Discover the Magic of Polygon Machine Vision Systems

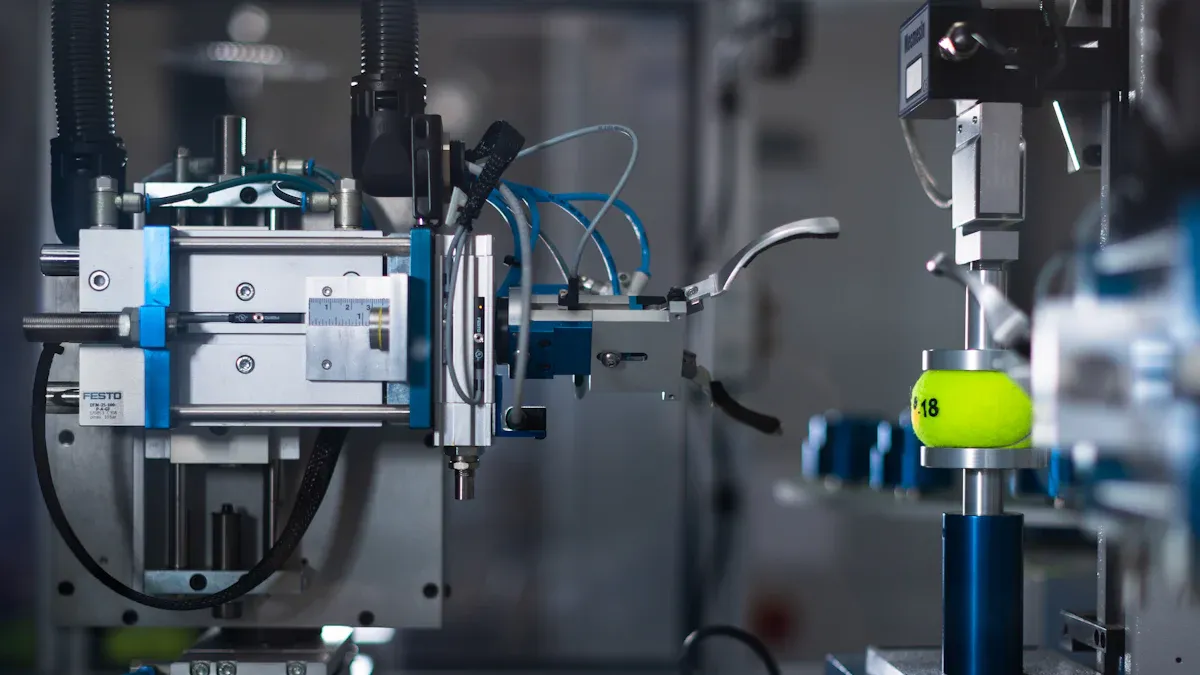

A polygon machine vision system is a cutting-edge technology that combines cameras and advanced image processing to interpret visual data. Its primary goal is to enable machines to analyze their surroundings with exceptional precision. For instance, polygon mirror-based laser scanners, recognized as the fastest opto-mechanical scanning systems, significantly enhance measurement speed. These systems are often used in optical micrometers to measure dimensions and positions with high accuracy. By analyzing energy received by photodetectors during scanning, they ensure efficient and reliable performance. Such capabilities drive advancements in computer vision and automation, making these systems indispensable in modern industries.

Key Takeaways

- Polygon vision systems improve accuracy by marking shapes and patterns clearly.

- These systems save time by automating work and reducing mistakes.

- They use AI to get smarter, learning from new information to work better.

- Many industries like factories, hospitals, and farms use this technology.

- Good polygon tools make these systems work even better for detailed tasks.

How Does a Polygon Machine Vision System Work?

Core Technology Behind the System

A polygon machine vision system relies on advanced optical and computational technologies to achieve its precision. At its core, the system uses polygon mirrors, which rotate at high speeds to direct laser beams across a surface. This mechanism enables rapid scanning and ensures accurate data collection. The system also incorporates polygon segmentation, a technique that divides images into smaller, manageable regions. This segmentation allows the system to focus on specific areas, improving the accuracy of detection and analysis.

