Neck Machine Vision Systems: Bridging Technology and Manufacturing

A neck machine vision system is a specialized technology designed to inspect and analyze the neck of products, such as bottles and containers, during manufacturing. You rely on this system to ensure every product meets precise standards. By automating inspections, it eliminates human error and reduces defects. Research shows that machine vision enhances product quality and boosts efficiency by detecting flaws and measuring dimensions with incredible accuracy. Advanced image processing and Big Data integration further improve quality control, giving you a powerful tool to innovate and streamline industrial processes.

Key Takeaways

- Neck machine vision systems check products automatically. This lowers mistakes and improves quality checks.

- Special lenses give clear images without distortion. This helps measure things correctly during checks.

- AI makes finding problems faster and more accurate. It can spot issues early.

- Camera systems work in many industries. They make factories safer and more efficient.

- Regular system updates and calibration keep inspections following rules and ensure good product quality.

Technology Behind Neck Machine Vision Systems

Core Components and Their Functions

A neck machine vision system relies on several key components to perform its tasks effectively. The camera serves as the system's eyes, capturing high-resolution images of the neck area. Lighting ensures the neck is evenly illuminated, highlighting any defects or irregularities. The lens focuses the image, allowing the system to capture precise details. A processor or computer analyzes the images using advanced algorithms, identifying flaws or deviations from the standard. Finally, the software interface lets you monitor and control the system, ensuring seamless operation. Together, these components create a robust machine vision system capable of delivering accurate and reliable results.

Role of Telecentric Lenses in Precision Imaging

Telecentric lenses play a crucial role in enhancing the accuracy of neck inspections. Unlike conventional lenses, they provide distortion-free imaging, which is essential for precise measurements. These lenses maintain constant magnification, even when the focus changes, ensuring consistent image quality. They also reduce parallax effects, making them ideal for inspecting complex neck designs. The table below highlights the advantages of telecentric lenses:

| Advantage | Description |

|---|---|

| Distortion-free imaging | Telecentric lenses provide images without distortion, crucial for accurate measurements. |

| Constant magnification | They maintain magnification regardless of focus changes, ensuring consistent imaging quality. |

| Reduced parallax effects | Telecentric systems minimize parallax distortion, enhancing the accuracy of inspections. |

| High accuracy for complex shapes | Ideal for imaging parts with intricate designs, especially in three-dimensional inspections. |

| Constant brightness | Unlike conventional lenses, brightness remains stable across varying focal lengths. |

| Multiple image capture | Can capture several images at different focus settings while keeping magnification constant. |

By using telecentric lenses, you can achieve unparalleled precision in neck inspections, ensuring your products meet the highest standards.

AI Integration for Advanced Analysis

Artificial intelligence (AI) has revolutionized machine vision systems, making them smarter and more efficient. AI algorithms analyze images of the neck with incredible speed and accuracy, detecting defects that might go unnoticed by traditional methods. For example, AI systems in healthcare have achieved 99% accuracy in detecting breast cancer in mammograms. Similarly, in manufacturing, AI enhances defect detection and reduces errors.

AI also enables predictive analysis, helping you identify potential issues before they occur. This proactive approach minimizes downtime and improves overall efficiency. With AI integration, your neck machine vision system becomes a powerful tool for maintaining quality and boosting productivity.

Camera-Based Systems for Versatile Applications

Camera-based systems bring unmatched versatility to neck machine vision applications. These systems use high-resolution cameras to capture detailed images of the neck area, enabling precise inspections across various industries. You can rely on these systems to identify defects, measure dimensions, and ensure compliance with quality standards.

One standout example is the iSight 20/20 Neck Finish inspection system. This system uses dual cameras to inspect neck profiles and sealing surfaces of containers. It performs complex inspections without requiring predefined parameters, making it adaptable to different manufacturing needs. Additionally, it simplifies ownership transfer and increases yield rates, giving you a reliable solution for improving productivity.

Tip: Dual-camera setups allow you to inspect multiple aspects of a product simultaneously, saving time and reducing errors.

Camera-based systems also enhance worker safety and productivity. By automating inspections, they reduce the need for manual checks, minimizing the risk of workplace injuries. Industries like construction, robotics, and automotive have even integrated motion capture technology into these systems, further boosting efficiency and precision.

