Why Pipeline Machine Vision Systems Are Transforming Inspections

Pipeline machine vision systems are redefining how inspections are conducted. These systems use advanced computer vision technologies to analyze images and detect anomalies with remarkable precision. For instance, models tested in recent experiments achieved a mean average precision (mAP50) of up to 90% in identifying faulty pipes. Another framework combining Faster R-CNN and semantic segmentation delivered an impressive F1-score of 88.21%. Beyond accuracy, these systems enhance scalability. Automated inspection pipelines have reduced inspection times by nearly 47.3%, proving their efficiency and adaptability across industries. With these advancements, you can achieve safer and more reliable operations.

Key Takeaways

- Pipeline machine vision systems use machines to check for problems.

- They quickly look at images and find issues right away.

- Adding AI makes these systems smarter and helps fix things early.

- These systems can grow to handle more data without slowing down.

- Factories and hospitals use them to save money and stay safe.

Understanding Pipeline Machine Vision Systems

What Is a Pipeline Machine Vision System?

A pipeline machine vision system is a specialized technology designed to automate inspection processes by analyzing visual data. It combines advanced computer vision techniques with a structured pipeline architecture to identify defects, anomalies, or patterns in real-time. These systems are widely used in industries where precision and efficiency are critical, such as manufacturing, healthcare, and infrastructure maintenance.

At its core, this system operates through a series of interconnected steps. First, it captures images or videos using high-resolution cameras or sensors. Then, it processes this data through a machine learning pipeline, which includes tasks like data preprocessing, model training, and object classification. The final output provides actionable insights, such as defect detection or performance metrics, enabling you to make informed decisions quickly.

By automating repetitive and error-prone tasks, pipeline machine vision systems reduce human intervention and improve accuracy. For example, studies show that integrating AI into industrial inspections not only enhances efficiency but also minimizes downtime and improves worker safety by handling hazardous tasks. This transformative impact makes these systems indispensable in modern industries.

How Computer Vision Powers These Systems

Computer vision is the driving force behind pipeline machine vision systems. It enables machines to interpret and analyze visual data, mimicking the way humans perceive the world. Through algorithms and models, computer vision extracts meaningful information from images or videos, such as shapes, textures, and patterns.

The process begins with data collection, where cameras or sensors capture raw visual inputs. These inputs undergo preprocessing to enhance quality and remove noise. Next, the system applies feature extraction techniques to identify key attributes, such as edges or contours. Finally, the data is fed into a trained model for tasks like object detection, recognition, or classification.

For instance, convolutional neural networks (CNNs) play a significant role in computer vision. They excel at recognizing patterns in images, making them ideal for tasks like defect detection in pipelines. Studies have shown that CNNs outperform traditional methods in recognizing small leak signals, demonstrating their effectiveness in industrial applications.

The integration of computer vision into a pipeline architecture ensures seamless data flow and processing. This approach not only improves accuracy but also enhances scalability, allowing you to handle large-scale operations with ease. By leveraging computer vision, you can achieve faster inspections, better decision-making, and higher productivity.

The Role of Object Detection in Inspections

Object detection is a critical component of pipeline machine vision systems. It involves identifying and localizing specific objects within an image or video. In the context of inspections, object detection helps pinpoint defects, anomalies, or areas of interest with high precision.

Advanced models like YOLO (You Only Look Once) have revolutionized object detection by delivering state-of-the-art results. These models analyze large volumes of visual data quickly and accurately, outperforming human inspectors in many cases. For example, the YOLOX-Ray model has demonstrated exceptional effectiveness in industrial inspections, detecting and localizing defects more reliably than traditional methods.

The benefits of object detection extend beyond accuracy. By automating the inspection process, you can reduce human error, save time, and improve overall efficiency. A study by Dong et al. highlights how machine vision systems achieved a coverage rate exceeding 80% in weld defect detection, showcasing their practicality and reliability.

