Understanding Inspection Machine Vision Systems in 2025

Imagine a world where machines can inspect products with the precision of a microscope and the speed of light. An inspection machine vision system makes this possible by automating quality control and inspection processes. These systems use cameras, sensors, and software to detect defects, verify assembly, and ensure product quality.

In industries like manufacturing, logistics, and food production, accuracy and efficiency are critical. Machine vision systems are transforming these sectors by reducing errors and speeding up operations. For instance:

- The global machine vision inspection market is expected to grow from $11.9 billion in 2025 to $28.2 billion by 2033, with a CAGR of 11.7%.

- Stricter safety regulations and the adoption of Industry 4.0 technologies are driving their rapid adoption.

By 2025, advancements like artificial intelligence and IoT integration promise to make these systems even smarter and faster, opening doors to new possibilities.

Key Takeaways

- Machine vision systems check product quality fast and correctly.

- They cut down mistakes and work faster, helping factories and food companies.

- By 2025, AI and IoT will make these systems smarter with live data checks.

- Good cameras and programs help find problems, saving money and improving products.

- These systems can be used in many areas like shipping and gadgets to make work easier.

What is an Inspection Machine Vision System?

Definition and Purpose

An inspection machine vision system is a technology-driven solution designed to automate the process of inspecting and analyzing products. These systems use cameras, sensors, and advanced software to capture and interpret visual data. By doing so, they ensure that products meet predefined standards for quality and accuracy.

You can think of these systems as the "eyes" of modern production lines. They excel at tasks like detecting defects, verifying labels, and measuring dimensions. For example:

- Presence/Absence: They check whether all required components are present in a product.

- Product Verification: They confirm that labels match the product, which is especially important in industries like food and pharmaceuticals.

- Character Inspection and Barcode Reading: They validate both human-readable text and machine-readable codes.

- Measurements/Dimensions: They ensure that products meet precise size specifications.

- Positioning/Alignment: They inspect the alignment of labels or components for a polished appearance.

| Metric | Description |

|---|---|

| Accuracy | Measures the overall correctness of a classifier, calculated as the number of correctly classified items divided by the total number of items. |

| Precision | Measures the accuracy of a classifier's positive predictions, calculated as the number of true positive predictions divided by the total number of positive predictions made. |

| Recall | Measures the ability of a classifier to identify all instances of a particular class, calculated as the number of true positive predictions divided by the total number of actual instances of the class. |

| F1 Score | Combines precision and recall into a single score, calculated as the harmonic mean of precision and recall, with a higher score indicating better performance. |

These systems are not just about identifying flaws. They also play a critical role in maintaining consistency and ensuring that products meet customer expectations.

Role in Automation and Quality Control

Inspection machine vision systems are revolutionizing automation and quality control. They replace manual inspection processes, which are often slow and prone to human error, with high-speed, accurate, and reliable alternatives.

Machine vision inspection systems enhance operational efficiency by interpreting visual information faster than human inspectors. This capability ensures that quality control processes remain consistent, even during long production runs. For instance:

- High-resolution imaging improves defect detection accuracy.

- Fast processing speeds increase throughput rates.

- Scalability allows multiple products to be inspected simultaneously.

- Real-time inspection reduces defects and boosts output.

| Feature | Benefit |

|---|---|

| High-resolution imaging | Increases accuracy in defect detection |

| Fast processing | Enhances throughput rates |

| Scalability | Allows simultaneous inspection of multiple products |

| Real-time inspection | Reduces defects and increases output quantity |

Machine vision systems also support uniformity in production. By eliminating variability caused by human fatigue or subjective judgment, they ensure that every product meets the same high standards. This consistency is vital for industries where inspection quality directly impacts safety and customer satisfaction.

Incorporating these systems into your operations can transform how you approach quality and process control. They not only improve inspection quality but also help you achieve higher productivity and lower costs.

Core Components of Vision Inspection Systems

Hardware Components (Cameras, Sensors, Lighting)

The hardware in a vision inspection system forms its foundation. Cameras, sensors, and lighting work together to capture high-quality images for analysis. Each component plays a specific role in ensuring accurate inspections.

- Cameras: These are the "eyes" of the system. RGB cameras are ideal for detecting surface defects and analyzing colors. Area scan cameras capture detailed images of stationary objects, while line scan cameras excel in inspecting moving products like fabric rolls. High-resolution cameras are essential for identifying intricate defects, significantly improving quality control.

