The Future of Machine Vision Systems with Long-Tail Defect Simulation

Imagine a machine vision system that misses rare but critical defects during inspections. These overlooked flaws can disrupt production, compromise safety, or lead to costly recalls. This is the essence of the long tail problem. You encounter it when rare defects, hidden in a sea of common patterns, evade detection due to insufficient data or inadequate models. Long-Tail Defect Simulation machine vision systems tackle this challenge by creating synthetic examples of these rare flaws. They equip machines with the ability to spot even the most elusive irregularities, transforming industries that depend on automation into precision-driven powerhouses.

Key Takeaways

- Solving the long tail issue in machine vision is important. It helps find rare problems that can stop work or cause danger.

- Creating fake data helps train machine vision systems better. This makes it easier for them to spot rare problems.

- AI models, like self-supervised learning, need less labeled data. This makes defect detection systems more flexible and useful.

- Using IoT and edge computing helps find defects quickly. It allows faster fixes in fast-moving environments.

- Making machine vision tools available to everyone helps all businesses. They can improve quality checks without spending too much money.

The Long Tail Problem in Machine Vision

Defining the Long Tail Problem

The long tail problem refers to the challenge of identifying rare and unexpected defects in machine vision systems. These defects often occur infrequently, making them difficult to detect and predict. You might notice that most machine vision systems excel at recognizing common patterns but struggle with anomalies that fall outside their training data. This limitation arises because rare defects lack sufficient representation in datasets, leading to gaps in the system's ability to generalize.

The long tail is the indefinable, open-ended space of unexpected situations that arise in real life, to which agents are unable to adapt on the fly. Many such scenarios are unforeseen even by the developers themselves, who are then forced to write ad hoc, special-case code to account for the growing number of failures they observe.

When you rely on machine vision for object detection, this problem becomes even more pronounced. The system might misclassify or completely overlook rare defects, compromising its reliability. Addressing the long tail problem requires innovative approaches, such as generating synthetic data or leveraging advanced AI models, to ensure these systems can handle the full spectrum of real-world scenarios.

Challenges in Detecting Rare Defects

Detecting rare defects presents unique challenges that stem from the inherent limitations of current machine vision methodologies. One major issue is data imbalance. Most datasets contain an overwhelming number of examples for common defects but very few for rare ones. This imbalance skews the training process, causing the system to prioritize frequent patterns while neglecting anomalies.

Here are some specific challenges you might encounter:

- Anomaly detection often reformulates rare defect detection into a binary classification task, which oversimplifies the problem.

- Techniques like DCGAN architecture are used for anomaly detection on industrial datasets, but they struggle with scalability.

- The latent space of DCGAN encodes relevant information, yet it may fail to capture the nuances of rare defects.

- Limited research exists on using computer vision for nanoscale and mesoscale defects, leaving gaps in understanding.

- Insufficient annotated micrographs for training hinder the development of accurate models.

- Automatically extracting defect contours remains a significant technical hurdle.

These challenges highlight the need for more robust and adaptable solutions. By addressing these issues, you can improve the accuracy and reliability of object detection systems in identifying rare defects.

Implications for Automated Quality Control

The inability to detect rare defects has far-reaching implications for automated quality control. When your machine vision system misses these anomalies, it can lead to production inefficiencies, increased costs, and compromised product quality. However, overcoming the long tail problem can transform quality control processes, making them more precise and efficient.

Consider the following metrics that illustrate the potential improvements:

| Source | Improvement Metrics |

|---|---|

| Deloitte (2021) | 10-12% improvement in factory output, 10-20% decrease in quality costs, 15-30% reduction in inventory holdings |

| Manufacturing Institute (2022) | 25% reduction in downtime, 20% increase in equipment lifespan |

| International Federation of Robotics (2023) | 30% productivity increase, 25% quality improvements |

| PwC (2022) | 20-30% increase in throughput, 10-30% decrease in quality-related costs, 20-50% reduction in time to market |

These statistics demonstrate the transformative potential of addressing rare defect detection. By integrating advanced techniques into your machine vision systems, you can achieve significant gains in productivity, cost savings, and product quality. This not only enhances operational efficiency but also strengthens your competitive edge in the market.

Current Limitations in Long-Tail Defect Simulation Machine Vision Systems

Data Imbalance and Scarcity

You often face data imbalance when training machine vision systems. Most datasets contain abundant examples of common defects but very few instances of rare ones. This imbalance skews the learning process, making it harder for the system to recognize anomalies. Scarcity of annotated data further complicates the issue. Without enough labeled examples, your system struggles to generalize and adapt to real-world scenarios.

Synthetic data generation offers a partial solution, but it has its own limitations. Simulated defects may fail to capture the complexity of real-world failures. This gap between synthetic and real data reduces the effectiveness of the system in detecting rare anomalies.

