A Beginner’s Guide to Predictive Maintenance Machine Vision Systems

A predictive maintenance machine vision system uses advanced technologies like cameras and sensors to monitor equipment and predict failures before they happen. This approach has revolutionized modern industries by making maintenance smarter and more efficient. You can reduce repair costs, increase uptime, and extend equipment life using predictive tools.

In fact, predictive maintenance can lower maintenance costs by up to 30% and increase equipment uptime by 20–30%. Many companies, including those in the automotive sector, have saved millions annually while reducing downtime. Adopting these systems not only minimizes waste but also uncovers new improvement opportunities, enhancing overall productivity.

Key Takeaways

- Predictive maintenance systems use cameras and sensors to check machines.

- These systems can cut maintenance costs by 30% and boost uptime by 20-30%.

- They collect data and use AI to fix problems early.

- This helps avoid sudden breakdowns and makes machines last longer.

- Factories, energy plants, and hospitals use these systems to work safely.

- Begin with important areas, then grow as you save money and see results.

What Is a Predictive Maintenance Machine Vision System?

Definition and Key Features

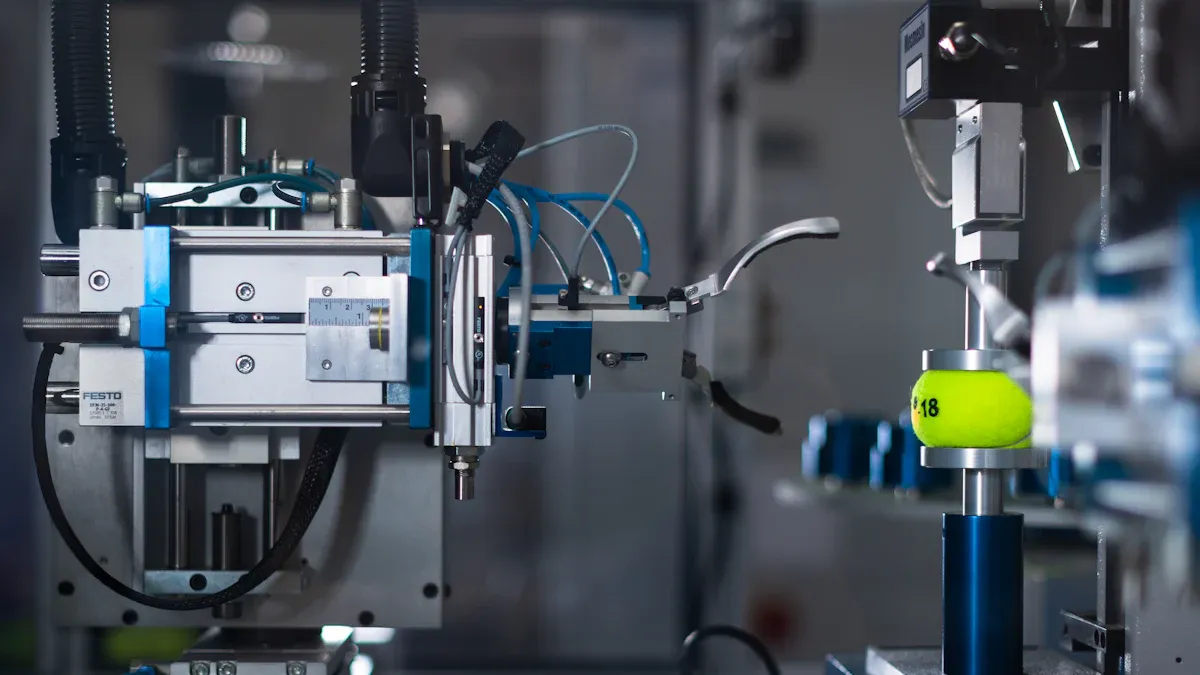

A predictive maintenance machine vision system combines advanced imaging technologies with artificial intelligence to monitor equipment and predict potential failures. These systems use cameras and sensors to capture real-time data about the condition of machines. By analyzing this data, they can identify patterns and detect early signs of wear or damage.

