Improving Machine Vision System Performance

A performance machine vision system refers to technology that uses cameras and software to analyze images for tasks like quality control and automation. It ensures processes run smoothly by identifying defects, guiding machines, or reading codes with precision. Improving its performance is vital for industrial efficiency, as it reduces errors, speeds up production, and minimizes manual labor.

Consider these facts:

- Automation through machine vision enhances accuracy and increases productivity.

- Real-time visual inspection optimizes processes and reduces human intervention.

- Quality assurance, the largest application segment, proves its critical role in maintaining high standards.

Optimizing your system not only boosts efficiency but also ensures consistent results across operations.

Key Takeaways

- Better machine vision systems help factories work faster with fewer mistakes.

- Important measures like accuracy, precision, and recall show how well systems work.

- Good lighting and clean spaces make images clearer and find defects better.

- Regular checks and fixes keep systems working well and lasting longer.

- Adding AI and machine learning makes defect finding smarter and more flexible.

What Defines Performance in Machine Vision Systems?

Key Metrics for Performance Evaluation

To evaluate the effectiveness of machine vision systems, you need to focus on measurable criteria. These metrics help you understand how well the system performs under different conditions.

- Accuracy: This metric reflects the system's overall success rate in identifying objects or patterns correctly.

- Precision: Precision measures how often the system's positive predictions are correct.

- Recall: Recall assesses the system's ability to detect all relevant instances.

- Gauge R&R: This ensures consistency in measurements across different operators and times.

- Execution Time: This metric evaluates how quickly the system processes images and identifies workpieces.

| Metric | Description |

|---|---|

| Accuracy | Overall success rate of the vision system. |

| Precision | Measures the correctness of positive predictions. |

| Recall | Assesses the ability to find all relevant instances. |

| Gauge R&R | Ensures consistency in measurements across different operators and times. |

| Execution Time | Time taken to identify and position workpieces. |

By focusing on these key performance metrics, you can ensure the system meets your operational needs effectively.

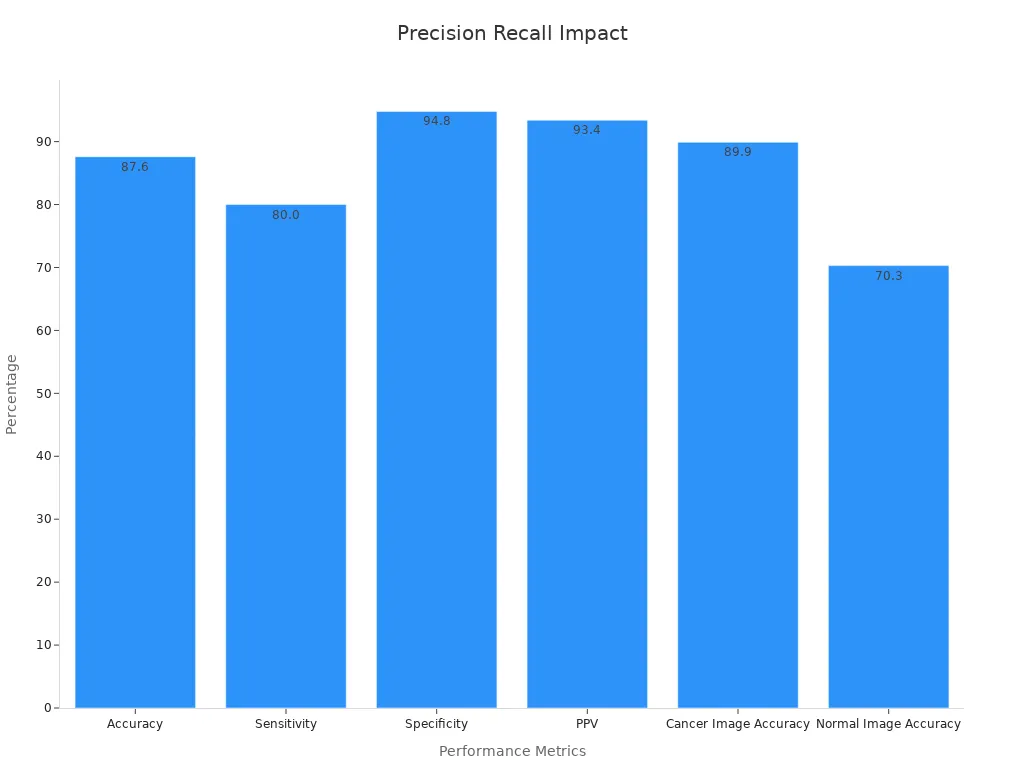

Importance of Precision and Recall in Machine Vision

Precision and recall play a critical role in determining the overall performance of machine vision systems. Precision ensures the system avoids false positives, while recall guarantees it captures all relevant objects or patterns.