Limitations of Traditional Detection Methods

Traditional detection methods rely heavily on assumptions about data distribution. These methods often require normal data patterns to function effectively, which limits their adaptability to rare defects. You might notice that static thresholds used in these systems lead to high false positives, misclassifying normal variations as anomalies.

Consider the following table that highlights key limitations:

| Limitation | Description |

|---|---|

| Assumption-based | Requires normal data distributions, limiting its effectiveness |

| Limited adaptability | Struggles with evolving patterns, making it less effective |

| High false positives | Static thresholds often misclassify anomalies, leading to inefficiency |

Real-world examples further illustrate these challenges. Cisco faced overwhelming data volumes that made manual anomaly detection inefficient. Evolving threats from sophisticated cyberattacks rendered traditional methods inadequate. High rates of false positives overwhelmed security teams, reducing their ability to respond effectively.

Computational Constraints in Rare Defect Detection

Rare defect detection demands significant computational resources. You need advanced algorithms capable of processing large datasets and identifying subtle anomalies. However, these algorithms often require high-performance hardware, which increases costs and limits accessibility.

Processing failures in real-time adds another layer of complexity. Systems must analyze data quickly to prevent disruptions, but computational bottlenecks can delay detection. These delays compromise the reliability of automated quality control processes.

To overcome these constraints, you need scalable solutions that balance accuracy and efficiency. Emerging technologies like edge computing and optimized AI models show promise, but their widespread adoption remains a challenge.

Advancements in Long-Tail Defect Simulation Techniques

Synthetic Data and Artificial Defect Simulation

Synthetic data generation has become a cornerstone in addressing the challenges of rare defect detection. When real-world data is scarce or imbalanced, synthetic data fills the gaps by simulating realistic scenarios. You can use these artificial datasets to train machine vision systems, enabling them to identify rare objects and defects more effectively.

Synthetic data offers several advantages:

- A synthetic histopathology image dataset improved model performance and was validated by a pathologist, ensuring realistic results.

- A pediatric imaging pipeline allowed virtual imaging trials without radiation exposure, enhancing AI device safety.

- The S-SYNTH framework generated synthetic skin images, improving lesion segmentation tasks across medical imaging applications.

These examples highlight the versatility of synthetic data in various fields. Synthetic data quality metrics also show high detail and variety in generated images. Tools like the Synthetic Medical Data Evaluation Scorecard standardize the evaluation of these datasets, ensuring their reliability. By incorporating synthetic data into your long-tail defect simulation machine vision system, you can overcome the limitations of traditional training data and improve detection accuracy.

AI and Self-Supervised Learning Models

AI has revolutionized how you approach rare defect detection. Self-supervised learning models, in particular, have emerged as powerful tools for training machine vision systems. These models learn from unlabeled data, reducing the dependency on extensive annotated datasets. This approach is especially useful when dealing with rare objects, where labeled examples are often unavailable.

Self-supervised learning enables your system to extract meaningful features from raw data. For example, contrastive learning techniques allow the model to distinguish between normal and defective patterns. This method enhances the system's ability to generalize, even when rare defects appear in unexpected forms. AI-driven models also adapt to evolving patterns, ensuring consistent performance over time.

By leveraging self-supervised learning, you can build a robust long-tail defect simulation machine vision system. This approach not only reduces the need for manual labeling but also improves the system's efficiency in detecting rare anomalies.

Transformer-Based Frameworks for Rare Defect Detection

Transformer-based frameworks have set new benchmarks in rare defect detection. These models excel at capturing complex relationships within data, making them ideal for identifying subtle anomalies. You can use transformers to process large datasets efficiently, ensuring accurate detection of rare objects.

Comparative studies highlight the superiority of transformer-based frameworks over traditional methods. For instance:

| Metric | Sparse Cross-Transformer Network (SCTN) | FCT (Traditional Method) |

|---|---|---|

| mAP (Scratch) | 65.06% | 60.11% |

| mAP (Sand Hole) | 59.88% | 56.62% |

| mAP (Wear) | 63.25% | 62.7% |

| Overall mAP | 85.29% (30-shot scenario) | N/A |

| Highest F1 Score | 0.8853 | N/A |

| Precision | 87.34% | N/A |

| Recall | 89.75% | N/A |

These metrics demonstrate the enhanced performance of transformer-based models in detecting rare defects. With higher precision and recall rates, transformers minimize false positives and false negatives, ensuring reliable quality control. By integrating transformers into your long-tail defect simulation machine vision system, you can achieve unparalleled accuracy and efficiency.