- Sensors: Sensors enhance the system's ability to detect and measure. High-resolution sensors capture fine details, ensuring no defect goes unnoticed. They also improve the system's speed, keeping up with fast-paced production lines.

- Lighting: Proper lighting ensures clarity in the images. LED lighting is energy-efficient and enhances visibility, while fluorescent lighting covers larger areas effectively. Halogen lighting provides excellent color rendering, making it suitable for tasks requiring high color accuracy.

| Component | Key Feature | Use Case |

|---|---|---|

| RGB Cameras | Surface defect detection | General inspection tasks |

| Line Scan Cameras | Continuous inspection of moving products | Rolls of fabric or conveyor belts |

| LED Lighting | Energy-efficient and enhances clarity | General inspections |

| High-Resolution Sensors | Captures intricate details | High-detail inspections |

Software Components (Image Processing, Algorithms)

Software components bring intelligence to the system. Image processing algorithms analyze the captured images, identifying defects, verifying dimensions, and ensuring product quality. The efficiency of these algorithms depends on factors like contrast, resolution, and exposure. A well-designed imaging system ensures the software can reliably detect defects.

Advanced tools like ZEISS Quality Software enable precise analysis and reporting. They support holistic quality management, making it easier for you to monitor production processes. AI and deep learning further enhance performance by allowing systems to learn and improve over time. These technologies simplify programming, making the systems more intuitive to use.

For example, the TIMI image measuring machine uses advanced algorithms to measure multiple parameters, such as outer diameter and angles, in just one second. This level of precision and speed ensures your production line operates efficiently.

Tip: Investing in high-end hardware and software ensures better image processing, sharper images, and reduced noise, leading to more reliable inspections.

How Does a Machine Vision Inspection System Work?

Image Acquisition Process

The first step in a machine vision inspection system is image acquisition. This process involves capturing high-quality images of the product or object being inspected. Cameras, sensors, and lighting work together to ensure the images are clear and detailed. The choice of camera plays a significant role. Monochrome cameras are often preferred in industrial settings because they require less processing power and deliver sharper images. On the other hand, color cameras are better for applications where color accuracy is critical.

Lighting is equally important. Techniques like hue-saturation-luminance (HSL) conversion help maintain consistent color detection, even when lighting conditions vary. For moving objects, linescan cameras are ideal. They capture images one pixel at a time, making them perfect for inspecting cylindrical or continuous materials like fabric rolls. Area-scan cameras, however, are better suited for stationary objects but require precise timing to avoid blurring.

| Aspect | Description |

|---|---|

| Camera Selection | Monochrome cameras offer sharper images with lower processing needs, while color cameras excel in color accuracy. |

| Lighting Techniques | HSL conversion ensures consistent color detection under varying lighting conditions. |

| Linescan vs Area-scan | Linescan cameras inspect moving parts, while area-scan cameras work best for stationary objects. |

To streamline the development of vision inspection systems, combining high-level prototyping tools with low-level vision software libraries allows for rapid testing and adjustments. This approach ensures the system can adapt to different conditions and requirements.

Tip: Always choose the right combination of cameras, sensors, and lighting to match your specific inspection needs. This ensures accurate and reliable image acquisition.

Image Processing and Analysis

Once the system captures an image, the next step is processing and analysis. Advanced algorithms analyze the visual data to identify defects, measure dimensions, and verify product quality. Real-time data processing plays a crucial role here. It enables the system to detect flaws instantly, reducing human error and improving inspection accuracy.

For example, Ricoh's image recognition technology uses machine learning to detect anomalies, even with limited sample images. This capability makes it easier to identify defects in complex production environments. Metrics like Intersection over Union (IoU) are used to evaluate the accuracy of object detection. These metrics compare the system's predictions with actual results, ensuring high precision.

Real-time processing also allows the system to handle large volumes of data efficiently. This is particularly useful in industries where speed and accuracy are critical. By leveraging machine learning, vision inspection systems can continuously improve their performance, adapting to new challenges over time.

Note: Investing in systems with advanced image processing capabilities can significantly enhance your production line's efficiency and reliability.

Decision-Making and Output

The final stage of a machine vision inspection system is decision-making and output. After analyzing the images, the system decides whether the product meets quality standards. If it detects a defect, it can trigger actions like rejecting the faulty item or alerting operators.

Machine vision systems excel in this area because they process millions of data points quickly and consistently. They inspect parts faster than humans and provide more reliable results. Automated systems also reduce human error, ensuring that only high-quality products reach the market.

- Machine vision systems inspect parts at high speeds, improving efficiency.