For example, studies show that machine vision systems achieve an accuracy of 87.6%, with sensitivity at 80.0% and specificity at 94.8%. These metrics highlight the importance of balancing precision and recall to optimize system performance.

When precision and recall are optimized, you can trust the system to deliver consistent results, even in complex scenarios like medical imaging or industrial quality control.

Role of Speed and Accuracy in Industrial Applications

Speed and accuracy are vital for machine vision systems in industrial settings. Faster processing times reduce bottlenecks, while high accuracy ensures fewer errors during production.

A research paper titled Performance Evaluation of Computer Vision Algorithms in a Programmable Logic Controller: An Industrial Case Study highlights how programmable logic controllers (PLCs) enhance image processing speed and accuracy. This combination is essential for maintaining efficiency in automated workflows.

By prioritizing speed and accuracy, you can improve overall performance and meet demanding production schedules without compromising quality.

Factors Influencing Machine Vision System Performance

Optics and Lighting Stability

The stability of optics and lighting plays a crucial role in the performance of machine vision systems. Proper lighting ensures that the system captures high-quality images, which directly impacts its defect detection capability. When lighting conditions fluctuate, the resolution of the sensor may fail to capture fine details, leading to errors in product quality assessment.

You should aim to maintain consistent lighting conditions in your setup. For instance, environmental light can increase the total light intensity, introducing noise into the image data. This noise reduces the system's ability to identify defects accurately. Dust and humidity also affect image sensors by impairing image quality or causing water vapor to adhere to components.

| Factor | Impact on Performance |

|---|---|

| Environmental Light | Increases total light intensity and adds noise to image data output. |

| Dust | Impairs imaging quality, leading to inaccuracies in detection. |

| Humidity | Water vapor can adhere to components, affecting imaging. |

By optimizing lighting and ensuring clean, stable environments, you can enhance the resolution of the sensor and improve overall system performance.

Hardware Specifications and Integration

The hardware you select for your machine vision system significantly influences its performance. High-quality sensors, processors, and memory components ensure faster execution time and better defect detection capability. For example, the resolution of the sensor determines how well the system can capture fine details in an image.

Modern industrial automation systems often rely on advanced processors and GPUs to handle complex tasks. A faster processor reduces the time required for model performance evaluation, while GPUs or TPUs enable efficient training of machine learning models. Memory capacity also plays a vital role in managing large datasets, which is essential for maintaining product quality in high-volume production environments.

| Hardware Specification | Impact on Performance Metrics |

|---|---|

| Processor type and speed | Affects training time and inference speed |

| GPUs/TPUs | Influences model complexity and training efficiency |

| Memory capacity and type | Determines the ability to handle large datasets |

| Storage type and capacity | Impacts data access speed and overall system latency |

When integrating hardware, ensure compatibility between components. A well-integrated system minimizes latency and maximizes efficiency, which is critical for industrial automation.

Software Algorithms and Model Performance Evaluation

The software algorithms powering your machine vision system determine its ability to analyze images accurately. Advanced algorithms improve defect detection capability by identifying patterns and anomalies that might go unnoticed by simpler methods. Regular model performance evaluation ensures that the system continues to meet your quality standards.

Research shows that machine learning algorithms significantly enhance the performance of machine vision systems. For example, a study on medical decision support systems highlights how optimized algorithms improve accuracy and reduce errors. Another study on large datasets demonstrates the importance of evaluating models to ensure consistent results.

| Article Title | Source |

|---|---|

| Performance Evaluation of the Machine Learning Algorithms Used in Inference Mechanism of a Medical Decision Support System | Link |

| Performance evaluation of machine learning models on large dataset of android applications reviews | Link |

You should regularly update your algorithms and conduct model performance evaluations to maintain high standards of product quality. This practice ensures that your system adapts to changing requirements and continues to deliver accurate results.