When integrated into a machine learning pipeline, object detection becomes even more powerful. It works seamlessly with other components, such as data preprocessing and model training, to deliver comprehensive inspection solutions. This synergy ensures that your operations remain efficient, scalable, and adaptable to evolving industry needs.

Key Components of a Pipeline Machine Vision System

Image Acquisition and Preprocessing

Image acquisition serves as the foundation of any pipeline machine vision system. It involves capturing high-quality images or videos using cameras or sensors. Preprocessing then refines this raw data by enhancing image quality and removing noise, ensuring accurate analysis. For example, high-resolution cameras combined with advanced algorithms excel at detecting defects in pipeline materials. These systems also achieve over 82% accuracy in corrosion monitoring, making them highly reliable for industrial applications.

Preprocessing techniques vary depending on the application. For real-time inspections, systems process data in less than 20 milliseconds, enabling instant defect detection. Integration with Industry 4.0 technologies further enhances automated reporting and predictive maintenance.

| Application | Evidence |

|---|---|

| Defect Detection | Machine vision systems excel at identifying defects in pipeline materials using high-resolution cameras and advanced algorithms. |

| Corrosion Monitoring | Research shows that machine learning techniques combined with machine vision achieve over 82% accuracy in corrosion detection. |

| Real-time Inspection | These systems can process data in less than 20 milliseconds, allowing for instant defect identification. |

| Automated Reporting | Integration with Industry 4.0 technologies enables seamless reporting and predictive maintenance. |

Feature Extraction and Object Detection

Feature extraction identifies key attributes in an image, such as edges, textures, or patterns. This step simplifies the data, making it easier for the system to analyze. Object detection then pinpoints specific objects or anomalies within the image. Together, these processes form the backbone of image classification and defect detection.

Statistical metrics help evaluate the performance of these systems. For instance, Average Precision (AP) measures how accurately the model detects objects, while Intersection over Union (IoU) assesses the overlap between predicted and actual bounding boxes. Mean Average Precision (mAP) provides an overall accuracy score across all classes. These metrics ensure that your system delivers reliable results.

| Metric | Description |

|---|---|

| Average Precision (AP) | Measures the model's accuracy in detecting objects at different levels of precision. |

| Intersection over Union (IoU) | Measures the overlap between the predicted and ground-truth bounding boxes. |

| Mean Average Precision (mAP) | Average of the AP calculated at different levels of precision across all classes. |

| False-Positive Rate (FPR) | Proportion of negative samples incorrectly classified as positive. |

| Recall | Proportion of positive samples correctly identified by the model. |

Decision-Making and Reporting

Decision-making and reporting transform raw data into actionable insights. Advanced analytics and AI enable you to prioritize maintenance, reduce costs, and improve safety. Companies using these technologies report a 10-20% reduction in incidents and leaks, along with a 20-30% decrease in inspection costs. Asset availability also improves by 5-10%, ensuring smoother operations.

Platforms like NIMA enhance decision-making by digitalizing risk-based inspections. They organize data in a traceable manner, reducing paperwork and improving reporting. These tools support engineers in prioritizing maintenance, minimizing unplanned downtime, and ensuring pipeline integrity.

- Companies report a 10-20% reduction in incidents and leaks.

- Inspection and maintenance costs decrease by 20-30%.

- Asset availability improves by 5-10%.

- The NIMA platform digitalizes inspections, reducing paperwork and enhancing reporting.

- Engineers use these tools to prioritize maintenance and reduce downtime.

Integration with the Data Pipeline

Integrating machine vision systems with a data pipeline ensures seamless flow and processing of information. This integration allows you to collect, analyze, and act on visual data in real-time, enhancing operational efficiency and decision-making. A well-designed pipeline architecture connects imaging hardware, software algorithms, and analytics platforms, creating a unified system for inspections.