Here’s a quick look at the benefits of camera-based systems:

- High adaptability: Suitable for various industries, including packaging, pharmaceuticals, and automotive.

- Enhanced accuracy: Detects even the smallest defects with precision.

- Improved safety: Reduces manual intervention, protecting workers from potential hazards.

- Increased efficiency: Speeds up inspection processes, ensuring faster production cycles.

With their ability to execute complex tasks and adapt to diverse environments, camera-based systems are a cornerstone of modern manufacturing. By incorporating these systems, you can achieve higher quality standards while optimizing your operations.

Inspection Capabilities of Neck Machine Vision Systems

Monitoring Neck Threads for Structural Integrity

Neck threads play a critical role in ensuring the structural integrity of bottle necks. These threads allow caps or closures to fit securely, preventing leaks and maintaining product quality. A neck machine vision system inspects these threads with unmatched precision. It captures high-resolution images of the neck and analyzes them for defects such as incomplete threads, irregular spacing, or damage caused during molding.

You can rely on this advanced inspection system to detect even the smallest imperfections. For example, if a thread is slightly misaligned, the system flags it immediately. This ensures that every product leaving your production line meets industry standards. By automating this process, you eliminate the risk of human error and improve overall efficiency.

Tip: Regularly calibrate your inspection system to maintain accuracy and adapt to changes in thread designs.

Inspecting Sealing Surfaces for Leak Prevention

The sealing surface of a neck is another critical area that requires thorough inspection. Any defect in this region can lead to leaks, compromising the product's quality and safety. Machine vision systems excel at inspecting these surfaces. They use specialized cameras and lighting to highlight irregularities such as scratches, dents, or uneven surfaces.

With this technology, you can ensure that every sealing surface is flawless. The system measures the flatness and smoothness of the neck, ensuring it forms a perfect seal with the cap. This is particularly important in industries like pharmaceuticals and beverages, where leaks can have serious consequences.

Automated inspections also allow you to maintain consistent quality across large production volumes. By identifying and removing defective products early, you reduce waste and save costs. This proactive approach not only improves your bottom line but also enhances customer satisfaction.

Detecting Molding Defects and Imperfections

Molding defects can significantly impact the functionality and appearance of bottle necks. Issues like warping, sink marks, or flash can compromise the product's quality. A neck machine vision system helps you detect these defects early in the production process. It uses high-resolution imaging and AI-driven analysis to identify imperfections that might go unnoticed during manual inspections.

To ensure optimal results, you can implement several quality control measures. For instance, reviewing processing parameters like pressure and temperature helps align machine settings with material requirements. Inspecting the mold for wear or damage prevents recurring defects. Additionally, using simulation software allows you to predict potential issues before production begins.

| Quality Control Metric | Description |

|---|---|

| Review Processing Parameters | Examine machine settings like pressure, speed, and temperature. |

| Material Quality Check | Verify the plastic resin's quality, ensuring it is dry and contaminant-free. |

| Mold Inspection | Inspect the mold for wear, damage, or improper venting. |

| Simulation Software | Predict and analyze molten plastic flow to identify potential issues. |

| Automated Quality Control Systems | Use vision systems and AI-driven detection to identify defects early. |

| Precision Temperature Control Systems | Ensure accurate control over mold and melt temperatures. |

By combining these measures with continuous monitoring and data-driven decision-making, you can achieve higher production efficiency. Establishing benchmarks and key performance indicators (KPIs) also helps you track defect rates and improve over time. With a robust inspection system in place, you can deliver products that consistently meet the highest standards.

Ensuring Compliance with Industry Standards

Meeting industry standards is critical for maintaining product quality and ensuring customer trust. Neck machine vision systems play a vital role in helping you achieve compliance with these regulations. By automating inspections, these systems ensure that every product meets the required specifications, reducing the risk of non-compliance.

Different industries have unique compliance requirements. For example, the healthcare sector must adhere to HIPAA regulations, while the finance industry follows PCI DSS standards. Compliance reports provide a detailed overview of how your operations align with these standards. These reports often include:

- Security policies that protect sensitive data.

- Data management practices that ensure operational integrity.

- Tailored compliance measures specific to your industry.

