What You Need to Know About Prediction Machine Vision Systems

A prediction machine vision system uses advanced algorithms to analyze visual data and anticipate future outcomes. You encounter these systems in industries where precision and efficiency are critical. For example, they ensure manufacturing quality by detecting defects, a sector that held 52.3% of the machine vision market in 2023. Automotive manufacturers also rely on these systems, with 20.5% of the market dedicated to this sector. These systems transform industries by reducing errors, improving safety, and enhancing productivity.

Key Takeaways

- Prediction machine vision systems study images to guess future results. They help industries like factories and healthcare work better and faster.

- These systems use smart programs and data to find mistakes, warn about broken machines, and keep people safe. They are very important for today’s work.

- They check data quickly to watch for changes. This helps fix problems early, saves time, and boosts work output.

- Adding AI and machine learning makes these systems smarter. They can learn from data and give helpful ideas in many fields.

- Even with their good points, problems like bad data, high costs, and fairness issues need solving to use them well.

Understanding Prediction Machine Vision Systems

What Is a Prediction Machine Vision System?

A prediction machine vision system is a technology that combines computer vision with predictive algorithms to analyze visual data and anticipate outcomes. Unlike traditional systems that only process and interpret images, these systems go a step further by forecasting future events or trends based on the visual input. For example, they can predict equipment failures in manufacturing by analyzing subtle changes in machine behavior captured through images.

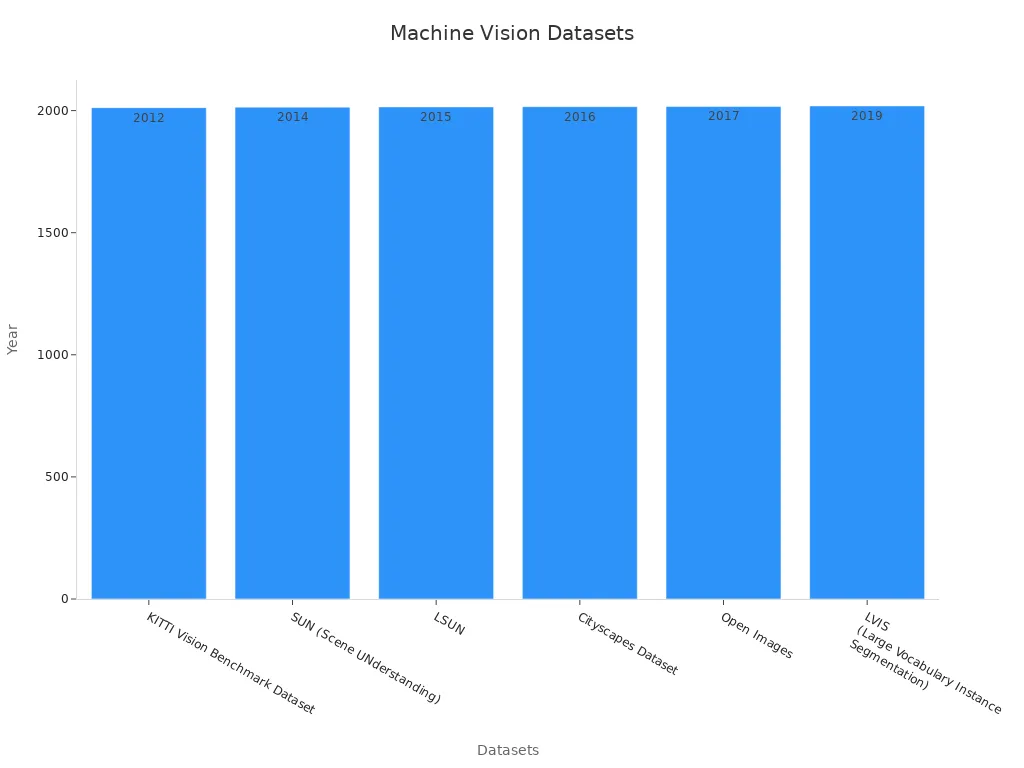

These systems rely on datasets to train their algorithms. Some of the most widely used datasets include SUN, LSUN, and Open Images. These datasets provide labeled images for tasks like object recognition, image classification, and image segmentation. Here's a quick overview of some key datasets:

