Key Features of Precision Machine Vision Systems You Should Know

Precision machine vision systems have revolutionized modern industries by delivering unmatched accuracy and consistency. You can find these systems driving advancements in sectors such as automotive, electronics, and pharmaceuticals. They ensure precise quality control, reduce errors, and automate repetitive tasks. For example, the global machine vision market is expected to grow from $15.83 billion in 2025 to $23.63 billion by 2030, fueled by the demand for high-efficiency production. These systems not only minimize material waste but also lower labor costs, making them indispensable for precision-critical operations.

Key Takeaways

- Precision machine vision systems help industries like cars and medicine. They make work more accurate and reduce mistakes.

- Picking the right camera, like matrix or line-scan, is important. It helps capture the best images for your needs.

- Good lighting makes pictures clearer. Try different setups to find the best one for your system.

- Smart software with machine learning checks quality automatically. This makes production faster and more reliable.

- Changing machine vision systems to fit industry needs works better. It boosts productivity and lowers costs.

Key Components of a Precision Machine Vision System

Cameras and Imaging Sensors

Cameras and imaging sensors form the backbone of any precision machine vision system. These components capture visual data, enabling the system to analyze and interpret images with remarkable accuracy. You can choose between matrix cameras and line-scan cameras based on your application needs. Matrix cameras capture entire images at once, making them ideal for static scenes. Line-scan cameras, on the other hand, excel in high-speed applications by capturing images line by line.

| Specification | Matrix Cameras | Line-scan Cameras |

|---|---|---|

| Image Capture | Captures entire images at once | Captures images line by line |

| Best Use Case | Static scenes and objects | Continuous or high-speed applications |

| Sensor Type | CMOS or CCD available | CMOS or CCD available |

| Sensitivity | Varies, generally lower than line-scan | Generally higher for continuous capture |

| Resolution | Higher resolution options available | Lower resolution options available |

| Shutter Type | Global or rolling shutters | Global shutters preferred for accuracy |

| Color vs Monochrome | Both options available | Both options available |

High-resolution cameras play a critical role in achieving high-resolution imaging, ensuring that even the smallest details are captured for analysis. By selecting the right camera type, you can optimize your machine vision system for tasks like quality control and defect detection.

Lighting and Illumination

Specialized lighting is essential for enhancing the performance of a machine vision system. Proper illumination highlights the features of the target object, improving image quality and ensuring accurate analysis. Techniques such as backlighting, diffuse lighting, and structured lighting can be tailored to your specific application.

| Component | Role in Performance Metrics |

|---|---|

| Lighting | Essential for highlighting features of the target object, affecting image quality. |

| Integration of Optics and Illumination | Ensures images are clear and well-lit, essential for high accuracy and reliability. |

Studies have shown that lighting conditions significantly impact outcomes in various scenarios. For example, short wavelength-enriched light reduces sleepiness during lectures, while enhanced melanopic light exposure improves concentration and reduces anxiety. These findings underscore the importance of selecting the right lighting setup for your machine vision system.

Tip: Always test different lighting configurations to find the optimal setup for your application. This ensures consistent results and reduces errors during image analysis.