Machine vision systems rely on automated data pipelines to handle large volumes of visual data. These pipelines streamline image acquisition, feature extraction, and reporting processes. For example, edge computer vision systems process data locally, reducing latency and enabling faster insights. This approach is particularly useful for industries requiring immediate responses, such as manufacturing and infrastructure maintenance.

Several best practices support successful integration. First, imaging hardware must align with the pipeline architecture to ensure compatibility. High-resolution cameras and sensors capture detailed images, while preprocessing algorithms refine the data for analysis. Second, deploying edge computing enhances equipment health monitoring by offering predictive capabilities. These systems detect anomalies early, preventing costly downtime and improving safety.

Key documentation highlights the effectiveness of this integration. Reports show that imaging hardware and software algorithms work together to establish efficient data pipelines. Additionally, real-time insights from computer vision systems verify equipment health, demonstrating the practical benefits of integration.

By connecting machine vision systems to a robust data pipeline, you gain access to actionable insights that drive better decisions. This integration reduces manual intervention, improves accuracy, and scales operations effortlessly. Whether you're monitoring pipelines for defects or optimizing production lines, a well-integrated system ensures reliable and efficient performance.

Benefits of Pipeline Machine Vision Systems

Enhanced Accuracy and Speed

Pipeline machine vision systems bring unmatched accuracy and speed to inspection processes. By leveraging computer vision, these systems analyze visual data with precision, identifying defects or anomalies that human inspectors might overlook. For example, convolutional neural networks (CNNs) excel at recognizing intricate patterns, enabling faster and more reliable inspections. This capability reduces the time required for manual checks, allowing you to scale operations efficiently.

The structured pipeline architecture ensures that data flows seamlessly through each stage, from data collection to model training and analysis. This design minimizes bottlenecks and accelerates decision-making. In manufacturing applications, automated data pipelines process images in milliseconds, enabling real-time defect detection. With this level of speed and accuracy, you can maintain high-quality standards while meeting tight production deadlines.

Reduction in Human Error

Human error often poses significant challenges in inspection processes. Fatigue, subjectivity, and limited attention spans can lead to missed defects or inconsistent results. Pipeline machine vision systems eliminate these issues by providing consistent, objective analysis. These systems rely on computer vision to detect even the smallest deviations, ensuring uniformity and quality control.

The following table highlights how machine vision reduces human error across various applications:

| Source | Evidence |

|---|---|

| Using Computer Vision for Automated Assembly Line Inspection | Machine vision enhances inspection by analyzing visual data to detect deviations, ensuring product uniformity and quality control. |

| UTILIZING MACHINE VISION FOR MANUFACTURING DEFECT DETECTION AND PREVENTION | Machine vision eliminates subjectivity and provides consistent results, significantly reducing human error. |

| Error Proofing in Manufacturing with Computer Vision | Computer vision systems can detect minute defects with high accuracy, minimizing the chances of overlooking errors. |

By automating inspections, you can achieve greater reliability and reduce costly mistakes. This consistency not only improves product quality but also enhances customer satisfaction, as fewer defective products reach the market.

Real-Time Monitoring and Predictive Insights

Real-time monitoring is a game-changer for industries that rely on continuous operations. Pipeline machine vision systems enable you to monitor processes in real time, identifying issues as they arise. This proactive approach minimizes downtime and prevents minor problems from escalating into major failures. For instance, edge computing allows data to be processed locally, delivering instant insights and reducing latency.

Predictive insights further enhance the value of these systems. By analyzing historical data, machine learning pipelines can forecast potential failures and recommend preventive actions. This predictive capability helps you optimize maintenance schedules, reduce unplanned downtime, and extend the lifespan of critical assets.