| Dataset Name | Description | Size | Type | Applications | Year | Authors |

|---|---|---|---|---|---|---|

| SUN (Scene UNderstanding) | Large database for scene and object recognition. | 131,067 images | Images, text | Object recognition, scene recognition | 2014 | J. Xiao et al. |

| LSUN (Large SUN) | Contains scene and object categories with labeled images. | ~60 million images | Images, text | Object recognition, scene recognition | 2015 | Yu et al. |

| Open Images | Large set of images with labels and bounding boxes. | 9,178,275 images | Images, text | Classification, object recognition | 2017 (V7: 2022) | N/A |

| Cityscapes Dataset | Pixel-level annotations in street scenes for autonomous vehicles. | 25,000 images | Images, text | Classification, object detection | 2016 | Daimler AG et al. |

| KITTI Vision Benchmark | Captures data for autonomous vehicles using cameras and laser scanners. | >100 GB of data | Images, text | Classification, object detection | 2012 | A. Geiger et al. |

These datasets form the backbone of prediction machine vision systems, enabling them to learn and improve their capabilities over time.

Key Features and Capabilities

Prediction machine vision systems stand out due to their advanced features. They excel in tasks like image classification, object detection, and object tracking. These systems use computer vision to analyze images and extract meaningful patterns. For instance, they can classify objects in a scene, detect anomalies, and track moving objects in real time.

Performance metrics validate their effectiveness. Metrics like accuracy, precision, recall, and F1 score measure how well these systems perform. Here's a breakdown of these metrics:

| Metric | Description |

|---|---|

| Accuracy | Percentage of correctly classified objects out of total inspected parts. |

| Precision | Measures the accuracy of positive predictions made by the classifier. |

| Recall | Measures the ability to identify all instances of a particular class. |

| F1 Score | Combines precision and recall into a single score, indicating overall performance. |

Recent advancements have further enhanced these systems. Event-based vision systems, for example, mimic human vision by capturing changes in a scene. This approach reduces processing requirements and improves precision. Additionally, innovations in lighting technology and faster cameras have made these systems more efficient, especially in industrial applications.

How It Differs from Traditional Machine Vision

Traditional machine vision systems focus on interpreting visual data without making predictions. They perform tasks like image recognition and object detection but lack the ability to forecast future events. Prediction machine vision systems, on the other hand, integrate computer vision with artificial intelligence to anticipate outcomes.

For example, traditional systems might identify a defect in a product, while prediction systems can forecast when a machine is likely to produce defective items. This predictive capability allows you to take proactive measures, reducing downtime and improving efficiency.

Another key difference lies in how these systems process data. Prediction systems often use event-based vision, which captures dynamic changes in a scene. This approach reveals details that traditional methods might overlook, such as subtle vibrations in machinery. By leveraging these insights, prediction systems enable advanced applications like predictive maintenance and real-time monitoring.

These differences highlight the transformative potential of prediction machine vision systems. They not only analyze the present but also provide actionable insights for the future.

The Role of Computer Vision in Prediction Systems

How Computer Vision Powers Prediction

Computer vision plays a crucial role in prediction systems by enabling machines to analyze and interpret images. These systems extract patterns and insights from visual data, which helps predict future events. For instance, in crime forecasting, deep neural networks (DNNs) have been used to predict crimes in cities like Chicago and Portland. These systems achieved accuracies of 75.6% and 65.3%, respectively, by analyzing not only crime data but also weather and transportation information. This demonstrates how computer vision enhances prediction accuracy across diverse scenarios.

In healthcare, video analysis combined with clinical data has been used to predict hospital admissions. By analyzing short video clips of patients, these systems outperform traditional models, showcasing the transformative potential of computer vision in medical prediction systems. These examples highlight how computer vision powers motion prediction and other forecasting tasks, making it an indispensable tool in modern industries.

Integration of AI and Machine Learning

The integration of artificial intelligence and machine learning amplifies the capabilities of prediction systems. Machine learning algorithms automate data collection and improve predictive accuracy. Neural networks identify complex patterns in visual data, while deep learning processes vast amounts of unstructured data to generate actionable insights. For example, natural language processing (NLP) can analyze text-based data, providing insights into customer sentiment and emerging trends.