Vision Processing Software

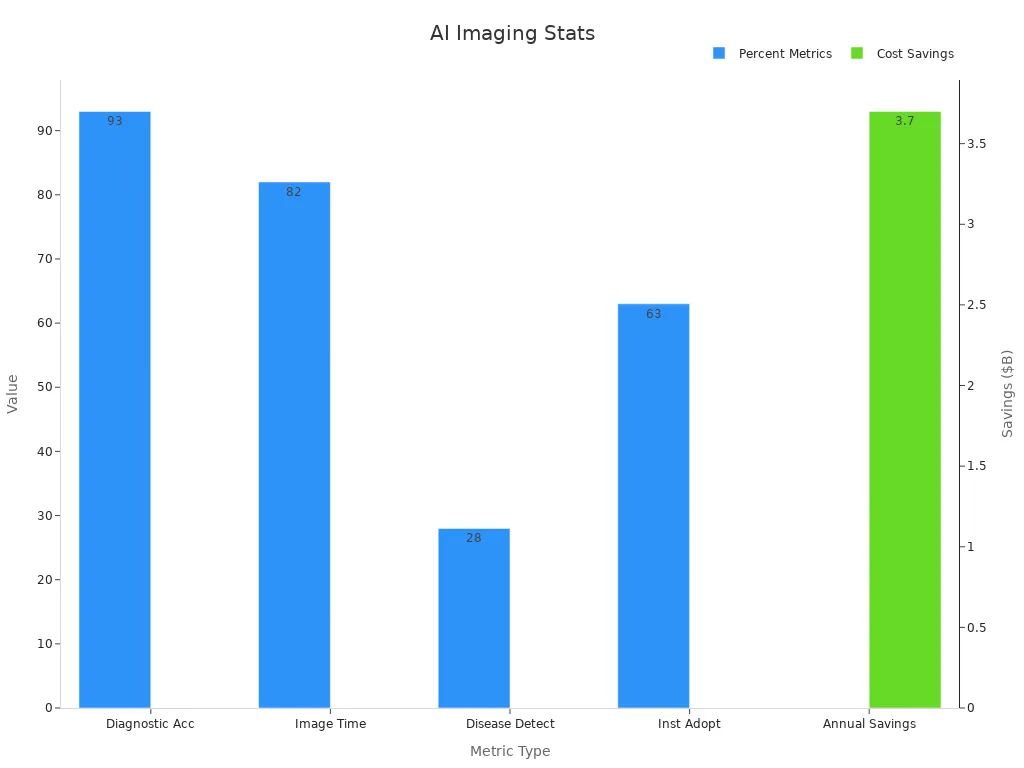

Image processing software is the brain of a precision machine vision system. It analyzes captured images, extracts relevant data, and makes decisions based on predefined criteria. Advanced software integrates machine learning and deep learning algorithms, enabling your system to learn complex patterns and improve over time.

- Machine learning algorithms enhance statistical process control (SPC) by identifying non-linear patterns that traditional methods might miss.

- A case study demonstrated that Epicor Advanced MES SPC systems predicted yield issues with 92% accuracy, leading to a 15% increase in overall yield.

By leveraging cutting-edge image processing software, you can automate quality control processes, improve production efficiency, and achieve consistent results. This software is indispensable for applications requiring high precision and reliability.

Lenses and Optics

Lenses and optics are critical components in precision machine vision systems. They determine how light interacts with the imaging sensor, directly influencing image clarity and accuracy. Selecting the right lens ensures that your system captures high-quality images, even in challenging environments.

Key Roles of Lenses and Optics:

- Focus and Magnification: Lenses control the focus and magnification, allowing you to capture fine details of objects.

- Field of View (FOV): The lens determines the area visible to the camera, which is essential for inspecting large or small objects.

- Distortion Correction: High-quality optics minimize distortion, ensuring accurate measurements and analysis.

Tip: Always match the lens specifications with your camera's resolution and sensor size. This ensures optimal performance and avoids issues like vignetting or blurring.

Impact of Advanced Lenses on Imaging Accuracy:

Advanced lenses and optics significantly enhance imaging performance. Studies have shown measurable improvements in image quality across various modalities:

- Retinal imaging with infrared (IR) lenses achieved the highest quality scores (8.25±1.99).

- Convolutional neural networks (CNNs) used for image quality prediction demonstrated an impressive mean absolute error (MAE) of 0.9.

- IR lenses showed greater resilience to environmental factors, with a correlation of -0.19 compared to other modalities.

These findings highlight the importance of investing in high-quality lenses for applications requiring precision and reliability.

Integration with Robotics and Hardware

Integrating machine vision systems with robotics and hardware unlocks new levels of automation and efficiency. Vision-guided robots use real-time visual data to perform tasks with exceptional accuracy and adaptability.

Benefits of Vision-Guided Robotics:

- Enhanced Precision: Robots equipped with vision systems can identify and handle objects with remarkable accuracy.

- Increased Efficiency: Automated systems complete tasks faster and more consistently than manual operations.