Machine vision systems simplify the process of generating these reports. They collect and analyze data during inspections, providing you with accurate records of your production quality. This documentation not only demonstrates compliance but also builds trust with your clients and regulatory bodies.

In addition to regulatory compliance, these systems help you meet internal quality benchmarks. For instance, they can verify that bottle necks conform to precise dimensions, ensuring compatibility with caps and closures. This level of precision minimizes product recalls and enhances your brand's reputation.

Note: Regularly updating your machine vision system ensures it stays aligned with evolving industry standards. This proactive approach helps you avoid penalties and maintain a competitive edge.

By integrating neck machine vision systems into your manufacturing process, you can streamline compliance efforts and focus on delivering high-quality products. These systems not only safeguard your operations but also position your business as a leader in quality and reliability.

Benefits and Applications of Machine Vision in Manufacturing

Improved Yield Rates and Reduced Waste

Machine vision systems significantly improve yield rates and reduce waste in manufacturing processes. By automating inspections, these systems identify defects early, preventing defective products from advancing through production. This proactive approach minimizes material waste and ensures that only high-quality products reach the market.

For example, a pharmaceutical manufacturer increased its yield by 15% through process optimization enabled by machine vision. This improvement resulted in $22 million in additional annual revenue. Similarly, an automotive manufacturer reduced defect rates by 37% in the first year of implementation, saving $15 million in warranty claims. The table below highlights these and other examples of how machine vision systems enhance yield and reduce waste:

| Evidence Type | Description | Impact on Yield/Waste |

|---|---|---|

| Quality Improvement | Automotive manufacturer reduced defect rates by 37% in the first year. | Saved $15 million in warranty claims. |

| Cycle Time Reduction | Semiconductor manufacturer reduced cycle time by 22%. | Increased throughput worth $43 million annually. |

| Predictive Maintenance | Heavy equipment manufacturer achieved 92% accuracy in predicting failures. | Reduced unplanned downtime by 35%. |

| Yield Optimization | Pharmaceutical manufacturer increased yield by 15% through optimization. | Realized $22 million in additional annual revenue. |

Statistical Yield Limits (SYL) also play a crucial role in improving yield rates. SYL defines acceptable yield ranges, helping you maintain consistent quality while minimizing waste. By implementing SYL, you can optimize processes, reduce defective items, and lower operational costs.

Tip: Regularly monitor your production data to identify trends and adjust processes for continuous improvement.

Enhanced Precision and Reliability

Machine vision systems excel in delivering precision and reliability. These systems maintain consistent inspection criteria, ensuring that no defects go unnoticed. They also detect minute imperfections that human inspectors might overlook, enhancing the overall accuracy of inspections.

