Defining Pixel Machine Vision for Modern Applications

Pixel machine vision systems analyze visual data at the level of individual pixels, enabling them to perform tasks with unmatched precision. These systems have revolutionized industries by improving accuracy and reducing human error.

The global computer vision market, valued at $11.7 billion in 2021, is projected to grow to $21.3 billion by 2023, reflecting its increasing importance.

Industries like manufacturing and healthcare benefit greatly from machine vision. For instance:

- Robotics cells manage diverse products without production delays.

- Vision systems reduce downtime, enhance safety, and detect flaws efficiently.

- Automated processes minimize manpower needs and repair times.

The precision and adaptability of these systems continue to drive innovation across sectors.

Key Takeaways

- Pixel machine vision systems study images one pixel at a time. This makes results more accurate and lowers mistakes in fields like factories and hospitals.

- Picking the right camera and sensor is very important. Area scan cameras help find objects, while line scan cameras check long materials.

- Good lighting makes pictures clearer. Backlighting can make images sharper and remove shadows for better study.

- Smart AI programs do jobs like finding defects and sorting objects. This saves time and lowers human mistakes.

- Regularly adjusting and improving your machine vision system keeps it working well. It also helps it handle changes in the environment.

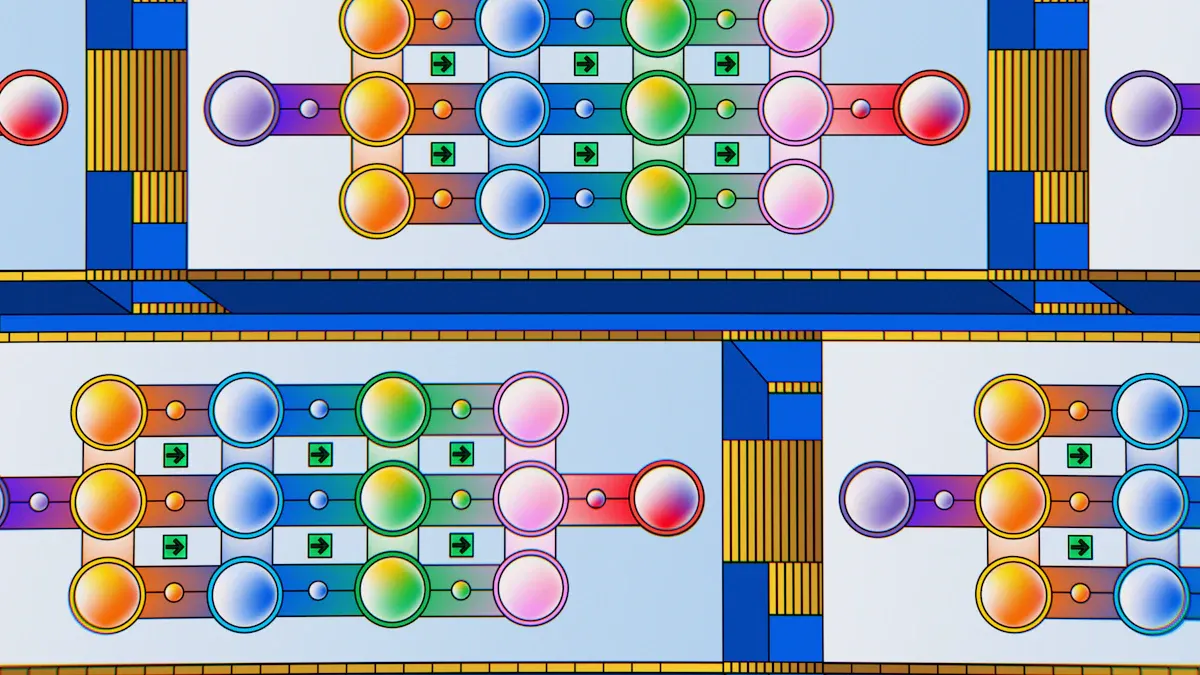

Core Components of a Pixel Machine Vision System

Cameras and Imaging Sensors

Cameras form the backbone of any pixel machine vision system. They capture visual data by converting light into digital signals, enabling precise imaging. You’ll find two main types of cameras used in machine vision: area scan cameras and line scan cameras. Area scan cameras capture entire images at once, making them ideal for applications like object recognition. Line scan cameras, on the other hand, scan one line of pixels at a time, which is perfect for inspecting continuous materials like textiles or paper.