AI also automates the integration of data from various sources, creating unified datasets for better analysis. This synergy between computer vision, AI, and machine learning enables systems to perform advanced tasks like motion recognition and prediction with remarkable precision. By leveraging these technologies, you can unlock new possibilities in fields ranging from manufacturing to urban mobility.

Examples of Computer Vision in Action

Real-world applications of computer vision demonstrate its versatility and impact. In manufacturing, Darwin Edge developed a system trained on over 5,000 images to detect defects in real time, reducing manual inspection time. Similarly, BMW uses AI-driven image recognition to spot assembly issues, ensuring quality and reducing repetitive tasks.

In construction, Shawmut Design and Construction employs AI to monitor job site safety and predict incidents. This approach has improved compliance and safety, especially during the COVID-19 pandemic. In urban mobility, Viso.ai’s Automatic Number Plate Recognition system enhances traffic management and security. These examples illustrate how computer vision drives innovation across industries, from motion prediction in transportation to real-time defect detection in manufacturing.

Dynamic Machine Vision and Motion Recognition

What Is Dynamic Machine Vision?

Dynamic machine vision refers to a cutting-edge technology that processes visual data in motion. Unlike static systems, it captures and analyzes dynamic changes in real-time, enabling machines to interpret and respond to moving objects or environments. This approach relies on advanced tools like the dynamic vision reservoir, which mimics the human brain's ability to process visual stimuli. By combining retinomorphic photomemristor-reservoir computing with dynamic data processing, these systems achieve remarkable accuracy in motion prediction tasks.

Dynamic machine vision systems have evolved significantly. Early versions struggled with poor image quality and required controlled conditions. Today, advancements in hardware, such as 3D imaging and edge-cloud integration, and software, like convolutional neural networks (CNNs), have made these systems more adaptable and efficient. They now excel in diverse environments, from manufacturing floors to autonomous vehicles.

| Aspect | Description |

|---|---|

| Machine Vision Definition | Application of computer vision in manufacturing to detect visual cues and infer actionable insights. |

| Automation Intelligence | Utilizes operational cues, including vision-based insights, to optimize production and alert operators. |

| Historical Challenges | Early machine vision faced issues like poor image quality and required controlled conditions, limiting adaptability. |

| Software Advancements | Deep learning has enabled sophisticated vision systems capable of handling diverse manufacturing conditions, including CNNs for complex feature recognition. |

| Hardware Advancements | Innovations like 3D imaging and edge-cloud integration enhance the capabilities and efficiency of machine vision systems. |

| Barriers to Overcome | Challenges include disparate systems, the need for new skills, and managing increased data volume. |

