What Is Machine Learning Machine Vision Technology Today?

Imagine a machine that can see, interpret, and analyze visual data just like you. A machine learning machine vision system makes this possible by combining the power of machine learning with advanced vision technology. These systems allow machines to understand images and videos, enabling them to perform tasks that once required human effort, such as identifying defects or guiding robotic systems.

You might wonder how widely these systems are used. Their applications are growing rapidly across industries. For example:

- Quality control systems are projected to reach a value of $3.5 billion by 2024, ensuring product standards.

- Inspection tools will likely hit $3.0 billion, improving productivity by detecting flaws.

- Guidance technologies, valued at $2.5 billion, enhance robotic navigation.

This growth highlights the critical role of the machine learning machine vision system in automating visual tasks and transforming industries worldwide.

Key Takeaways

- Machine learning vision systems help machines see and understand pictures.

- They automate tasks like checking quality and finding mistakes.

- These systems are growing fast in healthcare, factories, and stores.

- They make work faster and more accurate in these industries.

- Important parts include lights, sensors, and software to process images.

- These parts work together to give clear and exact results.

- Machine learning helps them learn from data and adjust to changes.

- This means they don’t need new programming for different tasks.

- Training and improving these systems keep them useful and dependable.

- They stay effective for many jobs in different areas.

How Machine Learning Powers Machine Vision Systems

Machine learning has revolutionized the way machine vision systems operate. By enabling machines to process and interpret visual data, it has unlocked new possibilities for automation and precision. To understand this better, let’s explore the key components of a machine vision system, the role of machine learning in visual data processing, and how these systems are trained and optimized.

Key Components of a Machine Vision System

A machine vision system relies on several critical components to function effectively. Each plays a unique role in ensuring accurate image capture, processing, and analysis. Here are the main components:

- Lighting: Proper lighting is essential for capturing clear images. Techniques like backlighting or diffuse lighting are chosen based on the object’s characteristics.

- Sensors: These capture visual data, often using cameras or depth sensors. High-resolution sensors improve detection accuracy.

- Image Processing Software: This software analyzes images for tasks like object detection, pattern recognition, and defect identification.

- Processing Units: CPUs and GPUs handle computational tasks. High-performance units enable real-time image analysis.

- Hardware Interfaces: These connect the system’s components, ensuring seamless communication.

- Calibration Tools: These tools maintain system reliability by ensuring accurate measurements and images.

- Integration and System Design: Careful selection and configuration of components optimize the system’s performance.

Tip: Understanding the components of machine vision systems helps you grasp how they work together to achieve precise results.

Machine Learning's Role in Visual Data Processing

Machine learning enhances the capabilities of machine vision systems by enabling them to process complex visual data. Traditional algorithms rely on predefined rules, but machine learning models learn patterns from data, making them more adaptable and efficient. Here’s how machine learning transforms visual data processing:

- Deep Learning Algorithms: These algorithms, particularly convolutional neural networks (CNNs), excel at tasks like object detection and image analysis. They identify patterns in data, allowing systems to detect defects or recognize objects with high accuracy.

- Automation: Machine learning automates tasks like sorting and classification, reducing the need for manual intervention.

- Adaptability: Models trained on diverse datasets can handle variations in lighting, object position, and even product changes without reprogramming.

For example, deep learning algorithms have shown remarkable success in integrating with machine vision sensors. They enhance visual interpretation by processing depth camera data, which is particularly useful in applications like physiotherapy. In fact, systems like the Visual Feedback Balance Training system have achieved a Pearson correlation coefficient exceeding 98%, proving their reliability in clinical settings.