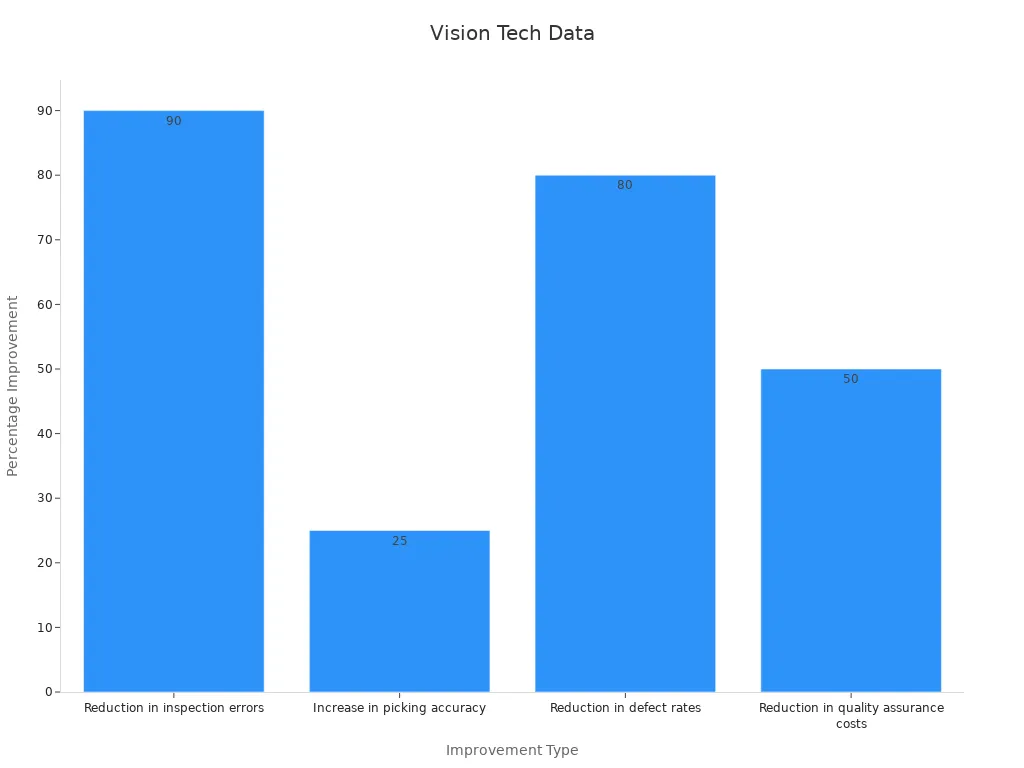

Technical performance data underscores the reliability of these systems. For instance, machine vision reduces inspection errors by over 90% compared to manual checks. It also decreases defect rates by up to 80%, ensuring higher product quality. The chart below illustrates these improvements:

Additional benefits include real-time feedback, which allows you to make immediate adjustments during production. This capability minimizes waste and ensures consistent quality. Machine vision systems also reduce quality assurance costs by approximately 50%, as fewer staff are needed for repetitive tasks. Instead, your team can focus on higher-level analysis and decision-making.

- Key Advantages of Enhanced Precision and Reliability:

- Consistent application of inspection criteria ensures no defects are missed.

- Real-time feedback improves production quality and reduces waste.

- Automated systems enhance accuracy, reducing false positives and negatives.

By adopting machine vision, you can achieve unparalleled precision and reliability, setting a new standard for quality in your industry.

Versatility Across Industries, Including Packaging and Pharmaceuticals

The versatility of machine vision systems makes them indispensable across various industries. In packaging, these systems ensure that products meet strict quality standards. For example, they inspect bottle necks for defects, ensuring compatibility with caps and closures. In pharmaceuticals, machine vision plays a critical role in monitoring packaging processes to prevent contamination and ensure compliance with regulations.

Automatic pharmaceutical packaging systems are particularly valuable in sterile drug-manufacturing facilities. These systems produce vaccines and biologics while maintaining strict contamination control. They also adapt to varying consumer demands, such as different dosage formats. Advanced blister machines, for instance, accommodate unit-dose systems for clinical trials and can be retrofitted for eco-friendly materials.

- Applications of Machine Vision in Packaging and Pharmaceuticals:

- Monitoring sealing surfaces to prevent leaks in bottle necks.

- Ensuring compliance with industry standards for sterile packaging.

- Adapting to diverse packaging formats, including blister packs and eco-friendly materials.

- Tracking production data to improve efficiency and reduce waste.

Machine vision systems also enhance mobility in manufacturing. They integrate seamlessly with automated production lines, enabling real-time tracking and monitoring. This capability improves therapeutic exercise in production workflows, ensuring that processes remain efficient and adaptable.

By leveraging the versatility of machine vision, you can optimize operations across industries, from packaging to pharmaceuticals. These systems not only improve quality but also enhance your ability to meet evolving market demands.

Cost-Effectiveness and Scalability

Machine vision systems offer a cost-effective solution for modern manufacturing. By automating inspections, you reduce labor costs and minimize waste. These systems identify defects early, preventing defective products from advancing through production. This proactive approach saves resources and ensures higher-quality output.

Economic Impact of Machine Vision

Studies show that machine vision systems significantly improve operational efficiency. For example, predictive maintenance powered by AI can lower downtime by 50% and extend equipment lifetime by up to 40%. This reduces repair costs and maximizes the value of your machinery. Additionally, defect detection rates improve by up to 90%, ensuring fewer recalls and higher customer satisfaction.

| Study/Source | Key Findings |

|---|---|

| PWC Analysis | AI predicted to boost production by 40% by 2035. |

| ASQ | Defects account for up to 20% of sales revenue. |

| McKinsey Study | Predictive maintenance can save costs by up to 40%, lower downtime by 50%. |

These findings highlight the economic advantages of adopting machine vision systems. By reducing defects and optimizing maintenance, you can achieve substantial cost savings and improve profitability.