Environmental Conditions and Variability

Environmental conditions significantly impact the performance of machine vision systems. Factors like temperature, humidity, vibration, and dust can alter the system's ability to capture accurate images. Understanding these variables helps you design a more robust and reliable setup.

How Environmental Factors Affect Performance

-

Temperature Fluctuations

Extreme temperatures can cause hardware components to overheat or malfunction. Sensors may lose calibration, leading to inaccurate image capture. For example, high heat can distort the lens or degrade electronic circuits. -

Humidity and Moisture

Excessive humidity introduces condensation on lenses and sensors. This reduces image clarity and increases the risk of corrosion in electronic components. -

Vibration and Movement

Vibrations from nearby machinery or unstable mounting can blur captured images. This affects the system's ability to detect fine details or defects. -

Dust and Particles

Dust accumulation on lenses or sensors obstructs the optical path. This results in lower image quality and missed detections.

Tip: Regularly inspect your system for environmental wear and tear. Early detection prevents long-term damage and ensures consistent performance.

Strategies to Mitigate Environmental Challenges

You can take proactive steps to minimize the impact of environmental variability on your machine vision system.

-

Temperature Control

Install cooling systems or heat-resistant enclosures to protect hardware from extreme temperatures. Use thermal sensors to monitor and maintain optimal operating conditions. -

Humidity Management

Deploy dehumidifiers or moisture-resistant coatings to safeguard sensitive components. Ensure proper ventilation to reduce condensation risks. -

Vibration Isolation

Mount cameras and sensors on vibration-dampening platforms. This stabilizes the system and prevents image distortion caused by movement. -

Dust Prevention

Use sealed enclosures to shield lenses and sensors from dust. Regular cleaning schedules keep optical paths clear and maintain image quality.

Environmental Monitoring Tools

Modern tools help you monitor and adapt to changing environmental conditions.

| Tool Name | Purpose | Benefit |

|---|---|---|

| Thermal Cameras | Detect temperature hotspots | Prevent overheating issues |

| Hygrometers | Measure humidity levels | Reduce condensation risks |

| Vibration Sensors | Monitor mechanical vibrations | Ensure stable image capture |

| Air Quality Monitors | Detect dust and particles | Maintain clean optical pathways |

By integrating these tools into your setup, you can identify and address environmental challenges before they affect system performance.

Real-World Example

Imagine a machine vision system used in a factory with high dust levels. Without proper enclosures, dust accumulates on the camera lens, reducing image clarity. This leads to missed defect detections and compromises product quality. Installing a sealed enclosure and air quality monitor prevents dust buildup and ensures consistent performance.

Note: Environmental conditions vary across industries. Tailor your mitigation strategies to suit your specific operational environment.

By addressing environmental variability, you enhance the reliability and accuracy of your machine vision system. This ensures optimal performance even in challenging conditions.

Strategies to Enhance Machine Vision System Performance

Optimizing Lighting and Optical Configurations

Lighting and optical setups form the backbone of any machine vision system. Proper configurations ensure that the system captures clear and accurate images, which directly impacts its ability to detect defects or anomalies.

You should carefully select lighting techniques based on the specific application. For instance, experimental tests have shown that backlighting works exceptionally well for internal inspections. It enhances contrast and minimizes glare, making it easier to identify fine details like syringe graduations or cavities. In contrast, an off-axis light source at a 45° angle often causes excessive reflections, reducing the visibility of internal features.

To optimize your setup:

- Use backlighting for applications requiring internal feature visibility.

- Avoid lighting angles that create glare or reflections.

- Regularly test different configurations to find the most effective setup for your needs.

Tip: Consistent lighting conditions improve image quality and reduce errors in defect detection. Consider using enclosures to shield your system from external light sources.

By fine-tuning your lighting and optical configurations, you can significantly enhance the performance of your machine vision system.

Selecting High-Performance Hardware Components

The hardware you choose determines how well your machine vision system performs. High-quality components ensure faster processing, better image resolution, and more accurate defect detection.