Training and Optimizing Machine Vision Models

Training machine vision models involves feeding them large datasets to help them learn patterns and improve their performance. Optimization techniques further enhance their efficiency and adaptability. Here are some proven methods:

| Optimization Technique | Benefit |

|---|---|

| Adversarial Training | Increases robustness against adversarial attacks by 30-50%. |

| Meta-Learning | Reduces training time for new tasks by 50-80%. |

| Differentiable Architecture Search (DARTS) | Achieves state-of-the-art performance while reducing search time by 90%. |

| Quantization | Reduces model size by up to 75% while maintaining accuracy. |

| Pruning | Decreases model size by up to 90% without significant accuracy loss. |

| Knowledge Distillation | Improves student model accuracy by 3-5%. |

| Automated Hyperparameter Tuning (HPO) | Enhances model performance by 20-30% compared to manual tuning. |

These techniques ensure that machine vision systems remain scalable, efficient, and adaptable to new challenges. For instance, models optimized for specific hardware platforms, like TPUs, achieve up to 80% speedup compared to GPU-based implementations. This makes them ideal for large-scale applications.

Note: Training and optimization are ongoing processes. Regular updates to datasets and models ensure that machine vision systems stay accurate and reliable.

Applications of Machine Learning Machine Vision Technology

Machine vision technology, powered by AI, has transformed industries by automating visual tasks and improving efficiency. Let’s explore how AI machine vision is making a difference in healthcare, manufacturing, and retail.

AI Machine Vision in Healthcare

AI machine vision has revolutionized healthcare by enabling accurate and efficient diagnosis, treatment, and monitoring. These systems analyze medical images, detect abnormalities, and assist healthcare professionals in making informed decisions. Here are some notable examples:

- Diabetic Retinopathy Detection: DeepMind developed a machine learning model that analyzes eye images to detect diabetic retinopathy. This innovation has significantly improved screening processes and achieved accuracy comparable to human experts.

- Clinical Performance Metrics: Studies emphasize the importance of evaluating AI models using metrics like sensitivity, specificity, and predictive values. These metrics ensure that AI systems perform reliably in clinical settings.

- Advanced Imaging Techniques: AI-powered imaging systems identify tumors, fractures, and other conditions with remarkable precision. This reduces diagnostic errors and enhances patient outcomes.

AI machine vision also supports remote monitoring and telemedicine. For instance, it enables doctors to analyze patient data from a distance, ensuring timely interventions. By integrating AI into healthcare, you can expect faster diagnoses, improved accuracy, and better patient care.

Machine Vision Systems in Manufacturing

Manufacturing has embraced machine vision systems to enhance productivity, quality, and safety. These systems automate inspection tasks, identify defects, and optimize production processes. Here’s how they contribute:

| Aspect | Benefit |

|---|---|

| Quality Inspection | Identifies tiny defects and their root causes with high accuracy. |

| Automation | Reduces human intervention, leading to faster processes. |

| Cost Reduction | Lowers costs by minimizing the need for expensive machinery. |

| Customization | Enables product tweaks for specific categories, reducing turnaround time. |

| Remote Monitoring | Allows for quality checks from a distance, enhancing operational efficiency. |

For example, AI-driven drones inspect power lines, saving costs and improving accuracy. In addition, machine vision systems ensure precise measurements, helping manufacturers meet strict quality standards. By integrating AI, factories can achieve higher efficiency and reduce downtime.

Retail Applications of Machine Vision Systems

Retailers use machine vision systems to enhance customer experiences and streamline operations. These systems analyze shopper behavior, optimize store layouts, and improve inventory management. Key applications include:

| Metric | Description |

|---|---|

| Average time spent (dwell time) | Insights into customer engagement and marketing effectiveness. |

| People counting and flow analytics | Tracks customer paths and visualizes them for better store layout and product placement. |

| Shopper behavior analysis | Analyzes customer interactions with self-checkouts and other areas of interest. |

| Hot zones and hot shelves | Identifies popular areas in the store to optimize promotions and product placements. |

| Queue detection | Measures customer wait times at service points to improve service efficiency. |

AI machine vision also powers self-checkout systems, reducing wait times and enhancing convenience. By analyzing customer demographics and emotions, retailers can create personalized marketing campaigns. These insights help you understand customer preferences and improve overall satisfaction.

Transportation and Autonomous Vehicles

Machine vision systems have become the backbone of modern transportation, especially in the development of autonomous vehicles. These systems enable vehicles to "see" and interpret their surroundings, ensuring safer and more efficient travel. By processing data from cameras, LiDAR, and radar sensors, machine vision helps self-driving cars make real-time decisions, such as detecting pedestrians, recognizing traffic signs, and avoiding obstacles.

