How Neural Network Machine Vision Systems Are Transforming Automation in 2025

Neural network machine vision systems are revolutionizing automation in 2025. These systems allow machines to interpret images and videos with unmatched precision. You benefit from advancements like real-time processing and edge computing, which make operations faster and smarter. For example, automation in manufacturing grows rapidly due to vision systems replacing manual tasks. Software sales for vision applications are projected to increase by 52% from 2024 to 2029, driven by AI-powered deep learning. Google’s Document AI achieves a remarkable accuracy rate of 99.2%, outperforming older technologies significantly. These breakthroughs redefine how industries use AI to solve complex visual challenges.

Key Takeaways

- Neural networks help machines see and understand pictures easily.

- These systems make tasks like checking quality and fixing problems better.

- Fast processing lets machines decide quickly, useful for self-driving cars and traffic control.

- Machine vision changes industries like factories, hospitals, and stores by automating work.

- Using machine vision saves money over time and works better for businesses.

What Are Neural Network Machine Vision Systems?

Definition and Core Components

A neural network machine vision system is a technology that enables machines to interpret and analyze visual information, such as images and videos, with remarkable precision. You can think of it as a combination of hardware and software working together to mimic human vision. These systems rely on advanced algorithms and AI to process visual data and make decisions based on what they "see."

The core components of a machine vision system include cameras, sensors, and processors. Cameras capture high-quality images or videos, while sensors gather additional data like depth or motion. Processors, often powered by AI, analyze this information to identify patterns, objects, or anomalies. Neural networks play a critical role in this process, as they allow the system to learn and improve its performance over time.

Machine vision systems also use specialized software for tasks like image processing and feature extraction. For example, AI image processing software can enhance image quality, detect defects, or classify objects. These components work together seamlessly, enabling applications in industries ranging from manufacturing to healthcare.

Role of Neural Networks and Deep Learning

Neural networks and deep learning are the backbone of modern machine vision systems. Neural networks are computational models inspired by the human brain. They consist of layers of interconnected nodes that process data and learn patterns. Deep learning, a subset of AI, uses these networks to perform complex tasks like object recognition and image classification.

Deep learning methods revolutionize machine vision by automating the extraction of meaningful information from visual data. Unlike traditional algorithms that rely on handcrafted features, deep learning algorithms use convolutional neural networks (CNNs) to learn features directly from large datasets. This approach improves accuracy and effectiveness, especially in tasks like defect detection and quality control.

Here’s how deep learning enhances machine vision capabilities:

- Pose Estimation: Deep learning algorithms estimate poses using depth and RGB data, which is essential for robotics and augmented reality.

- Semantic Segmentation: This technique, crucial for medical imaging and autonomous driving, allows systems to identify and classify objects within an image.

- Object Recognition: Deep learning models excel at recognizing objects, even in complex environments, making them ideal for applications like inventory management.

- Image Classification: By learning complex patterns directly from data, deep learning surpasses traditional methods in accuracy and efficiency.

Deep learning also enables continuous improvement through training. As you feed more data into the system, the models refine their understanding and deliver better results. This adaptability makes machine vision systems highly effective in dynamic environments.

In industries like manufacturing, deep learning methods improve productivity by detecting defects and ensuring quality control. In healthcare, they assist in diagnosing diseases through medical imaging. These advancements highlight the transformative power of neural networks and deep learning in machine vision systems.

How Neural Network Machine Vision Systems Work

Data Input and Preprocessing

The first step in a neural network machine vision system involves capturing visual data. Cameras and sensors collect images or videos from various sources, such as production lines or medical devices. This raw data often contains noise or inconsistencies that can affect analysis. Preprocessing transforms it into a clean, structured format suitable for deep learning algorithms.

Preprocessing techniques include resizing, noise reduction, and normalization. For example, resizing ensures images fit the input dimensions of convolutional neural networks, while noise reduction removes unwanted artifacts. These steps improve the reliability of AI image processing and enhance the accuracy of subsequent analyses.