When selecting hardware, focus on key criteria:

| Criteria | Description |

|---|---|

| Optical Resolution | Determines the lens's ability to distinguish between various feature sizes. |

| Magnification | Calculated by dividing the smallest field of view measurement by the sensor's smallest dimension. |

| Light Source | Creates contrast; requires precise calculations for different techniques. |

| Testing | Verifies that components meet performance specifications. |

| Evaluation References | Includes field of vision, image quality, object definition, and defect detection capabilities. |

For example, high-speed cameras enable real-time inspections on fast production lines, while advanced sensors capture intricate details. GPUs or TPUs accelerate processing, making them ideal for handling complex tasks like training machine learning models.

Note: Always test your hardware to ensure it meets your system's requirements. Testing helps you avoid bottlenecks and ensures compatibility between components.

Investing in high-performance hardware components ensures your machine vision system operates efficiently and delivers consistent results.

Improving Algorithms with AI and Machine Learning

Algorithms are the brain of your machine vision system. By integrating artificial intelligence (AI) and machine learning, you can unlock new levels of performance. These technologies allow your system to adapt, learn, and improve over time.

AI-powered systems offer several advantages:

- Robust Defect Detection: AI can identify subtle defects that traditional methods might miss.

- Consistency: Unlike humans, AI operates continuously without fatigue, ensuring uniform performance.

- Speed: Machine learning algorithms process data quickly, enabling real-time inspections.

- Adaptability: AI learns to recognize new defects or variations, making it highly versatile.

- Data Gathering: Inspections generate valuable data for analytics and process improvements.

For example, AI systems can monitor products throughout production, analyze trends, and even adjust parameters to resolve quality issues. Predictive maintenance becomes possible by analyzing defect patterns, helping you prevent equipment failures before they occur.

Callout: Machine learning algorithms not only improve defect detection but also provide detailed analytics for informed decision-making.

By leveraging AI and machine learning, you can transform your machine vision system into a powerful tool for automation and quality control.

Regular Calibration and Maintenance Practices

Regular calibration and maintenance ensure your machine vision system performs consistently and accurately. These practices prevent errors, extend the lifespan of components, and reduce downtime. Neglecting them can lead to degraded performance, missed detections, and costly repairs.

Why Calibration Matters

Calibration aligns your system’s sensors, cameras, and other components to their optimal settings. It ensures measurements remain accurate over time. For example, a misaligned camera might produce blurry images, making defect detection unreliable.

Tip: Schedule calibration checks at regular intervals to maintain accuracy. Use calibration tools designed for your specific hardware to achieve the best results.

Key Maintenance Practices

You can follow these essential maintenance steps to keep your machine vision system in top condition:

- Inspect Components Regularly

Check lenses, sensors, and cables for wear and tear. Replace damaged parts immediately to avoid performance issues. - Clean Optical Surfaces

Dust and smudges on lenses reduce image clarity. Use lint-free cloths and approved cleaning solutions to keep surfaces spotless. - Update Software

Install the latest software updates to improve algorithm efficiency and fix bugs. Outdated software can slow down processing and reduce accuracy. - Monitor System Logs

Review logs for signs of hardware or software errors. Early detection prevents minor issues from escalating into major problems.

Calibration Tools and Techniques

Using the right tools simplifies calibration and ensures precise adjustments.

| Tool Name | Purpose | Benefit |

|---|---|---|

| Calibration Targets | Align cameras and sensors | Improves image accuracy |

| Test Charts | Evaluate resolution and focus | Ensures consistent image quality |

| Alignment Lasers | Adjust optical components | Reduces misalignment errors |

| Diagnostic Software | Analyze system performance | Identifies calibration needs |

Note: Always follow the manufacturer’s guidelines when using calibration tools. Incorrect usage can damage components or produce inaccurate results.

Real-World Example

Imagine a machine vision system used in a packaging line. Over time, vibrations cause the camera to shift slightly, leading to misaligned images. Regular calibration detects the issue early and realigns the camera, restoring accuracy. Without calibration, the system might fail to identify defective packages, resulting in customer complaints and financial losses.

Maintenance Scheduling

Create a maintenance schedule to keep your system running smoothly.

- Daily Checks

Inspect lenses and sensors for dust or damage. Verify that lighting conditions remain stable. - Weekly Tasks

Clean optical surfaces and review system logs for errors. Test calibration settings to ensure accuracy. - Monthly Maintenance

Perform a full calibration using diagnostic tools. Update software and firmware to the latest versions.

Callout: A well-planned maintenance schedule minimizes downtime and ensures consistent performance.