Polygon annotation plays a crucial role in training these systems. By marking objects or regions within an image, developers create datasets that teach the system to recognize patterns. For example, a polygon annotation tool can outline irregular shapes, providing more precise data annotation compared to traditional bounding boxes. This precision is essential for applications requiring detailed analysis, such as quality control in manufacturing or medical imaging.

Tip: Polygon segmentation and annotation are particularly effective in scenarios where objects have complex shapes or overlap with one another.

The Role of Cameras, Sensors, and Algorithms

Cameras, sensors, and algorithms form the backbone of a polygon machine vision system. Each component contributes uniquely to the system's performance. Cameras capture visual data, while sensors measure physical properties like depth or motion. Algorithms process this data, enabling the system to interpret and act on the information.

Different types of cameras enhance the system's capabilities. RGB cameras capture detailed color information, making them ideal for applications requiring high visual fidelity. Event cameras excel in recording rapid changes, such as detecting fast-moving objects. Depth cameras provide 3D geometry, which is crucial for understanding spatial relationships. The combination of these modalities significantly improves imaging quality, even in challenging conditions.

| Camera Type | Contribution to Performance Improvements |

|---|---|

| RGB Cameras | Capture detailed color information, enhancing rendering fidelity. |

| Event Cameras | Record rapid scene changes with microsecond resolution. |

| Depth Cameras | Provide 3D scene geometry, improving structural accuracy. |

| Overall Impact | Fusion of these modalities leads to significant enhancements in imaging quality, especially in challenging conditions. |

Algorithms further refine the system's capabilities. Machine learning models analyze patterns within the data, enabling tasks like object detection and classification. These models rely on annotated datasets, often created using polygon annotation tools, to learn and improve over time. This synergy between hardware and software ensures the system's adaptability across various industries.

The Process of Capturing and Analyzing Visual Data

The process begins with the system capturing images or videos using its cameras. Sensors then collect additional data, such as depth or motion, to complement the visual information. This raw data undergoes preprocessing, where algorithms remove noise and enhance image quality. Polygon segmentation divides the image into smaller regions, allowing the system to focus on specific areas for detailed analysis.

Once segmented, the system applies polygon annotation to identify and label objects within the image. This step is crucial for tasks like object detection, where the system must recognize and classify items accurately. For instance, in manufacturing, the system can detect defects in products by comparing them to predefined standards. In healthcare, it can analyze medical images to identify abnormalities, streamlining diagnostic workflows.

Case studies highlight the efficiency of this process. Zebra Medical Vision, for example, uses polygon machine vision systems to enhance diagnostic accuracy in healthcare. The U.S. Postal Service employs these systems to sort billions of mail items annually, reducing manual labor and increasing processing speed. General OCR applications benefit from automated data extraction, improving efficiency across industries like finance.

| Case Study | Industry | Impact on Efficiency |

|---|---|---|

| Zebra Medical Vision | Healthcare | Streamlined workflows and enhanced diagnostic accuracy, improving patient care. |

| U.S. Postal Service (USPS) | Mail Sorting | Increased processing speed and reduced manual labor, managing billions of items annually. |

| General OCR Applications | Various | Automates data extraction, reduces manual tasks, and improves efficiency across industries like finance. |

This seamless integration of capturing, processing, and analyzing data makes the polygon machine vision system a powerful tool for automation and innovation.

Key Features of Polygon Machine Vision Systems

High-Speed Image Processing

Polygon machine vision systems excel in high-speed image processing. Their ability to handle large volumes of visual data in real time makes them indispensable in industries requiring rapid decision-making. By leveraging polygon segmentation, these systems divide images into smaller regions, enabling faster and more efficient analysis. This approach reduces processing time while maintaining high precision. For example, in manufacturing, the system can quickly detect defects on assembly lines, ensuring smooth operations without delays. The combination of advanced hardware and optimized algorithms ensures that these systems deliver exceptional performance under demanding conditions.