- They deliver consistent results, reducing variability in inspections.

- Automated systems minimize human error, enhancing reliability.

- These systems process vast amounts of data, enabling smarter decision-making.

| Aspect | Description |

|---|---|

| Automation | Enhances quality assurance by automating inspection processes. |

| Precision | Combines high-resolution imaging with AI for improved accuracy. |

| Real-time Alerts | Provides immediate notifications for production issues. |

| Defect Detection | Identifies a wide range of product defects in real-time. |

By integrating these systems into your operations, you can achieve better quality control and operational efficiency. The ability to make quick, accurate decisions ensures that your production line runs smoothly and meets customer expectations.

Applications of Machine Vision Systems Across Industries

Defect Detection in Manufacturing

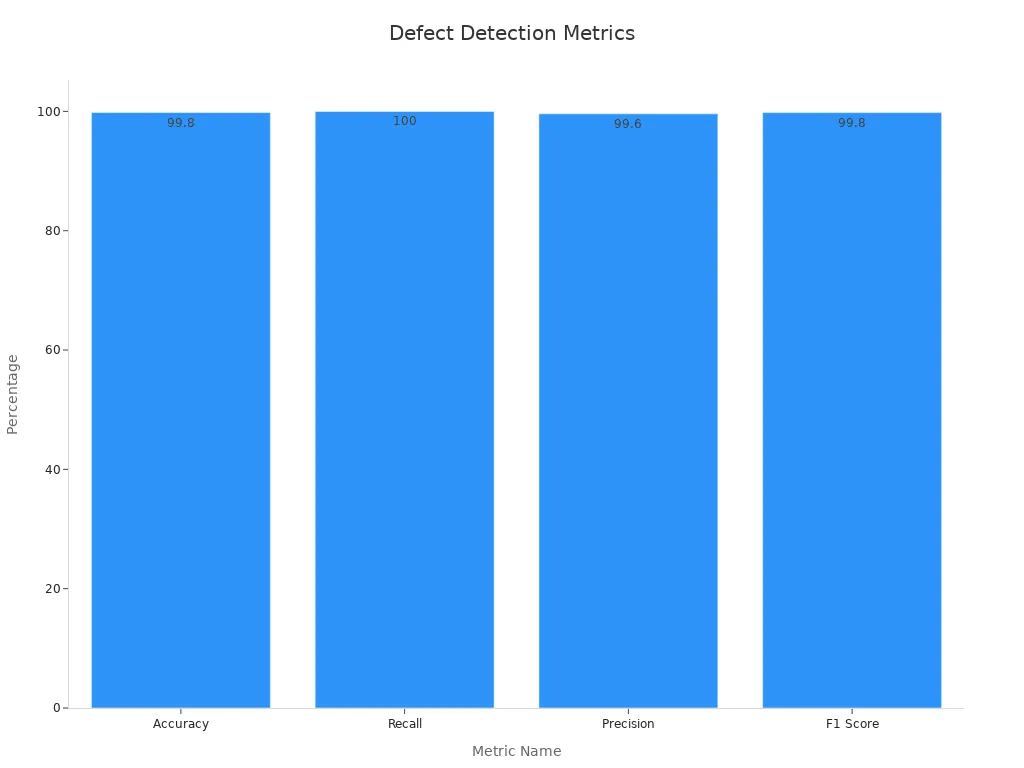

Machine vision inspection systems play a vital role in identifying defects and flaw detection on production lines. These systems ensure that every product meets quality control standards by analyzing visual data with exceptional precision. For example, a multi-stage computer vision system used for inspecting laser-engraved industrial nameplates achieved remarkable results:

| Metric | Value |

|---|---|

| Accuracy | 99.8% |

| Recall | 100% |

| Precision | 99.6% |

| F1 Score | 99.8% |

| AUC | High |

These metrics highlight the effectiveness of vision inspection systems in manufacturing. By automating defect detection, you can reduce waste, improve product quality, and maintain consistency across production lines.

Barcode Reading in Logistics

In logistics, machine vision inspection systems streamline barcode reading processes, ensuring accurate product verification and tracking. Image-based readers excel in overcoming challenges like quiet zone violations and damaged codes. This technology not only improves efficiency but also saves costs. For instance:

| Statistic | Impact |

|---|---|

| 0.9% increase in read rates | Saves up to $270,000 per year in labor costs |

| Image-based readers | Overcome quiet zone violations and code damage issues |

| Continuous improvement | Analyzing no-reads helps identify setup and quality issues |

By integrating these systems into your logistics operations, you can enhance productivity and reduce errors in barcode scanning, ensuring seamless product verification.