By prioritizing regular calibration and maintenance, you protect your investment and ensure your machine vision system delivers reliable results.

Evaluating and Benchmarking Performance Improvements

Metrics for Model Performance Evaluation

Evaluating the performance of your machine vision system requires reliable metrics. These metrics help you measure how well the system performs and identify areas for improvement. Each metric provides unique insights into the system's accuracy and efficiency.

| Metric | Description |

|---|---|

| Mean Absolute Error (MAE) | Measures the average absolute difference between predicted and actual values. |

| Mean Squared Error (MSE) | Calculates the average of the squared differences between predicted and actual values. |

| Root Mean Squared Error (RMSE) | Provides the error in the same units as the target variable, making it interpretable. |

| R-squared (R2) Score | Measures the proportion of variance in the target variable explained by the model. |

| Adjusted R-squared | Adjusts R-squared for the number of predictors, providing a more accurate measure of model fit. |

| Mean Absolute Percentage Error (MAPE) | Expresses error as a percentage of the actual value, useful for understanding relative error. |

By using these metrics, you can assess the system's performance comprehensively. For example, MAE and RMSE highlight prediction errors, while R-squared shows how well the model explains the data.

Tools and Techniques for Benchmarking Machine Vision

Benchmarking your machine vision system involves comparing its performance against industry standards or previous results. This process ensures your system meets operational goals and remains competitive.

You can use tools like diagnostic software to analyze system performance. These tools evaluate metrics such as accuracy, speed, and defect detection rates. For instance, test charts can help you assess image resolution and focus, while calibration targets ensure precise alignment of cameras and sensors.

Another effective technique is stress testing. This involves running the system under challenging conditions to identify its limits. For example, you might test the system with varying lighting or environmental conditions to see how it performs.

Tip: Regular benchmarking helps you identify weaknesses and implement improvements before they affect production.

Continuous Monitoring for Sustained Performance

Continuous monitoring is essential for maintaining the long-term performance of your machine vision system. It allows you to detect issues early and adapt to changing conditions.

Monitoring ensures the system remains accurate, secure, and fair. It helps you identify performance drifts caused by real-world data that differ from training datasets. For example, if the system starts missing defects due to new product variations, monitoring will alert you to the problem.

This practice also supports model updates. By analyzing real-world data, you can refine algorithms and improve accuracy. Additionally, monitoring helps you address ethical concerns, such as biases that may arise in diverse scenarios.

Callout: Continuous monitoring not only enhances accuracy but also protects your system from security threats like adversarial attacks.

Using frameworks like MLOps, you can establish feedback loops to gather performance data. This ensures your system stays relevant and effective over time.

Improving the performance of your machine vision system is essential for achieving operational excellence. By focusing on key factors like lighting, hardware, and algorithms, you can enhance accuracy and efficiency. Regular calibration and maintenance ensure consistent results, while AI integration unlocks advanced capabilities.

Tip: Benchmark your system frequently to measure progress and identify areas for improvement.

Continuous evaluation helps you adapt to changing conditions and maintain long-term success. With these strategies, you can optimize your system and stay ahead in industrial automation.

FAQ

What industries benefit the most from machine vision systems?

Industries like manufacturing, automotive, electronics, and pharmaceuticals rely heavily on machine vision systems. These systems improve quality control, enhance production speed, and reduce human error.

How does automated inspection improve efficiency?

Automated inspection eliminates manual errors and speeds up defect detection. It ensures consistent quality by analyzing products in real-time, which reduces downtime and increases throughput.

Can machine vision systems adapt to new tasks?

Yes, modern systems use AI and machine learning to adapt to new tasks. They learn from data and improve over time, making them versatile for various applications.

How often should you calibrate a machine vision system?

You should calibrate your system monthly or after significant environmental changes. Regular calibration ensures accuracy and prevents performance degradation.

What is the role of lighting in machine vision performance?

Lighting determines image clarity and defect detection accuracy. Proper lighting setups reduce glare, enhance contrast, and ensure consistent results.

See Also

Do Filtering Techniques Improve Machine Vision System Precision?

The Influence of Frame Rate on Machine Vision Effectiveness

The Role of Deep Learning in Advancing Machine Vision

Understanding Image Processing Within Machine Vision Systems

Comparing Firmware-Based Machine Vision to Conventional Systems