Advanced Pattern Recognition Capabilities

Pattern recognition lies at the heart of polygon machine vision systems. These systems use polygon annotation to train machine learning models, allowing them to identify complex shapes and patterns with remarkable accuracy. Unlike traditional bounding boxes, polygon annotation provides detailed outlines of irregular objects, enhancing detection capabilities. This feature proves invaluable in applications like medical imaging, where precise data annotation can impact diagnostic outcomes. A polygon annotation tool enables developers to create datasets that improve the system's ability to recognize subtle differences, such as distinguishing between healthy and diseased tissue. This advanced capability ensures reliable performance across diverse industries.

Scalability and Adaptability to Different Environments

Polygon machine vision systems adapt seamlessly to various environments, showcasing their scalability. Their versatility stems from the use of polygon segmentation and annotation, which allow them to handle complex scenarios. These systems thrive in:

- Autonomous vehicles, where overlapping or distorted objects require accurate detection.

- Medical imaging, where high precision is critical for diagnosis.

- Agritech, where subtle leaf contours differentiate plant species or diseases.

- Retail AI, where accurate object segmentation enhances augmented reality experiences.

This adaptability ensures consistent performance, regardless of the application or setting. By leveraging polygon annotation and segmentation, these systems maintain accuracy and efficiency, even in challenging conditions.

Integration with AI and Machine Learning

Polygon machine vision systems achieve remarkable precision and adaptability by integrating artificial intelligence (AI) and machine learning (ML). These technologies enhance the system's ability to analyze complex visual data and improve over time.

AI algorithms enable the system to identify patterns, classify objects, and make predictions based on visual inputs. Machine learning models, trained on annotated datasets, allow the system to learn from experience. For example, a system trained with polygon annotations can recognize irregular shapes or overlapping objects with high accuracy. This capability proves essential in industries like healthcare, where detecting subtle abnormalities in medical images can save lives.

Note: Machine learning models rely on high-quality annotated datasets to improve their accuracy. Polygon annotation tools play a critical role in creating these datasets.

The integration of AI and ML also enables real-time decision-making. Systems equipped with neural networks can process visual data instantly, making them ideal for applications requiring speed and precision. Autonomous vehicles benefit from this feature by detecting obstacles and navigating safely. Retail environments use AI-powered systems to track inventory and optimize store layouts.

Key Advantages of AI Integration

- Continuous Improvement: Machine learning models adapt to new data, ensuring the system remains effective in dynamic environments.

- Enhanced Accuracy: AI algorithms reduce errors by analyzing data with precision.

- Scalability: Systems can handle increasing volumes of data without compromising performance.

| Feature | Impact |

|---|---|

| Real-Time Decision-Making | Enables instant responses in critical applications like autonomous driving. |

| Pattern Recognition | Improves detection of complex shapes and overlapping objects. |

| Data Adaptability | Ensures consistent performance across diverse industries. |

AI and ML transform Polygon machine vision systems into intelligent tools capable of driving innovation across multiple sectors. Their integration ensures these systems remain at the forefront of technological advancements.

Benefits of Using a Polygon Machine Vision System

Improved Accuracy and Efficiency in Operations

A polygon machine vision system enhances operational accuracy by leveraging advanced technologies like polygon segmentation and polygon annotation. These systems analyze visual data with precision, enabling machines to detect and classify objects effectively. Unlike traditional methods that rely on bounding boxes, polygon annotation provides detailed outlines of irregular shapes, improving detection accuracy. For example, in manufacturing, these systems can identify defects on production lines faster than human inspectors, ensuring consistent quality control.

Efficiency also improves significantly. High-speed image processing allows these systems to handle large volumes of data in real time. This capability proves invaluable in industries like logistics, where rapid sorting of packages is essential. By automating repetitive tasks, the system reduces processing time and ensures smooth operations. The combination of accuracy and efficiency makes these systems indispensable in modern industries.

Tip: Using a polygon annotation tool to create high-quality datasets can further enhance the system's performance, especially in applications requiring detailed data annotation.