The image sensor inside the camera plays a critical role in determining the quality of the captured image. A CCD image sensor is widely used for its ability to produce high-quality images with minimal noise. The resolution of the sensor, defined by the number of pixels, dictates the smallest object or defect you can detect. Additionally, the lens focuses light onto the sensor, influencing the field of view and working distance. Proper lighting design further enhances contrast and visibility, ensuring accurate imaging even in challenging environments.

| Metric | Description |

|---|---|

| Quantum Efficiency (QE) | Indicates how effectively the camera converts incoming light into digital signals. |

| Dark Noise | Represents unwanted variations in the image caused by thermal activity within the sensor. |

| Dynamic Range | Defines the range of light intensities the camera can capture, ensuring clarity in both bright and dark areas. |

Processing Units and Software

Processing units and software are the brains of a machine vision system. Once the camera captures pixel-level data, the processing unit analyzes it using advanced algorithms. These units rely on AI-powered software to perform tasks like defect detection, object recognition, and visual inspection. AI systems adapt to environmental changes, such as variations in lighting or surface texture, making them far more efficient than traditional systems.

For example, AI-driven software can upscale video streams, reduce noise, and enhance low-light performance. Neural networks embedded in the software learn complex patterns, enabling accurate object detection and classification. This adaptability allows you to automate processes like quality control and materials inspection, reducing human error and increasing throughput.

Vision Sensors and Their Role in Image Processing

Vision sensors are essential for enhancing the accuracy of image processing. These sensors work alongside cameras to capture high-resolution imagery in real time. Integrated with AI technologies, vision sensors improve image quality by reducing noise and upscaling video streams. They also excel in low-light conditions, ensuring consistent performance across various environments.

Modern vision systems leverage AI transformers to outperform traditional convolutional neural networks (CNNs). These transformers learn intricate patterns, enabling precise object detection and classification. Whether you’re working in manufacturing or healthcare, vision sensors ensure your machine vision system delivers reliable results.

Tip: When selecting vision sensors, prioritize those with high spatial resolution and dynamic range to capture detailed images in diverse conditions.

How Pixel Data is Processed in Machine Vision

Capturing Pixel-Level Data with Cameras

Cameras are the foundation of any machine vision system. They capture pixel-level data by converting light into digital signals. Area scan cameras and line scan cameras are commonly used for this purpose. Area scan cameras capture two-dimensional images, making them ideal for tasks like object identification and verification. Line scan cameras, on the other hand, scan one line of pixels at a time, which is perfect for inspecting continuous materials such as textiles or paper.

The choice of sensor technology plays a critical role in capturing high-quality data. CCD sensors excel in quantum efficiency, ensuring precise image acquisition even in low-light conditions. CMOS sensors, however, offer higher frame rates and region-of-interest capabilities, making them suitable for dynamic environments. The EMVA Standard 1288 provides essential parameters for evaluating sensor performance, including sensitivity and noise characteristics. These metrics help you understand how cameras capture and process visual data effectively.

Tip: When selecting cameras for your machine vision system, consider the trade-offs between CCD and CMOS sensors based on your application's speed and accuracy requirements.

Image Processing for Tasks Like Inspection and Measurement

Image processing transforms raw pixel data into actionable insights. This step involves analyzing images to detect flaws, measure dimensions, and verify object characteristics. For example, in manufacturing, image processing ensures measurement accuracy by identifying defects as small as a few microns.

Statistical evidence highlights the efficiency of image processing techniques in inspection and measurement tasks:

| Measurement Type | Resolution Achieved | Accuracy Achieved | Notes |

|---|---|---|---|

| Distance measurement (1m field) | 1 mm | 500 times pixel | Using a 1,000 x 1,000 pixel camera |

| Width measurement of square object | 0.1 mm | 500 times pixel | Improved by measuring 100 pixels |

| Stationary object measurement | 10 µm | 500 times pixel | 100 measurements in one second |

| Capillary tube opening measurement | 5 nm | 12 µm opening | Achieved with light wavelength of 500 nm |

| General accuracy | 2 µm | 500 times pixel | For a one-meter scene |

These results demonstrate how image processing enhances precision across various applications. By leveraging advanced algorithms, you can achieve high-resolution measurements and reliable defect detection, ensuring consistent quality control.