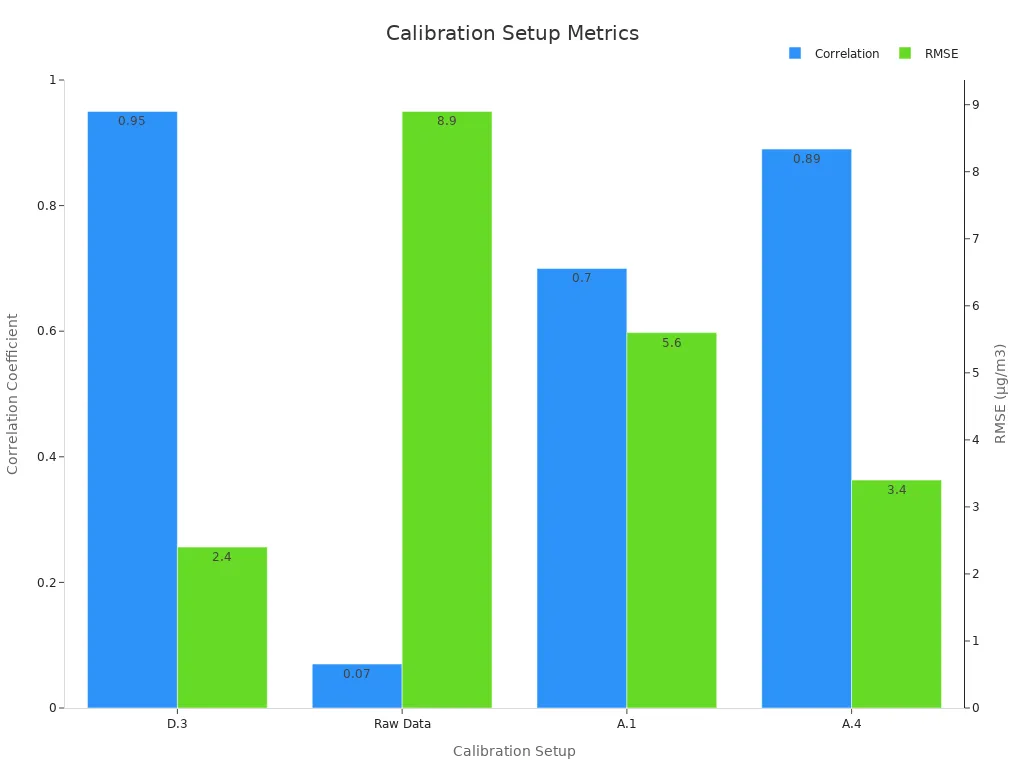

A technical report highlights the importance of preprocessing. It shows that calibration setups with optimized input integration improved correlation coefficients from 0.7 to 0.89 and reduced RMSE from 5.6 to 3.4 µg/m3. This demonstrates how preprocessing directly impacts performance.

Neural Network Processing

Once the data is preprocessed, neural networks analyze it. These networks use deep learning methods to extract features and identify patterns. Convolutional neural networks play a key role here, as they specialize in processing visual data. Layers within the network detect edges, textures, and shapes, gradually building a detailed understanding of the image.

Deep learning algorithms automate feature extraction, eliminating the need for manual intervention. For instance, models trained on large datasets can recognize objects, classify images, and detect anomalies. Training improves the system's performance over time, making it adaptable to new challenges.

Output Generation and Decision Making

After processing, the system generates outputs based on its analysis. These outputs can range from object classifications to actionable decisions. For example, in manufacturing, the system might identify defective products and trigger their removal from the production line.

Performance metrics like precision, recall, and F1 score measure the effectiveness of output generation. A case study on YOLOv11x showed a precision of 0.949 and a recall of 0.850, with mean average precision (mAP50) reaching 0.901. These results highlight the robustness of deep learning models in decision-making tasks.

Neural network machine vision systems excel at interpreting visual data and delivering actionable insights. Their ability to adapt through training ensures they remain effective in dynamic environments.

Applications of Machine Vision Systems in Automation (2025)

Neural network machine vision systems are reshaping industries by enabling machines to perform tasks that once required human intervention. These systems leverage AI, deep learning, and computer vision to deliver unparalleled accuracy and efficiency. Below, you’ll explore how machine vision technology is transforming manufacturing, healthcare, and transportation in 2025.

Manufacturing: Quality Control and Predictive Maintenance

In manufacturing, machine vision systems play a critical role in ensuring product quality and operational efficiency. These systems use AI-powered algorithms to inspect products for defects, measure dimensions, and verify assembly accuracy. By automating these tasks, you can achieve faster production rates and reduce human error.

Machine vision technology excels in defect detection, with accuracy rates reaching up to 99.9%. For example, automated inspection systems identify flaws in materials or components at high speeds, ensuring only high-quality products reach the market. This consistency minimizes costly rework and enhances customer satisfaction.

