What Makes Machine Vision System Outputs So Important

Machine vision systems have revolutionized modern industries by delivering outputs that drive precision and automation. These systems excel in tasks like automated inspection, where they continuously monitor and detect defects faster than humans. Their ability to provide consistent evaluations eliminates variability, ensuring product quality. With high-speed processing, they accelerate production lines, reducing delays and human error.

By capturing detailed data, an output machine vision system also supports traceability and process optimization. This aligns with Industry 4.0, where smarter manufacturing processes are key. Whether reducing waste or enhancing safety, the outputs of these systems are indispensable for achieving efficiency and innovation.

Key Takeaways

- Machine vision systems help industries work better by automating tasks like finding defects and checking quality.

- These systems give dependable results by studying images, keeping product quality steady, and cutting down on waste.

- They can process information quickly, helping make fast decisions, which boosts productivity and lowers costs.

- Adding AI and machine learning makes these systems smarter and more flexible, making them important for today’s factories and shipping.

- Using machine vision technology can save money over time by reducing mistakes and improving how things are done.

Understanding Output Machine Vision Systems

What Are Machine Vision System Outputs

Machine vision system outputs are the results generated after analyzing visual data captured by cameras or sensors. These outputs provide actionable insights that help you make decisions or automate processes. For example, they can identify defects in products, count objects on a conveyor belt, or ensure that items meet quality standards. The outputs are not just raw data; they are processed and refined to deliver meaningful information.

The performance of these systems depends on several factors, such as the quality of the captured images, the algorithms used for image processing, and the hardware's efficiency. Metrics like accuracy, precision, and recall are often used to evaluate how well these systems perform. For instance:

| Metric | Description |

|---|---|

| Accuracy | Measures the overall correctness of a classifier, calculated as the number of correctly classified items divided by the total number of items. |

| Precision | Measures the accuracy of a classifier's positive predictions, calculated as the number of true positive predictions divided by the total number of positive predictions made. |

| Recall | Measures the ability of a classifier to identify all instances of a particular class, calculated as the number of true positive predictions divided by the total number of actual instances of the class. |

| F1 Score | Combines precision and recall into a single score, calculated as the harmonic mean of precision and recall, with a higher score indicating better performance. |

These metrics ensure that the outputs are reliable and meet the requirements of various applications.

Examples of Outputs: Defect Detection, Object Counting, and Quality Control

Machine vision systems excel in generating outputs for tasks like defect detection, object counting, and quality control. These outputs are crucial in industries where precision and efficiency are essential.

- Defect Detection: High-resolution cameras can identify defective parts, such as broken or chipped items, ensuring only high-quality products reach the market. For example, inspection systems in manufacturing can detect imperfections in materials with a time resolution of just 5 microseconds.

- Object Counting: These systems can count objects in real-time, such as measuring particle sizes on conveyors with over 99% accuracy at speeds of 500,000 pixels per second. This capability is vital in industries like logistics and packaging.

- Quality Control: Machine vision systems automatically inspect products to ensure they meet predefined standards. For instance, they can classify bottle caps and reject defective ones or check PCB components to confirm all parts are present.

| Application Area | Evidence Description | Performance Metrics |

|---|---|---|

| Particle/Object Size | Real-time control and measurement of particle sizes on conveyors. | Counting precision over 99% at 500,000 px/s |

| Quality Control | Automatic detection of imperfections in manufacturing materials. | 5 µs time resolution, blur-free output |

These examples highlight how machine vision systems transform raw visual data into outputs that enhance productivity and maintain high standards.

How Machine Vision Systems Generate Outputs

Machine vision systems generate outputs by following a systematic process that involves capturing, analyzing, and interpreting visual data. Here's how it works:

- Image Capture: Cameras or sensors capture high-quality images of the target objects. Proper lighting is crucial at this stage to ensure clear and accurate images.

- Image Processing: Image processing software analyzes the captured images to extract useful information. Tasks like pattern recognition, defect detection, and object classification occur during this step.

- Data Interpretation: Advanced algorithms, often powered by AI and machine learning, interpret the processed data to generate actionable outputs. For example, they can classify objects, detect defects, or count items.

