Medical Devices Machine Vision Systems: Key Features and Benefits

A medical devices machine vision system is a technology that uses cameras and software to inspect, analyze, and ensure the quality of medical products. You can rely on this system to detect defects, verify dimensions, and confirm proper assembly during manufacturing. It plays a crucial role in maintaining precision and meeting the strict standards of the medical industry. By automating inspections, it reduces human error and guarantees consistent results. This technology ensures that every device meets safety and performance requirements, ultimately protecting patients and improving healthcare outcomes.

Key Takeaways

- Machine vision systems check devices automatically. This lowers mistakes and keeps quality steady in making medical tools.

- These systems are very precise. They find tiny problems to keep medical products safe.

- Adding AI and machine learning helps these systems find more defects. It also makes them work better and smarter.

- These systems can grow to fit different device types and production sizes. This makes them flexible for factories.

- Using machine vision systems saves money. They cut down waste and use resources wisely during production.

Understanding Medical Devices Machine Vision Systems

Definition and Core Components

A medical devices machine vision system combines advanced imaging technology with precise measurement tools to inspect and analyze medical products. These systems rely on high-quality cameras, specialized software, and calibration tools to ensure accurate measurements and defect detection.

Key components include:

- Cameras: Capture high-resolution images of medical devices for analysis.

- Software: Processes images using algorithms, including traditional and deep learning models, to identify defects or verify specifications.

- Lighting: Enhances image clarity by illuminating the product during inspection.

- Calibration Tools: Maintain measurement accuracy over time.

| Specification | Description |

|---|---|

| Algorithms | Traditional and deep learning-based models for image analysis. |

| Data Requirements | Diverse and plentiful data is crucial for model performance. |

| Computational Needs | Traditional models can run on microcontrollers; deep learning requires GPUs. |

| Edge Cases | Traditional methods handle fewer edge cases; deep learning excels in variability. |

These components work together to deliver high accuracy, repeatability, and resolution, ensuring that every medical device meets stringent quality standards.

How Machine Vision Works in Medical Device Manufacturing

Machine vision systems operate by capturing images of medical devices and analyzing them for defects or inconsistencies. The process begins with a camera taking high-resolution images of the product. The software then processes these images using algorithms to detect flaws, measure dimensions, or verify assembly.

For example, Eli Lilly uses machine vision to inspect vials, ensuring they are upright and have the correct cap color. This saves time and reduces waste. Similarly, in stent production, machine vision systems achieve 100% accuracy in surface scans, even at high production speeds.

These systems also support predictive maintenance by identifying equipment wear early. This prevents unexpected downtimes and ensures smooth manufacturing operations.

Role in Quality Control and Inspection

Machine vision plays a critical role in maintaining product quality in medical device manufacturing. It detects defects that are invisible to the human eye, ensuring that every product meets safety and performance standards.

Key benefits include:

- Enhanced Accuracy: Machine vision systems can identify minute defects, such as surface irregularities in surgical instruments or misalignments in implantable devices.

- Efficiency: Automating inspection processes reduces human error and speeds up production.

- Cost-Effectiveness: While initial investments may be high, the long-term savings from reduced waste and improved efficiency make it worthwhile.

In the 1980s, manufacturers began using machine vision systems to meet FDA standards for high-volume inspections. Today, 85-90% of these systems are used for inspection tasks, with the rest assisting in assembly. For instance, inspecting a pack of surgical staples costs about $45, but the pack sells for $800 or more, highlighting the value of this technology.

By integrating machine vision into your manufacturing process, you can ensure consistent quality, improve efficiency, and enhance patient safety.

Key Features of Medical Devices Machine Vision Systems

Precision and Accuracy in Inspections

Machine vision systems excel in delivering unmatched precision and accuracy during inspections. These systems use high-resolution cameras and advanced algorithms to detect even the smallest defects in medical devices. For instance, a study on machine vision inspection for complex biomechanical devices highlights a shift from destructive testing to real-time monitoring. This approach ensures higher accuracy and repeatability, which is critical in regulated manufacturing environments.