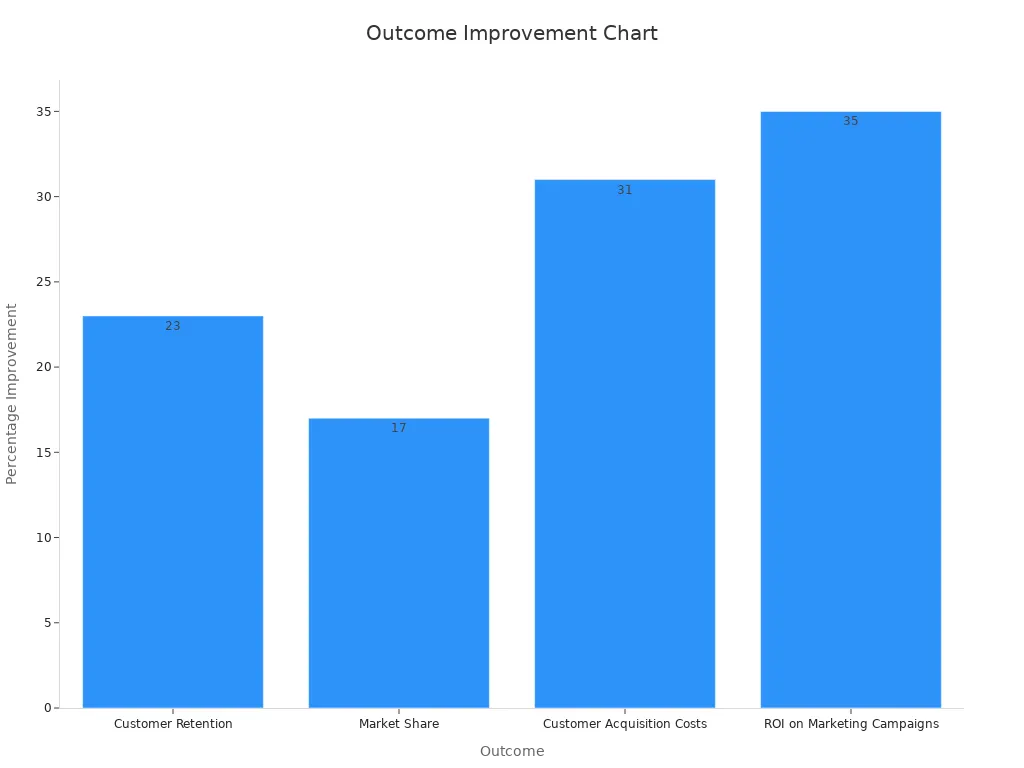

Recent studies have documented measurable outcomes from real-time monitoring and predictive insights:

| Outcome | Percentage Improvement |

|---|---|

| Customer Retention | 23% |

| Market Share | 17% |

| Customer Acquisition Costs | 31% |

| ROI on Marketing Campaigns | 35% |

| Reduction in Unplanned Downtime | 25% |

These improvements demonstrate the transformative impact of real-time monitoring and predictive analytics. By integrating machine vision systems with a robust data pipeline, you can unlock actionable insights that drive better decisions and improve operational efficiency.

Scalability for Large-Scale Operations

Pipeline machine vision systems excel at handling large-scale operations, making them ideal for industries that process massive amounts of data. These systems adapt to growing demands without compromising performance, ensuring smooth and efficient workflows. Whether you're managing thousands of inspection points or analyzing millions of images, scalability becomes a critical factor in maintaining operational efficiency.

Traditional systems often struggle with scalability. Monolithic architectures, for instance, face performance bottlenecks when processing large datasets. If one module encounters an issue, the entire system can slow down or fail. This limitation makes it difficult to scale operations effectively. In contrast, pipeline machine vision systems leverage modular designs, such as microservices, to isolate faults and maintain reliability. You can update individual components without disrupting the entire system, enabling faster innovation and adaptability.

Tip: Modular systems allow you to scale specific features independently, ensuring your operations remain agile and responsive to changing demands.

Key Advantages of Scalability in Machine Vision Systems

- Efficient Data Processing: These systems handle high volumes of visual data without delays. For example, an eCommerce platform can process millions of product images seamlessly, ensuring accurate categorization and defect detection.