Predictive maintenance is another key application. Machine vision systems monitor equipment for signs of wear or damage, allowing you to address issues before they lead to downtime. By capturing detailed data during inspections, these systems provide valuable insights for process optimization. The table below highlights the benefits of machine vision in manufacturing:

| Evidence Type | Description |

|---|---|

| Automated Inspection | Enables high-speed, accurate inspection, improving product quality. |

| Consistent Evaluation | Reduces bias and fatigue associated with human inspectors. |

| High-Speed Inspection | Enhances production efficiency by inspecting at faster rates than manual methods. |

| Reduced Human Error | Minimizes costly mistakes related to product quality and rework. |

| Traceability and Data Analytics | Captures detailed inspection data for predictive maintenance and process optimization. |

| Flexibility and Adaptability | Adapts to various products, meeting changing production needs. |

| Cost-effective | Reduces labor costs while improving efficiency and minimizing defects. |

The manufacturing sector’s adoption of machine vision systems is growing rapidly. In 2025, the market size is projected to reach $12.89 billion, driven by trends like Industry 4.0 integration and robotic vision.

Healthcare: Medical Imaging and Diagnostics

Machine vision systems are revolutionizing healthcare by enhancing medical imaging and diagnostics. These systems use AI and deep learning to analyze medical images, enabling faster and more accurate diagnoses. For instance, AI image processing can detect anomalies in X-rays, MRIs, and CT scans with remarkable precision.

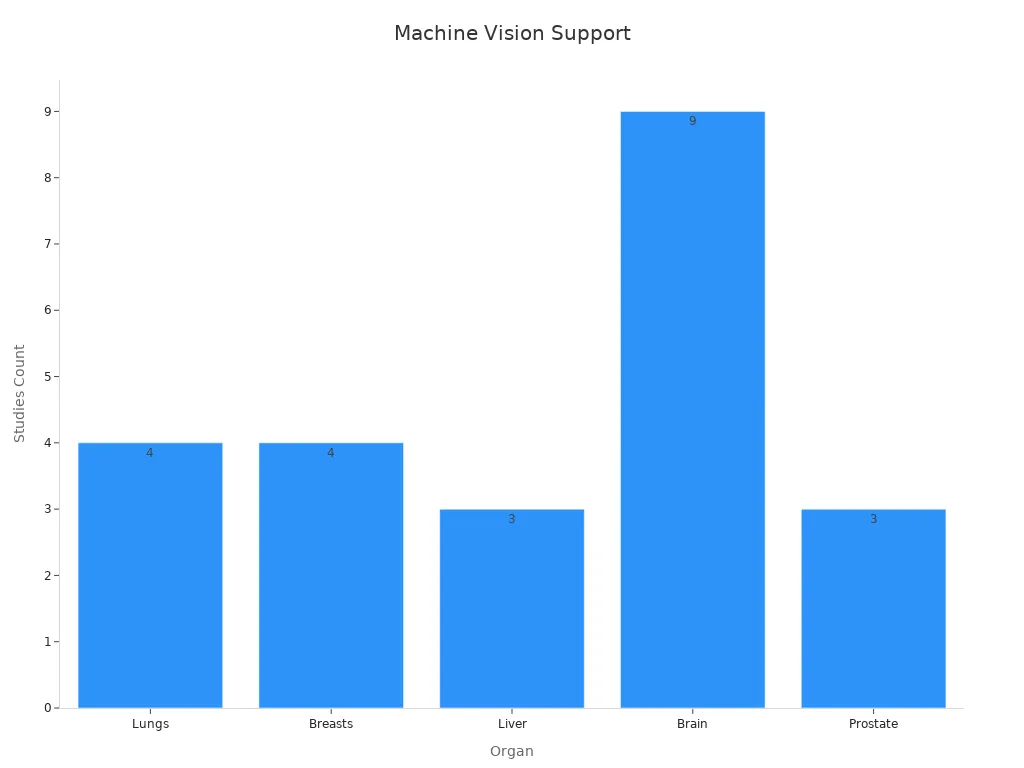

Deep learning algorithms excel in tasks like segmentation, classification, and object recognition. In medical imaging, segmentation helps identify specific regions within an image, such as tumors or lesions. Classification algorithms categorize these findings, aiding in disease diagnosis. The chart below illustrates the number of studies supporting machine vision applications in diagnostics:

Machine vision systems also support predictive analytics in healthcare. By analyzing historical data, these systems can predict disease progression or treatment outcomes. This capability empowers healthcare providers to make data-driven decisions, improving patient care.