The effectiveness of these systems has been quantified in several studies:

| Study Title | Findings |

|---|---|

| Industrial robot product inspection system based on 3D vision guidance | Highlights effectiveness in performing dimensional measurements and ensuring quality control. |

| A machine vision based automated quality control system for product dimensional analysis | Provides quantitative data on performance in industrial applications. |

| Experimental comparison of optical inline 3D measurement and inspection systems | Offers quantitative insights into accuracy and reliability for dimensional inspections. |

By adopting machine vision, you can ensure that every product meets stringent quality standards, enhancing product quality and patient safety.

Automation and Workflow Efficiency

Automated systems powered by machine vision significantly improve workflow efficiency in medical device manufacturing. These systems perform high-speed inspections, reducing the time required for manual checks. Automated inspection ensures consistent evaluation, minimizing variability and human error.

Key benefits include:

| Benefit | Description |

|---|---|

| Automated Inspection | Enables high-speed and accurate inspection, leading to improved product quality. |

| Consistent Evaluation | Provides objective assessments, reducing variability compared to human inspectors. |

| High-Speed Inspection | Increases production speed by performing inspections faster than manual methods. |

| Reduced Human Error | Minimizes costly mistakes associated with manual inspections, enhancing overall quality. |

| Traceability and Data Analytics | Captures detailed inspection data for process optimization and predictive maintenance. |

| Flexibility and Adaptability | Can be programmed for various products, adapting to changing production needs. |

| Cost-effective | Reduces labor costs and minimizes defects, leading to overall efficiency improvements. |

By integrating automated systems into your production line, you can achieve faster turnaround times and maintain consistent product quality.

Integration with AI and Machine Learning

The integration of AI and machine learning has revolutionized machine vision systems. These technologies enhance the system's ability to identify defects, measure dimensions, and adapt to new challenges. Machine learning algorithms improve performance in applications like surface defect detection and automated recognition of materials.

Some notable applications include:

- Surface defect detection for medical devices.

- Automated recognition of product features to ensure compliance with specifications.

- Optical Character Recognition (OCR) for reading labels and markings.

- Vision-guided robotics for precise assembly and inspection tasks.

AI-driven machine vision systems also enable predictive maintenance by analyzing data trends to identify potential issues before they occur. This reduces downtime and ensures smooth operations. By leveraging AI, you can stay ahead in a competitive market while maintaining high standards of quality.

Scalability for Diverse Applications

Machine vision systems offer remarkable scalability, making them suitable for a wide range of applications in medical device manufacturing. You can adapt these systems to meet the needs of different production scales, device types, and inspection requirements.

Key Advantages of Scalability

-

Flexibility Across Device Types

Machine vision systems can inspect various medical devices, from small surgical instruments to large diagnostic equipment. You can program these systems to handle different shapes, sizes, and materials without compromising accuracy. -

Adaptability to Production Volumes

Whether you manufacture devices in small batches or at high volumes, machine vision systems scale to match your production needs. For example, you can use them for prototype testing or full-scale production lines. -

Customizable Inspection Parameters

These systems allow you to adjust inspection criteria based on your product specifications. You can set parameters for dimensions, surface quality, or assembly verification, ensuring compliance with industry standards.

Tip: Start with a basic setup and expand capabilities as your production grows. This approach minimizes initial costs while maintaining flexibility for future upgrades.

Real-World Applications

| Application Area | Scalability Benefits |

|---|---|

| Surgical Instrument Inspection | Handles diverse shapes and sizes with consistent precision. |

| Implantable Device Testing | Adapts to complex geometries and high-volume production. |

| Diagnostic Equipment Analysis | Scales to inspect intricate components and large assemblies. |

| Packaging Verification | Ensures quality across varying packaging designs and sterilization methods. |

Why Scalability Matters

Scalability ensures that your machine vision system grows with your business. You can expand its capabilities to accommodate new products or higher production demands. This flexibility reduces downtime and eliminates the need for frequent system replacements. By investing in scalable technology, you future-proof your manufacturing process and maintain a competitive edge in the medical device industry.

Benefits of Medical Devices Machine Vision Systems

Enhanced Accuracy and Reliability

Medical devices machine vision systems deliver exceptional accuracy and reliability during inspections. These systems use advanced imaging technology and algorithms to detect even the smallest defects in medical devices. You can rely on them to ensure that every product meets stringent quality standards, reducing the risk of errors and improving overall product quality.

