Masking Machine Vision Systems Enhancing Safety Standards in 2025

Advancements in machine vision are transforming how you approach safety. A masking machine vision system ensures precision and reliability in detecting safety risks, such as improper mask wearing. These systems, powered by autonomous machine vision technology, outperform traditional methods. For example, they reduce inspection errors by over 90% and improve defect detection accuracy by 20%. During the covid-19 pandemic, face mask detection became vital. This innovation now extends to various environments, safeguarding public health and workplace safety with unparalleled efficiency.

Key Takeaways

- Masking machine vision systems cut detection mistakes, boosting safety by 90%.

- Watching in real-time helps find risks fast and fix them quickly.

- Using AI and machine learning makes detection better and fits different places.

- Better safety rules mean fewer injuries and cheaper costs for workers and companies.

- Using these tools now keeps companies ready for new safety rules.

Current Challenges in Safety Standards

Limitations of traditional safety systems

Traditional safety systems often fail to meet the demands of modern environments. These systems rely heavily on manual processes, which can lead to errors in detection and delayed responses. Without advanced tools, identifying risks such as improper mask usage becomes challenging. Many organizations struggle because management does not prioritize safety initiatives. Employees may hesitate to report safety concerns due to a lack of effective communication. Additionally, traditional systems rarely involve employees in safety processes, which limits their effectiveness. This outdated approach cannot keep up with the fast-paced changes in safety-critical industries.

The need for real-time monitoring and adaptability

Real-time monitoring has become essential for maintaining safety standards. It allows you to detect issues immediately and take corrective action before they escalate. For example, continuous monitoring ensures that systems function correctly and alerts you to potential problems. This proactive approach not only prevents accidents but also protects your organization’s reputation. In safety-critical environments, real-time access to accurate data enables quick decision-making. Enhanced monitoring systems also help resolve discrepancies faster, ensuring smooth operations. Adaptability is equally important. Modern systems must adjust to dynamic conditions, such as fluctuating mask compliance during the covid-19 pandemic, to maintain safety.

Rising complexity in safety-critical environments

Safety-critical environments are becoming increasingly complex due to evolving technologies and stricter regulations. Industries must now comply with standards like IEC 61508 and ISO 26262, which address new challenges. High initial and maintenance costs add to the complexity, making it harder for organizations to implement effective safety measures. The need for advanced safety instrumented systems has grown across industries. These systems must handle intricate tasks, such as the detection of safety risks in real time. As environments become more demanding, traditional methods fall short, highlighting the need for innovative solutions.

Advancements in Masking Machine Vision Systems

Technological innovations driving masking capabilities

Technological advancements have revolutionized the way you approach safety through masking machine vision systems. These systems now leverage cutting-edge algorithms and techniques to enhance detection accuracy and reliability. For instance, the YOLOv3 algorithm has become a cornerstone in mask detection models. It achieves a mean average precision of 89.8% during training and 100% during testing, ensuring high performance in real-world applications. Detection accuracy ranges from 40.03% to 65.03% per frame, depending on environmental conditions. Techniques like deep learning, data augmentation, and object detection further refine these systems, making them indispensable in safety-critical environments.

| Key Findings | Description |

|---|---|

| Algorithm Used | YOLOv3 |

| Mean Average Precision | 89.8% during training, 100% during testing |

| Detection Accuracy | Ranges from 40.03% to 65.03% per frame |

| Techniques Employed | Deep learning, data augmentation, object detection |

These innovations ensure that masking machine vision systems can identify safety risks, such as improper mask usage, with unparalleled precision. By adopting these technologies, you can significantly reduce errors and improve overall safety standards.

Integration of AI and machine learning in autonomous machine vision systems

Artificial intelligence (AI) and machine learning have transformed autonomous machine vision systems, enabling them to perform complex tasks with remarkable accuracy. These systems learn from their environment, improving their behavior over time and reducing human error. For example, AI-driven vision systems for detecting pedestrians have reduced error rates to below 2%. Deep learning algorithms in autonomous vehicles now classify objects with 99% accuracy, showcasing the potential of AI in enhancing detection capabilities.

- Machine learning enhances autonomous navigation, allowing systems to adapt to dynamic conditions and improve safety.

- In 2022, over 22,000 workplace safety violations were reported in the U.S., highlighting the need for automated solutions to mitigate risks.