- Improved Safety: Vision systems help robots detect obstacles, reducing collision risks and ensuring workplace safety.

| Advantage | Description |

|---|---|

| Flexibility and Adaptability | Robots can adjust to changing conditions and perform diverse tasks. |

| Cost-Effective | Long-term savings result from reduced labor costs and increased productivity. |

| Handling of Complex Tasks | Robots excel at intricate operations, such as assembling small components or sorting irregular objects. |

Real-World Success Stories:

- A vision-guided robotics system with deep learning algorithms improved tracking accuracy and system responsiveness.

- Companies reported a 27% increase in production throughput and a 34% reduction in waste caused by false positives.

- In healthcare, vision-guided robots enhanced patient safety by minimizing human error during surgeries.

Note: To maximize the benefits of integration, ensure your system uses modular software and hardware. This allows for easy updates and scalability as your needs evolve.

By combining advanced optics with robotics, you can create a powerful system capable of handling complex tasks with precision and efficiency. This integration not only boosts productivity but also sets the foundation for future advancements in automation.

Features That Ensure Accuracy and Consistency in Machine Vision

Precision and consistency are the cornerstones of any effective machine vision system. To achieve these, several features and techniques come into play, ensuring that your system delivers reliable results every time. Let’s explore the key aspects that contribute to accuracy and consistency in machine vision.

Calibration Techniques

Calibration is essential for aligning your machine vision system with real-world measurements. Without proper calibration, even the most advanced systems can produce inaccurate results. You can use several techniques to enhance calibration and improve system accuracy.

| Technique | Description |

|---|---|

| High-Quality Calibration Targets | Use high-quality targets to improve precision in measurements. |

| Distortion Correction Models | Apply appropriate models to account for lens distortions affecting accuracy. |

| Known Targets | Utilize checkerboard patterns or precision blocks for regular recalibration. |

| Regular Calibration Routines | Implement frequent recalibration to maintain accuracy, especially after system movement. |

| Advanced Calibration Techniques | Employ high-quality targets and distortion correction models to address system-specific factors. |

For example, using known calibration targets like checkerboard patterns can correct lens distortion and perspective errors. Regular calibration routines, such as weekly or monthly checks, ensure your system maintains its accuracy over time. Advanced techniques, including distortion correction models, address system-specific factors, further enhancing precision.

Tip: Always recalibrate your system after moving it or changing its components. This simple step can prevent errors and maintain consistency in your visual inspection processes.

Repeatability and Reliability

Repeatability and reliability are critical for ensuring that your machine vision system performs consistently across multiple inspections. These metrics validate how well your system can reproduce the same results under identical conditions.

| Concept | Description |

|---|---|

| Repeatability | Indicates how close individual measuring results are. |

| Variance | Calculated by squaring the distances of measured values from the average, then averaging them. |

| Standard Deviation | The square root of the variance, providing a measure of spread in the data. |

| Golden Sample Method | Using a known component to assess repeatability by measuring it multiple times in the inspection cell. |

| Factors Affecting Precision | Quality of camera images and software impact the precision and repeatability of measurements. |

For instance, the golden sample method involves repeatedly measuring a known component to assess your system’s repeatability. Metrics like variance and standard deviation help quantify the spread of your measurements, ensuring adherence to quality standards. High-quality cameras and robust software also play a significant role in maintaining precision and reliability.

In industrial applications, machine vision systems have demonstrated superior repeatability compared to manual methods. They minimize defects, ensure adherence to specifications, and store data for compliance and future analysis. By relying on these systems, you can achieve consistent results in your defect detection process.

Image Processing and Optimization

Image processing is the backbone of any machine vision system. Advanced algorithms analyze captured images, optimize visual quality, and extract meaningful data for decision-making. These algorithms ensure that your system can handle complex tasks like defect detection automation with ease.

Here are some of the most effective image processing techniques:

- Anisotropic Diffusion: This method reduces noise while preserving edges, making it ideal for applications like magnetic resonance imaging.

- Image Restoration: This technique replaces corrupted parts of images with realistic fragments, effectively reversing blurriness and noise.

- Neural Networks: Convolutional neural networks (CNNs) excel at interpreting visual data, leveraging large datasets to improve accuracy in tasks like defect detection automation.