Algorithms and Decision-Making in Machine Vision

Algorithms are the driving force behind decision-making in machine vision systems. They analyze processed data to identify patterns, classify objects, and make predictions. Metrics like recall, F1 score, and AUC help evaluate algorithm performance and ensure reliable outcomes.

| Metric | Purpose | Importance | Explanation |

|---|---|---|---|

| Recall | Identify all positive instances | High | Essential when missing positive cases is costly or when detecting all positive instances is vital. |

| F1 Score | Balanced performance | High | Useful when dealing with imbalanced datasets or when false positives and false negatives have different costs. |

| AUC | Overall classification performance | High | Important for assessing the model’s performance across various classification thresholds and when comparing different models. |

Machine vision algorithms adapt to changing conditions, such as variations in lighting or object orientation. Neural networks, for instance, learn complex patterns, enabling accurate identification and classification. These capabilities allow you to automate processes like defect detection and verification, reducing human error and increasing efficiency.

Note: When implementing algorithms in your machine vision system, prioritize those with high recall and F1 scores to ensure balanced and accurate performance.

Factors Influencing Accuracy in Machine Vision Systems

Lighting and Environmental Conditions

Lighting plays a crucial role in the performance of a machine vision system. Proper lighting ensures that the system captures clear and accurate images. For example:

- Backlights create black silhouettes behind objects, enhancing edge clarity for precise gaging and measurement.

- Line scan cameras require specialized lighting to inspect fast-moving materials like textiles without flickering.

- High-powered bar lights illuminate parcels in logistics, ensuring accurate barcode reading.

Environmental conditions, such as humidity and temperature, also impact accuracy. Poor lighting can lead to low-quality images, making it harder for deep learning models to analyze data effectively. You can improve accuracy by optimizing lighting setups to reduce shadows and reflections.

Resolution and Sensor Quality

The resolution of your camera determines the level of detail it can capture. Higher resolution allows the system to detect smaller defects and measure objects with greater precision. Image resolution is especially important in applications like quality control, where even minor flaws can affect product performance.

High-quality sensors and optics are essential for capturing clear images. CCD sensors provide excellent image resolution, while CMOS sensors offer faster frame rates. Algorithms like edge detection further enhance accuracy by processing captured images effectively. Regular calibration ensures that the system maintains its accuracy over time, even in challenging environments.

Calibration and Optimization Techniques

Calibration ensures that your machine vision system operates at peak accuracy. Techniques like Measurement System Analysis (MSA) validate the reliability of the system by identifying errors. Gage R&R studies assess repeatability and reproducibility, ensuring consistent performance.

| Evidence Type | Description |

|---|---|

| Measurement System Analysis (MSA) | Validates system reliability by analyzing measurement variability. |

| Gage R&R Studies | Evaluates repeatability and reproducibility in machine vision applications. |

| Statistical Tests | Compares measurements using tools like the 2-sample T-test. |

Optimization techniques, such as adjusting lighting and fine-tuning algorithms, further enhance accuracy. These steps help you achieve consistent results, even when environmental conditions change.

Applications of Pixel Machine Vision in Modern Industries

Manufacturing and Quality Control

Pixel machine vision systems have transformed manufacturing by enabling precise and efficient quality control. These systems use cameras to perform automated inspections, ensuring consistent product quality. High-speed cameras capture detailed images of products, allowing the system to detect defects at the pixel level. This capability reduces human error and improves production efficiency.

For example, automated inspections can identify flaws in materials or assembly lines without slowing down production. The system evaluates product quality objectively, free from human biases or fatigue. It also collects inspection data, which helps optimize processes and predict maintenance needs.

| Performance Metric | Description |

|---|---|

| Automated Inspection | Enables continuous monitoring and rapid detection of defects, improving product quality. |

| Consistent and Objective Evaluation | Provides reliable assessments, free from human biases and fatigue. |

| High-Speed Inspection | Allows for faster production lines compared to manual inspection. |

| Reduced Human Error | Minimizes costly mistakes associated with manual inspections. |

| Traceability and Data Analytics | Captures detailed inspection data for process optimization and predictive maintenance. |

| Flexibility and Adaptability | Can be programmed for various products, adapting to changing production needs. |

| Cost-effective | Reduces labor costs and minimizes defects, leading to overall savings in production. |

By integrating cameras and advanced algorithms, you can achieve unparalleled accuracy in defect inspection and visual inspection tasks. This ensures that your products meet the highest standards of quality.