How Machine Vision Enhances Safety and Performance

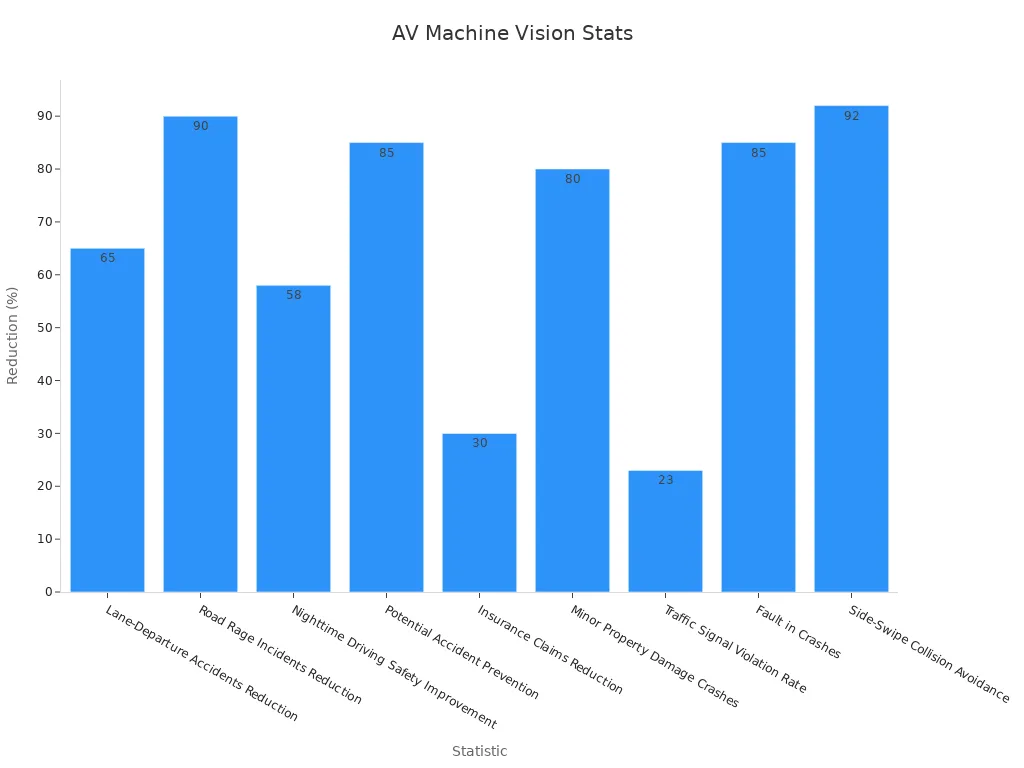

Autonomous vehicles equipped with machine vision systems have demonstrated remarkable improvements in safety and accident prevention. The following table highlights key performance data:

| Statistic Description | Value | Comparison |

|---|---|---|

| Disengagement Rate | 0.02 per 1,000 miles | Down from 0.8 per 1,000 miles |

| Fatal Crashes (Waymo) | 0 over 20 million miles | Contrast to human-driven vehicles |

| Lane-Departure Accidents Reduction | 65% | Compared to human-driven trucks |

| Road Rage Incidents Reduction | 90% | Compared to human drivers |

| Nighttime Driving Safety Improvement | 58% fewer crashes | Compared to human drivers |

| Potential Accident Prevention | 85% | If AV adoption reaches 75% |

| Insurance Claims Reduction | 30% | Due to fewer high-severity crashes |

| Minor Property Damage Crashes | 80% | Involves no injuries |

| Economic Savings | $800 billion annually | From reduced crash-related costs |

| Traffic Signal Violation Rate | 23% lower | Compared to human drivers |

| Fault in Crashes | 85% | Involves human-driven vehicles at fault |

| Side-Swipe Collision Avoidance | 92% | Compared to human drivers |

These statistics highlight the transformative impact of machine vision on transportation. For instance, self-driving cars have achieved a disengagement rate of just 0.02 per 1,000 miles, a significant improvement over earlier rates. Additionally, autonomous vehicles have reduced nighttime crashes by 58%, making roads safer for everyone.