Assembly Verification in Electronics

Assembly verification is critical in electronics manufacturing, where precision and accuracy are paramount. Machine vision systems inspect production lines to ensure components meet design specifications and are assembled correctly. These systems gauge dimensions, verify the presence of components, and detect defects early in the process. Key benefits include:

- Identifying and rectifying issues before they escalate.

- Ensuring compliance with design tolerances.

- Reducing faulty products and costly rework.

Accurate measurements also play a crucial role in maintaining product quality. For example, inspecting weld seams for cracks or porosity ensures that standards are met before products proceed to final assembly. By catching defects early, you can save time, money, and resources while delivering high-quality products.

Quality Control in Food Production

In food production, maintaining high standards of quality control is essential. Machine vision systems have revolutionized this process by automating inspections and ensuring consistent results. These systems use advanced cameras and AI-driven algorithms to detect defects in milliseconds, helping you deliver safer and higher-quality products to consumers.

One of the most significant advantages of machine vision systems is their ability to identify even the smallest imperfections. For example, they can spot contaminants, such as foreign objects or discoloration, in food items. This level of precision reduces the risk of defective products reaching the market. By catching these issues early, you can minimize waste and improve overall efficiency.

Lighting plays a crucial role in these inspections. Proper illumination ensures that the system captures clear images, even in challenging environments. Techniques like hyperspectral imaging allow the system to analyze food composition, ensuring that products meet nutritional and safety standards. For instance, this technology can verify the fat content in meat or detect bruises on fruits.

Machine vision systems also enhance packaging inspections. They verify that labels are correctly applied and legible, ensuring compliance with industry regulations. Additionally, they check for proper sealing to prevent contamination during transportation. These capabilities contribute to improved quality control and customer satisfaction.

- Key Benefits of Machine Vision in Food Production:

- Detects defects in milliseconds, ensuring higher product quality.

- Reduces waste by identifying issues early in the production process.

- Enhances safety by spotting contaminants and verifying packaging integrity.

By integrating these systems into your operations, you can achieve improved quality control while meeting the growing demands of consumers and regulatory bodies.

Advancements in Inspection Machine Vision Systems in 2025

AI Integration for Smarter Systems

Artificial intelligence is transforming machine vision inspection. By 2025, AI-powered systems will become smarter and more efficient. These systems will use deep learning algorithms to identify defects with greater precision. For example, AI can now detect subtle flaws in complex manufacturing processes that were previously missed. Companies are also integrating real-time AI capabilities to enhance quality control and traceability. Advantech's partnership with Overview to launch the Snap platform is a prime example of this trend.

Key advancements include the adoption of 3D imaging, edge computing for real-time data processing, and adaptive lighting technologies. These innovations allow vision inspection systems to adapt to changing conditions, ensuring consistent performance. The AI visual inspection market is projected to grow at a CAGR of 25.3%, reaching $74.60 billion by 2029. This growth reflects the increasing demand for flawless products and predictive maintenance.

Improved Accuracy and Speed

Machine vision inspection systems are achieving unprecedented levels of accuracy and speed. Recent studies show that automated systems can measure up to nine decimal places, far surpassing traditional methods. This improvement ensures precise defect detection and consistent results. High-resolution cameras and advanced sensors contribute to this enhanced performance.

Real-time processing capabilities also play a crucial role. These systems analyze vast amounts of data instantly, reducing inspection times and increasing efficiency. For industries like manufacturing, this means faster production lines and fewer errors. By investing in these technologies, you can achieve higher accuracy and increased efficiency in your operations.

Expanded Use Cases Across New Industries

Machine vision systems are finding applications in new sectors. The global market reached $4.13 billion in 2024, driven by industries like automotive, healthcare, and security. Automotive manufacturers, for instance, are using vision-equipped robotic arms to reduce error rates. In healthcare, these systems assist in detecting abnormalities in medical imaging.

The market is expected to grow further, adding $12 billion in revenue by 2033. This expansion highlights the versatility of vision inspection systems. Whether you're in manufacturing or a newer industry, these systems offer solutions for improving quality control and operational efficiency.

Enhanced Connectivity with IoT

Inspection machine vision systems are evolving to leverage the Internet of Things (IoT). This connectivity transforms how you monitor, analyze, and optimize production processes. IoT-enabled systems allow devices to communicate seamlessly, creating smarter and more efficient workflows.

