Understanding Non-Destructive Machine Vision Systems for Modern Industries

A non-destructive machine vision system uses advanced imaging technologies to inspect objects without causing damage. You can find these systems in industries where precision and efficiency are critical. By combining innovations like hyperspectral and 3D imaging, they offer detailed views of materials. These systems also leverage AI and machine learning to adapt to new challenges, ensuring consistent accuracy. As a result, they play a vital role in improving quality control and streamlining operations.

Key Takeaways

- Non-destructive machine vision systems check items without harming them. They are great for industries like factories and car-making.

- These systems work faster by automating checks, cutting labor costs, and lowering mistakes.

- Using AI helps them analyze instantly, making them more accurate and flexible in finding problems.

- Buying these systems can save money and help businesses stay ahead.

- New ideas in AI and automation are helping these systems work in more industries.

What is a Non-Destructive Machine Vision System?

Definition and Core Principles

A non-destructive machine vision system is a technology that inspects and analyzes objects without causing any damage. It uses advanced imaging techniques to capture detailed information about an object’s surface and internal structure. This system operates on the principle of non-invasive inspection, ensuring that the object remains intact during the process. By combining imaging technologies with artificial intelligence, it can identify defects, measure dimensions, and verify quality with high precision.

You can think of it as a digital eye that sees beyond what the human eye can detect. These systems rely on algorithms to process the captured data and provide actionable insights. This makes them ideal for industries where accuracy and efficiency are critical.

Tip: Non-destructive machine vision systems are particularly useful in industries like manufacturing, electronics, and automotive, where maintaining the integrity of the product is essential.

Key Components of the System

A non-destructive machine vision system consists of several key components that work together seamlessly. Each part plays a vital role in ensuring the system’s effectiveness. Here’s a breakdown of the main components:

- Cameras: These capture visual data. Modern systems often use smart cameras with built-in processing capabilities.

- Frame Grabbers: These devices digitize the images captured by the cameras. Advanced frame grabbers use PCIe technology for faster data transfer.

- Optics: These determine the field of view and resolution. Customized optics enhance the system’s performance for specific applications.

- Lighting: Proper illumination is crucial for capturing high-quality images. LED lighting provides uniform brightness, improving image clarity.

- Processors and Software: These handle data processing and analysis. AI-powered software enables tasks like object recognition and defect detection.

Each component contributes to the system’s ability to deliver accurate and reliable results. For example, the integration of AI in processors allows the system to adapt to new challenges, making it more versatile.

How the Technology Operates

The operation of a non-destructive machine vision system involves several steps. First, the system captures images of the object using its cameras and optics. The lighting ensures that the images are clear and free from shadows. Next, the frame grabber digitizes the images, converting them into a format that the processor can analyze.

The processor, equipped with AI algorithms, examines the images for defects, measurements, or other parameters. It compares the data against predefined standards to determine if the object meets quality requirements. Finally, the system generates a report or sends the results to a connected device for further action.

To understand the effectiveness of these systems, consider the following findings from industry reports:

| Key Findings | Description |

|---|---|

| Shift to Automation | Robotic NDT systems represent a significant transition from manual to automated inspection methods. |

| Enhanced Accuracy | Integration of machine vision and other sensors improves defect detection and measurement in complex geometries. |

| Comprehensive Analysis | Fusion of visual and acoustic sensors allows for detailed understanding of materials, enhancing fault characterization. |

These systems not only improve accuracy but also streamline processes, making them a valuable asset in modern industries.

Benefits of Non-Destructive Machine Vision Systems

Enhanced Efficiency and Speed

Non-destructive machine vision systems significantly improve the speed and efficiency of industrial processes. You can rely on these systems to automate inspections that would otherwise require manual effort. Advanced computer vision algorithms play a key role in this automation. They quickly detect material flaws and ensure consistent quality across production lines.

For example, techniques like X-rays and thermal imaging utilize these algorithms to identify defects with precision. These systems also scale effectively, handling both large and small datasets. This scalability makes them suitable for industries with varying production volumes.

| Evidence Type | Description |

|---|---|

| Computer Vision Algorithms | Automate inspections and detect material flaws quickly and accurately. |

| Scalability | Handle large and small datasets, improving efficiency across applications. |

| Inspection Techniques | Use X-rays and thermal imaging for precise flaw detection. |

Note: AI-powered optical inspection reduces false calls and improves accuracy compared to human inspection. This trend toward automation maximizes efficiency, especially in repetitive tasks.