For example, anisotropic diffusion enhances image clarity by removing noise without compromising edge details. Image restoration improves visual quality by correcting blurriness, while neural networks enable your system to learn from data and adapt to new challenges. These techniques optimize your visual inspection processes, ensuring high precision and consistency.

Note: Regularly update your image processing software to take advantage of the latest algorithms. This keeps your system at the forefront of quality inspection automation.

Error Detection and Correction Mechanisms

Error detection and correction mechanisms play a vital role in ensuring the reliability of machine vision systems. These features allow your system to identify and fix errors during operations, maintaining accuracy and reducing downtime. By implementing these mechanisms, you can enhance the performance of defect detection automation and improve overall productivity.

How Error Detection Works

Error detection involves identifying discrepancies in the visual data captured by your machine vision system. Advanced algorithms analyze images to spot anomalies, such as defects or misalignments, that deviate from predefined standards. For example, systems trained on erroneous movements outside the target often outperform those trained on movements inside the target. This approach ensures that your system can detect even subtle errors with high precision.

The Role of Correction Mechanisms

Once an error is detected, correction mechanisms step in to resolve the issue. These mechanisms adjust the system's parameters or provide feedback to operators, ensuring that errors do not propagate further. For instance, task performance improves significantly when error correction reduces operational time (OT) and task transition time (TTT). This not only enhances efficiency but also minimizes the risk of defective products reaching the end user.

Quantitative Impact of Error Detection and Correction

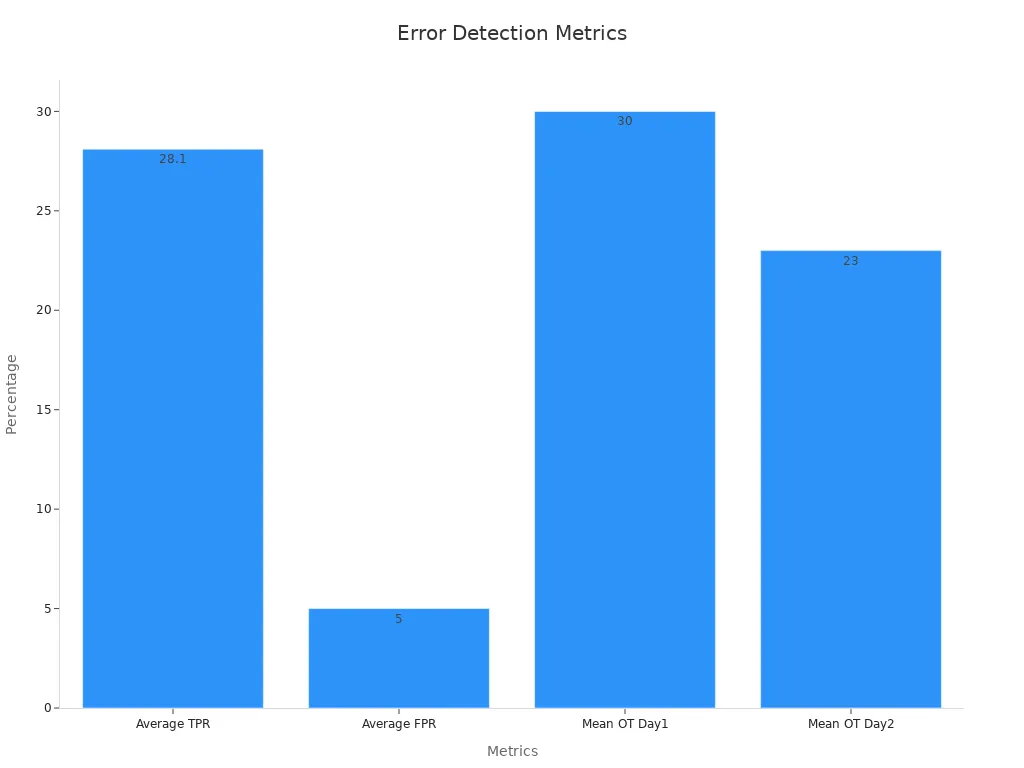

The effectiveness of error detection and correction mechanisms can be measured through various metrics. The table below highlights key findings:

| Metric | Value | Significance |

|---|---|---|

| Average True Positive Rate (TPR) | 28.1% | N/A |

| Average False Positive Rate (FPR) | ~5% | N/A |

| Reduction in Task Transition Time (TTT) | 69.91 ms | N/A |

| Reduction in Operational Time (OT) | 118 ms | N/A |

| Mean OT with correction (Day 1) | 30% reduction | p = 0.00026 |

| Mean OT with correction (Day 2) | 23% reduction | p = 0.0111 |

These metrics demonstrate how error correction mechanisms significantly reduce operational inefficiencies, leading to better outcomes in defect detection automation.