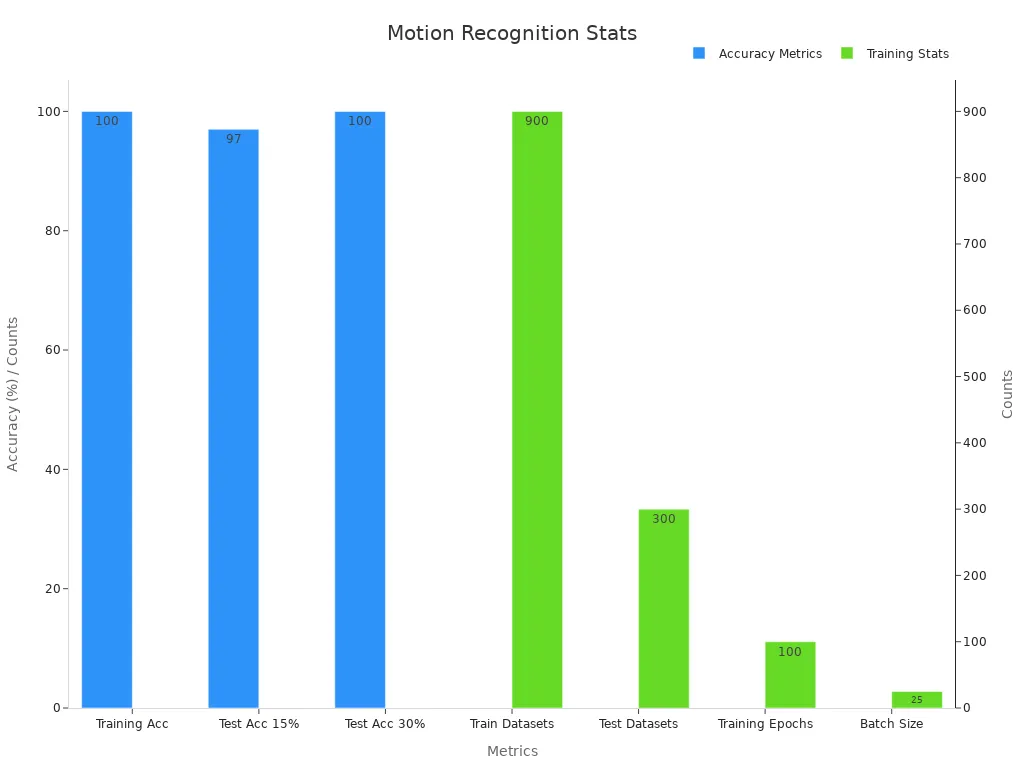

Motion Recognition and Prediction in Real-Time

Motion recognition and prediction in real-time allow machines to detect and anticipate movements with precision. These systems use the dynamic vision reservoir to analyze motion patterns and predict future actions. For example, in sports, they monitor player movements to provide tactical insights. In manufacturing, they predict equipment failures by identifying subtle vibrations.

Real-time performance metrics validate the effectiveness of these systems. Spikes in the DMD spectrum indicate successful motion detection and recognition. Receiver operating characteristic curves assess the balance between true positive and false positive rates. Optimizing detection thresholds minimizes errors, ensuring reliable motion prediction.

| Metric | Value |

|---|---|

| Training Accuracy | 100% |

| Test Accuracy (15% noise) | 97% |

| Test Accuracy (30% noise) | 100% |

| Datasets for Training | 900 |

| Datasets for Testing | 300 |

| Training Epochs | 100 |

| Batch Size | 25 |

Applications of Dynamic Machine Vision

Dynamic machine vision has diverse applications across industries. In healthcare, it analyzes medical imaging to detect anomalies, improving diagnosis accuracy. In agriculture, it uses drone imagery to monitor crop health and optimize resources. Manufacturing benefits from quality control and automation, enhancing production efficiency.

Other applications include:

- Augmented reality for gaming and retail.

- Spatial analysis for urban planning and logistics.

- Face recognition for security and authentication.

- Sports performance analysis and tactical planning.

This technology also enhances real-time perception in autonomous vehicles, ensuring safety and efficiency. By leveraging retinomorphic photomemristor-reservoir computing, dynamic vision recognition systems continue to revolutionize industries.

Applications of Prediction Machine Vision Systems

Manufacturing and Quality Control

Prediction machine vision systems have revolutionized manufacturing by enhancing quality control processes. These systems analyze images of products in real time to detect defects, ensuring that only high-quality items reach the market. Unlike human inspectors, who may miss subtle flaws due to fatigue, these systems maintain consistent accuracy. They also operate at speeds that far exceed manual inspection, reducing production time and increasing efficiency.

For example, a prediction machine vision system can identify surface imperfections on a car part or detect misaligned components on an assembly line. By automating these tasks, you can eliminate human error and optimize resource use. The benefits of these systems in quality control are well-documented:

| Quality Control Benefit | Description |

|---|---|

| Improved Accuracy | Provides enhanced precision in detecting defects compared to human inspectors. |

| Increased Speed | Allows for faster inspection processes, reducing production time. |

| Enhanced Efficiency | Streamlines quality control, minimizing waste and optimizing resource use. |

| Elimination of Human Error | Reduces the likelihood of mistakes caused by fatigue or oversight. |

| Cost Savings | Contributes to significant cost reductions by reducing waste and improving efficiency. |

By leveraging computer vision applications, you can achieve unparalleled precision and efficiency in manufacturing. These systems not only improve product quality but also reduce operational costs, making them an essential tool for modern industries.

Healthcare and Medical Imaging

In healthcare, prediction machine vision systems play a critical role in medical imaging. These systems analyze medical images, such as X-rays, MRIs, and CT scans, to detect anomalies and predict potential health issues. By combining artificial intelligence with machine learning, they can identify patterns that may not be visible to the human eye.

