What Role Does Image Recognition Play in Machine Vision Quality Control

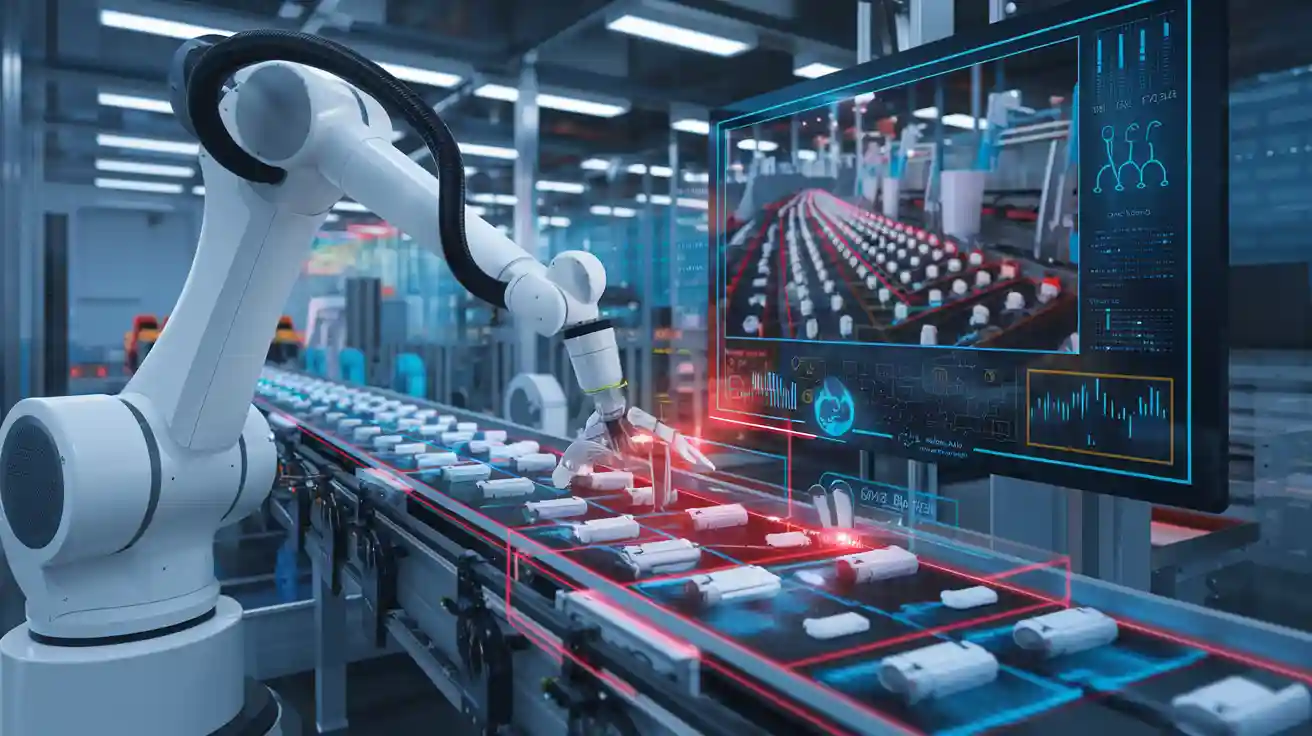

Image recognition, a key subset of computer vision, enables machines to interpret and analyze visual data. It plays a vital role in automating quality control processes by identifying defects, measuring dimensions, and ensuring assembly accuracy. This technology reduces human involvement in repetitive tasks, improving both speed and reliability.

Modern industries rely on machine vision systems to maintain consistent product quality. These systems automate inspections, detect errors early, and provide real-time production insights. For example:

- Manufacturers using advanced systems report a 20% increase in yield and throughput.

- Error rates dropped from 10% to 5.5% over three years, saving companies an average of $5M.

By adopting an image recognition for quality control machine vision system, you can achieve higher efficiency and fewer defects in production.

Key Takeaways

- Image recognition helps check quality faster and more accurately.

- Using image recognition with machine vision lowers mistakes from 25% to less than 2%. This keeps product quality steady.

- Better cameras and smart programs make inspections more accurate. This helps factories meet high standards.

- AI tools can spot problems before they happen. This allows quick fixes and less work stoppage.

- Machines can check thousands of items in minutes. This saves time and cuts costs.