- The NVIDIA Drive PX platform performs 320 trillion operations per second, ensuring the efficiency of autonomous systems.

- Training an AI for driving requires over 100 terabytes of data, emphasizing the importance of robust datasets.

By integrating AI and machine learning, autonomous machine vision systems can achieve higher detection accuracy and adapt to diverse scenarios. These advancements not only improve safety but also enhance operational efficiency across industries.

Enhanced adaptability to dynamic environments

Dynamic industrial environments demand flexible machine vision solutions that can adapt to changing conditions. Masking machine vision systems now incorporate advanced techniques to enhance their adaptability. For example, autoencoders reconstruct normal data patterns and flag anomalies, making them effective in noisy environments. Isolation Forest algorithms isolate outliers, providing robust solutions for subtle anomalies. These techniques ensure that the systems maintain high detection accuracy even in challenging conditions.

| Technique | Contribution to Adaptability |

|---|---|

| Autoencoders | Reconstruct normal data patterns and flag significant reconstruction errors as anomalies, effective in noisy environments. |

| Isolation Forest | Isolates outliers using random forests, providing robust solutions for subtle anomalies. |

| Deep SVDD | Learns a hypersphere around normal data points, enhancing detection performance with limited labeled data. |

| Self-supervised techniques | Leverages anomalous training data via iterative latent token masking to improve model adaptability and performance. |

| Knowledge distillation techniques | Preserves essential characteristics during model training, addressing limitations of traditional methods. |

| Model Agnostic Meta Learning (MAML) | Prepares models to handle diverse datasets and adapt to unseen data conditions without extensive retraining. |

| Algorithm for continuous adaptation | Systematically enhances detection capabilities by recalibrating model parameters in response to real-time data. |

These advancements make masking machine vision systems more resilient and capable of handling the complexities of modern industries. By implementing these solutions, you can ensure that your safety systems remain effective, even in unpredictable environments.

Applications in Safety-Critical Industries

Healthcare: Ensuring patient safety and operational precision

In healthcare, maintaining safety standards is critical. Masking machine vision systems play a vital role in ensuring patient safety and operational precision. These systems monitor compliance with mask-wearing protocols, which became essential during the covid-19 pandemic. By detecting improper mask usage, they help reduce the spread of respiratory illnesses. For example, a face mask detection system developed using MATLAB achieved an accuracy of 89.17% with specific cropping ratios. This adaptability allows the system to identify various mask colors and types, making it effective in diverse healthcare settings.

You can also use these systems to enhance quality inspection processes. They ensure that medical staff adhere to hygiene protocols, reducing the risk of contamination during surgeries or procedures. Real-time monitoring capabilities allow immediate detection of safety violations, enabling swift corrective actions. This proactive approach minimizes errors and improves patient outcomes. By integrating these technologies, healthcare facilities can achieve higher safety standards and operational efficiency.

Manufacturing: Reducing workplace hazards and improving quality control

Manufacturing environments often face significant safety challenges. Masking machine vision systems address these challenges by reducing workplace hazards and improving quality inspection processes. These systems detect safety risks, such as improper mask wearing, and ensure compliance with safety protocols. For instance, real-time monitoring can identify workers not wearing protective masks in hazardous areas, preventing potential injuries.

The financial impact of workplace injuries is substantial. In the U.S., work-related injuries cost $167 billion annually, with an average cost of $40,000 per medically consulted injury. By implementing masking machine vision systems, you can reduce these costs. These systems have been shown to lower insurance expenses by 15% and increase environmental health and safety (EHS) productivity by 40%. Additionally, they enhance quality inspection by identifying defects in products, ensuring that only high-quality items reach consumers. This dual benefit of improved safety and quality makes these systems indispensable in manufacturing.

| Statistic | Value |

|---|---|

| Total cost of work-related injuries | $167 Billion |

| Average annual cost per worker | $1,040 |

| Average cost per medically consulted injury | $40,000 |

| Average cost of a workplace fatality | $1.39 Million |

| Weekly cost paid by U.S. employers in workers' comp | $1 Billion |

| Maximum penalty per OSHA violation (2025) | Up to $165,514 |

Public safety: Enhancing surveillance and face mask detection

Public safety relies heavily on effective surveillance systems. Masking machine vision systems enhance these systems by improving face mask detection capabilities. During the covid-19 pandemic, ensuring compliance with mask-wearing protocols became a priority. These systems now play a crucial role in monitoring public spaces, identifying individuals not wearing masks, and ensuring community safety.