For instance, a system trained on thousands of medical images can predict the likelihood of a tumor being malignant. This early detection capability allows doctors to intervene sooner, improving patient outcomes. Clinical performance metrics highlight the effectiveness of these systems:

| Metric | Description |

|---|---|

| Accuracy | Measures the proportion of correct predictions over total predictions. |

| Precision | Focuses on the proportion of true positive predictions among all positive predictions. |

| Recall (Sensitivity) | Measures the proportion of true positive predictions among all actual positives. |

| Dice-Sørensen Coefficient | Combines precision and recall into a single metric, useful for assessing overlap in predictions. |

| Jaccard Index (IoU) | Measures the overlap between predicted and actual values, penalizing small errors more than Dice. |

| Hausdorff Distance | Measures the maximum distance between the predicted and actual values, focusing on worst-case scenarios. |

These metrics demonstrate how prediction systems enhance diagnostic accuracy and reliability. By integrating motion prediction capabilities, these systems can also analyze video data, such as monitoring a patient’s movements to predict falls or other risks. This makes them invaluable in both diagnostics and preventive care.

Autonomous Vehicles and Transportation

Prediction machine vision systems are at the heart of self-driving technology, enabling autonomous vehicles to navigate safely and efficiently. These systems process images from cameras and sensors to recognize objects, predict motion, and make real-time decisions. For example, they can anticipate the movement of pedestrians or other vehicles, allowing the car to react accordingly.

The benefits of these systems extend beyond safety. By optimizing driving patterns and route planning, they improve traffic flow and reduce congestion in urban areas. This contributes to a more intelligent transport system, enhancing the overall travel experience. Key statistics highlight their impact:

| Benefit | Description |

|---|---|

| Enhanced Road Safety | Anticipates potential risks and reacts accordingly, significantly improving overall safety. |

| Improved Traffic Flow | Optimizes driving patterns and route planning, reducing congestion in urban areas. |

| Superior Passenger Experience | Provides a safer, more comfortable, and predictable travel experience for passengers. |

By combining artificial intelligence with motion prediction, these systems transform transportation. They not only make roads safer but also pave the way for a future where intelligent transport systems are the norm.

Security, Surveillance, and Retail Insights

Prediction machine vision systems are transforming security, surveillance, and retail industries by providing advanced tools for monitoring, analysis, and decision-making. These systems use visual data to predict behaviors, detect anomalies, and optimize operations, making them indispensable in modern environments.

Enhancing Security and Surveillance

You can use prediction machine vision systems to improve security and surveillance by identifying threats before they escalate. These systems analyze video feeds in real time, detecting unusual activities or patterns that might indicate risks. For example, they can recognize suspicious movements in crowded areas or detect unauthorized access in restricted zones.

Key features include:

- Behavior Analysis: Systems monitor individuals' movements to identify potential threats.

- Facial Recognition: Advanced algorithms match faces against databases to flag unauthorized personnel.

- Anomaly Detection: Systems identify irregular patterns, such as abandoned objects or unusual crowd behavior.

Tip: Deploying these systems in public spaces, such as airports or stadiums, can significantly enhance safety by providing early warnings of potential incidents.

Revolutionizing Retail Insights

In retail, prediction machine vision systems help you understand customer behavior and optimize store operations. These systems analyze foot traffic, monitor shelf inventory, and even predict purchasing trends. By leveraging this data, you can improve customer experiences and boost sales.

Here’s how they make an impact:

- Customer Behavior Analysis: Systems track shoppers' movements to identify popular areas and products.

- Inventory Management: Cameras monitor shelves to detect low stock levels and trigger restocking alerts.

- Personalized Marketing: Systems predict customer preferences, enabling targeted promotions and advertisements.

🛍️ Example: Imagine a clothing store using prediction systems to analyze which sections attract the most customers. This data helps you rearrange displays to maximize engagement and sales.

Benefits Across Both Industries

The advantages of prediction machine vision systems extend beyond their immediate applications. They offer:

- Improved Efficiency: Automating tasks like monitoring and analysis reduces manual effort.

- Cost Savings: Early detection of issues minimizes losses and operational costs.

- Enhanced Decision-Making: Predictive insights enable you to make informed choices quickly.

| Industry | Application | Benefit |

|---|---|---|

| Security | Threat detection | Prevents incidents proactively |

| Surveillance | Anomaly recognition | Improves situational awareness |

| Retail | Customer behavior analysis | Boosts sales and customer satisfaction |

By integrating prediction machine vision systems into your operations, you can unlock new levels of efficiency and accuracy. Whether you aim to enhance security or optimize retail strategies, these systems provide the tools you need to stay ahead in a competitive landscape.