Healthcare Imaging and Diagnostics

Pixel machine vision systems play a vital role in healthcare by enhancing imaging and diagnostics. These systems analyze medical images with remarkable precision, helping doctors detect diseases early. Cameras capture high-resolution images, which are processed to identify abnormalities at the pixel level.

You can rely on these systems for tasks like tumor detection, infection prevention, and surgical assistance. Automated detection algorithms flag suspicious areas in medical images, enabling early diagnosis. Deep learning technologies improve detection accuracy by analyzing subtle changes in large datasets. This makes healthcare more efficient and reliable.

- Tumor and cancer detection

- Early diagnosis

- Medical image analysis

- Infection prevention

- Surgical real-time assistance

- Automated health monitoring

Pixel machine vision systems also support healthcare research and medical staff training. By providing accurate segmentation of tumors and other abnormalities, these systems enhance the quality of care and save lives.

Robotics and Autonomous Systems

Robotics and autonomous systems benefit greatly from pixel machine vision. These systems use cameras to navigate and interact with their environment. High-resolution cameras capture detailed images, allowing robots to perform complex tasks with precision.

For instance, autonomous vehicles rely on cameras to detect obstacles and make real-time decisions. Robots in warehouses use machine vision to identify and pick items accurately. These systems adapt to changing conditions, ensuring consistent performance in dynamic environments.

Pixel machine vision systems also enhance safety by detecting potential hazards. By processing pixel-level data, they enable robots to operate efficiently and safely in various industries. This technology continues to drive innovation in robotics and automation.

Pixel machine vision systems offer unmatched accuracy, efficiency, and scalability, making them indispensable across industries. You can rely on these systems to automate inspections, improve diagnostics, and enhance operational safety. For example, the machine vision market is projected to grow from $6.5 billion in 2022 to $9.3 billion by 2028, driven by increasing demand in manufacturing, healthcare, and logistics.

Ongoing advancements, such as neuromorphic imaging and AI integration, continue to refine these systems. Neuromorphic technology captures dynamic changes, reducing data redundancy and enabling real-time processing. These innovations unlock new possibilities, from autonomous vehicles to precision agriculture. As industries evolve, pixel machine vision systems will remain at the forefront of technological progress, transforming how you approach automation and problem-solving.

FAQ

What is the difference between CCD and CMOS sensors in machine vision?

CCD sensors provide high-quality images with minimal noise, making them ideal for precision tasks. CMOS sensors, however, offer faster frame rates and are better suited for dynamic environments. Your choice depends on the application's speed and accuracy needs.

How does lighting affect machine vision accuracy?

Lighting ensures clear image capture by reducing shadows and enhancing contrast. Poor lighting can lead to low-quality images, making it harder for algorithms to analyze data. Use proper lighting setups like backlights or bar lights to improve accuracy.

Can machine vision systems work in low-light conditions?

Yes, modern machine vision systems use advanced sensors and AI to perform well in low-light environments. Vision sensors with high dynamic range and noise reduction capabilities ensure consistent performance even in challenging lighting conditions.

What industries benefit most from pixel machine vision?

Industries like manufacturing, healthcare, and robotics benefit greatly. You can use these systems for quality control, medical imaging, and autonomous navigation. Their precision and adaptability make them valuable across various sectors.

How do algorithms improve machine vision systems?

Algorithms analyze pixel data to detect patterns, classify objects, and make decisions. Advanced techniques like neural networks enhance accuracy by learning complex patterns. This allows you to automate tasks like defect detection and object recognition efficiently.

Tip: Regularly update your machine vision software to leverage the latest algorithm advancements for better performance.

See Also

Understanding Image Processing Within Machine Vision Systems

Fundamentals of Camera Resolution in Machine Vision Systems

Essential Insights Into Computer Vision Versus Machine Vision