- Output Delivery: The system delivers the final outputs in a format that can be used for decision-making or automation. This could include triggering an alert, rejecting a defective product, or updating inventory records.

| Metric | Description |

|---|---|

| Improved quality control | Consistently detects defects and inconsistencies to ensure high product quality |

| Increased efficiency | Streamlines processes, reduces downtime, and optimizes throughput by automating tasks |

| Cost savings | Lowers operational costs by minimizing errors, waste, and the need for manual inspections |

| Flexibility | Easily adapts to different production environments and requirements, applicable across various industries |

By leveraging these steps, machine vision systems deliver outputs that are accurate, efficient, and reliable. This process ensures that the systems can adapt to various types of machine vision systems and applications, making them indispensable in modern industries.

Why Machine Vision System Outputs Are Valuable

Accuracy in Defect Detection and Object Classification

Machine vision systems excel in delivering precise results, especially in defect detection and object classification. These systems analyze visual data with remarkable accuracy, ensuring that even the smallest imperfections are identified. For instance, automated inspection systems can detect defects in products with a 60% higher accuracy compared to traditional methods. This improvement not only enhances product quality but also reduces waste by ensuring only flawless items proceed through the production line.

Object classification also benefits significantly from machine vision systems. By leveraging advanced image processing software, these systems can categorize objects based on their features, such as size, shape, or color. This capability proves invaluable in industries like manufacturing and logistics, where sorting and organizing items efficiently is critical. Continuous learning through machine learning algorithms further refines these systems, enabling them to adapt to new challenges and maintain high performance.

With a 30% boost in productivity across various industries, machine vision systems demonstrate their ability to transform operations. Their outputs ensure that your processes remain accurate, efficient, and reliable.

Speed in Processing and Delivering Results

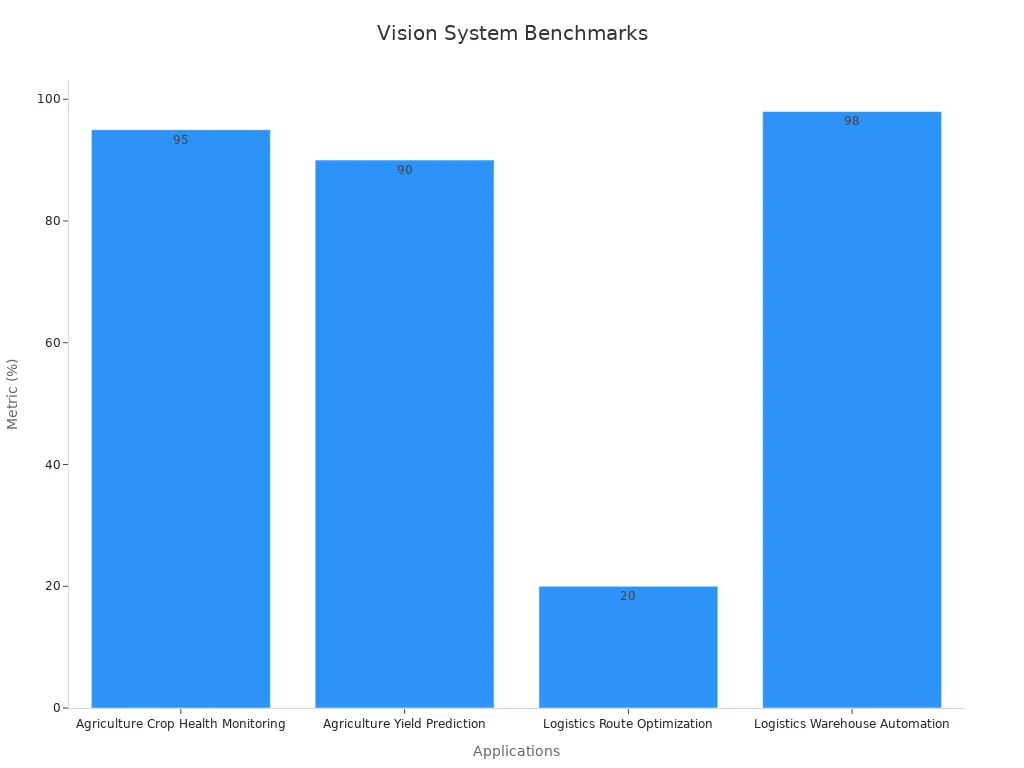

The speed at which machine vision systems process and deliver results is another key factor that makes them indispensable. These systems can analyze vast amounts of visual data in real time, enabling faster decision-making and automation. For example, in agriculture, machine vision systems achieve a 95% accuracy rate in detecting crop diseases, reducing crop loss and improving yield. Similarly, in logistics, they optimize routes, cutting delivery times by 20% and lowering fuel costs.