Studies have shown that machine vision systems significantly enhance inspection accuracy. For example, in the electronics industry, automated systems detect micro-level defects in circuit boards and components, reducing defective products by 99%. This improvement minimizes waste and ensures consistent quality.

| Industry | Application Description | Numerical Impact |

|---|---|---|

| Electronics | Automated systems detect micro-level defects in circuit boards and components. | Reduces defective products by 99%. |

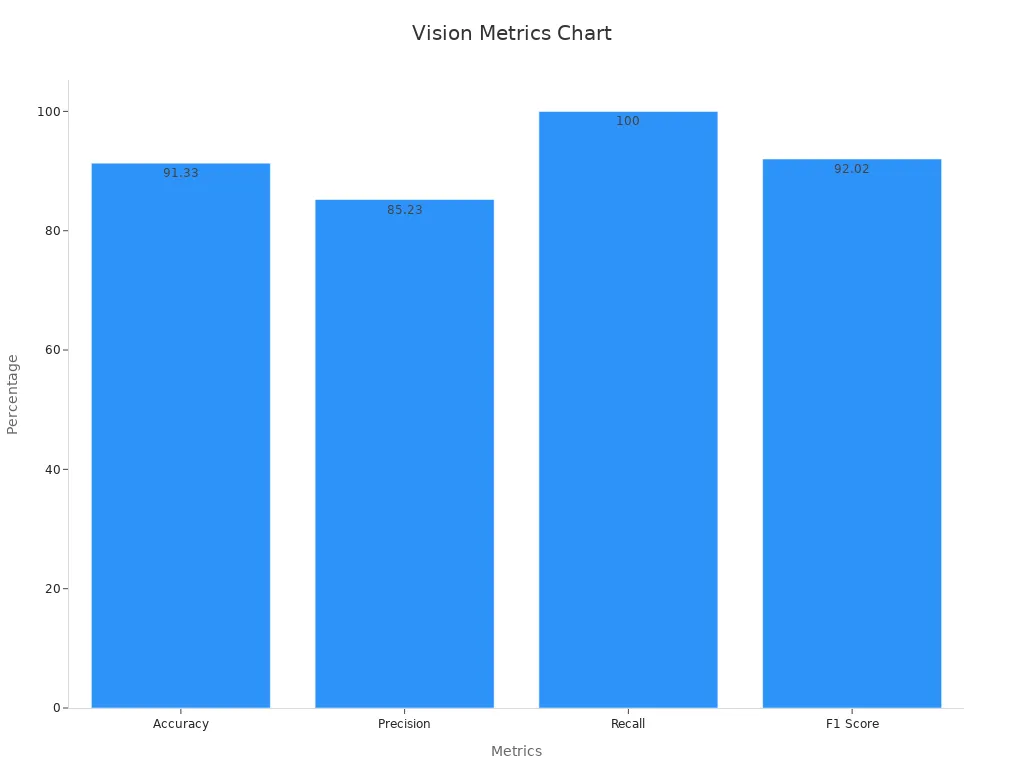

Additionally, machine vision systems achieve high performance metrics, as illustrated below:

| Metric | Value |

|---|---|

| Accuracy | 91.33% |

| Precision | 85.23% |

| Recall | 100% |

| F1 Score | 92.02% |

By adopting these systems, you can achieve unparalleled accuracy and reliability, ensuring that your medical devices meet the highest standards of safety and performance.

Improved Patient and Provider Safety

Machine vision systems play a vital role in improving patient and provider safety. These systems ensure that medical devices are free from defects, reducing the risk of device failure during use. For example, they can identify surface irregularities in surgical instruments or misalignments in implantable devices, preventing potential harm to patients.

You can also use machine vision systems to verify sterilization and packaging processes. This ensures that medical devices remain uncontaminated and safe for use. By automating these inspections, you eliminate human error and guarantee consistent results, further enhancing safety.

Note: Ensuring the safety of medical devices not only protects patients but also builds trust in your brand and products.

Increased Manufacturing Efficiency

Machine vision systems significantly improve processes in medical device manufacturing. By automating visual tasks, these systems reduce labor costs and errors, allowing production lines to operate at maximum efficiency. Faster production cycles and increased output are direct benefits of this technology.

Key efficiency metrics highlight the advantages of machine vision systems:

- They ensure production lines operate at maximum efficiency, leading to faster production cycles.