Core Components of Image Recognition for Quality Control Machine Vision System

Cameras and Digital Sensors

Cameras and digital sensors form the foundation of any image recognition for quality control machine vision system. These components capture high-resolution images, enabling precise analysis. Modern sensors often exceed 25 megapixels, ensuring sharpness and clarity. Higher resolution improves the detection of even the smallest defects, such as anomalies as tiny as 1.5 micrometers. CMOS sensors, known for their broader dynamic range, are particularly effective for high-contrast imaging and accurate measurements.

The choice of camera and sensor directly impacts the system's performance. For example, a sensor with a higher pixel density enhances the ability to identify subtle surface irregularities. This capability is crucial for industries like electronics and automotive manufacturing, where precision is non-negotiable.

Image Processing Algorithms

Image processing algorithms are the brain of a machine vision system. These algorithms analyze the captured images to extract meaningful information. Convolutional Neural Networks (CNNs) are widely used for this purpose. They identify features such as shapes, textures, and colors with remarkable accuracy. Advanced systems achieve accuracy rates that rival or even surpass human performance in specific tasks.

The transition from traditional machine learning models to deep learning has revolutionized image recognition. Deep learning models handle complex tasks with greater efficiency, making them ideal for quality control. For instance, algorithms can process over 2,000 pages per minute, with character accuracy exceeding 99%. This speed and precision ensure real-time defect detection and classification.

| Metric | Value |

|---|---|

| Character accuracy | >99% |

| Processing speed | 2,000+ pages/minute |

| Field detection rate | 95–99% |

Integration of Image Recognition in Machine Vision

Integrating image recognition into machine vision systems enhances their capabilities. This fusion allows for automated quality inspections, defect detection, and assembly verification. Companies like Dell Technologies and Cognex have successfully implemented such integrations in smart manufacturing. These systems use deep learning to analyze images for defects, outperforming traditional methods.

By combining image recognition with machine vision, you can automate complex inspection tasks. This integration reduces human error and increases efficiency. For example, a machine vision system equipped with image recognition can inspect thousands of products in minutes, ensuring consistent quality.

Tip: Investing in a robust image recognition for quality control machine vision system can significantly improve your production processes.

Applications of Image Recognition in Quality Control

Defect Detection and Classification

Image recognition plays a critical role in identifying and classifying defects during production. By analyzing images captured by machine vision systems, you can detect even the smallest irregularities in products. This ensures that defective items are identified before they reach customers. Advanced models like ConvNeXt have achieved remarkable accuracy, with some systems reaching 100% reliability when classifying standardized products. This level of precision helps you maintain consistent quality across your manufacturing processes.

In addition to classification, image recognition excels at localizing defects. For example, PatchCore has proven more effective than other methods in pinpointing the exact location of anomalies. This capability is essential for understanding the nature of defects and determining the necessary corrective actions. By leveraging these technologies, you can enhance your quality control efforts and reduce waste.

Dimensional Accuracy and Measurement

Maintaining dimensional accuracy is vital in industries where precision is non-negotiable. Machine vision systems equipped with image recognition can measure product dimensions with incredible accuracy. These systems analyze images to ensure that every component meets the required specifications. This eliminates the need for manual measurements, saving you time and reducing the risk of human error.

For example, in the automotive industry, image recognition ensures that parts fit together perfectly. By comparing captured images to predefined standards, the system can identify any deviations in size or shape. This process guarantees that only products meeting the highest quality standards move forward in the production line. With this technology, you can achieve consistent results and avoid costly errors.

Assembly Verification and Completeness Checks

Ensuring that products are assembled correctly is another area where image recognition excels. Machine vision systems use object detection to verify that all components are present and properly placed. This technology allows you to inspect assembled products quickly and accurately, ensuring they meet quality standards before shipping.

Deep learning models enhance this process by learning the normal appearance of complex assemblies. These systems can account for variations that might affect quality, making them more reliable than traditional methods. For example, they can segment specific regions of an image for detailed inspection, ensuring that every component is in its correct position. This capability is particularly useful in challenging manufacturing environments where conditions may vary.

Automated systems also excel at identifying incomplete or faulty assemblies. By analyzing representative samples, they can learn to recognize defects and confirm assembly integrity. This ensures that your products match the capabilities of skilled human inspectors while operating at a much faster pace. With these tools, you can maintain high standards of quality and improve customer satisfaction.

Surface Inspection for Textures and Patterns

Surface inspection is a critical aspect of quality control, especially in industries where textures and patterns define product functionality or aesthetics. Machine vision systems equipped with image recognition technology excel at identifying surface anomalies, ensuring that products meet stringent quality standards.

