spaces.

Recent advancements in COTS (Commercial Off-The-Shelf) camera sensors have made them more powerful and affordable. These improvements attract manufacturers aiming to optimize industrial image processing. Embedded vision systems, while less powerful, offer easier integration and lower operational costs. However, they may require higher initial investments due to tailored hardware.

Lighting and Illumination

Lighting plays a critical role in machine vision. Up to 90% of a system's performance depends on proper lighting. Without adequate illumination, even the best image processing software struggles to deliver accurate results. Optimizing lighting can improve defect detection rates by as much as 30%.

You should consider lighting strategies that suit your application. For instance, diffuse lighting minimizes shadows, while directional lighting highlights surface defects. Deep learning algorithms cannot compensate for poor lighting, so configuring it correctly ensures reliable performance.

| Evidence Description | Impact on Machine Vision Performance |

|---|---|

| Adequate lighting conditions | Account for up to 90% of system performance. |

| Optimized lighting strategies | Improve defect detection rates by 30%. |

Processors and Software

Processors and image processing software are the brains of machine vision systems. They analyze captured images and make decisions. Techniques like Blob Analysis, Morphology, and Geometric Pattern Matching have been pivotal in advancing machine vision. These methods remain essential in modern image processing software.

Embedded systems often use less powerful processors but benefit from reduced computational needs. This trade-off lowers operational costs. Selecting the right processor and software ensures your system meets specific application requirements. For example, hybrid systems combining COTS and open-source solutions improve equipment design and operational outcomes.

Communication Interfaces

Communication interfaces act as the bridge between machine vision systems and other devices in your production line. They ensure smooth data transfer, enabling the system to share information with processors, controllers, or external networks. Without reliable communication interfaces, even the most advanced machine vision system would struggle to function effectively.

Types of Communication Interfaces

You’ll find several types of communication interfaces in machine vision systems. Each serves a specific purpose depending on the application:

- Ethernet (GigE Vision): Ideal for high-speed data transfer over long distances. It supports multiple cameras and is widely used in industrial environments.

- USB (Universal Serial Bus): Common in applications requiring short-distance communication. USB 3.0 offers faster data rates, making it suitable for high-resolution imaging.

- Camera Link: A high-performance interface designed for machine vision. It provides low-latency communication, ensuring real-time image processing.

- CoaXPress (CXP): Perfect for applications needing ultra-high-speed data transfer. It supports long cable lengths and is often used in high-end systems.

- Serial Interfaces (RS-232/RS-485): Useful for simple, low-speed communication tasks. These interfaces are reliable and cost-effective.

Importance of Communication Interfaces

Efficient communication interfaces improve the overall performance of your machine vision system. They ensure data flows seamlessly between components, reducing delays and errors. For example, GigE Vision allows multiple cameras to operate simultaneously without compromising speed. This capability enhances productivity in industries like manufacturing and logistics.

Tip: Always choose a communication interface that matches your system’s requirements. Consider factors like data speed, distance, and compatibility with other devices.

By selecting the right communication interface, you can maximize the efficiency and reliability of your machine vision system. This ensures smooth operations and better results in your industrial processes.

Applications of Machine Vision Systems

Manufacturing and Quality Control

Machine vision systems play a pivotal role in manufacturing applications by ensuring consistent quality control. These systems excel in real-time inspections, detecting flaws that human inspectors might miss. For instance, companies using machine vision systems report over 99% accuracy in defect detection. Object detection accuracy reaches 98.5%, significantly reducing false positives. This level of precision minimizes waste and enhances profitability.

Implementing strong inspection systems can reduce defect-related costs by as much as 30%. Machine vision systems also streamline rejection processes by identifying defective products early. This prevents flawed items from advancing through manufacturing operations, saving time and resources. Rejection systems integrated with machine vision ensure only high-quality products reach customers, boosting brand reputation.

Healthcare and Medical Imaging

In healthcare, machine vision systems revolutionize medical imaging and diagnostics. These systems leverage deep learning and computer vision techniques to enhance accuracy. Research shows that deep-learning models can match physicians in identifying conditions like skin cancer. Early detection through machine vision improves patient outcomes and saves lives.