Reduction in Human Error

Polygon machine vision systems minimize human error by automating complex tasks. These systems rely on machine learning algorithms trained with polygon annotation to identify patterns and discrepancies. Automation reduces the need for manual intervention, ensuring consistent and reliable results. For instance, in inventory management, the system uses polygon segmentation to track items accurately, even in cluttered environments.

Several real-world applications highlight this benefit:

- AI enhances demand forecasting by analyzing historical data, optimizing stock levels, and reducing errors.

- Predictive maintenance ensures equipment reliability by identifying potential failures before they occur.

- Real-time inventory tracking improves order fulfillment accuracy by providing up-to-date information.

- Machine learning algorithms detect and correct discrepancies in inventory records, minimizing manual errors.

These capabilities demonstrate how the system reduces errors across various industries, from retail to manufacturing.

Cost-Effectiveness Over Time

While the initial investment in a polygon machine vision system may seem significant, its long-term cost-effectiveness outweighs the upfront expense. Automation reduces labor costs by minimizing the need for manual inspections and repetitive tasks. Additionally, the system's ability to detect defects early prevents costly recalls or rework in manufacturing.

The integration of polygon segmentation and polygon annotation further enhances cost savings. These techniques improve the system's adaptability, allowing it to handle diverse applications without requiring frequent upgrades. For example, a single system can transition seamlessly from inspecting automotive parts to analyzing medical images, maximizing its utility across industries.

Moreover, the system's scalability ensures that it can grow with the business. As data volumes increase, the system maintains its performance without requiring significant additional investment. This adaptability makes it a cost-effective solution for businesses looking to optimize their operations.

Note: Investing in a polygon annotation tool can streamline the creation of training datasets, further reducing development costs and improving the system's efficiency.

Enhanced Decision-Making Through Real-Time Data Analysis

Polygon machine vision systems empower industries with enhanced decision-making capabilities through real-time data analysis. These systems process visual data instantly, providing actionable insights that improve operational outcomes. By leveraging polygon annotation, they achieve unparalleled precision in identifying patterns and anomalies. This accuracy ensures that decisions are based on reliable and up-to-date information.

Real-time data analysis eliminates the reliance on outdated historical data. Instead, it captures dynamic changes as they occur, enabling businesses to respond swiftly to evolving conditions. For example, in commercial real estate, advanced data analytics combined with geospatial intelligence identifies emerging market trends. This approach uncovers hidden patterns, helping investors make informed decisions and gain a competitive edge.

| Evidence Description | Source |

|---|---|

| Advanced data analytics and geospatial intelligence enhance decision-making in commercial real estate through real-time data analysis. | Link |

| Traditional methods rely on outdated historical data, while real-time data captures dynamic market shifts. | Link |

| Combining geospatial data with market trends helps identify upcoming hotspots, providing a competitive edge. | Link |

| Advanced data analytics uncovers hidden patterns, enhancing investment decisions with actionable insights. | Link |

In manufacturing, polygon annotation plays a critical role in detecting defects during production. The system analyzes visual data in real time, ensuring that faulty products are identified and removed before reaching consumers. This process not only improves accuracy but also reduces waste and enhances overall efficiency.

Healthcare also benefits significantly from real-time data analysis. Medical imaging systems equipped with polygon annotation tools can identify abnormalities in scans with exceptional accuracy. This capability allows doctors to make quicker and more precise diagnoses, ultimately improving patient outcomes. For instance, detecting subtle changes in tissue structure becomes easier when the system highlights irregular shapes or patterns.

The integration of polygon annotation with real-time data analysis extends to logistics and supply chain management. These systems track inventory levels and monitor shipments in real time, ensuring that resources are allocated efficiently. By analyzing data as it is generated, businesses can optimize their operations and reduce costs.

Tip: To maximize the benefits of real-time data analysis, businesses should invest in high-quality polygon annotation tools. These tools create detailed datasets that enhance the system's ability to recognize complex patterns and improve decision-making accuracy.