One of the standout features of these systems is their ability to perform visual inspections without human intervention. They can detect anomalies, such as cracks, misalignments, or overheating, that might go unnoticed during manual checks. This capability provides a more comprehensive understanding of equipment health. Additionally, machine vision systems operate continuously, ensuring that no critical issue is missed.

Another key feature is their integration with predictive maintenance technologies like IoT sensors and AI algorithms. These tools work together to process large volumes of data quickly and accurately. As a result, you can make informed decisions about when to perform maintenance, avoiding unnecessary repairs or unexpected breakdowns.

Importance in Modern Industries

Predictive maintenance machine vision systems play a vital role in today’s industries. They help businesses reduce downtime, improve efficiency, and extend the lifespan of their equipment. For example, in manufacturing, these systems ensure that production lines run smoothly by identifying potential issues before they escalate. This proactive approach minimizes disruptions and keeps operations on track.

Industries like energy, transportation, and healthcare also benefit from these systems. In energy plants, they monitor turbines and other critical machinery to prevent costly failures. In transportation, they inspect vehicles and infrastructure to ensure safety and reliability. In healthcare, they help maintain medical equipment, ensuring that devices like MRI machines function correctly.

The integration of computer vision enhances predictive maintenance capabilities across all these sectors. By automating inspections, machine vision systems reduce the need for manual labor and improve accuracy. They also provide valuable insights into equipment performance, enabling you to optimize operations and allocate resources more effectively.

Tip: Adopting predictive maintenance machine vision systems can save your business time and money while boosting productivity. Start small by implementing them in high-priority areas and expand as you see results.

How Predictive Maintenance Machine Vision Systems Work

Predictive Maintenance Technologies (IoT Sensors, AI, Digital Twins)

Predictive maintenance technologies combine cutting-edge tools like IoT sensors, artificial intelligence (AI), and digital twins to revolutionize how you monitor and maintain equipment. These technologies work together to provide real-time monitoring and accurate failure prediction, ensuring your machines stay operational and efficient.

- IoT Sensors: These sensors collect real-time data from equipment, such as temperature, vibration, and pressure. They act as the eyes and ears of your predictive maintenance system, continuously tracking the condition of your machines.

- AI: AI algorithms analyze the data collected by IoT sensors. They identify patterns, predict potential failures, and optimize maintenance schedules. This ensures you can address issues before they escalate.

- Digital Twins: A digital twin is a virtual replica of a physical asset. It allows you to simulate real-time performance and assess the health of your equipment. By using digital twins, you can test maintenance strategies and predict outcomes without disrupting operations.

These technologies enhance predictive maintenance capabilities by providing actionable insights and enabling proactive decision-making. For example, AI-powered predictive maintenance systems can reduce downtime by up to 50% and save millions annually in industries like automotive and manufacturing.

Data Collection and Analysis

Data collection and analysis form the backbone of any predictive maintenance machine vision system. The process involves gathering critical information about your equipment and using advanced techniques to interpret it.

| Key Steps in Data Collection | Description |

|---|---|

| Identification of Critical Data Points and Sensors | Identify relevant data points like temperature, vibration, and pressure for equipment health. |

| Statistical Analysis | Use statistical techniques to summarize data, identify patterns, and establish performance baselines. |

| Data Quality | Ensure data is accurate, complete, and timely for reliable predictions and reduced false alarms. |

Once the data is collected, AI algorithms process it to detect anomalies and predict failures. Techniques like cost-sensitive learning and ensemble learning improve prediction accuracy, especially for rare events. By ensuring high-quality data, you can minimize false alarms and make confident maintenance decisions.

Real-time monitoring plays a crucial role in this process. It allows you to track equipment performance continuously and respond to issues as they arise. This approach not only prevents unexpected breakdowns but also extends the lifespan of your machines.

Role of AI in Predictive Maintenance

AI in predictive maintenance is a game-changer. It enables you to analyze vast amounts of data quickly and accurately, making it easier to predict failures and optimize maintenance schedules.

AI algorithms excel at identifying patterns and trends that might go unnoticed during manual inspections. For instance, they can detect subtle changes in vibration or temperature that indicate potential issues. By addressing these problems early, you can avoid costly repairs and downtime.