Challenges and Limitations

Data Quality and Bias in Predictions

The success of prediction machine vision systems depends heavily on the quality of the data they process. Poor data quality can lead to flawed predictions, which may undermine the reliability of these systems. For example, if the training data contains errors or inconsistencies, the system might misinterpret visual inputs. This can result in inaccurate forecasts or missed anomalies.

Note: Low-quality data can hinder the deployment of AI and machine learning projects, making it essential to ensure clean and well-labeled datasets.

Bias in data also poses a significant challenge. If the training data reflects societal biases, the system may replicate these biases in its predictions. For instance, a facial recognition system trained on a dataset lacking diversity might struggle to identify individuals from underrepresented groups. To address this, you should prioritize diverse and balanced datasets during the training phase.

Infrastructure and Computational Demands

Prediction machine vision systems require robust infrastructure to handle their computational needs. Multi-modal learning systems, which process data from various sources like images, videos, and sensors, demand significant resources. The complexity increases when these systems must fuse large volumes of data from different formats.

- Missing or incomplete data can reduce system performance.

- Misaligned data from multiple sources may cause errors, requiring advanced alignment techniques.

- Efficient representation of diverse data types is critical to manage these challenges.

Processing such data often requires high-performance hardware, such as GPUs or TPUs, which can be costly. Additionally, maintaining the infrastructure to support these systems may strain organizational budgets.

Ethical and Privacy Concerns

Ethical and privacy issues are critical when deploying prediction machine vision systems. These systems often process sensitive data, such as facial images or medical records. Without proper safeguards, this data could be misused or exposed to unauthorized access.

Tip: Implementing strong encryption and anonymization techniques can help protect user privacy while maintaining system functionality.

Ethical concerns also arise when these systems are used for surveillance. For example, using facial recognition in public spaces may infringe on individuals' rights to privacy. To mitigate these risks, you should establish clear guidelines and ensure compliance with data protection laws. Balancing innovation with ethical responsibility is key to building trust in these technologies.

Overcoming Integration Barriers

Integrating prediction machine vision systems into your existing workflows can feel overwhelming. These systems often require significant changes to infrastructure, processes, and skill sets. However, understanding the common barriers and how to address them can simplify the process.

1. Compatibility with Legacy Systems

Many organizations rely on older systems that may not support modern machine vision technologies. This incompatibility can slow down integration efforts. To overcome this, you should:

- Invest in Middleware: Middleware acts as a bridge between old and new systems, ensuring smooth communication.

- Adopt Modular Solutions: Modular systems allow you to upgrade components gradually without overhauling the entire setup.

Tip: Start with a pilot project to test compatibility before scaling up.

2. Skill Gaps in the Workforce

Prediction machine vision systems require specialized knowledge in AI, machine learning, and data analysis. If your team lacks these skills, integration may stall. Address this by:

- Providing Training: Offer workshops or online courses to upskill your team.

- Hiring Experts: Bring in professionals with experience in machine vision to guide the process.

3. High Initial Costs

The upfront investment in hardware, software, and training can seem daunting. To manage costs effectively:

- Leverage Cloud-Based Solutions: Cloud platforms reduce the need for expensive on-site hardware.

- Seek Grants or Partnerships: Many governments and organizations offer funding for AI-driven projects.

| Barrier | Solution |

|---|---|

| Legacy System Incompatibility | Use middleware or modular systems |

| Workforce Skill Gaps | Provide training or hire experts |

| High Initial Costs | Opt for cloud solutions or grants |

Note: Breaking the integration process into smaller, manageable phases can help you reduce risks and costs.

By addressing these barriers strategically, you can unlock the full potential of prediction machine vision systems without disrupting your operations.

The Future of Prediction Machine Vision Systems

Emerging Trends in Dynamic Machine Vision

Dynamic machine vision continues to evolve with groundbreaking innovations. Event-based imaging, inspired by biological systems, processes changes in light intensity asynchronously. This approach focuses only on changes in a scene, making image processing faster and more efficient. For example, it allows machines to detect subtle movements or shifts in real time, which is crucial for applications like robotics and autonomous vehicles.