Applications extend to X-ray radiography, ultrasound, MRI, and endoscopy. Machine vision enhances visualization of organs and tissues, aiding in accurate diagnosis. Convolutional neural networks (CNNs) excel in classifying and detecting abnormalities in medical images. By automating these processes, machine vision reduces diagnostic errors and supports healthcare professionals in delivering better care.

Automotive and Robotics

The automotive industry relies heavily on machine vision systems for precision and efficiency. Robots equipped with machine vision perform high-precision tasks like welding and painting. These systems eliminate variability associated with human labor, ensuring consistent speed and accuracy. Robots also operate continuously without breaks, significantly boosting production rates.

Advanced robotic systems adapt to diverse product variants, meeting evolving consumer demands. For example, rejection systems identify defective components during assembly, preventing costly errors. A report by the Boston Consulting Group highlights a 50% rise in service levels due to robotics integration in warehouse automation. Machine vision systems enhance manufacturing operations by improving productivity and reducing downtime.

Agriculture and Food Processing

Machine vision systems have transformed agriculture and food processing by improving efficiency and ensuring product quality. You can use these systems to automate tasks that were once labor-intensive, saving time and resources.

Key Applications in Agriculture

Machine vision systems help farmers monitor crops and livestock with precision. For example, drones equipped with cameras can capture aerial images of fields. These images allow you to detect issues like pest infestations or water stress early. By addressing these problems quickly, you can prevent crop losses and improve yields.

In livestock management, machine vision systems monitor animal health. Cameras analyze behavior and detect signs of illness, enabling you to take timely action. This technology ensures healthier animals and higher productivity.

Food Processing and Quality Control

In food processing, machine vision systems inspect products for defects or contamination. For instance, you can use these systems to sort fruits and vegetables based on size, color, or ripeness. This ensures only high-quality produce reaches consumers.

Tip: Machine vision systems can detect foreign objects in food, such as plastic or metal, reducing the risk of contamination and recalls.

These systems also enhance packaging processes. They verify labels, check seals, and ensure proper alignment. By automating these tasks, you can maintain consistency and reduce errors.

Benefits for the Industry

Machine vision systems improve productivity and reduce waste in agriculture and food processing. They help you make data-driven decisions, leading to better resource management. With these systems, you can meet consumer demands for safe, high-quality products while minimizing costs.

By adopting machine vision technology, you can revolutionize your agricultural and food processing operations, ensuring efficiency and quality at every step.

Benefits of Machine Vision Systems

Enhanced Quality Control

Machine vision systems revolutionize quality control by automating inspection processes. These systems identify defects early in production, reducing waste and improving product standards. For example, implementing computer vision can cut defect rates by 50%, saving manufacturers significant costs. Early detection also enhances tracking of defect origins, allowing you to address issues quickly and prevent recurrence.

The table below illustrates the financial impact of enhanced quality control:

| Metric | Value |

|---|---|

| Current defect rate | 5% |

| Annual production | 100,000 doors |

| Defective doors per year | 5,000 doors |

| Daily warranty claims | 10 claims |

| Cost per claim | $150 |

| Annual warranty claim cost | $1,277,500 |

| Potential savings with computer vision | $273,750 annually |

Machine vision systems provide continuous monitoring, ensuring consistent quality assurance. Unlike manual inspection systems, they operate tirelessly, delivering real-time insights into production flaws. This automation and quality assurance improve reliability and reduce costly rework or warranty claims.

Increased Efficiency and Productivity

Machine vision systems significantly boost productivity by automating complex tasks. These systems analyze visual data faster than human inspectors, enabling quicker decision-making. For instance, predictive maintenance powered by machine vision detects defects before they cause downtime, ensuring uninterrupted operations.

You can maximize asset utilization by integrating machine vision with Industry 4.0 technologies. This approach minimizes delays and enhances labor efficiency. Machine vision systems also streamline rejection processes, identifying defective products instantly and preventing them from advancing through production lines.