Cost-Effectiveness in Industrial Processes

Non-destructive machine vision systems offer a cost-effective solution for industries aiming to optimize their operations. By automating inspections, you can reduce labor costs and minimize the risk of human error. These systems also lower material waste by identifying defects early in the production cycle.

The historical shift toward automation in manufacturing highlights the financial benefits of these systems. They streamline processes, reduce downtime, and enhance productivity. Over time, the savings from improved efficiency and reduced waste outweigh the initial investment in the technology.

Tip: Investing in non-destructive machine vision systems not only saves money but also boosts your competitive edge in the market.

Improved Accuracy and Reliability

Accuracy and reliability are critical in industries like food processing, automotive, and electronics. Non-destructive machine vision systems excel in these areas by leveraging deep learning and artificial intelligence. You can trust these systems to deliver consistent results, even in complex scenarios.

Researchers have demonstrated the effectiveness of these systems in various applications:

- Xie et al. used CNN models to identify defective carrots, showcasing their ability to detect flaws.

- Deng et al. combined machine vision with deep learning for automatic grading, enhancing recognition intelligence.

- Zhu et al. introduced a dense capsule network for carrot quality detection, improving accuracy by reducing background interference.

- Rong et al. achieved 100% accuracy in identifying peach varieties using deep learning models.

- Muoz et al. found CNNs accurately detected intramuscular fat content in dry cured ham, proving their reliability in food quality assessment.

These examples highlight how non-destructive machine vision systems outperform traditional methods in accuracy and reliability.

Callout: With these systems, you can achieve higher precision in inspections, ensuring your products meet the highest standards.

Applications of Non-Destructive Machine Vision Systems

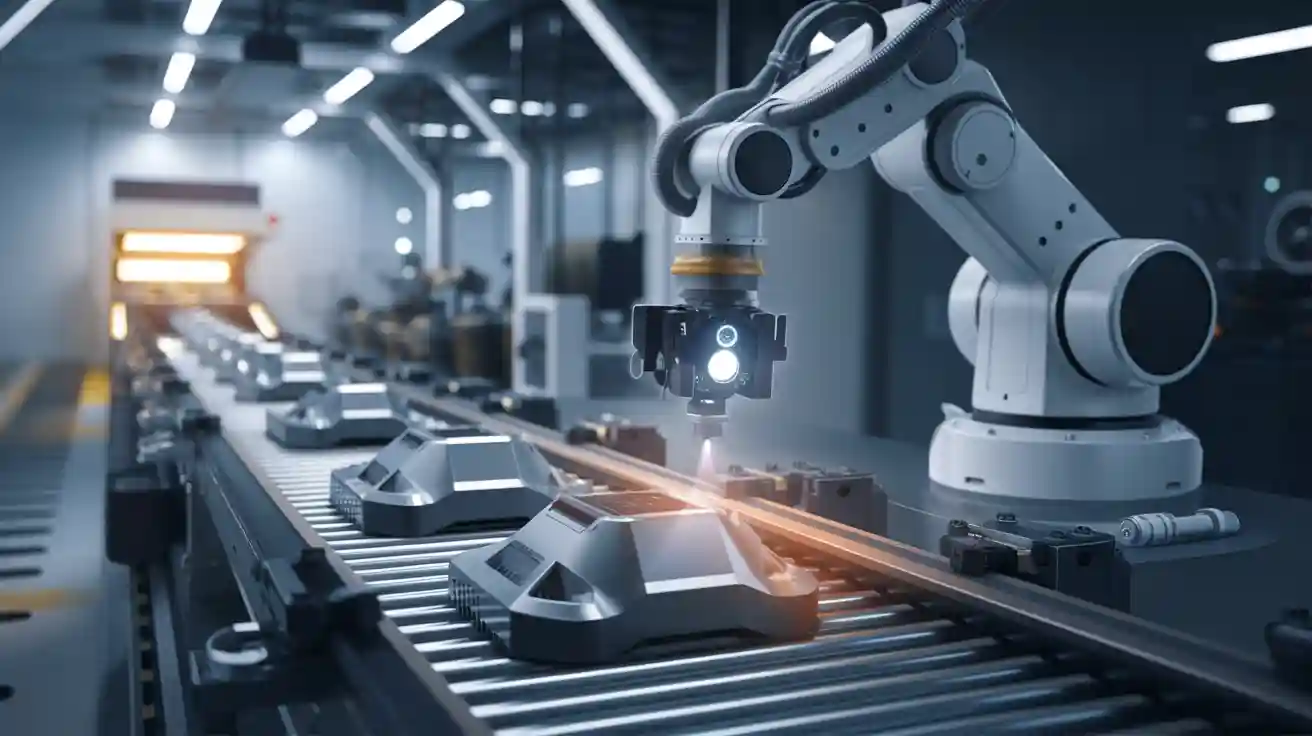

Quality Control in Manufacturing

Non-destructive machine vision systems have revolutionized quality control in manufacturing. These systems automate the inspection process, ensuring every product meets strict quality standards. By using advanced imaging techniques, they detect defects that are often invisible to the human eye. This capability reduces errors and enhances product reliability.