A study by the National Institute of Standards and Technology (NIST) highlighted the challenges of facial recognition with masked individuals. Some algorithms failed to authenticate masked faces up to 50% of the time, while the best-performing algorithm still had a 5% failure rate. Masking machine vision systems address these issues by incorporating advanced detection algorithms. They ensure accurate mask identification, even in crowded or dynamic environments.

These systems also improve real-time monitoring of safety violations. They trigger immediate alerts to supervisors for critical issues, enabling quick responses. For example, they can enhance airbag compliance rates in vehicles from below 25% to over 90%. By adopting these technologies, you can create safer public spaces and reduce the risks associated with non-compliance.

Benefits of Enhanced Safety Standards

Improved quality assurance and operational efficiency

Enhanced safety standards significantly improve automated quality assurance and operational efficiency. By integrating advanced masking machine vision systems, you can achieve higher detection accuracy in identifying safety risks. These systems streamline processes, reduce errors, and ensure compliance with safety protocols. For example, in healthcare, improved safety measures have led to:

- A reduction in infection rates, including cases of methicillin-resistant S. aureus.

- Fewer in-hospital cardiac arrests due to better monitoring.

- Enhanced documentation of adverse drug reactions, ensuring patient safety.

These improvements demonstrate how advanced safety systems not only protect individuals but also optimize workflows, saving time and resources. By adopting these technologies, you can ensure that your operations run smoothly and efficiently.

Reduction in risks and accidents

Implementing advanced safety standards reduces risks and accidents across industries. Metrics such as Total Recordable Incident Rate (TRIR) and Days Away, Restricted, or Transferred Rate (DART) highlight the impact of these measures.

| Metric | Description | Impact on Safety |

|---|---|---|

| TRIR | Measures incidents per 100 full-time employees. | Indicates overall safety performance. |

| DART | Tracks injuries leading to work restrictions. | Reflects operational efficiency. |

| LTIFR | Measures lost time injuries per million hours worked. | Focuses on serious incidents. |

| Severity Rate | Quantifies the severity of injuries in terms of lost workdays. | Highlights the impact on workforce. |

| Near-Miss Reporting Rate | Tracks reported near-miss events, indicating proactive safety culture. | Suggests vigilance and hazard reporting. |

Organizations using AI-driven detection systems have achieved significant reductions in TRIR and DART rates. Increased near-miss reporting reflects a proactive safety culture, while targeted strategies based on AI insights further enhance safety outcomes. These advancements create safer environments for employees and reduce the likelihood of costly incidents.