- Independent Updates: Microservices architecture enables you to update features independently, reducing downtime and accelerating innovation.

- Fault Isolation: Issues in one module won't affect the entire system, improving reliability and minimizing disruptions.

Real-World Impact of Scalability

Scalability transforms industries by enabling large-scale operations to function smoothly. In manufacturing, machine vision systems inspect thousands of products daily, ensuring consistent quality. In infrastructure maintenance, these systems monitor extensive networks of pipelines, detecting defects in real time. Their ability to scale ensures that even the most complex operations remain efficient and reliable.

A modular approach also enhances flexibility. You can integrate new technologies, such as AI-powered predictive analytics, without overhauling the entire system. This adaptability allows you to stay ahead of industry trends and meet growing demands with ease.

Why Scalability Matters for You

Scalability isn't just about handling more data; it's about doing so efficiently and reliably. By adopting pipeline machine vision systems, you gain the ability to expand your operations without sacrificing performance. Whether you're scaling up production lines or monitoring vast infrastructure networks, these systems ensure that your processes remain streamlined and effective.

Note: Investing in scalable systems today prepares your operations for future growth, ensuring long-term success and competitiveness.

Real-World Applications

Manufacturing and Quality Control

Pipeline machine vision systems have revolutionized manufacturing by automating inspection processes and ensuring consistent quality control. These systems monitor product integrity in real time, helping you maintain high standards and avoid production disruptions. For example:

- Machine vision systems automate packaging verification, reducing errors and improving compliance with food safety regulations.

- Foxconn implemented a system that identified 13 types of defects on an assembly line for handheld electronics, cutting the labor force for inspections by 50%.

- Automated optical inspection (AOI) flags deviations from master images, ensuring flawless production.

In advanced manufacturing, these systems also enable real-time monitoring of complex products like biomechanical catheters. By detecting defects during critical stages, they eliminate the need for destructive testing and ensure built-in quality. This approach not only saves time but also reduces waste, making your operations more efficient.

Healthcare Diagnostics and Monitoring

In healthcare, machine vision systems play a vital role in diagnostics and patient monitoring. These technologies analyze medical images with near-perfect precision, identifying patterns and anomalies that might escape human recognition. For instance:

- Computer vision systems measure blood loss during surgeries, enabling timely interventions.

- In oncology, they track tumor growth, aiding in treatment planning and improving outcomes.

- They also analyze health metrics, empowering patients to make informed decisions about their care.

The impact of these systems is evident in the statistics. The medical imaging and diagnostics segment accounted for 50% of global revenue in 2022, reflecting the growing reliance on these technologies. With advancements in computer vision, diagnostic accuracy continues to improve, offering early detection and precise diagnoses.

| Statistic/Fact | Description |

|---|---|

| 50.0% share of global revenue | The medical imaging and diagnostics segment led the market in 2022. |

| Near 100% precision | Advancements in computer vision suggest very high levels of diagnostic accuracy. |

| Improved diagnostic accuracy | Helps identify patterns and anomalies, leading to early detection. |

Security and Surveillance

Machine vision systems have become indispensable in security and surveillance, offering advanced capabilities to protect people and assets. These systems use deep learning to recognize objects, detect anomalies, and analyze human behavior. For example:

- Real-time object detection identifies weapons or protective gear in video feeds.

- Emergency management systems classify natural events and send alerts to law enforcement when necessary.

- Human behavior analysis recognizes specific actions, helping you detect suspicious activities.

These systems also enhance surveillance by summarizing video content automatically. This feature allows you to review hours of footage in minutes, saving time and improving efficiency. In addition, facial recognition technology plays a key role in identifying individuals, making it easier to secure restricted areas or track unauthorized access.

| Capability | Description |

|---|---|

| Real-time object detection | Identifies and localizes objects like weapons in video feeds. |

| Emergency management | Detects anomalies and sends alerts to law enforcement. |

| Human behavior understanding | Recognizes specific actions and behavior patterns. |

| Illegal activity detection | Identifies suspicious activities using motion pattern detection. |

| Automated video summarization | Provides quick insights into video content. |

By integrating these systems into your operations, you can enhance security measures, improve response times, and ensure safer environments.