For instance, automated optical inspection (AOI) is a widely used application. It identifies flaws in components like circuit boards or packaging materials. The benefits are clear when you consider the statistics:

| Improvement Type | Statistic |

|---|---|

| Reduction in inspection errors | Over 90% reduction compared to manual inspection |

| Reduction in defect rates | Up to 80% reduction in defects |

| Reduction in quality assurance labor costs | Approximately 50% reduction in labor costs |

| Reduction in cycle time | Up to 20% reduction in cycle time |

These systems not only improve efficiency but also save costs by minimizing waste and rework.

Tip: Implementing these systems in your production line can significantly boost your operational efficiency.

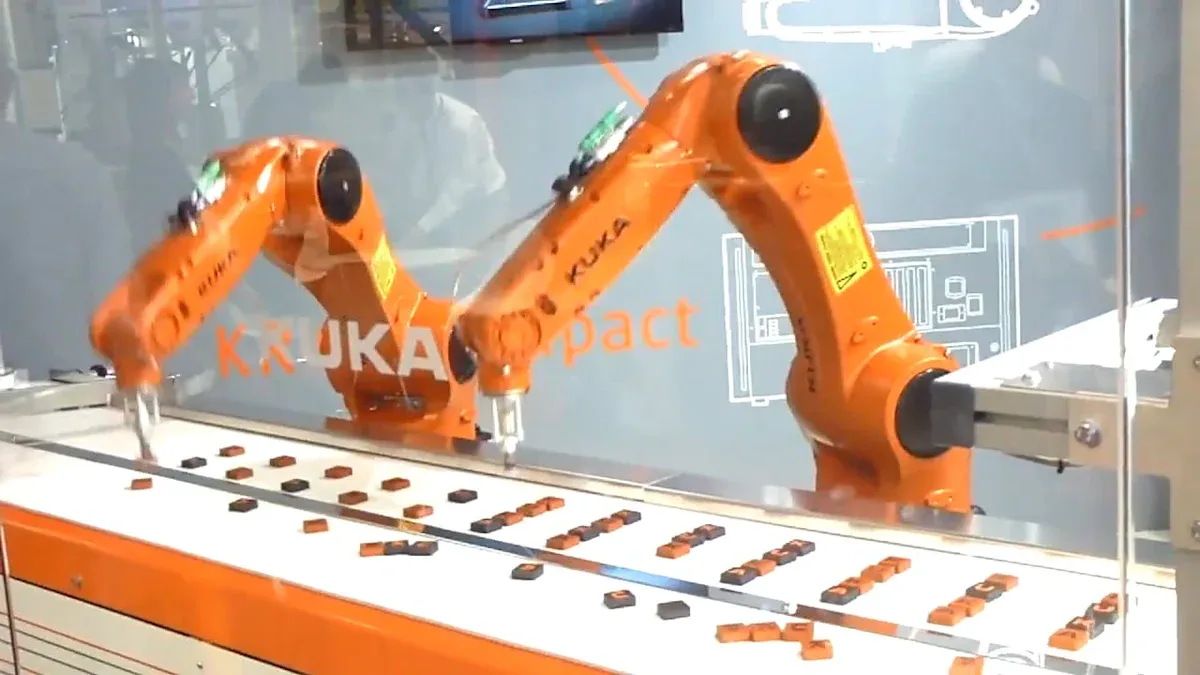

Defect Detection in the Automotive Industry

The automotive industry relies heavily on non-destructive machine vision systems for defect detection. These systems inspect components like engine parts, tires, and body panels with unmatched precision. By identifying flaws early, they prevent costly recalls and ensure vehicle safety.

Leading companies like BMW and Volvo Trucks have adopted this technology. Their results highlight its effectiveness:

| Company | Defect Detection Rate | Improvement in Repair Efficiency | Reduction in Diagnostic Time | Reduction in Repair Time |

|---|---|---|---|---|

| BMW | N/A | Yes | N/A | N/A |

| Volvo Trucks | N/A | N/A | 70% | 25% |

These systems also enhance repair efficiency by providing detailed diagnostic data. This reduces downtime and accelerates the repair process.