The table below summarizes key applications of machine vision in medical imaging:

| Application | Number of Studies | Imaging Modalities |

|---|---|---|

| Detection | 8 | MRI, CT, Radiography |

| Classification | 5 | MRI, CT |

| Segmentation | 4 | Various |

| Prediction | 7 | Various |

By integrating machine vision technology, healthcare facilities can enhance diagnostic accuracy, reduce workload for medical professionals, and improve patient outcomes.

Transportation: Autonomous Vehicles and Traffic Management

In transportation, machine vision systems are essential for autonomous vehicles and intelligent traffic management. These systems use computer vision and AI to interpret visual data, enabling vehicles to navigate safely and efficiently.

Autonomous vehicles rely on machine vision for tasks like traffic sign recognition, lane detection, and obstacle avoidance. For example, image recognition tools classify road signs and signals, ensuring compliance with traffic rules. These systems also adapt to changing road conditions, such as detours or temporary signage, enhancing safety.

Traffic management benefits significantly from machine vision technology. Real-time anomaly detection helps identify and respond to traffic incidents, improving flow and reducing congestion. Cities like Barcelona and Singapore have implemented computer vision systems to enhance road safety and decrease emissions. The following list highlights key advancements in transportation:

- Traffic Sign and Signal Recognition: Ensures vehicles comply with road rules by interpreting visual cues.

- Real-Time Anomaly Detection: Enhances safety by identifying and addressing traffic incidents promptly.

- Edge Computing: Reduces latency by processing data closer to its source, improving traffic monitoring efficiency.

- Enhanced Data Analytics: Provides insights into traffic patterns, enabling data-driven decision-making.

The integration of machine vision systems into transportation is transforming how cities manage traffic and how vehicles operate. These advancements promise safer roads and more efficient travel.

Retail: Inventory Management and Customer Insights

Machine vision systems are revolutionizing the retail industry by enhancing inventory management and providing deeper customer insights. These systems use advanced applications like object recognition, segmentation, and image classification to streamline operations and improve decision-making.

Inventory Management

Managing inventory efficiently is critical for retail success. Machine vision technology enables you to monitor stock levels in real time, reducing errors and improving accuracy. Cameras equipped with machine vision systems scan shelves and storage areas to detect missing or misplaced items. This ensures that products are always available for customers, minimizing lost sales opportunities.

Retailers using machine vision systems report significant improvements in inventory tracking. For example, the R2-score for inventory accuracy has increased by 2.873%, while the mean absolute percentage error (mAPE) has improved by 29.31%. These metrics highlight how machine vision applications enhance inventory precision and reduce discrepancies.

| Improvement Metric | Value |

|---|---|

| R2-score Improvement | 2.873% |

| mAPE Improvement | 29.31% |

By automating inventory checks, you can save time and reduce labor costs. Vision-guided robotics also play a role in inventory management by scanning and organizing products in warehouses. This technology adapts to various retail environments, making it a versatile solution for businesses of all sizes.

Customer Insights

Understanding customer behavior is essential for creating personalized shopping experiences. Machine vision systems analyze visual data to uncover patterns in how customers interact with products. For instance, these systems track which items shoppers pick up, examine, or return to the shelf. This data helps you identify popular products and optimize store layouts.

Retailers increasingly rely on machine vision applications to gain actionable insights. Studies show that 58% of retailers plan to implement computer vision into their operations. This adoption unlocks a 5% operating margin and a 4.5% increase in sales, as reported by Coresight.

- 58% of retailers have definite plans to implement computer vision into their operations.

- Unlocking a 5% operating margin and 4.5% sales increase as reported by Coresight.

Machine vision systems also enhance customer service. Facial recognition technology identifies returning customers, enabling staff to offer tailored recommendations. Additionally, segmentation techniques analyze foot traffic patterns, helping you understand how customers navigate your store. This information allows you to optimize product placement and improve the overall shopping experience.

The Future of Retail Automation

As machine vision technology evolves, its applications in retail will continue to expand. From defect detection in packaging to advanced image classification for product categorization, these systems offer endless possibilities. By adopting machine vision systems, you can stay ahead of the competition and deliver exceptional value to your customers.