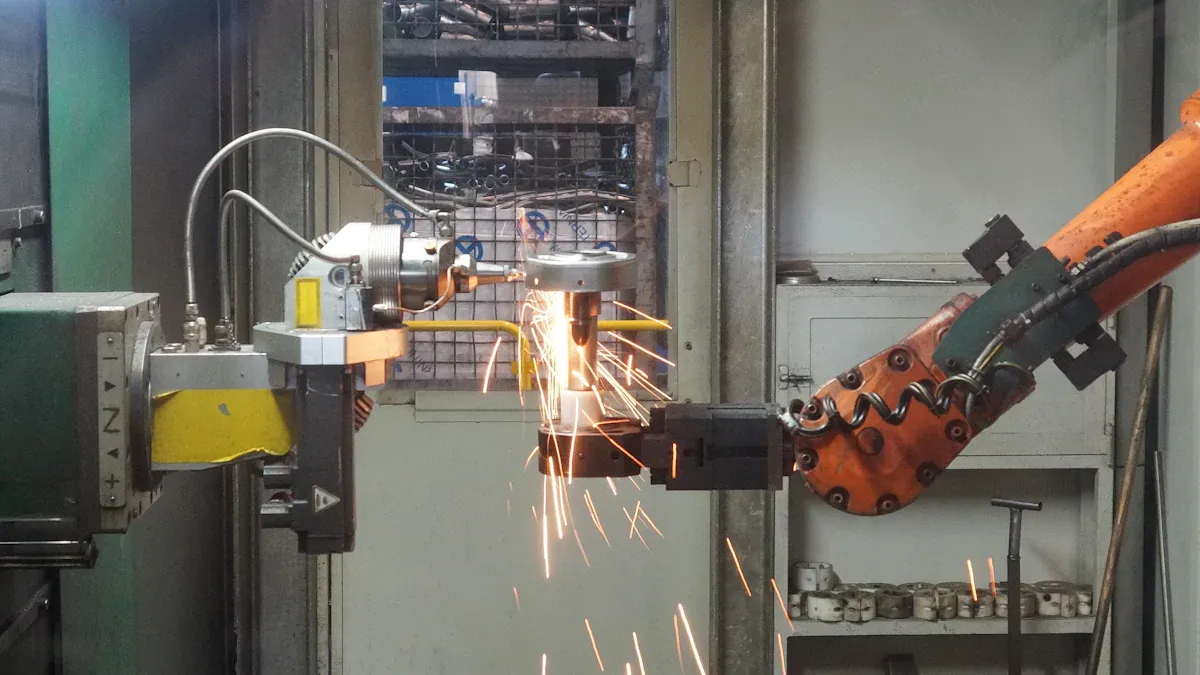

Infrastructure and Pipeline Maintenance

Pipeline machine vision systems have become essential for maintaining infrastructure and ensuring pipeline integrity. These systems use advanced imaging technologies to detect defects, monitor conditions, and predict potential failures. By automating inspections, you can reduce risks, improve efficiency, and extend the lifespan of critical assets.

In-line inspection (ILI) plays a vital role in pipeline maintenance. It identifies defects and potential failure points, helping you address issues before they escalate. Machine learning models analyze corrosion data to predict pipeline failures, giving you actionable insights. Data analytics further enhances this process by filtering and interpreting ILI data, allowing you to assess corrosion severity and growth accurately.

Robotic inspections using CCTV are another powerful tool. These systems rely on hardware like imaging sensors, illumination systems, and computation units to capture detailed visuals of pipeline interiors. The choice of light sources and sensors significantly impacts the quality of the data collected. Advanced techniques, such as intensity-based optical systems and laser profilers, improve image clarity, making it easier to identify problems.