Callout: Adopting these systems can help you maintain high safety standards while reducing operational costs.

Precision Inspection in Electronics

Electronics manufacturing demands extreme precision, and non-destructive machine vision systems excel in this area. They inspect tiny components like microchips and solder joints, ensuring they meet exact specifications. Automated visual inspection equipment eliminates variability, delivering consistent results.

Key metrics demonstrate their effectiveness:

| Metric | Description |

|---|---|

| Accuracy | Measures the correctness of classifications, ensuring reliable defect detection. |

| Precision | Evaluates the accuracy of positive predictions, reducing false positives. |

| Recall | Assesses the ability to identify all instances of a defect, minimizing overlooked flaws. |

| F1 Score | Combines precision and recall into a single metric for overall performance evaluation. |

These systems use metrics like precision and recall to identify flaws accurately. This ensures that every product meets high-quality standards, reducing the risk of failures in the field.

Note: Investing in these systems can help you achieve higher yields and maintain a competitive edge in the electronics market.

Comparing Non-Destructive and Traditional Inspection Methods

Differences in Methodology and Approach

Non-destructive machine vision systems and traditional inspection methods differ significantly in their approach. Traditional methods often involve physical contact or invasive techniques, such as cutting or disassembling components to inspect for defects. These methods can damage the product, making it unsuitable for further use. In contrast, non-destructive systems rely on advanced imaging technologies like X-rays, thermal imaging, and hyperspectral analysis. These techniques allow you to inspect objects without causing harm, preserving their integrity.

For example, a study on printed circuit boards (PCBs) highlights these differences. Traditional inspection methods focus on surface-level defects and require manual effort. Non-destructive systems, however, use multiple imaging techniques to detect both surface and internal flaws. This comprehensive approach ensures higher accuracy and reliability. By adopting non-destructive methods, you can achieve better results while maintaining the quality of your products.

Advantages of Non-Destructive Systems

Non-destructive systems offer several advantages over traditional methods. First, they save time by automating the inspection process. You no longer need to rely on manual checks, which are slow and prone to errors. Second, these systems reduce waste. By identifying defects early, they prevent damaged products from progressing through the production line. This minimizes material loss and lowers costs.

Another key advantage is their ability to handle complex tasks. Non-destructive systems use artificial intelligence to analyze data and adapt to new challenges. This makes them ideal for industries requiring high precision, such as electronics and automotive manufacturing. With these systems, you can improve efficiency, reduce costs, and maintain high-quality standards.

Tip: Investing in non-destructive systems can enhance your operational efficiency and give you a competitive edge in the market.

Real-World Examples of Superiority

Real-world applications demonstrate the superiority of non-destructive machine vision systems. Companies like Volkswagen and Ford have integrated these systems into their production lines. Volkswagen uses AI-driven optimization to improve assembly line efficiency and product quality. Ford employs digital twins to monitor performance and identify energy losses, enhancing overall productivity.

| Company | Application | Impact |

|---|---|---|

| Volkswagen | AI-driven assembly line optimization | Enhanced production effectiveness |

| Ford | Digital twins for performance monitoring | Improved energy efficiency and productivity |

| Whirlpool | Robotic quality control | Increased accuracy and reduced errors |

In agriculture, these systems monitor crop health with 95% accuracy, reducing losses and improving yields. Logistics companies use them for route optimization, cutting delivery times by 20%. These examples highlight how non-destructive systems outperform traditional methods in various industries.

Note: By adopting these systems, you can achieve higher accuracy, reduce costs, and improve overall efficiency.

Challenges and Future Trends

Current Challenges in Implementation

Non-destructive machine vision systems face several hurdles during implementation. Supply chain disruptions have created shortages of essential components like sensors and integrated circuits. These shortages lead to longer lead times, delaying production schedules. Skilled labor shortages also impact productivity. Manufacturers struggle to find workers with expertise in operating and maintaining these advanced systems.