Benefits of Implementing Error Detection and Correction

By integrating error detection and correction mechanisms into your machine vision system, you can achieve several benefits:

- Improved Accuracy: Systems with robust error detection can identify defects with greater precision.

- Reduced Downtime: Correction mechanisms minimize delays by addressing errors in real time.

- Enhanced Productivity: With fewer errors, your system can maintain a steady workflow, boosting overall efficiency.

- Cost Savings: Detecting and correcting errors early reduces waste and prevents costly rework.

For example, average TTT and OT decrease significantly during error correction, allowing your system to operate more efficiently. These improvements make defect detection automation solutions more reliable and effective across various industries.

Tip: Regularly update your error detection algorithms to keep up with evolving challenges. This ensures your system remains accurate and efficient over time.

Applications and Benefits of Automated Inspection

Automated inspection systems have transformed industries by improving production quality and streamlining operations. These systems use advanced technologies like machine vision to automate inspection processes, ensuring consistent product quality inspection and reducing defects. Let’s explore their key applications and benefits.

Defect Detection and Quality Control

Automated optical inspection systems excel at identifying defects and maintaining quality control. They analyze inspection data in real time, detecting even the smallest irregularities that manual methods might miss. By integrating statistical methods like Six Sigma and Statistical Quality Control (SQC), these systems predict issues before they occur, enhancing production quality.

| Statistical Method | Description |

|---|---|

| Statistical Quality Control (SQC) | Monitors production trends and variations to detect potential issues early. |

| Six Sigma | Reduces defects to 3.4 per million opportunities by analyzing processes. |

| Total Quality Management (TQM) | Promotes continuous improvement by involving all employees in quality initiatives. |

Automated inspection reduces warranty claims and product returns, protecting your revenue and brand reputation. It also minimizes the risk of expensive recalls, ensuring consistent product quality inspection across operations.

Tip: Use automated inspection systems to continuously improve processes and enhance innovation in quality control.

Automation in Manufacturing Processes

Automation in manufacturing processes powered by machine vision systems delivers remarkable results. These systems reduce inspection errors by over 90% compared to manual methods and cut defect rates by up to 80%. They also optimize cycle times, reducing them by up to 20%.

| Improvement Type | Statistic |

|---|---|

| Reduction in inspection errors | Over 90% reduction compared to manual inspection |

| Reduction in defect rates | Up to 80% reduction in defects |

| Reduction in quality assurance labor costs | Approximately 50% reduction in labor costs |

| Reduction in cycle time | Up to 20% reduction in cycle time |

Automated inspection systems allow skilled workers to focus on complex tasks, optimizing system performance. They also ensure quality inspection automation, enabling manufacturers to meet high standards consistently.

Enhanced Productivity and Cost Savings

Automated inspection systems significantly enhance productivity while reducing costs. These systems measure thousands of components per hour, improving throughput and operational efficiency. Real-time analytics support continuous improvement, reducing waste and ensuring consistent quality control.

| Metric/Benefit | Description |

|---|---|

| Improved Accuracy | Machine vision systems eliminate human error, ensuring consistent results across operations. |

| Increased Speed | These systems can measure thousands of components per hour, enhancing throughput. |

| Enhanced Operational Efficiency | Real-time data supports continuous improvement and optimizes resource use, reducing waste. |

| Labor Cost Reduction | Automation allows handling larger workloads without increasing labor costs. |

| Quality Control | Improved quality control ensures consistent product standards, enhancing customer satisfaction. |

| Real-time Analytics | Enables quick decision-making, improving delivery efficiency and reducing waste. |

Automated inspection systems also deliver economic benefits. For example:

- Downtime costs for industrial facilities range from $5,000 to $50,000 per hour.