Real-world applications of these technologies demonstrate their effectiveness. For example, machine vision systems monitor extensive pipeline networks in real time, ensuring safety and reliability. They also integrate seamlessly with security and surveillance systems, providing an added layer of protection. By using these systems, you can enhance quality control and reduce the likelihood of costly failures.

Pipeline machine vision systems not only improve inspection accuracy but also enable predictive maintenance. This proactive approach minimizes downtime and ensures that your infrastructure remains in optimal condition. With these tools, you can confidently manage large-scale operations while maintaining high standards of safety and efficiency.

Future Potential and Innovations

AI Integration in Machine Vision Systems

AI is reshaping pipeline machine vision systems, making inspections faster and more accurate. By analyzing images and video streams in real time, AI-driven systems detect even the smallest defects that human inspectors might miss. These systems reduce error rates to below one percent, compared to a 10% error rate for manual inspections. You can rely on AI to improve quality control and minimize production delays.

Machine learning algorithms empower these systems to adapt and learn from historical data. This capability optimizes inspection processes over time, ensuring continuous improvement. For example, AI models trained on one type of defect can quickly adapt to new ones, saving time and reducing the need for extensive data collection. Integrating data from multiple sensors, such as cameras and thermal imagers, further enhances inspection accuracy. These systems provide a comprehensive view of product quality, helping you make better decisions.

AI also supports predictive maintenance by identifying potential equipment failures before they occur. This proactive approach minimizes downtime and ensures uninterrupted production. With AI, you can achieve real-time defect detection and long-term operational efficiency.

Advancements in Predictive Analytics

Predictive analytics is transforming how you manage inspections and maintenance. By analyzing historical data, machine learning pipelines forecast potential failures and recommend preventive actions. This capability reduces unplanned downtime and extends the lifespan of critical assets.

Performance metrics highlight the effectiveness of predictive analytics in pipeline machine vision systems:

| Metric | Description |

|---|---|

| Latency | Measures the time delay in processing data, crucial for real-time systems. |

| Throughput | Indicates the amount of data processed in a given time, reflecting efficiency. |

| Error Rates | Tracks the frequency of errors in predictions, essential for reliability. |

These metrics ensure that your system delivers accurate and timely insights. For example, low latency enables real-time monitoring, while high throughput ensures efficient data processing. By leveraging predictive analytics, you can optimize maintenance schedules and improve operational reliability.

Emerging Hardware and Sensor Technologies

Innovations in hardware and sensors are enhancing the capabilities of pipeline machine vision systems. Neuromorphic sensors, for instance, outperform traditional sensors in dynamic environments. These sensors excel in applications like autonomous vehicles, drones, and healthcare. For example, they enable real-time crop monitoring in agriculture and precise tracking of high-speed objects in sports analytics.

The following table compares the benefits of neuromorphic sensors with traditional sensors:

| Application Domain | Benefits of Neuromorphic Sensors | Traditional Sensors Limitations |

|---|---|---|

| Autonomous Vehicles | Enhanced performance in dynamic urban settings with event-based SLAM systems. | Struggle in complex environments. |

| Drones | Operate effectively under variable lighting conditions. | Limited adaptability to changing light. |

| Agriculture | Real-time crop monitoring through event-based vision. | Slower response times in traditional methods. |

| Healthcare | Sensitivity to rapid physiological changes for surgical assistance and patient monitoring. | Less effective in capturing subtle changes. |

| Sports Analytics | Precise tracking of high-speed objects without motion blur. | Motion blur in traditional high-speed cameras. |

| Heavy Industry | Improved temporal resolution and data efficiency under harsh conditions. | Limited data efficiency in dynamic environments. |

Emerging technologies like high-resolution cameras and spectral sensors are also driving advancements. These tools improve image clarity and enable more accurate defect detection. As industries adopt smart factories and interconnected systems, the demand for advanced hardware will continue to grow. By investing in these technologies, you can stay ahead of industry trends and enhance your inspection processes.