Real-World Applications

Machine vision systems are not limited to self-driving cars. They also play a crucial role in advanced driver-assistance systems (ADAS), which include features like lane-keeping assistance, adaptive cruise control, and automatic emergency braking. These technologies enhance driver safety and reduce human error, which is responsible for 85% of traffic accidents.

In public transportation, autonomous buses and shuttles are becoming more common. These vehicles rely on machine vision to navigate complex urban environments, ensuring timely and efficient service. By adopting these technologies, cities can reduce traffic congestion and improve mobility for residents.

Agriculture and Smart Farming

Machine vision systems are revolutionizing agriculture by enabling precision farming techniques that boost productivity and sustainability. These systems analyze visual data from drones, cameras, and sensors to monitor crop health, detect pests, and optimize resource usage. By integrating machine learning, farmers can make data-driven decisions that improve yields and reduce environmental impact.

Precision Agriculture in Action

Machine vision systems empower farmers to monitor their fields with unprecedented accuracy. For example, drones equipped with machine vision can capture high-resolution images of crops, identifying areas that require irrigation, fertilization, or pest control. This targeted approach minimizes waste and maximizes efficiency.

A 2022 study published in Nature Sustainability revealed the following benefits of machine vision in agriculture:

- Farms using machine learning for precision agriculture achieved a 10-15% increase in yields.

- These farms also reduced their environmental footprint by 35%.

In the UK, Arable Farms implemented machine learning for variable rate technology. This innovation led to a 12.5% increase in wheat production and an 8% reduction in input costs. These results demonstrate how machine vision can enhance both profitability and sustainability.

Key Applications in Smart Farming

Machine vision systems support a wide range of agricultural tasks, including:

- Crop Monitoring: Detecting diseases, nutrient deficiencies, and pest infestations early.

- Harvesting Automation: Guiding robotic harvesters to pick fruits and vegetables with precision.

- Livestock Management: Monitoring animal health and behavior using cameras and sensors.

- Weed Detection: Identifying and removing weeds without harming crops.

By adopting these technologies, you can optimize farm operations and reduce labor costs. For instance, robotic harvesters equipped with machine vision can work around the clock, ensuring timely harvests and minimizing losses.

Tip: Combining machine vision with IoT devices can further enhance smart farming. Sensors can provide real-time data on soil moisture, temperature, and weather conditions, enabling even more precise decision-making.

Benefits of Machine Learning Machine Vision Systems

Enhanced Accuracy and Efficiency

Machine learning machine vision systems deliver unmatched accuracy and speed in visual tasks. Traditional methods often fall short in precision and efficiency, but AI-driven systems excel. For example, automated inspection systems achieve over 99.5% accuracy, compared to 85-90% with older techniques. They also process units in just 0.2 seconds, far faster than the 2-3 seconds required by traditional methods.

| Metric | Traditional Methods | AI-Driven Systems |

|---|---|---|

| Accuracy | 85-90% | 99.5%+ |

| Speed | 2-3 seconds/unit | 0.2 seconds/unit |

These advancements translate into real-world benefits. A consumer electronics team reduced defect rates by 75% while inspecting 500 units per minute. Similarly, an automotive supplier cut inspection costs by 62%, leading to 78% fewer product returns. By adopting machine vision technology, you can achieve higher accuracy and faster processing, improving overall efficiency.

Automation of Visual Tasks

Machine vision systems powered by machine learning automate complex visual tasks with remarkable reliability. Neural networks enhance performance metrics, boosting accuracy from 73.95% to 74.15% through progressive training methods. In medical imaging, semantic segmentation identifies tumors with high precision, aiding early diagnosis. These systems also streamline facial recognition processes, as demonstrated by the 2019 FRVT evaluation of 189 algorithms using over 18 million images.