- Automated drone inspections cost 30% to 50% less than manual methods.

- Quality failures in manufacturing result in annual losses of $1.3 trillion.

By automating inspection processes, you can reduce defects, improve product quality inspection, and achieve substantial cost savings.

Real-World Examples Across Industries

Machine vision systems have transformed industries by delivering innovative solutions to complex challenges. These systems improve efficiency, reduce costs, and enhance accuracy. Let’s explore how different industries have successfully implemented machine vision technologies.

Agriculture

Drones equipped with computer vision cameras are revolutionizing farming. These drones identify crop diseases and irrigation issues early, helping you maximize yields. By addressing problems before they escalate, farmers can improve sustainability and reduce waste. This technology ensures healthier crops and more efficient resource use.

Power Line Inspection

Inspecting power lines manually is time-consuming and costly. Hepta Airborne has introduced drones with machine vision to inspect 250 kilometers of power lines in just five minutes. This approach saves 3 million euros annually and detects 400% more unique defects compared to traditional methods. You can see how this innovation enhances safety and reduces operational costs.

Manufacturing

Tesla has integrated machine vision systems into its production lines to detect defects. These systems work alongside humans, reducing errors and increasing efficiency. By automating quality control, Tesla ensures consistent product standards while optimizing production speed. This collaborative approach highlights the potential of machine vision in modern manufacturing.

| Application Area | Implementation Details | Numerical Impact |

|---|---|---|

| Agriculture | Drones with computer vision cameras identify disease and irrigation issues in crops. | Maximizes yields and drives efficiency in the agriculture sector. |

| Power Line Inspection | Hepta Airborne uses drones to inspect 250 km of power lines in 5 minutes. | Saves 3,000,000 euros annually and detects 400% more unique defects compared to manual inspection. |

| Manufacturing | Tesla integrates machine vision for defect detection in their production processes. | Reduces human error and enhances efficiency through a collaborative approach between machines and humans. |

Tip: Consider how machine vision systems can address challenges in your industry. These examples show how innovation can lead to significant improvements in productivity and cost savings.

Emerging Trends in Comprehensive Inspection Automation Solutions

AI and Machine Learning Integration

AI-powered machine vision is transforming inspection automation by enabling systems to handle complex tasks with remarkable efficiency. These technologies analyze large datasets, identify patterns, and adapt to changing environments, making them indispensable for modern industries.

- AI automates intricate inspection processes, reducing the need for manual intervention.

- Machine learning enhances decision-making by analyzing data and predicting outcomes.

- Systems equipped with AI improve accuracy, minimizing false positives and reducing waste.

Unlike traditional machine vision systems, which rely on rigid instructions, state-of-the-art AI allows dynamic analysis. This flexibility ensures that your inspection processes remain effective even in unpredictable conditions. For example, AI integration in quality inspections has significantly improved efficiency and accuracy, driving innovation in manufacturing.

Tip: Consider adopting AI-powered solutions to reduce costs and improve inspection reliability. These systems adapt to your needs, ensuring consistent performance over time.

Advanced Imaging Technologies (e.g., 3D Vision, Hyperspectral Imaging)

Advanced imaging technologies like 3D vision and hyperspectral imaging are redefining precision in inspection automation. These tools offer unparalleled accuracy, efficiency, and automation, making them ideal for industries where precision is critical.

| Benefit | Description |

|---|---|

| High Accuracy | 3D scanners achieve single-shot accuracy as high as 0.005mm, ensuring precise measurements. |

| Efficiency | Quickly identify defects and verify product specifications. |

| Automation | Reduce human error and improve consistency in quality control. |

| Economic Benefits | Lower total installed costs by up to 7% and reduce rework contingencies to less than 2%. |

| Application in Industries | Valuable in sectors like automotive and healthcare where precision matters. |

Hyperspectral imaging is becoming more accessible and affordable, expanding its applications across industries such as agriculture, environmental monitoring, and biomedicine. Its ability to analyze materials with high spectral and spatial resolution makes it a powerful tool for comprehensive inspection automation solutions.

Note: Investing in advanced imaging technologies can enhance your inspection processes, reduce costs, and improve product quality.