Tip: Regularly monitor your system's performance to ensure it operates at peak efficiency. This helps you maximize cost savings and maintain consistent quality.

Scalability for Growing Manufacturing Needs

Machine vision systems adapt easily to increasing production demands. AI-based visual inspection systems scale more effectively than traditional methods. They handle complex tasks with ease, making them ideal for industries with diverse product lines. For instance, AI systems can increase productivity by up to 50% compared to human inspection.

- Key Benefits of Scalability:

- Handle higher production volumes without compromising quality.

- Adapt to new product designs and manufacturing processes.

- Reduce the need for additional labor as production scales.

Scalability also ensures long-term viability. As your business grows, these systems evolve to meet your needs. They integrate seamlessly with existing workflows, allowing you to expand operations without significant disruptions.

Real-World Applications

In the automotive industry, machine vision systems detect defects in components with unmatched precision. This reduces warranty claims and enhances customer trust. Similarly, pharmaceutical manufacturers use these systems to inspect packaging for contamination, ensuring compliance with strict regulations. These examples demonstrate the versatility and scalability of machine vision systems across industries.

By investing in machine vision technology, you gain a cost-effective and scalable solution that supports your business's growth. These systems not only reduce operational costs but also position your company as a leader in quality and innovation.

Real-World Applications and Success Stories

Beverage Industry: Ensuring Quality in Bottle Neck Inspection

In the beverage industry, neck machine vision systems play a vital role in maintaining product safety and quality. These systems inspect bottle necks to ensure they meet strict standards, preventing leaks and contamination. You can rely on features like telecentric lenses for distortion-free imaging, which guarantees accurate inspections regardless of bottle shape or orientation. Multi-camera setups further enhance efficiency by performing simultaneous inspections, saving time and increasing throughput.

The table below highlights key features and benefits of neck machine vision systems in beverage production:

| Feature | Benefit |

|---|---|

| Telecentric lenses | Ensures accurate inspections regardless of bottle shape and orientation. |

| Neck thread verification | Confirms that neck threads are fully formed, preventing defects. |

| Sealing surface inspection | Checks for planarity, enhancing sealing integrity and reducing leaks. |

| Detection of molding flash | Identifies defects that could compromise product safety. |

| Multi-camera system | Allows simultaneous inspections, increasing efficiency and throughput. |

| Quick changeover capability | Adapts to different bottle sizes easily, ensuring flexibility in production. |

| Comprehensive inspection coverage | Inspects sidewalls and bottoms for contamination and defects, ensuring overall product quality. |

By integrating these systems, you can achieve higher production efficiency and deliver beverages that meet the highest safety standards.

Pharmaceutical Packaging: Precision and Safety

Precision is critical in pharmaceutical packaging, where even minor defects can compromise product safety. Neck machine vision systems excel in detecting flaws in saline bottles, vials, and other packaging formats. These systems achieve remarkable accuracy, with metrics like a 99.3% mAP50 for saline bottle datasets and an inference speed of 79.25 FPS. Such performance ensures that every package meets stringent industry regulations.

The table below showcases the precision metrics of these systems:

| Metric | Value |

|---|---|

| mAP50 (custom dataset) | 97.4% |

| Inference Speed | 79.25 FPS |

| mAP50 (saline bottle dataset) | 99.3% |

You can depend on these systems to inspect sealing surfaces, detect contamination, and verify packaging integrity. This level of precision not only reduces waste but also enhances patient safety by ensuring sterile and secure packaging.

Automotive Components: Defect Detection and Quality Assurance

In the automotive industry, neck machine vision systems ensure the reliability of critical components. These systems detect defects with a high level of accuracy, achieving a detection rate of 95% and a recall rate of 90%. They also maintain a mean average precision (mAP) of 0.92 and a mean intersection over union (mIoU) of 0.85.

Key performance highlights include:

- Detection accuracy: 95%

- Recall rate: 90%

- Mean Average Precision (mAP): 0.92

- Mean Intersection over Union (mIoU): 0.85

- Confidence level for most defects: ≥ 0.8

By automating inspections, you can identify defects early, reducing warranty claims and improving customer satisfaction. These systems also streamline production processes, ensuring consistent quality across large volumes. With their advanced capabilities, neck machine vision systems set a new standard for defect detection and quality assurance in automotive manufacturing.