Key benefits include:

- Enhanced operational efficiency in manufacturing environments.

- 24/7 operations that increase throughput and reduce bottlenecks.

- Improved quality assurance through precise defect detection.

By automating inspection systems, machine vision ensures increased productivity while maintaining high-quality standards.

Cost Reduction and ROI

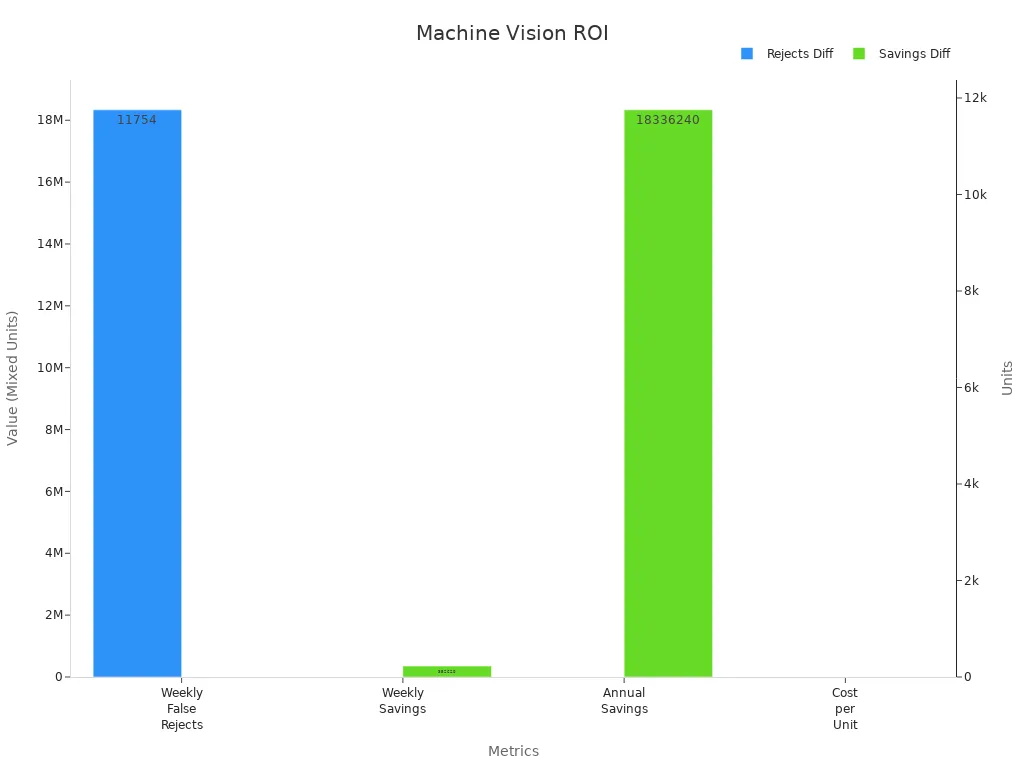

Machine vision systems deliver substantial cost savings and a favorable return on investment. These systems reduce false rejects, saving manufacturers millions annually. For example, Averroes.ai reduces weekly false rejects from 12,000 units to just 246 units, resulting in annual savings of over $18 million per production line.

The chart below highlights the financial benefits:

Labor costs also decrease with machine vision systems. Automated inspection systems require fewer personnel, cutting annual labor expenses by $691,200. These savings, combined with increased productivity and improved quality assurance, make machine vision a cost-effective solution for modern industries.

| Metric | Manual | Averroes.ai | Savings |

|---|---|---|---|

| Personnel | 60 | 24 | -36 |

| Annual Labor Costs | $720,000 | $28,800 | -$691,200 |

By adopting machine vision systems, you can achieve consistent quality, higher productivity, and significant cost reductions, ensuring a strong ROI for your investment.

Improved Safety and Accuracy

Machine vision systems significantly enhance workplace safety and product accuracy. By automating inspection and monitoring tasks, these systems reduce the need for human involvement in hazardous environments. For example, they can inspect machinery or products in high-risk areas, keeping you and your team out of harm's way. This proactive approach minimizes workplace accidents and injuries, creating a safer work environment.