Real-time data analysis transforms decision-making processes across industries. By providing instant insights and improving accuracy, polygon machine vision systems enable organizations to stay ahead in competitive markets. Their ability to adapt to various applications ensures that they remain a valuable asset in driving innovation and efficiency.

Applications of Polygon Machine Vision Systems

Manufacturing and Quality Control

Polygon machine vision systems play a vital role in manufacturing by ensuring precision and efficiency in quality control processes. These systems use polygon segmentation to divide images into smaller regions, enabling detailed analysis of products on assembly lines. By leveraging polygon annotation, they can detect defects in complex shapes that traditional bounding boxes might miss. For example, a system can identify cracks, scratches, or irregularities in automotive parts with remarkable accuracy.

Studies highlight the effectiveness of these systems in monitoring tool wear. One study measured the flank wear of carbide cutting tools with only a 3% error rate compared to a digital microscope. Another study demonstrated how digital image processing accurately assessed tool wear, correlating with expected wear characteristics. These findings underscore the reliability of polygon machine vision systems in industrial settings.

| Study Title | Findings | Error Rate |

|---|---|---|

| Development and application of a machine vision System for measurement of tool wear | The system measures flank wear of carbide cutting tools with an average error of 3% compared to a digital microscope. | 3% |

| Assessment and visualisation of machine tool wear using computer vision | Digital image processing effectively assesses tool wear and correlates with expected wear characteristics. | N/A |

| Use of image processing to monitor tool wear in micro milling | Image processing methods show a 5% difference between predicted and actual worn area, meeting industrial requirements. | 5% |

These systems enhance manufacturing by reducing errors, improving efficiency, and ensuring consistent product quality.

Healthcare and Medical Imaging

In healthcare, polygon machine vision systems revolutionize medical imaging by providing precise data annotation for diagnostic purposes. Polygon annotation allows these systems to outline irregular shapes in medical scans, such as tumors or lesions, with exceptional accuracy. This capability improves detection rates and supports early diagnosis.

Research validates the impact of these systems in medical imaging. A two-step adversarial debiasing approach reduced biases in AI models used for analyzing chest X-rays and mammograms. This method maintained diagnostic performance while addressing fairness across diverse datasets. Additionally, imaging informatics has linked variations in heart shape, derived from MRI scans, to cardiovascular risk factors. These insights demonstrate how polygon machine vision systems contribute to understanding and improving patient health.

Digitized tissue slides further showcase the potential of these systems. They enable detailed analysis of tissue morphology, aiding in the development of biomarkers that predict treatment outcomes. By integrating polygon segmentation and annotation, these systems enhance the accuracy and efficiency of medical imaging workflows.

Automotive and Autonomous Vehicles

Polygon machine vision systems are indispensable in the automotive industry, particularly for autonomous vehicles. These systems rely on polygon annotation to detect and classify objects in real time, ensuring safe navigation. Unlike traditional bounding boxes, polygon annotation provides detailed outlines of overlapping or irregular objects, improving detection accuracy.

Performance metrics highlight the success of these systems. They achieve high accuracy by using Intersection Over Union (IOU) to compare detected results with ground truth. Response times under 90 milliseconds enable real-time control, essential for urban driving. However, challenges like power dissipation and data privacy remain critical considerations.

| Metric | Description |

|---|---|

| Accuracy | Measures the difference between detected results and ground truth, using metrics like Intersection Over Union (IOU). |

| Timeliness | Ensures real-time control, with response times under 90ms for effective vehicle operation at urban speeds. |

| Power | Addresses power dissipation issues, impacting vehicle mileage and overall system performance. |

| Cost | Highlights the high costs associated with level 4 autonomous vehicles, including hardware and operational expenses. |

| Reliability | Focuses on the need for systems to handle failures and ensure safety through reliable performance. |

| Privacy | Discusses the importance of data privacy in capturing and processing sensor data from the environment. |

By integrating polygon segmentation and annotation, these systems enhance the safety, reliability, and efficiency of autonomous vehicles, paving the way for smarter transportation solutions.