| Industry | Application | Key Metric | Impact |

|---|---|---|---|

| Agriculture | Crop Health Monitoring | Disease detection accuracy: 95% | Reduced crop loss and improved yield |

| Agriculture | Yield Prediction | Forecast accuracy: 90% | Better planning and resource allocation |

| Logistics | Route Optimization | Delivery time reduction: 20% | Faster deliveries and lower fuel costs |

| Logistics | Warehouse Automation | Sorting accuracy: 98% | Increased operational efficiency |

System benchmarks also play a crucial role in evaluating performance. They assess machine vision systems across various scales and workloads, ensuring that the outputs meet real-world demands. These benchmarks provide insights into hardware selection and system design, which are essential for improving processing speed and efficiency.

By delivering results quickly and accurately, machine vision systems help you streamline operations and stay ahead in competitive industries.

Reliability in Consistent Performance Across Applications

Reliability is a cornerstone of machine vision systems. These systems consistently deliver high-quality outputs across a wide range of applications, from manufacturing to healthcare. For example, in the catheter manufacturing industry, automated vision systems have proven their robustness by meeting stringent regulatory requirements. Their measurement accuracy, with differences within 0.01 mm, matches that of standard measurement systems. This level of precision ensures that the outputs are dependable and suitable for critical applications.

| Aspect | Findings |

|---|---|

| Measurement Accuracy | Comparable to standard systems, with differences within 0.01 mm. |

| Gage Linearity and Bias | Good results observed; average bias requires further investigation. |

| Gage RandR Results | Reliable results for extreme product sizes. |

| System Robustness | Meets stringent regulatory requirements in catheter manufacturing. |

| Comparison with Others | Other systems lack repeatability and accuracy, highlighting robustness. |

Machine vision systems also adapt to various environments, whether they involve 2D or 3D imaging. This flexibility allows them to handle diverse tasks, such as inspecting flat surfaces or analyzing complex structures. Their ability to maintain consistent performance ensures that you can rely on them for critical operations, regardless of the application.

By integrating machine vision systems into your processes, you gain a reliable partner that delivers consistent results, enhances efficiency, and supports innovation.

Applications of Machine Vision System Outputs

Manufacturing: Automated Quality Control and Defect Detection

In manufacturing, machine vision systems play a pivotal role in automating quality control and defect detection. These systems use image processing software to inspect products for flaws, ensuring compliance with safety standards and improving production efficiency. For example, automated defect detection systems analyze large volumes of data quickly, identifying issues without delays. This reduces the defect rate and ensures only high-quality products reach customers.

Organizations that adopt these systems often see significant cost savings. Automating quality control minimizes manual inspections, which lowers the likelihood of defective products entering the market. Some companies spend up to 40% of their operational costs on quality-related tasks, but machine vision systems help reduce this burden.

| Metric | Impact on Productivity |

|---|---|

| Defect Rate | Average defect rate reduced to 1%. |

| Smart Labor Management | Reduces defects by optimizing personnel roles. |

| Continuous Training | Keeps teams updated on defect prevention. |

Healthcare: Medical Imaging and Diagnostics

Machine vision systems revolutionize healthcare by enhancing medical imaging and diagnostics. These systems analyze complex datasets, improving accuracy in disease detection. For instance, deep learning algorithms can detect diabetic retinopathy from retinal images, enabling early treatment and reducing advanced care costs.

The ability to process vast amounts of visual data minimizes misdiagnosis and improves patient outcomes. Early detection of diseases through machine vision systems not only saves lives but also reduces the financial burden on healthcare providers.

| Evidence Type | Description |

|---|---|

| Study | Detects diabetic retinopathy using retinal photographs. |

| Benefit | Early detection improves treatment outcomes. |

| Impact | Reduces misdiagnosis by analyzing large datasets. |

Logistics: Package Sorting and Inventory Management

In logistics, machine vision systems streamline package sorting and inventory management. These systems use 2D and 3D imaging to sort thousands of parcels with near-perfect accuracy, reducing manual labor and speeding up shipping. Real-time inventory updates ensure accurate stock counts, alerting managers to low stock or misplaced items.

Automated systems also provide real-time supply chain insights. Cameras monitor inventory and delivery routes, preventing bottlenecks and delays. By automating sorting and inspections, you can reduce wait times and focus on more complex tasks.

| Efficiency Metric/Operational Data | Description |

|---|---|

| Accuracy in Package Sorting | Near-perfect accuracy speeds up shipping. |

| Real-time Inventory Updates | Alerts managers to low stock or misplaced items. |

| Reduced Wait Times | Faster shipments and improved worker focus. |

Machine vision systems transform logistics by improving accuracy, efficiency, and operational insights.