Compliance with evolving safety regulations

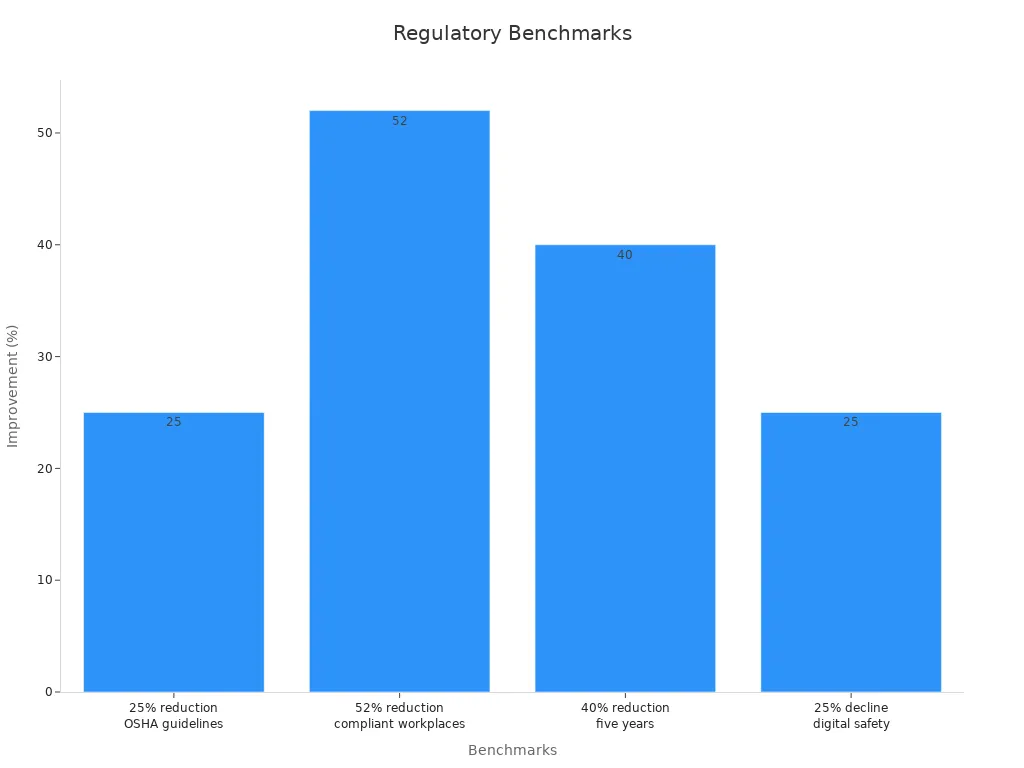

Staying compliant with evolving safety regulations is essential for maintaining a safe and efficient workplace. Enhanced safety standards help you meet these requirements by leveraging advanced detection technologies. For instance, companies adhering to updated OSHA guidelines have seen a 25% reduction in workplace accidents.

Other benchmarks include:

- A 52% reduction in injury rates for compliant workplaces.

- A 40% decrease in work-related injuries over five years for organizations following stringent safety regulations.

- A 25% decline in workplace injuries within the first year of implementing digital safety management systems.

By adopting these measures, you can ensure compliance, reduce liability, and foster a culture of safety within your organization.

Masking machine vision systems are transforming safety standards across industries. These systems reduce error rates in detection and improve operational efficiency. For example, the INSPEKTO S70 system minimizes setup time and adapts quickly to new production needs. It inspects critical mask components, ensuring defects do not compromise safety. Recent installations have demonstrated reliable quality assurance, flagging defective masks effectively.

| Feature/Benefit | Description |

|---|---|

| Error Rate Reduction | Manual inspection has a very high error rate, which the machine vision system aims to significantly reduce. |

| Speed of Setup | The INSPEKTO S70 is ready to use with minimal setup time, unlike traditional systems that take weeks or months. |

| Flexibility in Production | The system can learn new product characteristics quickly, allowing for adaptability in production lines. |

| Critical Inspection Areas | The system inspects crucial components of face masks, preventing defects that could lead to safety issues. |

| Positive Installation Results | Recent installations have shown accurate and reliable quality assurance, flagging defective masks effectively. |

By 2025, these systems will play a pivotal role in creating safer workplaces and communities. Their ability to adapt to dynamic environments ensures they remain effective as safety challenges evolve. Adopting these technologies now positions you ahead in safety innovation, ensuring compliance and fostering a culture of safety.

FAQ

What are masking machine vision systems?

Masking machine vision systems use advanced algorithms to identify and analyze objects, such as detecting if someone is wearing a mask. These systems enhance safety by automating the detection process, ensuring compliance with safety protocols in real-time.

How do these systems improve safety in workplaces?

They monitor environments continuously, detecting risks like improper mask usage. This real-time detection helps prevent accidents and ensures adherence to safety standards, reducing workplace hazards and improving operational efficiency.

Can these systems adapt to different environments?

Yes, they use advanced techniques like autoencoders and machine learning to adapt to dynamic conditions. Whether in healthcare or manufacturing, these systems maintain high detection accuracy, even in challenging or noisy environments.

Are masking machine vision systems cost-effective?

While initial costs may seem high, these systems reduce long-term expenses by minimizing accidents, improving detection accuracy, and ensuring compliance with safety regulations. They also lower insurance costs and enhance productivity.

What industries benefit most from these systems?

Healthcare, manufacturing, and public safety benefit significantly. In healthcare, they ensure mask compliance and hygiene. In manufacturing, they detect safety risks and improve quality control. For public safety, they enhance surveillance and mask detection in crowded spaces.

See Also

Understanding FOV in Machine Vision Technologies for 2025

Determining ROI for Automated Visual Inspection Systems in 2025

The Impact of Deep Learning on Machine Vision Systems