The impact of AI in predictive maintenance is supported by impressive statistics:

| Impact Area | Numerical Evidence |

|---|---|

| Potential downtime reductions | 30-50% |

| Maintenance cost savings | 15-30% |

| Increase in equipment uptime | 20-30% |

| Annual savings in automotive | $20 million |

| Reduction in downtime in automotive | 15% |

| Cost savings compared to preventive | 8% to 12% |

| Cost savings compared to reactive | up to 40% |

AI-powered predictive maintenance systems also improve scalability. As your operations grow, these systems can handle larger datasets and more complex analyses without compromising accuracy. This makes them an invaluable tool for businesses looking to stay competitive in today’s fast-paced industries.

Note: By leveraging AI in predictive maintenance, you can transform your approach to equipment management. Start by integrating AI algorithms into your existing systems and gradually expand their use as you see results.

Benefits of Predictive Maintenance Machine Vision Systems

Cost Savings and Downtime Reduction

Predictive maintenance machine vision systems help you save money and reduce unplanned downtime. By identifying issues early, these systems prevent costly repairs and production delays. For example, industries lose an estimated $50 billion annually due to unplanned downtime. Poor maintenance can lower productive capacity by up to 20%.

Machine vision systems streamline inspections, allowing you to detect machine failure before it disrupts operations. A global automaker reduced inspection time for welding robots by 70% and improved welding quality by 10%. Another manufacturer saved millions by implementing AI across 10,000 machines, achieving a return on investment within three months.

These systems also optimize your predictive maintenance strategy. Real-time monitoring ensures you address problems as they arise, keeping your equipment running smoothly. By reducing downtime, you can increase uptime and maintain consistent production schedules.

Enhanced Safety and Efficiency

Predictive maintenance methodologies improve safety and operational efficiency. Machine vision systems automatically monitor equipment health, reducing the risk of accidents caused by machine failure. They also extend equipment lifespan by addressing wear and tear early.

Real-time data analysis enhances efficiency by minimizing unexpected breakdowns. For instance, predictive maintenance systems achieved over $1 million in production gains per site and provided a 30-minute prediction window for compressor downtime. With 80% accuracy in predicting failures, these systems ensure proactive actions through automatic notifications to field service teams.

By consistently meeting production targets without interruptions, you can maintain a safer and more reliable workplace. Predictive maintenance methodologies empower you to focus on long-term goals rather than reacting to emergencies.

Scalability and Long-Term Value

Predictive maintenance machine vision systems scale effortlessly as your operations grow. They handle larger datasets and more complex analyses without compromising accuracy. This scalability ensures you can adapt your predictive maintenance strategy to meet evolving business needs.

Case studies highlight the long-term value of these systems. BASF and Schneider Electric implemented EcoStruxure Asset Advisor for remote monitoring and predictive analytics, improving maintenance strategies and reducing unexpected shutdowns. Wärtsilä upgraded its IoT engine to process asset condition data, enhancing reliability and performance while minimizing unplanned downtime.

Machine vision systems also provide lasting benefits by improving equipment reliability and reducing maintenance costs. Their ability to integrate with IoT and AI technologies ensures they remain relevant as industries adopt smarter solutions.

Tip: Start small by applying predictive maintenance methodologies to critical areas. Gradually expand their use to maximize scalability and long-term value.

Applications of Predictive Maintenance Machine Vision Systems

Manufacturing and Automation

Predictive maintenance machine vision systems have transformed manufacturing and automation by enabling real-time monitoring and proactive maintenance. These systems help you identify potential issues in machinery before they cause downtime. For instance, manufacturers use machine vision systems to inspect assembly lines, ensuring that equipment operates efficiently. This approach reduces unplanned downtime and improves productivity.

A notable example is General Motors, which implemented IoT sensors and AI to monitor assembly line robots. This initiative reduced unexpected downtime by 15%, saving $20 million annually. Similarly, an automobile manufacturer integrated FAT FINGER’s workflows into its production lines, decreasing breakdowns and boosting productivity. These success stories highlight the value of predictive maintenance in manufacturing.