Retail and Inventory Management

Polygon machine vision systems have transformed retail operations by streamlining inventory management and enhancing customer satisfaction. These systems utilize advanced object detection models, such as YOLOv8 and YOLOv5, to monitor stock levels and identify empty shelves in real time. By automating these processes, retailers can ensure timely restocking and maintain product availability.

One of the key advantages of these systems lies in their cost-effectiveness. Unlike traditional methods that require additional sensors, polygon machine vision systems rely solely on visual data, reducing operational costs. This approach also minimizes the need for manual labor, allowing employees to focus on more strategic tasks. For instance, YOLOv8 has been used to detect empty shelves, improving operational efficiency and ensuring a seamless shopping experience for customers.

| Key Findings | Implications |

|---|---|

| Utilizes YOLOv8 for real-time detection of empty shelves | Enhances operational efficiency and customer satisfaction |

| Cost-effective solution without additional sensors | Streamlines inventory management and reduces labor costs |

| Automated detection process | Ensures product availability and timely restocking |

In addition, YOLOv5 has proven effective in identifying the stock status of supermarket items. This model evaluates both the precision and speed of item recognition, providing reliable data for inventory management. By preventing oversupply and ensuring accurate stock levels, these systems help retailers optimize their operations and reduce waste.

| Key Findings | Implications |

|---|---|

| YOLOv5 used for identifying stock status of supermarket items | Helps prevent oversupply and manage inventory effectively |

| Model evaluates precision and speed of item recognition | Provides reliable stock information for supermarket managers |

Through these applications, polygon machine vision systems empower retailers to make data-driven decisions, improve efficiency, and enhance the overall shopping experience.

Agriculture and Precision Farming

In agriculture, polygon machine vision systems play a pivotal role in advancing precision farming practices. These systems integrate artificial intelligence (AI) and Internet of Things (IoT) technologies to optimize resource utilization and improve productivity. By automating tasks such as weeding, planting, and harvesting, they reduce labor costs and enhance profitability for farmers.

Research highlights the growing adoption of smart agriculture technologies, particularly among larger farms. Studies by Franco and Balogh reveal that land size significantly influences the adoption rate of these systems. Larger farms benefit from economies of scale, enabling them to implement advanced technologies more effectively. Additionally, younger farmers show a higher willingness to embrace smart agriculture, as noted by Jaafar and Kharroubi.

| Research Study | Findings | Impact on Agriculture |

|---|---|---|

| Franco's Study | Land size positively impacts smart agriculture adoption | Larger farms adopt smart agriculture faster |

| Balogh's Study | Larger farm sizes facilitate faster adoption | Enhanced efficiency in agricultural practices |

| Jaafar and Kharroubi's Study | Younger farmers show higher acceptance of smart agriculture | Increased willingness to adopt new technologies |

| Lachia's Survey | 150 self-guided weeding robots in use | Improved efficiency in weeding processes |

| Rial-Lovera's Interviews | Labor shortage drives development of autonomous machinery | Increased automation in farming operations |

These systems also contribute to sustainable agricultural development. By optimizing resource management, they minimize waste and promote environmentally friendly practices. For example, self-guided weeding robots have improved efficiency in weed control, while AI-powered systems analyze soil and crop conditions to maximize yields. Farmers can now make informed decisions based on real-time data, ensuring better outcomes for both their operations and the environment.

- Improved productivity through automation

- Reduced labor costs due to autonomous machinery

- Enhanced profitability for farmers via efficient resource utilization

- Integration of AI and IoT for precision farming practices

- Sustainable agricultural development through optimized resource management

Polygon machine vision systems continue to revolutionize agriculture by enabling smarter, more efficient farming practices. Their ability to adapt to diverse agricultural applications ensures their relevance in addressing modern farming challenges.

How Does It Compare to Other Machine Vision Systems?