Benefits of Neural Network Machine Vision Systems

Improved Accuracy and Efficiency

Neural network machine vision systems significantly enhance accuracy and operational efficiency. By leveraging deep learning, these systems excel at tasks like object detection, image recognition, and anomaly detection. For instance, deep learning models such as YOLO-v3 outperform traditional algorithms like SSD and Faster R-CNN in accuracy, precision, and F1 score when tested on the Microsoft COCO dataset. This superior performance ensures that your applications deliver reliable results, whether in manufacturing, healthcare, or retail.

Training efficiency also improves with advanced methods. A study comparing PLP, DEMON, and SGD techniques based on the Vgg16 net shows that PLP achieves faster convergence and lower loss in about 50% of tests. This means you can deploy machine vision systems more quickly and with better initial performance. These advancements make neural networks indispensable for applications requiring high precision and speed.

Scalability and Adaptability

Machine vision systems powered by AI and deep learning adapt seamlessly to various environments and tasks. Whether you’re deploying them in large-scale factories or compact mobile devices, these systems scale effectively. Benchmarks like MLPerf Inference and EEMBC’s MLMark demonstrate their ability to perform under diverse computational constraints, from high-throughput servers to microcontrollers.

| Benchmark Type | Focus Area |

|---|---|

| Macro-benchmarks | Model-level performance metrics (accuracy, memory, throughput, latency) |

| MLPerf Inference | Comprehensive testing for various computational environments |

| MLPerf Mobile | Evaluation under mobile device constraints |

| MLPerf Tiny | Focus on microcontroller deployments |

| EEMBC’s MLMark | Performance and power efficiency for embedded systems |

| AI-Benchmark | Mobile platform evaluations across diverse tasks |

| End-to-end benchmarks | Evaluation of the entire AI system pipeline |

This adaptability allows you to implement machine vision systems across industries, from autonomous vehicles to retail inventory management. Their ability to learn and improve over time ensures they remain effective even as your operational needs evolve.

Cost-Effectiveness and ROI

Investing in machine vision systems delivers substantial returns. By automating tasks like quality control and predictive maintenance, you reduce labor costs and minimize errors. These systems also optimize resource allocation, ensuring you get the most out of your investments.

For example, in manufacturing, machine vision systems detect defects with up to 99.9% accuracy, reducing waste and rework costs. In retail, automated inventory management improves stock accuracy, saving time and preventing lost sales. The long-term benefits of these systems far outweigh their initial implementation costs, making them a cost-effective solution for businesses of all sizes.

Moreover, the continuous improvement enabled by deep learning ensures that your machine vision applications remain relevant and efficient. This adaptability maximizes ROI, helping you stay competitive in a rapidly evolving market.

Challenges and Considerations in Machine Vision Systems

High Implementation Costs

Deploying machine vision systems can be expensive, especially for small and medium-sized businesses. You need to invest in high-quality hardware, advanced software, and system integration. These initial costs can be overwhelming. Additionally, ongoing maintenance adds to the financial burden. Regular updates, repairs, and system monitoring require resources that may strain your budget.

The complexity of these systems also demands specialized expertise. Hiring skilled professionals for installation and operation increases costs further. The table below highlights key cost-related challenges:

| Key Points | Description |

|---|---|

| High Implementation Costs | The initial investment for hardware, software, and integration is substantial. |

| Maintenance Costs | Ongoing maintenance adds to the overall cost, creating a barrier to adoption. |

| Complexity and Expertise | Specialized expertise is required, increasing operational expenses. |

These factors make it essential to evaluate your budget and long-term goals before adopting machine vision technology.

Data Privacy and Ethical Concerns

Machine vision systems often process large amounts of personal data. This raises significant privacy and ethical concerns. For example, AI-driven profiling can infringe on individual privacy and threaten civil liberties. Informational privacy becomes a concern when systems collect and analyze personal data without clear consent.

Predictive harm is another issue. AI can infer sensitive details from seemingly harmless data, leading to unintended consequences. Group privacy is also at risk, as algorithms analyze datasets to make decisions that may result in discrimination. Additionally, autonomy harms occur when AI manipulates behavior without your knowledge.

- AI-driven profiling may violate privacy and civil liberties.

- Predictive harm arises when sensitive information is inferred.

- Group privacy issues can lead to algorithmic discrimination.

- Autonomy harms may manipulate behavior without consent.

To address these concerns, you should implement strict data governance policies and ensure transparency in how data is used.