Automated inspection systems eliminate the need for manual intervention, reducing errors and saving time. For instance, in manufacturing, these systems detect defects and ensure quality control without human oversight. By automating visual tasks, you can focus on higher-value activities while maintaining consistent results.

Improved Decision-Making with AI Machine Vision

AI machine vision systems empower you to make better decisions by providing accurate and actionable insights. These systems analyze vast amounts of visual data, uncovering patterns and anomalies that might go unnoticed. For example, in agriculture, machine vision identifies crop health issues early, enabling timely interventions. In healthcare, it supports doctors by pinpointing abnormalities in medical images, improving diagnostic accuracy.

By integrating machine vision technology, you gain access to reliable data that enhances decision-making across industries. Whether you're optimizing production lines or improving patient care, these systems help you achieve better outcomes with confidence.

Scalability Across Diverse Industries

Machine learning machine vision systems adapt seamlessly to diverse industries, making them a cornerstone of modern innovation. Their ability to handle complex visual tasks ensures they meet the unique demands of various sectors, from manufacturing to healthcare. This adaptability drives their widespread adoption and fuels market growth.

The global machine vision market is projected to reach $20.4 billion by 2024, with a compound annual growth rate (CAGR) of 13% from 2025 to 2030. Industries like automotive, pharmaceuticals, and chemicals are leading adopters, leveraging machine vision for safety, quality control, and regulatory compliance. The following table highlights key market trends:

| Segment/Region | Market Size/Share (2024) | Projected CAGR (2025-2030) | Key Drivers/Applications |

|---|---|---|---|

| Global Machine Vision Market | USD 20,378.6 million | 13.0% | Quality inspection, productivity, automation integration |

| Automotive Segment | Largest market share | N/A | Vehicle perception, driver assistance, safety, parts traceability |

| Pharmaceuticals & Chemicals | N/A | Fastest CAGR | Regulatory compliance, quality control, defect detection |

| North America | N/A | Over 11% | Development of 3D technology, demand for automation |

| U.S. | N/A | Over 12% | Key vendors developing 3D technology, automation demand |

| Europe | N/A | Over 10% | Industrial automation applications, government initiatives |

| Asia-Pacific | Over 43% market share | N/A | Rapid industrialization, manufacturing expansion, automation in various applications |

You’ll notice that the automotive industry leads in adoption, using machine vision for tasks like vehicle perception and driver assistance. Pharmaceuticals and chemicals are also seeing rapid growth due to strict quality control requirements. In North America, advancements in 3D technology drive adoption, while Asia-Pacific dominates the market with over 43% market share, fueled by industrialization and automation.

Machine vision systems scale effortlessly because they integrate with existing workflows and adapt to new challenges. Whether you’re in manufacturing, healthcare, or retail, these systems enhance productivity and ensure precision. Their scalability makes them a valuable asset across industries, helping you stay competitive in a rapidly evolving market.

Tip: To maximize the benefits of machine vision, consider how its adaptability can address your industry-specific challenges.

Challenges in Machine Learning Machine Vision Technology

Data Quality and Availability Issues

Machine vision systems rely on high-quality data to function effectively. However, obtaining such data often presents challenges. Simulation studies show that poor data quality can significantly reduce model accuracy. Missing or inconsistent data leads to biased results, while outdated information produces irrelevant outputs. For example, if a dataset lacks critical variables like lighting conditions or object angles, the system may fail in defect detection tasks.

Key metrics like accuracy, consistency, and completeness are essential for reliable machine vision applications. Accuracy ensures correct outcomes, while consistency maintains a standard format for processing. Completeness addresses missing data, which is vital for comprehensive training. Increasing the number of observations also improves model performance. For instance, supervised learning models perform better with datasets containing up to 250 events. Ensuring data availability and quality is crucial for achieving reliable results in quality control and inspection tasks.

Ethical and Privacy Concerns

Ethical and privacy issues pose significant challenges in deploying machine vision systems. Biased algorithms in facial recognition have led to wrongful arrests, disproportionately affecting Black individuals. Similarly, retail applications have misclassified customer demographics, causing marketing errors and dissatisfaction. In healthcare, machine vision systems trained on non-diverse datasets have missed conditions in underrepresented groups, leading to unequal treatment.