You can use these systems to detect scratches, dents, pitting, and dust on surfaces. High-resolution cameras capture detailed images of product surfaces, while advanced algorithms analyze these images to identify irregularities. This process ensures that even the smallest defects are detected before products reach customers.

Surface inspection systems offer measurable benefits. For example, scientific studies have shown that these systems achieve a 100% detection rate for scratches, ensuring high accuracy. However, distinguishing between pitting and dust remains challenging, with a 13.4% false positive rate for dust being classified as pitting. These findings highlight the importance of refining algorithms to improve accuracy further.

| Benefit Description | Measurement | Result |

|---|---|---|

| Detection of scratches | 100% detection rate | High accuracy in recognizing scratches |

| Recognition of pitting/dust | Lower recognition rate | 13.4% false positive for dust as pitting |

Surface inspection systems also excel at analyzing textures and patterns. For example, in textile manufacturing, these systems can identify inconsistencies in fabric weaves or patterns. By comparing captured images to predefined standards, they ensure that every product meets design specifications. This capability reduces waste and enhances customer satisfaction.

Automated surface inspection systems save time and improve efficiency. Unlike manual inspections, which rely on human judgment, these systems provide consistent results. You can inspect thousands of products in minutes, ensuring uniform quality across your production line. This speed and precision make image recognition indispensable for industries like electronics, automotive, and packaging.

Tip: To maximize the benefits of surface inspection, invest in machine vision systems with high-resolution cameras and advanced algorithms. These tools ensure accurate defect detection and pattern analysis, helping you maintain high-quality standards.

Benefits of Image Recognition in Machine Vision Systems

Enhanced Inspection Accuracy

Image recognition significantly improves the accuracy of inspections in machine vision systems. By analyzing images with advanced algorithms, these systems detect even the smallest defects that human inspectors might overlook. For example, scratches, dents, or misaligned components can be identified with precision. This ensures that only high-quality products move forward in the production process.

Unlike manual inspections, which rely on subjective judgment, machine vision systems provide consistent and objective results. You can trust these systems to maintain the same level of accuracy across thousands of inspections. This consistency is especially important in industries like electronics and automotive manufacturing, where precision is critical.

By using image recognition, you can achieve inspection accuracy rates that surpass human capabilities. This not only enhances product quality but also builds trust with your customers.

Tip: To maximize inspection accuracy, choose machine vision systems equipped with high-resolution cameras and advanced image processing algorithms.

Improved Efficiency and Speed

Machine vision systems equipped with image recognition dramatically increase the efficiency and speed of quality control processes. These systems analyze images in real time, enabling faster decision-making and reducing production delays. For instance, they can immediately detect misaligned components or improperly applied labels, allowing you to address issues before they escalate.

The efficiency of these systems also minimizes downtime. Quick adjustments to machinery can be made without halting production, saving you time and resources. Additionally, automated alerts and real-time analysis ensure that your production line operates smoothly and maintains high-quality output.

| Performance Metric | Description |

|---|---|

| Early Error Detection | Enables immediate identification of misaligned components or improperly applied labels, reducing waste and resource use. |

| Reduced Downtime | Allows for quick adjustments to machinery without halting production, minimizing costly delays. |

| Faster Decision-Making | Facilitates real-time analysis and automated alerts, leading to quicker responses and maintaining high-quality output. |

By integrating image recognition into your machine vision systems, you can inspect thousands of products in minutes. This speed and efficiency not only improve productivity but also reduce operational costs.

Reduction in Human Error

Human error is a common challenge in manual quality control processes. Fatigue, distractions, and subjective judgment can lead to mistakes that compromise product quality. Machine vision systems eliminate these issues by automating inspections and relying on objective data.

With image recognition, you can reduce human error rates from 25% to under 2%. This dramatic improvement ensures that your products consistently meet quality standards. Automated systems also excel at repetitive tasks, maintaining accuracy and reliability over extended periods.

- Machine vision inspection reduces human error rates from 25% to under 2%.

By minimizing human error, you can enhance the overall quality of your products and reduce waste. This not only saves costs but also strengthens your reputation for delivering reliable and high-quality products.

Note: Investing in machine vision systems with robust image recognition capabilities can help you achieve near-perfect inspection accuracy while reducing reliance on manual labor.

Cost Savings in Manufacturing Processes

Implementing image recognition in machine vision systems can lead to significant cost savings in your manufacturing processes. These systems optimize operations by reducing waste, minimizing downtime, and improving overall workflow. By automating quality control, you can eliminate inefficiencies and achieve a more streamlined production process.