Technical Limitations and Maintenance

Machine vision systems are not without technical challenges. Hardware components like cameras and sensors can fail, disrupting operations. Software updates may introduce bugs or compatibility issues. These systems also require regular calibration to maintain accuracy.

Maintenance demands skilled technicians who understand the intricacies of machine vision technology. Without proper upkeep, system performance can degrade over time. You must plan for these technical challenges to ensure smooth operation and long-term reliability.

Future Trends in Deep Learning and Machine Vision

Real-Time Processing and Edge Computing

Real-time processing is transforming how you interact with machine vision systems. By integrating edge computing, these systems process data closer to its source, reducing latency and bandwidth usage. This approach allows faster decision-making, which is critical for applications like autonomous vehicles and smart cities. For example, edge computing optimizes traffic management by adjusting traffic lights in real time, improving flow and reducing congestion. Similarly, convolutional neural networks (CNNs) enable real-time visual data processing for tasks like surveillance and autonomous driving.

| Contribution | Description |

|---|---|

| Diffusion of Innovations Theory | Anchors future studies on edge computing and real-time data processing. |

| Resource-Based View (RBV) | Highlights the importance of investing in robust edge infrastructure. |

| Sociotechnical Systems Theory | Suggests the need for standardized protocols and best practices. |

These advancements make machine vision systems more efficient and adaptable. As edge computing evolves, you can expect even greater capabilities in real-time applications.

Integration with IoT and AI Technologies

The combination of IoT and AI is revolutionizing machine vision. IoT devices collect vast amounts of data, while AI processes this information to deliver actionable insights. For instance, in agriculture, IoT sensors track crop conditions, and machine vision systems analyze this data to optimize harvesting. In manufacturing, IoT-enabled sensors monitor equipment, while AI-driven vision systems detect defects, improving product quality.

Key technologies like machine learning algorithms and communication protocols enhance these integrations. Cloud and edge computing manage the exponential data growth from IoT devices, ensuring real-time processing. This synergy between IoT and AI expands the potential of machine vision systems, making them indispensable across industries.

Enhanced Human-Machine Collaboration

Human-machine collaboration is becoming a cornerstone of machine vision applications. These systems assist you in performing complex tasks by combining human intuition with AI precision. For example, in robotics, machine vision aids in object recognition and scene understanding, enabling robots to work alongside humans in dynamic environments.

Collaborative systems also improve safety and efficiency. In manufacturing, vision-guided robots handle repetitive tasks, allowing you to focus on higher-level decision-making. Advances in deep learning further enhance this collaboration by enabling machines to adapt to new challenges. As these systems evolve, they will continue to bridge the gap between human capabilities and AI-driven automation.

Neural network machine vision systems are reshaping automation by enabling machines to handle complex visual tasks with precision. You see their applications expanding across industries, driven by advancements in deep learning and edge computing. Predictive analytics and AI integration enhance decision-making, while edge computing processes data closer to its source for real-time applications. Innovations like quantum machine learning promise breakthroughs in problem-solving. Despite challenges like costs and ethical concerns, these systems continue to evolve, offering transformative possibilities for automation in the years ahead.

FAQ

What industries benefit the most from machine vision systems?

Manufacturing, healthcare, transportation, and retail see the most benefits. These systems improve quality control, enhance diagnostics, enable autonomous vehicles, and optimize inventory management. You can also find applications in agriculture, security, and logistics.

How do neural networks improve machine vision accuracy?

Neural networks learn patterns from large datasets. They use deep learning techniques like convolutional neural networks (CNNs) to process images. This allows them to detect objects, classify images, and identify anomalies with high precision.

Are machine vision systems expensive to implement?

Yes, initial costs can be high. You need to invest in hardware, software, and skilled professionals. However, these systems reduce long-term costs by improving efficiency, minimizing errors, and automating repetitive tasks.

Can machine vision systems work in real-time?

Yes, real-time processing is possible with edge computing. This technology processes data closer to its source, reducing delays. Applications like autonomous vehicles and traffic management rely on this capability for quick decision-making.

What are the ethical concerns with machine vision systems?

Privacy is a major concern. These systems often process personal data, which can lead to misuse or unauthorized access. You should ensure transparency and implement strict data governance policies to address these issues.

See Also

Is It Possible for AI to Supplant Human Vision?

Understanding Edge AI's Role in Machine Vision by 2025

The Impact of Neural Networks on Machine Vision Technology

Deep Learning's Transformative Effect on Machine Vision Systems