Overcoming Challenges in Machine Vision Outputs

Addressing Data Quality and Noise Issues

Data quality plays a critical role in the performance of machine vision systems. Poor-quality data introduces noise, which can lead to misjudgments or missed detections during material defect detection. For example, mislabeled data points often result in incorrect predictions, while unbalanced samples can cause biased model training. These issues reduce the reliability of inspection systems and hinder their ability to deliver accurate outputs.

| Data Quality Issue | Impact on Machine Vision Outputs |

|---|---|

| Mislabeled data points | Leads to incorrect predictions and model failures. |

| Unbalanced sample | Results in biased model training and poor generalization. |

| Difficulty accessing stored data | Causes delays and inefficiencies in model development. |

Preparing data for machine vision AI requires substantial effort. Annotated datasets are essential for training, but challenges like data fuzziness and noise interference complicate this process. To overcome these obstacles, you can implement robust data-cleaning techniques and use advanced image processing tools to filter out noise. This ensures that the system receives high-quality inputs, improving its overall performance.

Advancing Beyond Traditional Algorithms

Traditional algorithms in machine vision systems have served industries well, but modern advancements offer significant improvements. Firmware-based systems now process data directly within camera hardware, reducing latency and enabling real-time defect detection in high-speed manufacturing. These systems also lower the total cost of ownership due to their compact design, eliminating the need for additional hardware.

Modern machine vision technology incorporates advanced algorithms, including artificial intelligence and deep learning. These systems excel in detection speed and accuracy, even under challenging conditions like poor lighting. They can automatically identify defects and track objects in complex environments, making them ideal for diverse applications. While traditional systems remain flexible and adaptable, modern solutions provide unmatched efficiency and precision.

Leveraging AI and Machine Learning for Improved Outputs

AI and machine learning have revolutionized process monitoring in machine vision systems. These technologies enable systems to learn from data, improving their ability to detect patterns and anomalies over time. For instance, AI-powered inspection systems can identify subtle defects that traditional methods might overlook. This enhances quality control and reduces waste in manufacturing.

Machine learning algorithms also adapt to changing conditions, ensuring consistent performance across various applications. By integrating AI, you can achieve faster and more accurate outputs, streamlining operations and boosting productivity. As these technologies continue to evolve, they will further enhance the capabilities of machine vision systems, making them indispensable for process monitoring and automation.

Machine vision system outputs are transforming industries by driving precision, efficiency, and innovation. These systems inspect hundreds of parts per minute with over 99% accuracy, reducing downtime by 25% and minimizing costly errors. In healthcare, they enhance diagnostics by detecting anomalies earlier, improving patient safety.

- The global computer vision market is projected to grow from $17.2 billion in 2023 to over $45 billion by 2028.

- This growth highlights the increasing reliance on these technologies for automated inspections and quality assurance.

As technology advances, you can expect machine vision systems to revolutionize processes further, unlocking new possibilities across industries.

FAQ

What industries benefit the most from machine vision systems?

Machine vision systems benefit industries like manufacturing, healthcare, and logistics. They automate quality control, enhance medical diagnostics, and streamline inventory management. These systems improve efficiency, reduce errors, and save costs, making them essential for modern operations.

How do machine vision systems handle poor-quality images?

Machine vision systems use advanced image processing techniques to filter noise and enhance image clarity. AI algorithms improve detection accuracy by learning from data patterns. You can also optimize lighting and camera settings to capture better-quality images.

Can machine vision systems adapt to new tasks?

Yes, machine vision systems adapt to new tasks using AI and machine learning. They analyze data, learn patterns, and refine their algorithms. This flexibility allows you to use them for diverse applications, from defect detection to object classification.

Are machine vision systems expensive to implement?

Initial costs may seem high, but machine vision systems save money in the long run. They reduce waste, minimize errors, and lower labor costs. Their efficiency and reliability make them a cost-effective solution for industries.

What is the future of machine vision technology?

The future of machine vision lies in AI integration and real-time processing. These advancements will improve accuracy, speed, and adaptability. You can expect machine vision systems to play a larger role in automation and innovation across industries.

See Also

The Role of Deep Learning in Improving Machine Vision

The Impact of Machine Vision on Modern Agriculture

Understanding the Function of Cameras in Machine Vision