- Every product meets quality standards, reducing the need for rework and improving processes.

- Bottlenecks caused by slow manual inspections are eliminated, increasing overall output.

- Operational expenses decrease due to reduced labor costs and minimized errors.

- Cost savings and a strong ROI result from fewer defects and less waste.

By integrating machine vision systems into your manufacturing process, you can streamline operations, reduce costs, and maintain high product quality. This technology empowers you to meet growing production demands while ensuring consistent quality across all devices.

Cost Reduction and Waste Minimization

Medical devices machine vision systems help you reduce costs and minimize waste in manufacturing. These systems automate inspections, eliminating the need for manual checks. This reduces labor expenses and ensures consistent results. By identifying defects early, you can prevent faulty products from reaching later stages of production. This saves materials and avoids costly rework.

Waste reduction is another significant benefit. Machine vision systems detect even the smallest defects, ensuring only high-quality products move forward. For example, in the production of implantable devices, these systems identify surface irregularities or misalignments before assembly. This prevents the waste of expensive materials. Additionally, automated systems optimize resource usage by reducing overproduction and minimizing scrap.

You can also achieve cost savings through predictive maintenance. Machine vision systems monitor equipment performance and detect wear or misalignment early. This prevents unexpected breakdowns, reducing downtime and repair costs. Over time, these savings contribute to a strong return on investment.

Tip: Start with a small-scale implementation of machine vision systems. Gradually expand their use to maximize cost savings and minimize waste across your production line.

Compliance with Medical Regulations

Machine vision systems play a crucial role in helping you ensure compliance with medical regulations. These systems automate quality inspections, ensuring that every product meets strict industry standards. By providing real-time data and detailed documentation, they simplify regulatory audits and improve adherence to guidelines.

The table below highlights how machine vision systems support compliance with key regulatory frameworks:

| Regulatory Framework | Key Requirements | Role of Machine Vision Systems |

|---|---|---|

| Good Manufacturing Practices (GMP) | Consistent quality standards | Automates quality inspections to ensure adherence |

| Quality System Regulation (QSR) | Comprehensive documentation | Simplifies compliance audits with real-time data |

| ISO 13485 | Effective risk management | Enhances defect detection accuracy, reducing recall risks |

These systems also help you maintain product quality by detecting defects and ensuring that every device meets safety standards. For example, they verify dimensions, surface quality, and assembly accuracy. This reduces the risk of recalls and ensures compliance with regulations like ISO 13485.

By integrating machine vision systems, you can streamline your compliance processes. These systems provide detailed inspection records, making it easier to demonstrate adherence during audits. This not only saves time but also builds trust with regulatory bodies and customers.

Note: Staying compliant with medical regulations protects your business from penalties and ensures patient safety. Machine vision systems make this process more efficient and reliable.

Applications of Machine Vision in the Medical Field

Inspection of Surgical and Diagnostic Instruments

Machine vision systems play a vital role in inspecting surgical and diagnostic instruments. These systems ensure that every instrument meets strict quality standards. High-resolution cameras and advanced algorithms detect surface defects, irregularities, or misalignments that could compromise the instrument's performance. For example, they can identify tiny scratches on surgical scissors or ensure that diagnostic tools are assembled correctly.

You can rely on machine vision to perform inspections faster and more accurately than manual methods. This technology reduces human error and ensures consistent results. By automating the inspection process, you save time and improve the overall quality of your instruments.

Quality Assurance for Implantable Devices

Implantable devices, such as pacemakers and orthopedic implants, require the highest level of precision. Machine vision systems ensure these devices meet stringent safety and performance standards. They inspect dimensions, surface quality, and assembly accuracy to detect any flaws before the devices reach patients.

A documented case study highlights the effectiveness of machine vision in various medical applications:

| Application Area | Outcome Description | Performance Improvement |

|---|---|---|

| Cancer Detection | Deep-learning models achieved physician-level accuracy in identifying melanomas. | Significant reduction in human error. |

| Cell Counting | AI model detected and counted red blood cells 15 times faster than manual methods. | Drastic reduction in time and cost. |

| Medication Management | Technology increases patient safety and reduces workload for healthcare professionals. | Saves time and money in the long run. |

By using machine vision, you can ensure that implantable devices are safe, reliable, and ready for use in critical medical procedures.