To address these concerns, you can adopt practices like data minimization, anonymization, and differential privacy. Data minimization involves collecting only necessary information, aligning with privacy laws like GDPR. Anonymization techniques, such as selective blurring, protect sensitive data. Differential privacy adds random noise to outputs, safeguarding individual data points while preserving overall trends. These measures help ensure ethical and fair use of machine vision technology.

High Computational Costs

Training and deploying machine vision models require substantial computational resources, leading to high costs. Large models like OpenAI's GPT-3, with 175 billion parameters, demand specialized hardware such as NVIDIA’s H100 GPUs. Training these models involves significant expenses for data collection, infrastructure maintenance, and operational support. For example, training Grover, a model with 1.5 billion parameters, cost approximately $25,000 over two weeks using 256 TPU chips.

The costs extend beyond training. Fine-tuning models for specific applications and running them post-deployment also incur expenses. Failed training runs further increase costs. Despite these challenges, advancements in hardware and optimization techniques aim to reduce computational expenses, making machine vision systems more accessible for tasks like defect detection and quality control.

Managing Complex and Unstructured Data

Handling complex and unstructured data is one of the biggest challenges in machine learning machine vision systems. Unlike structured data, which fits neatly into rows and columns, unstructured data includes images, videos, and text. These types of data lack a predefined format, making them harder to process. You need advanced techniques to extract meaningful insights from such data.

Why Unstructured Data Is Challenging

Unstructured data often comes in large volumes and varies in quality. For example, images may have inconsistent lighting, angles, or resolutions. Videos might contain noise or irrelevant frames. These inconsistencies make it difficult for machine vision systems to analyze the data accurately.

Did you know? Over 80% of the data generated today is unstructured, yet it holds valuable insights for industries like healthcare, retail, and transportation.

How Machine Vision Systems Manage Complexity

Machine learning algorithms, especially deep learning models, excel at processing unstructured data. Here’s how they handle complexity:

- Feature Extraction: Models like convolutional neural networks (CNNs) identify patterns in images, such as edges, shapes, and textures.

- Data Augmentation: Techniques like flipping, rotating, and cropping images improve model performance by creating diverse training datasets.

- Noise Reduction: Preprocessing steps remove irrelevant data, such as background noise in images or videos.

Tools and Techniques for Better Results

You can use tools like TensorFlow and PyTorch to train machine vision models. These platforms support advanced techniques like transfer learning, which reduces training time by using pre-trained models. Additionally, frameworks like OpenCV help preprocess and clean unstructured data, ensuring better accuracy.

Tip: Always evaluate your data quality before training a model. High-quality data leads to better predictions and fewer errors.

By mastering these techniques, you can unlock the full potential of unstructured data and improve the performance of your machine vision systems.

Future Trends in AI Machine Vision

Integration with IoT and Smart Devices

The integration of machine vision with IoT and smart devices is transforming industries by enabling interconnected systems. In manufacturing, IoT sensors paired with machine vision optimize supply chains, reduce downtime, and improve predictive maintenance. For example, companies using these technologies report higher operational efficiency and a competitive edge.

A notable case involves a solar panel producer that implemented a computer vision system with sub-millimeter precision. This system replaced manual inspections with automated quality control, significantly reducing waste and increasing throughput. By combining IoT and machine vision, you can achieve similar results, streamlining operations and enhancing productivity.

Advancements in Edge Computing

Edge computing is revolutionizing machine vision by processing data closer to its source. This reduces latency and ensures real-time results, which are critical for applications like defect detection and autonomous vehicles. Enhanced hardware capabilities also improve processing speeds and data security, making edge computing a game-changer for machine vision systems.

| Technological Advancement | Impact on Machine Vision Performance |

|---|---|

| Real-time processing | Reduces latency, ensuring immediate results in counting tasks |

| AI integration | Enhances decision-making and operational efficiency |

| Proximity processing | Minimizes latency for real-time analytics |

These advancements allow you to deploy machine vision systems in environments where speed and accuracy are essential, such as manufacturing lines or smart cities.