Broader Adoption Across Industries

Pipeline machine vision systems are gaining traction across a wide range of industries. Their ability to process large volumes of data and deliver actionable insights makes them indispensable for modern operations. You can see their impact in sectors like agriculture, logistics, and energy, where efficiency and precision are critical.

AI plays a pivotal role in this widespread adoption. It analyzes historical data to predict potential issues, helping you optimize operations. For example, in agriculture, machine vision systems monitor crop health by analyzing images from drones. This approach allows you to detect diseases early and improve yields. In logistics, these systems streamline warehouse operations by automating inventory checks and identifying damaged goods.

A shared data ecosystem further enhances the value of these systems. By benchmarking your performance against industry standards, you can identify areas for improvement. This capability is particularly useful in energy and infrastructure sectors, where maintenance costs can be high. Aggregating data at scale also enables the development of advanced machine learning models. These models uncover inefficiencies, allowing you to make strategic decisions that boost resilience.

The modular design of pipeline machine vision systems ensures they adapt to diverse industry needs. Whether you manage a manufacturing plant or oversee a transportation network, these systems integrate seamlessly into your operations. Their scalability means you can expand their use as your business grows, ensuring long-term benefits.

By adopting these systems, you gain a competitive edge. They reduce costs, improve accuracy, and enhance productivity. As industries continue to embrace digital transformation, pipeline machine vision systems will play an even greater role in shaping the future of work.

Pipeline machine vision systems are revolutionizing inspections by automating processes and delivering unmatched accuracy. Their ability to scale operations efficiently makes them indispensable across industries. For example, a case study at Coors Ceramics Company demonstrated how these systems inspect ceramic substrates at a rate of one part every two seconds, highlighting their speed and precision. Similarly, advancements like in-camera video-stream processing reduce bandwidth requirements, enhancing efficiency in web inspections.

The economic impact of these systems is also significant. Industry reports project steady growth in the market size, as shown below:

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 12.92 | N/A |

| 2025 | 13.95 | N/A |

| 2030 | 20.81 | 8.32 |

As AI and hardware technologies evolve, these systems will continue to drive innovation, ensuring safer, more reliable, and cost-effective inspection processes.

FAQ

What industries benefit the most from pipeline machine vision systems?

Industries like manufacturing, healthcare, infrastructure maintenance, and security gain the most from these systems. They improve quality control, enhance safety, and reduce operational costs. For example, manufacturers use them for defect detection, while healthcare professionals rely on them for accurate diagnostics.

How do these systems reduce inspection costs?

Pipeline machine vision systems automate repetitive tasks, minimizing the need for manual labor. They also detect defects early, preventing costly repairs or product recalls. Studies show that companies using these systems reduce inspection costs by 20-30%, improving overall efficiency.

Can these systems handle real-time data processing?

Yes, they excel at real-time data processing. High-speed cameras and edge computing enable instant analysis of visual data. This capability ensures immediate defect detection and faster decision-making, which is crucial for industries like manufacturing and security.

Are pipeline machine vision systems scalable?

Absolutely! These systems use modular designs, allowing you to scale operations without performance issues. Whether you’re inspecting thousands of products daily or monitoring vast infrastructure networks, they adapt to growing demands while maintaining efficiency.

What role does AI play in these systems?

AI enhances the accuracy and adaptability of pipeline machine vision systems. It powers advanced features like predictive maintenance and real-time defect detection. By learning from historical data, AI ensures continuous improvement, helping you optimize processes and reduce downtime.

See Also

Improving Product Quality With Surface Inspection Vision Systems

Insights Into Inspection Vision Systems for 2025

Essential Features and Advantages of Medical Vision Systems

Defining Specialized Software for Automated Inspection Solutions

Investigating Machine Vision Applications in Steel Production