Monitoring and Testing of Diagnostic Equipment

Machine vision systems enhance the monitoring and testing of diagnostic equipment. These systems provide real-time data and improve accuracy in detecting equipment status. Studies show that machine vision significantly improves the condition monitoring of equipment like transformers, achieving accurate fault diagnosis and high operational efficiency.

In the medical field, this technology ensures that diagnostic machines, such as MRI scanners or blood analyzers, function correctly. Machine vision identifies potential issues early, preventing costly breakdowns and ensuring uninterrupted operation. By adopting this technology, you can maintain the reliability of your diagnostic equipment and deliver better outcomes for patients.

Verification of Sterilization and Packaging

Sterilization and packaging are critical steps in medical device manufacturing. You must ensure that every product is free from contamination and securely sealed to maintain sterility. Machine vision systems provide an efficient solution for verifying these processes with unmatched precision.

These systems inspect packaging for defects such as tears, misaligned seals, or incomplete closures. High-resolution cameras capture detailed images, while advanced algorithms analyze them to detect even the smallest irregularities. For sterilization, machine vision monitors indicators like color changes on sterilization strips or labels, confirming that the process was successful.

Did you know? The global demand for machine vision solutions in pharmaceutical and medical device production is growing at a CAGR of 10%. This trend reflects the increasing need for automation in sterile manufacturing environments.

Key benefits of using machine vision for sterilization and packaging include:

- Regulatory Compliance: These systems ensure adherence to strict industry standards, reducing the risk of recalls.

- Enhanced Quality Control: Automated inspections identify defects that human eyes might miss.

- Increased Throughput: Faster inspections allow you to meet production demands without compromising quality.

Digital transformation trends show rising investments in automation technologies like machine vision. These systems not only improve compliance but also enhance efficiency in sterile environments. By adopting this technology, you can ensure that your medical devices meet the highest safety and quality standards.

Tip: Regularly update your machine vision software to keep up with evolving regulatory requirements and maintain optimal performance.

Medical devices machine vision systems revolutionize manufacturing processes by enhancing safety, efficiency, and product quality. You can rely on these systems to improve diagnostic accuracy and operational outcomes. Their real-time analysis capabilities streamline decision-making, ensuring consistent manufacturing standards.

- Machine vision AI boosts defect detection and packaging integrity, addressing challenges in high-volume inspections.

- Advanced vision machines generate precise metrics, enabling immediate quality assessments and continuous improvement.

- Integration with Industry 4.0 facilitates data visualization, helping you optimize processes and maintain compliance.

By adopting this technology, you can transform your production line, ensuring better patient outcomes and operational excellence. Explore machine vision systems to elevate your manufacturing standards and stay ahead in the medical device industry.

FAQ

1. What are medical devices machine vision systems used for?

Medical devices machine vision systems inspect, analyze, and ensure the quality of medical products. You can use them to detect defects, verify dimensions, and confirm proper assembly during manufacturing. These systems help maintain precision and meet strict industry standards.

2. How do machine vision systems improve manufacturing efficiency?

Machine vision systems automate inspections, reducing the need for manual checks. They speed up production, minimize errors, and ensure consistent quality. By identifying defects early, you save time and resources, leading to faster production cycles and reduced costs.

3. Can machine vision systems adapt to different medical devices?

Yes, these systems are highly adaptable. You can program them to inspect various devices, from small surgical tools to large diagnostic equipment. They handle different shapes, sizes, and materials while maintaining accuracy and reliability.

4. Are machine vision systems compliant with medical regulations?

Machine vision systems help you comply with regulations like ISO 13485 and GMP. They automate quality inspections, provide real-time data, and simplify audits. This ensures your products meet safety and performance standards, reducing the risk of recalls or penalties.

5. How does AI enhance machine vision systems?

AI improves defect detection, dimension measurement, and adaptability. Machine learning algorithms enable systems to handle complex tasks like surface defect detection and predictive maintenance. This ensures higher accuracy, reliability, and efficiency in medical device manufacturing.

Tip: Regularly update your machine vision system to leverage the latest AI advancements for optimal performance.

See Also

A Comprehensive Overview Of Electronics Machine Vision Systems

Comparing Firmware Machine Vision With Conventional Systems

Ensuring Accurate Part Identification With Machine Vision Systems