Unique Advantages of the Polygon System

The polygon machine vision system offers several advantages that set it apart from traditional systems. Its use of polygon annotations enables it to achieve higher accuracy in object detection tasks. Unlike bounding box annotations, polygons can outline objects with precision, capturing their exact shapes. This capability allows the system to adapt effectively to transformations such as rotation and scaling. Additionally, polygons excel at managing complex or overlapping shapes, ensuring accurate localization and analysis. These features make the system particularly valuable in applications requiring detailed object recognition, such as medical imaging or autonomous navigation.

- Polygon annotations consistently achieve higher mAP50 values than bounding boxes.

- Polygons accurately represent object shapes, improving adaptability to transformations.

- They enhance localization accuracy and handle complex shapes effectively.

Differences in Technology and Performance

The polygon machine vision system employs advanced segmentation and annotation techniques that distinguish it from other systems. Traditional systems often rely on bounding boxes, which can struggle with irregular or overlapping objects. In contrast, polygon-based systems provide a more granular representation of visual data. This difference significantly improves performance in scenarios where precision is critical. For example, in manufacturing, the system can detect minute defects that might go unnoticed with less detailed methods. Its ability to process high-resolution images quickly also ensures superior performance in time-sensitive environments.

Moreover, the system integrates seamlessly with AI and machine learning technologies. This integration allows it to learn and improve over time, adapting to new challenges and datasets. Other systems may lack this level of adaptability, limiting their effectiveness in dynamic settings.

Why It Stands Out in the Market

The polygon machine vision system stands out due to its unparalleled combination of accuracy, adaptability, and versatility. Its ability to handle complex shapes and transformations makes it a preferred choice for industries with diverse needs. From healthcare to agriculture, its applications span a wide range of sectors, showcasing its flexibility. Furthermore, its integration with AI ensures continuous improvement, keeping it ahead of competitors in terms of innovation.

Businesses also benefit from its cost-effectiveness. While the initial investment may be higher, the system's scalability and efficiency result in long-term savings. Its ability to deliver precise results reduces waste and enhances productivity, making it a valuable asset for organizations aiming to optimize their operations.

The polygon machine vision system represents a groundbreaking advancement in technology. It enables machines to analyze visual data with precision, driving automation and innovation across industries. Its key features, such as high-speed image processing and advanced pattern recognition, enhance efficiency and accuracy. Applications range from manufacturing and healthcare to agriculture and retail, showcasing its versatility. By transforming operations and reducing human error, this system plays a pivotal role in shaping the future of technology.

FAQ

What makes polygon machine vision systems different from traditional systems?

Polygon systems use advanced segmentation and annotation techniques. They outline objects with precision, capturing irregular shapes and overlapping areas. This improves detection accuracy compared to traditional bounding boxes, making them ideal for industries requiring detailed analysis, such as healthcare and manufacturing.

Can polygon machine vision systems work in low-light environments?

Yes, these systems integrate specialized cameras like depth and event cameras. These cameras enhance imaging quality in challenging conditions, including low light. This capability ensures reliable performance across diverse environments, such as warehouses or outdoor settings.

How do polygon machine vision systems improve efficiency?

These systems process large volumes of visual data in real time. High-speed image processing and advanced algorithms reduce manual tasks. For example, they automate defect detection in manufacturing, saving time and ensuring consistent quality.

Are polygon machine vision systems compatible with AI technologies?

Polygon systems seamlessly integrate with AI and machine learning. AI algorithms analyze patterns, while machine learning models improve detection accuracy over time. This combination enables real-time decision-making and adaptability across industries like autonomous vehicles and retail.

What industries benefit the most from polygon machine vision systems?

Industries like manufacturing, healthcare, agriculture, and retail gain significant advantages. These systems enhance quality control, streamline inventory management, optimize farming practices, and improve diagnostic accuracy. Their versatility makes them valuable across diverse applications.

See Also

Understanding Pixel Machine Vision in Today's Technology

An Introduction to Metrology in Machine Vision Systems

A Comprehensive Guide to Image Processing in Machine Vision

Unexpected Insights into Pharmaceutical Machine Vision Systems