One of the primary ways image recognition reduces costs is through enhanced operational efficiency. AI-powered systems analyze production lines in real time, identifying bottlenecks and optimizing assembly workflows. This ensures that your manufacturing processes run smoothly, reducing delays and maximizing output. For example:

- Predictive maintenance powered by AI minimizes equipment failures. By analyzing patterns and predicting when maintenance is needed, you can avoid costly breakdowns and extend the lifespan of your machinery.

- Automated defect detection ensures that only high-quality products move forward, reducing waste and rework costs.

Tip: Investing in predictive maintenance tools can save up to 20% on repair costs and reduce unplanned downtime by 50%.

Another area where image recognition drives cost savings is in quality control. Traditional inspection methods often rely on manual labor, which can be time-consuming and prone to errors. Machine vision systems equipped with image recognition perform inspections faster and with greater accuracy. This reduces the need for human inspectors and lowers labor costs. Additionally, these systems can operate continuously without fatigue, ensuring consistent quality across all products.

| Cost-Saving Factor | Benefit Description |

|---|---|

| Predictive Maintenance | Reduces unplanned downtime and extends equipment lifespan. |

| Automated Defect Detection | Minimizes waste by identifying defects early in the production process. |

| Reduced Labor Costs | Decreases reliance on manual inspections, saving time and resources. |

| Optimized Workflow | Enhances assembly line efficiency, reducing delays and maximizing productivity. |

By integrating image recognition into your manufacturing processes, you can also reduce material waste. Defective products identified early in the production cycle prevent unnecessary use of additional resources. This not only saves costs but also supports sustainable manufacturing practices.

Incorporating these systems into your operations ensures long-term financial benefits. While the initial investment in machine vision technology may seem significant, the return on investment (ROI) is substantial. Companies that adopt these systems often report a reduction in overall production costs and an increase in profitability.

Note: Studies show that AI-driven quality control systems can reduce defect rates by up to 90%, leading to millions in annual savings for large-scale manufacturers.

By leveraging image recognition, you can transform your manufacturing processes into a cost-efficient and high-quality operation. This technology not only enhances your bottom line but also positions your business as a leader in innovation and reliability.

Integration of Image Recognition with AI and Machine Learning

AI-Powered Predictive Analytics

AI-powered predictive analytics enhances the capabilities of inspection systems by identifying potential issues before they occur. These systems analyze historical data and real-time production metrics to detect patterns that signal defects. For example, in industries like aerospace and pharmaceuticals, predictive analytics enables continuous quality monitoring. Operators receive alerts for anomalies, allowing timely interventions to maintain high standards.

AI models also anticipate defects by studying production trends. This proactive approach reduces downtime and ensures consistent quality. For instance, computer vision systems equipped with AI can analyze images to detect microscopic flaws. They scan multiple units simultaneously, improving both speed and accuracy. Over time, these systems refine their defect detection models, achieving higher precision.

| Industry | Case Study | Tactics | Impact |

|---|---|---|---|

| Agriculture | John Deere | 1. Image Recognition: Analyzes images of crops for diseases and pests. 2. Predictive Analytics: Predicts crop yields and optimal planting times. | Increased crop yields by 15%. Reduced fertilizer and pesticide use, leading to cost savings. |

| Healthcare | IBM Watson Health | 1. Natural Language Processing: Interprets clinical notes and research. 2. Machine Learning: Analyzes patient data for treatment suggestions. | Reduced diagnosis time from weeks to hours. Increased accuracy in identifying cancer types. |

By integrating predictive analytics into your inspection systems, you can automate processes and improve operational efficiency.

Automating Complex Inspection Tasks

Image recognition combined with AI simplifies complex inspection tasks. Advanced systems can identify defects like missing screws or misaligned components with near-perfect accuracy. For example, the AI-based Automatic Visual Inspection System uses Microsoft Azure AI Custom Vision Service. After training with sample images, it achieves nearly 100% accuracy in defect detection.

Robots equipped with machine vision further enhance automation. These robots recognize and handle diverse objects, making them ideal for tasks like picking, palletizing, and sorting. Advanced 3D vision systems enable robots to detect and localize mixed objects, allowing them to unload pallets or pick items from bins efficiently.

Automating these processes reduces human error and increases productivity. You can rely on these systems to inspect thousands of products quickly while maintaining consistent quality. This capability makes them indispensable for industries that demand precision and speed.