Applications of Long-Tail Defect Simulation Machine Vision Systems

Manufacturing and Industrial Automation

In manufacturing, long-tail defect simulation enhances efficiency by improving the detection of rare flaws in production lines. You can rely on these systems to identify subtle defects in materials or components that traditional methods might miss. This ensures higher product quality and reduces waste. For example, in pick and place operations, these systems excel at identifying uncommon objects or defects that could disrupt the process. By simulating rare scenarios, they prepare machines for real-world challenges, ensuring smooth picking and placing of items.

Automated quality control also benefits from these advancements. Machines equipped with long-tail defect simulation can handle tasks like picking and placing with greater precision. This reduces downtime and boosts efficiency. You can also improve safety in industrial environments by detecting hazards early. These systems ensure that even rare safety risks are addressed, protecting workers and equipment.

Healthcare and Medical Imaging

In healthcare, long-tail defect simulation transforms medical imaging by enabling AI to detect rare conditions. You can use these systems to analyze medical scans with unparalleled accuracy. Virtual Imaging Trials (VITs) play a crucial role here. They provide precise ground truth data for evaluating AI technologies in radiology. VITs also optimize clinical trials by determining the severity of diseases and the number of cases needed for effective evaluation. This reduces costs and speeds up the development of medical innovations.

By simulating rare medical conditions, these systems improve diagnostic accuracy. For instance, they help identify uncommon anomalies in scans that might otherwise go unnoticed. This enhances patient safety and ensures timely interventions. You can also use these systems to create digital twin populations, enabling personalized healthcare solutions.

Automotive and Aerospace Innovations

In the automotive and aerospace sectors, long-tail defect simulation ensures the reliability of critical components. You can use these systems to detect rare defects in engines, turbines, or structural materials. This prevents failures that could compromise safety. For example, during assembly, these systems excel at picking and placing parts with precision, ensuring that even uncommon objects are handled correctly.

Predictive maintenance also benefits from these advancements. By simulating rare failure scenarios, you can identify potential issues before they occur. This reduces downtime and enhances efficiency. In aerospace, where safety is paramount, these systems ensure that every component meets strict quality standards. You can rely on them to detect even the smallest anomalies, ensuring the safety of passengers and crew.

Future Trends in Machine Vision Systems

IoT and Edge Computing Integration

The integration of IoT and edge computing is reshaping how you approach machine vision systems. By processing data closer to the source, edge computing reduces latency and enhances real-time decision-making. This is especially critical when detecting rare defects in high-speed production environments. IoT devices, equipped with sensors and cameras, continuously monitor operations and feed data into these systems. This synergy allows you to identify anomalies faster and prevent costly machine malfunction.

The market for machine vision is projected to grow from $49.7 billion in 2023 to $159.2 billion by 2032, driven by advancements like IoT-enabled 3D vision systems. These systems accounted for nearly half of the market share in 2024 and are expected to grow at the fastest rate. As you adopt these technologies, you can expect improved quality assurance and real-time process control, ensuring fewer errors and higher efficiency.