High costs pose another challenge. Cutting-edge technologies require significant investment, making them less accessible for smaller businesses. Economic uncertainty and inflation further complicate matters. Companies hesitate to invest in new systems due to fluctuating market conditions. Despite these obstacles, the demand for automation continues to grow. Businesses aim to mitigate workforce shortages by adopting automated solutions.

| Challenge/Trend | Description |

|---|---|

| Supply Chain Disruptions | Ongoing shortages of sensors, integrated circuits, and other core technologies leading to long lead times. |

| Skilled Labor Shortages | A persistent issue affecting both manufacturers and technology producers, impacting productivity. |

| High Costs of Advanced Technologies | The financial burden associated with implementing cutting-edge machine vision systems. |

| Economic Uncertainty and Inflation | These factors contribute to a cautious market sentiment, affecting investment and growth projections. |

| Demand for Automation | Despite challenges, there is a strong push towards automation to mitigate workforce shortages. |

Tip: Addressing these challenges requires strategic planning and investment in workforce training programs.

Emerging Trends in AI and Automation

AI and automation are transforming non-destructive machine vision systems. You can see advancements in AI-driven machine vision that integrate with closed-loop quality systems. These systems enhance quality control by making real-time adjustments and enabling predictive maintenance. This reduces errors and improves efficiency in manufacturing processes.

Sensor technology and networking infrastructure are evolving rapidly. Continuous monitoring of production processes and product quality is now possible. Advanced data analysis tools identify patterns and trends, helping you optimize operations. Automated feedback mechanisms adjust production parameters based on quality data, ensuring consistent results.

- AI-driven machine vision enhances quality control processes.

- Real-time adjustments and predictive maintenance improve efficiency.

- Advanced sensors and networking make systems more accessible.

- Continuous monitoring ensures product quality.

- Automated feedback mechanisms optimize production parameters.

Note: These trends highlight the growing role of AI and automation in shaping the future of industrial inspection.

Expansion into New Industries

Non-destructive machine vision systems are expanding into new sectors. The global machine vision market is projected to exceed USD 25.71 billion by 2030. This growth is driven by automation and the need for stringent quality control measures. Advancements in sensor technologies and machine learning contribute to this expansion.

In North America, industries increasingly rely on machine vision for real-time inspection and precision measurement. Sectors like agriculture, healthcare, and logistics are adopting these systems. For example, agriculture uses machine vision to monitor crop health, while healthcare employs it for medical imaging. Logistics companies benefit from route optimization and package inspection.

- The machine vision market is expected to surpass USD 25.71 billion by 2030.

- Quality control measures and non-destructive testing drive demand.

- Sensor technologies and machine learning fuel market growth.

- North America sees increased demand for defect detection and precision measurement.

- Emerging industries like agriculture, healthcare, and logistics adopt machine vision systems.

Callout: Exploring these new industries opens up exciting opportunities for innovation and growth.

Non-destructive machine vision systems have transformed how industries approach quality control and efficiency. You can rely on these systems to enhance precision, safety, and productivity in various applications. By automating defect detection, they reduce manual intervention and lower operational costs. Their integration with AI enables real-time quality control, ensuring consistent product standards.

- They improve material defect detection, boosting production efficiency.

- Automation increases speed and reduces errors.

- AI integration enhances accuracy and adaptability.

These advancements not only streamline operations but also drive innovation, helping industries stay competitive in a rapidly evolving market.

FAQ

What industries benefit the most from non-destructive machine vision systems?

You’ll find these systems most useful in industries like manufacturing, automotive, electronics, and food processing. They ensure precision, reduce waste, and improve quality control. Emerging sectors like healthcare and agriculture are also adopting them for tasks like medical imaging and crop monitoring.

How do non-destructive machine vision systems improve quality control?

These systems use advanced imaging and AI to detect defects early. They analyze products in real-time, ensuring they meet quality standards. By automating inspections, they reduce errors and improve consistency across production lines.

Are non-destructive machine vision systems expensive to implement?

Initial costs can be high due to advanced technology. However, you’ll save money in the long run by reducing labor costs, minimizing waste, and improving efficiency. Many businesses find the investment worthwhile for the competitive edge it provides.

Can small businesses use non-destructive machine vision systems?

Yes, small businesses can adopt these systems. Scalable solutions and modular designs make them accessible. You can start with basic setups and expand as your needs grow, ensuring affordability and flexibility.

What role does AI play in non-destructive machine vision systems?

AI enhances these systems by enabling real-time analysis and adaptive learning. It helps identify patterns, detect defects, and optimize processes. With AI, you’ll achieve higher accuracy and efficiency, even in complex inspection tasks.

See Also

Understanding Pixel Machine Vision In Today's Technological Landscape

An Overview Of Cameras Used In Machine Vision Systems

Exploring Image Processing Techniques In Machine Vision Systems