These systems also excel in precision. They detect defects, measure dimensions, and align components with unmatched accuracy. Unlike human inspectors, machine vision systems apply consistent criteria to every evaluation. This consistency eliminates subjective errors and ensures uniform quality across all products. Whether you’re manufacturing electronics or packaging food, these systems maintain high standards.

The table below highlights the impact of machine vision systems on safety and accuracy:

| Evidence Type | Description |

|---|---|

| Workplace Safety Improvement | Deployment of machine vision technology correlates with a decrease in workplace accidents and injuries. |

| Precision in Quality Control | Machine vision systems excel in defect detection, alignment, and measurement, ensuring high product quality. |

| Consistency in Evaluation | These systems apply uniform criteria, reducing subjective inconsistencies found in human inspections. |

In addition to safety and precision, machine vision systems improve rejection processes. They identify defective items early, preventing them from advancing through production. This reduces waste and ensures only high-quality products reach your customers. By relying on these systems, you can achieve safer operations and more accurate results, ultimately boosting productivity and customer satisfaction.

Image processing machine vision systems empower industries to achieve precision and efficiency in automation. These systems consist of cameras, sensors, lighting, processors, and communication interfaces, working together to enhance quality control and productivity. Their applications span diverse fields, including healthcare, agriculture, and aerospace. For example, they guide robots in manufacturing, monitor crops in farming, and ensure compliance in pharmaceuticals.

| Application Area | Description |

|---|---|

| Positioning and Guidance | Essential for robotic guidance and alignment in manufacturing, enhancing efficiency and reducing errors. |

| Measurement | Enables accurate measurement of dimensions and parameters, crucial in industries like semiconductors. |

| Identification | Used for tracking products in logistics, improving inventory management and traceability. |

| Security and Surveillance | Applied in monitoring and threat detection, enhancing safety in various environments. |

| Agriculture | Supports precision farming through crop monitoring and sorting tasks. |

| Healthcare | Assists in diagnostic imaging and laboratory automation, improving accuracy in medical processes. |

| Food and Packaging | Ensures product quality and safety through inspection and verification tasks. |

| Aerospace | Employed in component inspection, ensuring high precision and quality standards. |

| Pharmaceuticals | Used for packaging inspection and compliance with regulatory standards. |

| Electronics | Critical for maintaining precision in the production of electronic components and devices. |

Machine vision systems are indispensable for modern industries, driving advancements in quality control and automation. Their growing importance ensures safer, faster, and more accurate operations across various sectors.

FAQ

What industries benefit the most from machine vision systems?

Machine vision systems benefit industries like manufacturing, healthcare, agriculture, and automotive. You can use them for tasks like quality control, defect detection, and robotic guidance. These systems improve efficiency and ensure consistent results across diverse applications.

How do machine vision systems differ from human inspectors?

Machine vision systems analyze images faster and more accurately than human inspectors. They operate continuously without fatigue, ensuring consistent quality. Unlike humans, these systems apply objective criteria to every inspection, eliminating subjective errors.

Can machine vision systems handle multiple tasks simultaneously?

Yes, machine vision systems can perform multiple tasks, such as defect detection, measurement, and object identification. You can integrate them with robotics to automate complex processes, improving productivity and reducing operational costs.

Are machine vision systems difficult to implement?

Modern machine vision systems are designed for easy integration. You can choose plug-and-play solutions or customize them for specific applications. Proper planning and training ensure smooth implementation and optimal performance.

What is the ROI for machine vision systems?

Machine vision systems deliver high ROI by reducing defects, improving productivity, and lowering labor costs. For example, automated inspection systems can save manufacturers millions annually by minimizing waste and enhancing efficiency.

See Also

Understanding Camera Resolution in Machine Vision Systems

Essential Insights Into Computer Vision and Machine Vision

Do Filters Enhance Accuracy in Machine Vision Systems?