Edge Computing and Real-Time Processing

Edge computing is revolutionizing real-time inspection by enabling faster data processing and decision-making. By analyzing data at the source, edge computing reduces latency and improves system responsiveness.

| Metric | Description |

|---|---|

| Inference success rates | Indicates the accuracy of object identification by the model. |

| Processing latency | Measures the time taken for the model to process inputs. |

| Frequency of detections | Counts the number of times specific objects are detected. |

| Device resource usage | Monitors the consumption of CPU, memory, and other resources. |

Real-time inspection systems powered by edge computing deliver higher accuracy and efficiency. They reduce operational delays and optimize resource usage, ensuring consistent performance. For example, these systems can detect defects instantly, allowing you to address issues before they impact production.

Tip: Implement edge computing to enhance your system’s speed and reliability. This technology ensures real-time processing, making it ideal for high-demand applications.

Industry-Specific Customization

Precision machine vision systems excel when tailored to meet the unique demands of specific industries. Customization ensures that these systems address challenges effectively, improving efficiency and accuracy in specialized applications.

Precision Agriculture

In agriculture, machine vision systems transform how you manage crops and livestock. These systems identify pests and weeds with remarkable accuracy, helping you optimize chemical applications and reduce waste. They monitor crop development to maximize yields and improve quality. Livestock management becomes more efficient with automated systems that reduce the need for manual inspections. By adopting a customized inspection system, you can streamline operations and enhance sustainability.

Manufacturing

Manufacturing benefits significantly from customized quality assurance inspection systems. Automated quality control ensures consistent product standards while boosting productivity. Monitoring solutions reduce inspection time and improve workplace safety. Predictive maintenance systems track equipment conditions, allowing you to anticipate failures and minimize downtime. These tailored solutions help manufacturers maintain high efficiency and reduce operational costs.

Why Industry-Specific Customization Matters

Customization allows machine vision systems to adapt to your industry's unique requirements. For example, agricultural systems focus on environmental factors like soil conditions and weather patterns. Manufacturing systems prioritize precision and speed to meet production demands. This flexibility ensures that your system delivers optimal results, whether you're managing crops or producing goods.

Tip: When selecting a machine vision system, consider how customization can address your specific challenges. Tailored solutions improve accuracy, reduce costs, and enhance productivity across industries.

Precision machine vision systems play a crucial role in modern industries. They help you achieve unmatched accuracy and consistency while automating complex tasks. With advanced imaging technologies and robust components, these systems drive innovation and efficiency in production processes. Emerging trends like AI integration and advanced imaging will further enhance their capabilities. You can expect these systems to revolutionize automated inspection and analysis, making them indispensable for precision-critical applications.

FAQ

What industries benefit the most from machine vision systems?

Machine vision systems are widely used in industries like manufacturing, automotive, electronics, agriculture, and healthcare. These systems improve quality control, automate inspections, and enhance productivity. For example, they help manufacturers detect defects, farmers monitor crops, and healthcare providers ensure accurate diagnostics.

How do you choose the right camera for your application?

You should consider factors like resolution, frame rate, and sensor type. For static objects, matrix cameras work best. For high-speed applications, line-scan cameras are ideal. Matching the camera to your specific needs ensures optimal performance.

Tip: Always test cameras in real-world conditions before finalizing your choice.

Can machine vision systems work in low-light environments?

Yes, they can. Proper lighting and specialized sensors allow these systems to perform well in low-light conditions. Infrared or hyperspectral imaging can further enhance visibility and accuracy in challenging environments.

How does AI improve machine vision systems?

AI enables machine vision systems to learn from data and adapt to new challenges. It improves defect detection, reduces false positives, and enhances decision-making. AI-powered systems handle complex tasks with greater efficiency and accuracy.

Are machine vision systems expensive to implement?

Initial costs can be high, but they offer long-term savings. By reducing defects, improving efficiency, and lowering labor costs, these systems provide a strong return on investment. Many industries find them cost-effective over time.

Note: Consider your specific needs and budget to determine the best solution for your operations.

See Also

Essential Features And Advantages Of Medical Vision Systems

How To Properly Position Equipment In Vision Systems

Understanding The Differences Between Computer And Machine Vision