One key advantage of IoT integration is flexibility. Platforms like OV20i adapt to diverse applications without requiring coding expertise. You can use these systems to meet specific needs, whether you're inspecting products or verifying assembly. They also save all relevant process data, creating a visual record for each unit. This traceability helps you analyze yield loss and improve production quality.

| Feature | Description |

|---|---|

| Flexibility | The OV20i platform meets diverse application needs without requiring coding expertise. |

| Data Traceability | Saves all relevant process data, creating a visual record for each unit, aiding in traceability and yield loss analysis. |

| AI Integration | Combines edge AI camera with deep learning technology for accurate defect inspection and assembly verification. |

| Ease of Use | Designed for users without high-level technical expertise, facilitating faster device setup and integration with existing systems. |

IoT also enhances real-time monitoring. Automated thermal imaging systems track equipment health, reducing downtime. AI algorithms inspect packaging, ensuring labels and barcodes are accurate. Smart cameras manage traffic flow and identify vehicles, showcasing the versatility of IoT-enabled systems.

Tip: Use IoT-enabled systems to gain deeper insights into your production processes. These systems simplify data collection and analysis, helping you make informed decisions.

IoT connectivity makes machine vision systems easier to use. You don’t need advanced technical skills to set up or integrate these devices. Faster deployment means you can start improving efficiency right away. By adopting IoT-enabled systems, you can achieve smarter inspections, better traceability, and streamlined operations.

Inspection machine vision systems have become indispensable in modern industries. They ensure consistent quality, reduce errors, and improve efficiency across sectors like manufacturing, logistics, and food production. The rise in industrial automation and the integration of AI and deep learning are driving their adoption. These systems enable 24/7 production while maintaining high standards, making them a cornerstone of automated quality control.

| Factor | Description |

|---|---|

| Industrial Automation Expansion | Enables continuous production and consistent quality standards. |

| AI and Deep Learning Integration | Enhances defect detection and reduces implementation time. |

| Growth in Automated Quality Inspection | Expands market opportunities across diverse industries. |

By 2025, advancements in vision inspection systems will revolutionize automation and quality control. Innovations like adaptive lighting and IoT connectivity will improve efficiency and traceability. Future projections show significant cost savings and quality improvements, reinforcing the business case for adopting these technologies.

| Equation | Description |

|---|---|

| Q = Q0 + ΔQ × e^(-λt) | Demonstrates how quality stabilizes over time with improved processes. |

| Cost Saving = Efficiency Gain × (Quality Improvement / Resource Utilization) | Highlights the correlation between efficiency and cost-effectiveness. |

| ROI = Net Benefits from Quality Control Innovations / Total Investment in Quality Control | Shows the financial benefits of investing in quality control systems. |

Exploring or adopting inspection machine vision systems can transform your operations. These technologies offer smarter inspections, better productivity, and reduced costs, ensuring your business stays competitive in an evolving market.

FAQ

What industries benefit the most from machine vision inspection systems?

Industries like manufacturing, logistics, electronics, and food production gain the most from these systems. They improve quality control, reduce errors, and enhance efficiency. For example, manufacturers use them for defect detection, while logistics companies rely on them for barcode scanning and product tracking.

How does AI improve machine vision systems?

AI enhances defect detection by learning from data and identifying patterns. It enables systems to adapt to new challenges, improving accuracy and speed. For instance, AI-powered systems can detect subtle flaws that traditional methods might miss, ensuring higher-quality products.

Are machine vision systems difficult to integrate?

Modern systems are designed for easy integration. Many come with user-friendly interfaces and require minimal technical expertise. IoT-enabled platforms, for example, allow you to set up and customize inspections without coding, making them accessible for various industries.

Can machine vision systems handle high-speed production lines?

Yes, they excel in high-speed environments. Advanced cameras and real-time processing ensure accurate inspections without slowing production. For instance, linescan cameras inspect moving objects like conveyor belts, maintaining precision even at high speeds.

What is the cost of implementing a machine vision system?

Costs vary based on system complexity and features. Entry-level systems may cost a few thousand dollars, while advanced setups with AI and IoT integration can be more expensive. However, the long-term savings from improved efficiency and reduced defects often outweigh the initial investment.

See Also

The Future of Segmentation in Machine Vision by 2025

Ensuring Precise Alignment with Machine Vision Systems in 2025

Understanding Image Processing Within Machine Vision Systems

The Role of Cameras in Machine Vision Systems Explained

Comparing Firmware Machine Vision Systems to Traditional Approaches