Future Trends in Neck Machine Vision Systems

AI-Driven Advancements in Defect Detection

Artificial intelligence continues to transform neck machine vision systems, making them smarter and more efficient. With AI, you can detect defects with greater speed and accuracy. These systems analyze images in real time, identifying flaws that human inspectors might miss. For example, AI-powered algorithms can recognize subtle variations in neck threads or sealing surfaces, ensuring every product meets quality standards.

AI also enables predictive capabilities. By analyzing historical data, the system can predict potential issues before they occur. This proactive approach reduces downtime and enhances productivity. You can also train AI models to adapt to new product designs, making your inspection process more flexible and future-proof.

Tip: Regularly update your AI models to improve their accuracy and keep up with evolving manufacturing needs.

Cloud-Based Systems for Real-Time Monitoring

Cloud-based systems are revolutionizing how you monitor and manage manufacturing processes. These systems allow you to access real-time data from anywhere, enabling centralized control and monitoring. For example:

- Cloud robotics improves operational efficiency by centralizing robotic system management.

- Real-time updates and predictive maintenance reduce downtime and boost productivity.

- Scalability lets you adjust resources based on demand, optimizing costs and resource use.

- Remote monitoring reduces the need for on-site personnel, saving costs and increasing agility.

Industries like automotive and electronics are already leveraging cloud-enabled robots to maintain quality and enhance productivity. You can quickly adapt to changing production needs without investing heavily in physical infrastructure. This flexibility makes cloud-based systems an essential tool for modern manufacturing.

Integration with IoT for Smarter Manufacturing Processes

The Internet of Things (IoT) is reshaping manufacturing by connecting devices and systems. When you integrate IoT with neck machine vision systems, you gain smarter, more interconnected processes. Sensors embedded in production lines can collect data and send it to your vision system for analysis. This allows for real-time adjustments, improving efficiency and reducing waste.

IoT also enhances traceability. You can track each product's journey through the production line, ensuring compliance with industry standards. Additionally, IoT-enabled systems provide valuable insights into machine performance, helping you optimize maintenance schedules and extend equipment lifespan.

By embracing IoT, you can create a smarter, more responsive manufacturing environment that meets the demands of the future.

Neck machine vision systems revolutionize manufacturing by combining precision, efficiency, and adaptability. You gain tools that detect defects, ensure compliance, and optimize production processes. These systems reduce waste, improve yield, and enhance product quality across industries.

Key Takeaway: By adopting this technology, you not only meet today’s manufacturing challenges but also prepare for future advancements like AI and IoT integration.

Their ability to evolve with industry demands positions them as a cornerstone of innovation, driving smarter, more reliable production systems.

FAQ

What is a neck machine vision system?

A neck machine vision system inspects bottle necks for defects. It uses cameras, lenses, and AI to detect flaws like uneven threads or sealing surface issues. You can rely on it to ensure product quality and prevent leaks.

How does AI improve defect detection?

AI analyzes images faster and more accurately than manual methods. It identifies subtle flaws in neck threads or surfaces. You can use AI to predict issues before they occur, reducing downtime and improving efficiency.

Can neck machine vision systems handle different bottle designs?

Yes, these systems adapt to various bottle shapes and sizes. Features like telecentric lenses and multi-camera setups ensure accurate inspections regardless of design. You can easily switch between products without compromising quality.

Are machine vision systems cost-effective?

Absolutely! They reduce labor costs, minimize waste, and improve yield rates. By automating inspections, you save resources and ensure consistent quality. You also avoid expensive recalls and warranty claims.

What industries benefit from neck machine vision systems?

Industries like beverages, pharmaceuticals, and automotive use these systems. You can inspect bottle necks for leaks, ensure sterile packaging, or detect defects in automotive components. Their versatility makes them essential across manufacturing sectors.

See Also

Comparing Firmware Machine Vision With Conventional Systems

Essential Features and Advantages of Medical Vision Systems

Transforming Aerospace Manufacturing Through Machine Vision Technology

Ensuring Accurate Part Identification With Machine Vision Systems

Understanding Electronics Machine Vision Systems and Their Functionality