Another trend is the rise of industrial streaming cameras. These devices integrate seamlessly into Industry 4.0 environments, enabling smarter and more interconnected systems. By combining these cameras with artificial intelligence and deep learning, you can achieve advanced image analysis and automation. These trends highlight how dynamic machine vision is becoming more adaptable and intelligent, paving the way for new possibilities in industries like manufacturing and healthcare.

- AI and machine learning enhance image analysis, enabling systems to learn and adapt without extensive reprogramming.

- 3D vision systems provide detailed depth information, essential for precise measurements.

- Edge computing reduces latency by processing data in real time, improving decision-making.

- Advanced software solutions simplify setup and management, making these systems more user-friendly.

Advancements in Hardware and Software

Hardware and software advancements are driving the capabilities of prediction machine vision systems to new heights. Modern hardware, such as high-resolution cameras and edge computing devices, allows you to process data faster and more accurately. For instance, 3D imaging systems now capture depth information with remarkable precision, which is vital for tasks like quality control and object tracking.

On the software side, deep learning algorithms have revolutionized computer vision. These algorithms analyze complex patterns in images, enabling systems to perform tasks like motion prediction and anomaly detection. Additionally, user-friendly interfaces make it easier for you to set up and manage these systems, even without extensive technical expertise. Together, these advancements ensure that prediction machine vision systems remain at the forefront of technological innovation.

Broader Adoption Across Industries

Prediction machine vision systems are finding applications in a growing number of industries. Non-automotive sectors now lead in adoption, with areas like precision agriculture and logistics seeing significant growth. In agriculture, these systems automate tasks such as weeding and fertilizer application, improving efficiency and reducing costs. In logistics, they enhance package tracking and volumetric analysis, streamlining operations.

Statistical forecasts also point to rapid market growth. The machine vision market, valued at USD 11.8 billion in 2022, is expected to reach USD 21.0 billion by 2030, with a compound annual growth rate (CAGR) of 7.5%. Similarly, the 3D machine vision market shows strong potential for expansion. These trends indicate that as technology advances, you can expect broader adoption of computer vision systems across diverse industries.

| Market Segment | Value (2022) | Forecast (2030) | CAGR (2023-2030) |

|---|---|---|---|

| Machine Vision Market | USD 11.8 billion | USD 21.0 billion | 7.5% |

By embracing these systems, industries can unlock new levels of efficiency, accuracy, and innovation.

Prediction machine vision systems combine computer vision and AI to analyze visual data and forecast outcomes. You’ve seen how these systems improve efficiency, accuracy, and safety across industries like healthcare, manufacturing, and transportation. Their ability to predict future events makes them invaluable for solving complex problems.

These systems don’t just interpret the present—they shape the future. By adopting them, you can unlock innovation and drive progress in your field. As technology advances, expect broader adoption and even greater impact across industries.

FAQ

What industries benefit the most from prediction machine vision systems?

Prediction machine vision systems benefit industries like manufacturing, healthcare, transportation, and security. They improve efficiency, reduce errors, and enhance safety. For example, they detect defects in manufacturing, analyze medical images in healthcare, and predict motion in autonomous vehicles.

How do prediction machine vision systems handle real-time data?

These systems use advanced algorithms and hardware to process visual data instantly. They analyze motion patterns, detect anomalies, and predict outcomes. Edge computing reduces latency, enabling faster decision-making in applications like autonomous driving and surveillance.

Are prediction machine vision systems expensive to implement?

Initial costs can be high due to hardware and software requirements. However, cloud-based solutions and modular systems reduce expenses. Over time, these systems save money by improving efficiency, reducing waste, and minimizing errors.

Can prediction machine vision systems work in low-light environments?

Yes, many systems use specialized cameras and lighting technologies to operate in low-light conditions. Event-based vision systems focus on changes in light intensity, making them effective for tasks like surveillance and autonomous navigation.

What challenges should you expect when integrating these systems?

You may face compatibility issues with older systems, skill gaps in your workforce, and high initial costs. Address these challenges by investing in middleware, providing training, and exploring cloud-based solutions to reduce expenses.

See Also

Understanding Predictive Maintenance Through Machine Vision Technology

Essential Insights on Computer Vision and Machine Vision Systems

An Overview of Image Processing in Machine Vision Systems

Exploring Computer Vision Models Within Machine Vision Systems