Real-Time Adaptation and Learning

AI-integrated inspection systems excel at real-time adaptation and learning. These systems continuously improve by analyzing new data, ensuring they stay effective in dynamic environments. For example, the integration of AI-driven computer vision with the Opentrons OT-2 robot enhances error detection and correction. This system achieves a mean average precision (mAP@50) of 0.995 and processes frames in just 1.1 seconds, making it suitable for high-throughput tasks.

Real-time learning allows inspection systems to adapt to changes in production conditions. They track anomalies and refine their algorithms to improve accuracy over time. This capability ensures that your inspection systems remain reliable, even as production demands evolve.

By leveraging real-time adaptation, you can automate processes and maintain high-quality standards across your operations. These systems not only improve efficiency but also position your business as a leader in innovation.

Examples of AI-Driven Quality Control Systems

AI-driven quality control systems have revolutionized inspection processes across industries. These systems combine machine vision with advanced algorithms to deliver faster and more accurate results. Below are examples of successful implementations that showcase their transformative impact.

One notable case study involves a German automotive manufacturer that deployed an active machine learning-based quality assurance system. This system identifies defective virtual car renderings with remarkable efficiency. By requiring fewer labeled instances, it reduces the time and resources needed for training. The result is a streamlined inspection process that improves productivity while lowering costs.

Another example highlights the use of convolutional neural networks (CNNs) for automated defect detection in screw manufacturing. Traditional methods often struggle with accuracy and speed, but this AI-driven approach achieves over 97% accuracy. The system classifies screws as defective or non-defective, ensuring consistent quality control. Manufacturers benefit from reduced costs and enhanced inspection efficiency, making this technology a game-changer for the industry.

Deep learning also plays a pivotal role in improving quality control processes. In the screw manufacturing case, the CNN model not only detects defects but also localizes them with precision. This capability eliminates the need for manual inspections, which are prone to errors and inefficiencies. By automating these tasks, you can achieve higher accuracy and faster production cycles.

These examples demonstrate how AI-driven systems optimize quality control. Whether it's identifying defects in automotive renderings or ensuring dimensional accuracy in screws, these technologies enhance inspection processes and deliver measurable benefits. By adopting machine vision systems powered by AI, you can transform your operations and maintain high-quality standards.

Tip: Explore AI-driven solutions tailored to your industry to maximize efficiency and reduce costs.

Image recognition revolutionizes quality control by automating inspections and ensuring precision. Integrating AI and machine learning enhances these systems, enabling faster error detection and predictive analysis. For example:

- AI expedites timelines by quickly sorting log files and detecting errors.

- Predictive tools anticipate defects, improving efficiency and support quality.

Future advancements promise even smarter systems. Experts predict real-time decision-making capabilities and faster responses through edge computing. The global machine vision market is also projected to grow from $6.5 billion to $9.3 billion by 2028. By adopting these technologies, you can stay ahead in innovation and quality assurance.

FAQ

What is the role of image recognition in reducing defective products?

Image recognition identifies flaws in real-time, ensuring defective products are removed from the production line. This technology enhances quality control by detecting even minor defects, preventing them from reaching customers. By automating inspections, you can maintain consistent product quality and reduce waste.

How does image recognition minimize rejection rates?

Image recognition systems analyze products with precision, identifying defects early. This reduces rejection rates by ensuring only high-quality items proceed through the production line. Early detection also prevents unnecessary rework, saving time and resources while maintaining customer satisfaction.

Can image recognition improve production line efficiency?

Yes, image recognition streamlines inspections by automating defect detection. This speeds up the production line, allowing you to inspect thousands of items in minutes. The technology ensures consistent quality, reducing delays caused by manual inspections or rejections due to overlooked defects.

How does image recognition handle complex inspection tasks?

Image recognition uses advanced algorithms to analyze intricate details. It can detect missing components, misalignments, or surface anomalies with high accuracy. This capability ensures that defective products are identified, even in complex assemblies, maintaining high standards across your production line.

Is image recognition cost-effective for quality control?

Yes, image recognition reduces costs by minimizing defective products and rejections. Automated systems lower labor expenses and improve efficiency. They also prevent material waste by identifying defects early, ensuring a streamlined and cost-effective production process.

See Also

Exploring Quality Assurance Through Machine Vision Technology

Grasping Defect Identification with Machine Vision Solutions

Improving Product Quality with Surface Inspection Vision Systems

A Comprehensive Guide to Image Processing Vision Systems

Ensuring Precision Alignment with Machine Vision Systems in 2025