Explainable AI in Machine Vision Systems

Explainable AI (XAI) is gaining traction as a way to make machine vision systems more transparent and trustworthy. XAI provides insights into how decisions are made, helping you understand why a system flagged a defect or classified an object. This is especially important in industries like healthcare, where accountability is critical.

By adopting XAI, you can ensure compliance with regulations and build trust with stakeholders. For instance, explainable models in medical imaging can highlight specific areas of concern, enabling doctors to validate AI-driven diagnoses. This transparency fosters confidence in machine vision systems and encourages broader adoption across industries.

Expansion into Emerging Markets

Emerging markets are witnessing rapid adoption of machine vision technology. These regions are leveraging its potential to enhance productivity, improve quality control, and drive innovation across industries. As businesses in these markets embrace automation, machine vision systems are becoming essential tools for staying competitive.

The market for machine vision in emerging economies is growing at an impressive rate. The following table highlights key statistics:

| Metric | Value |

|---|---|

| Market Size in 2024 | USD 14.1 Billion |

| Market Forecast in 2033 | USD 26.7 Billion |

| Market Growth Rate 2025-2033 | 6.97% |

This growth reflects the increasing demand for automation and quality assurance. Industries such as manufacturing, automotive, electronics, and pharmaceuticals are leading the way. For example, manufacturers use machine vision to detect defects and ensure consistent product quality. Automotive companies rely on it for tasks like vehicle assembly and safety inspections.

You’ll find that the integration of AI and deep learning is a game-changer in these markets. These technologies enhance the accuracy and versatility of machine vision systems, making them suitable for diverse applications. For instance:

- AI-powered systems can adapt to varying lighting conditions and object orientations.

- Deep learning models improve defect detection rates, reducing waste and boosting efficiency.

Emerging markets also benefit from the affordability of modern machine vision solutions. Advances in hardware and software have made these systems more accessible, enabling small and medium-sized enterprises to adopt them. By investing in machine vision, businesses in these regions can achieve higher productivity and compete on a global scale.

Tip: If you operate in an emerging market, consider how machine vision can streamline your processes and improve your product quality.

Machine learning machine vision systems have transformed industries by automating visual tasks and improving accuracy. You can see their impact in healthcare, manufacturing, transportation, and agriculture, where they boost productivity and reduce errors. These systems also open doors to innovation, enabling smarter solutions for complex challenges.

Note: While these technologies offer immense benefits, addressing challenges like data quality and ethical concerns remains crucial.

Ongoing research and development will unlock even greater possibilities. By staying informed and embracing advancements, you can leverage machine vision to drive efficiency and shape the future of your industry.

FAQ

What is the difference between machine vision and computer vision?

Machine vision focuses on industrial applications like quality control and automation. Computer vision, on the other hand, deals with broader tasks, such as facial recognition and image analysis. You’ll find machine vision systems optimized for speed and reliability in manufacturing environments.

How does machine learning improve machine vision systems?

Machine learning enables systems to learn patterns from data. This improves accuracy in tasks like defect detection and object recognition. You can train models to adapt to new challenges, making them more efficient and versatile compared to traditional algorithms.

Can machine vision systems work in low-light conditions?

Yes, machine vision systems can handle low-light environments using advanced sensors and lighting techniques. For example, infrared cameras capture images in darkness. You can also use adaptive lighting to enhance visibility and ensure accurate results.

Are machine vision systems expensive to implement?

Costs vary depending on the complexity of the system. Basic setups are affordable, while advanced systems with AI integration may require higher investment. You’ll find that the long-term benefits, such as reduced errors and improved efficiency, often outweigh the initial costs.

What industries benefit the most from machine vision technology?

Industries like manufacturing, healthcare, agriculture, and transportation benefit significantly. You can use machine vision for tasks like quality control, medical imaging, crop monitoring, and autonomous vehicle navigation. Its adaptability makes it valuable across diverse sectors.

See Also

Essential Insights Into Computer Vision And Machine Vision

The Role Of Deep Learning In Improving Machine Vision

Understanding Computer Vision Models And Machine Vision Systems