Predictive Analytics for Rare Defect Prevention

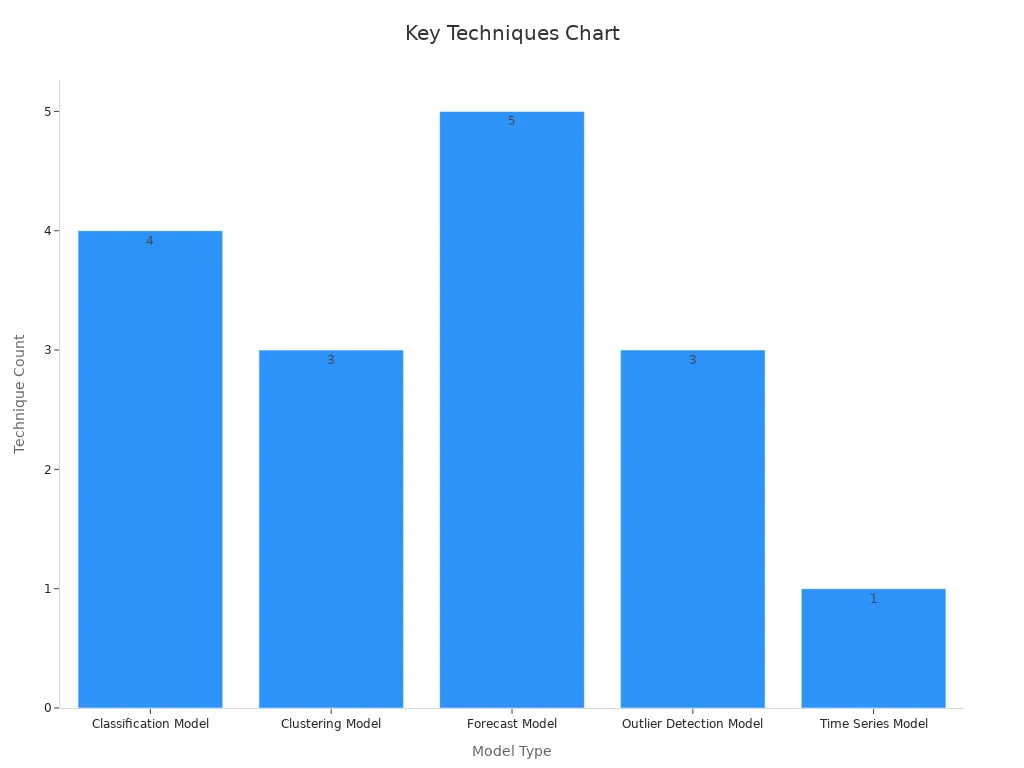

Predictive analytics is transforming how you prevent rare defects in automated systems. By analyzing historical data, these models forecast potential issues before they occur. This proactive approach minimizes downtime and reduces the risk of machine malfunction. For example, classification models like decision trees and random forests help you identify high-risk scenarios, while clustering models group similar defects for better analysis.

| Model Type | Key Techniques | Applications |

|---|---|---|

| Classification Model | Decision Trees, Random Forests, Naive Bayes, SVM | Identifying high-risk test cases, predicting defects |

| Clustering Model | K-Means, Hierarchical Clustering, Density-Based | Segmenting defects, grouping test cases |

| Forecast Model | ARIMA, Random Forests, SVM, Bagging, Boosting | Defect prediction, resource management |

| Outlier Detection Model | Z-Score, Isolation Forest, Local Outlier Factor | Detecting rare defects, improving data quality |

| Time Series Model | Time Series Analysis | Predicting test execution times, resource utilization |

These models ensure that your systems remain efficient and reliable. By leveraging predictive analytics, you can address rare defects before they escalate into larger problems.

Democratization of Machine Vision Technology

The democratization of machine vision technology is making advanced tools accessible to businesses of all sizes. You no longer need extensive resources to implement these systems. Open-source platforms and affordable hardware are leveling the playing field, enabling small and medium enterprises to adopt cutting-edge solutions. This shift empowers you to tackle complex tasks like rare defect detection without significant investment.

Market analyses highlight the growing potential of this trend. Secondary and primary research methods validate the increasing accessibility of machine vision tools. Approaches like data triangulation and stakeholder interviews ensure accurate market insights, helping you make informed decisions. As this technology becomes more widespread, you can expect a surge in innovation and efficiency across industries.

By embracing these trends, you position yourself at the forefront of technological advancements, ready to tackle any task with precision and confidence.

Addressing the long tail problem in machine vision systems is essential for improving accuracy and reliability. Rare defects, though infrequent, can have significant consequences if left undetected. By focusing on this challenge, you ensure that your systems perform effectively in real-world scenarios.

Innovative simulation techniques, such as synthetic data generation and AI-driven models, play a key role in overcoming current limitations. These advancements allow you to train systems on diverse datasets, enabling them to detect even the rarest anomalies with precision.

Tip: Embracing these technologies positions you to lead in automation and quality control, transforming industries like manufacturing, healthcare, and aerospace.

The future of machine vision lies in its ability to adapt and evolve. By adopting these advancements, you contribute to a new era of efficiency, safety, and innovation.

FAQ

What is the long tail of AI failures, and why does it matter in machine vision?

The long tail of AI failures refers to rare and unexpected defects that machine vision systems struggle to detect. These failures matter because they can compromise quality control, safety, and efficiency in automated processes. Addressing them ensures your system performs reliably in real-world scenarios.

How do robots benefit from long-tail defect simulation?

Robots equipped with long-tail defect simulation can identify rare flaws during automated tasks. This improves precision and reduces errors in manufacturing, healthcare, and other industries. By simulating rare scenarios, robots become more adaptable and reliable in handling complex challenges.

Can synthetic data improve rare defect detection?

Yes, synthetic data enhances rare defect detection by filling gaps in training datasets. It creates realistic examples of rare anomalies, helping machine vision systems learn to identify them. This approach reduces dependency on real-world data and improves detection accuracy.

What role does AI play in addressing rare defects?

AI, especially self-supervised learning models, helps detect rare defects by learning from unlabeled data. These models extract meaningful patterns and adapt to evolving scenarios. This makes your machine vision system more effective in identifying anomalies that traditional methods might miss.

Are transformer-based frameworks better for rare defect detection?

Transformer-based frameworks excel at detecting rare defects due to their ability to process complex data relationships. They offer higher precision and recall rates compared to traditional methods. This ensures your system minimizes false positives and negatives, improving overall reliability.

See Also

Exploring Defect Identification Through Machine Vision Technologies

Ensure No Defects Are Overlooked with Vision Systems

Defining Predictive Maintenance Through Machine Vision Solutions

Innovations in Assembly Verification Using Machine Vision Tools