Additionally, 72% of manufacturing organizations have adopted Industry 4.0 technologies, with predictive maintenance being a leading application. These systems enhance operational efficiency and minimize errors, making them indispensable for modern factories.

Energy and Utilities

In the energy and utilities sector, predictive maintenance machine vision systems ensure the reliability of critical infrastructure. They monitor turbines, generators, and pipelines in real-time, preventing costly failures and optimizing performance. Studies show that predictive maintenance delivers an ROI of 10:1, meaning you gain $10 in benefits for every $1 invested.

For example, predictive maintenance has led to a 20% reduction in maintenance costs and a 15% increase in turbine availability. Solar energy systems have seen a 10% improvement in energy output and a 25% reduction in maintenance costs. These systems also reduce unplanned downtime by 30% and improve overall plant efficiency by 20%. By adopting predictive maintenance, you can achieve significant cost savings and enhance energy output.

Transportation and Logistics

Predictive maintenance machine vision systems play a crucial role in transportation and logistics by improving safety and reducing downtime. These systems monitor vehicles, trains, and infrastructure in real-time, identifying potential issues before they escalate. This proactive approach enhances operational reliability and ensures timely deliveries.

Key performance indicators in this sector include incident detection times, alert accuracy, and intervention time reduction. For example, predictive maintenance minimizes unplanned downtime, extends the lifespan of assets, and improves vehicle safety. Companies that implement these systems report better compliance with safety regulations and fewer mechanical failures.

By leveraging predictive maintenance, you can enhance service levels and maintain a competitive edge in the transportation industry.

Healthcare and Medical Equipment

Predictive maintenance machine vision systems have transformed healthcare by ensuring medical equipment operates reliably. These systems monitor devices like MRI machines, CT scanners, and ventilators in real-time, identifying potential issues before they disrupt patient care. You can use them to prevent costly breakdowns and maintain the accuracy of diagnostic tools.

Key Benefits for Healthcare

- Improved Equipment Reliability: Machine vision systems detect early signs of wear or malfunction, allowing you to address problems before they escalate. This ensures critical devices remain operational during emergencies.

- Enhanced Patient Safety: By reducing the risk of equipment failure, these systems help you provide uninterrupted care. For example, they monitor infusion pumps to ensure medication delivery remains precise.

- Cost Savings: Predictive maintenance minimizes repair costs and extends the lifespan of expensive medical equipment. Hospitals have reported savings of up to 20% on maintenance expenses.

Real-World Applications

| Equipment Type | Predictive Maintenance Impact |

|---|---|

| MRI Machines | Reduced downtime and improved imaging accuracy |

| Ventilators | Continuous monitoring for uninterrupted operation |

| Surgical Robots | Early detection of mechanical issues |

How It Works

Machine vision systems use cameras and sensors to collect data on equipment performance. AI algorithms analyze this data to identify patterns and predict failures. For example, they can detect temperature changes in imaging devices or vibrations in surgical robots. These insights allow you to schedule maintenance at the right time, avoiding disruptions.

Tip: Start by implementing predictive maintenance for high-priority devices like imaging systems. Gradually expand to other equipment as you see results.

By adopting predictive maintenance machine vision systems, you can improve patient outcomes, reduce costs, and ensure your medical equipment remains reliable.

Future of Predictive Maintenance Technologies

Advancements in AI and Machine Vision

AI and machine vision systems are transforming predictive maintenance by enabling smarter and faster decision-making. AI algorithms analyze real-time data from equipment to identify patterns and predict failures before they occur. Machine vision systems enhance this process by providing detailed visual inspections, allowing you to detect subtle issues like cracks or misalignments that might otherwise go unnoticed.

Recent advancements include machine learning models that optimize maintenance schedules and improve equipment reliability. For example, AI-driven systems can forecast failures with high accuracy, ensuring timely interventions. Research highlights how these technologies are being applied in industries like automotive and manufacturing to reduce downtime and enhance operational efficiency.

| Title | Summary |

|---|---|

| AI-Enhanced Predictive Maintenance Systems for Industrial Equipment | Discusses how AI improves predictive maintenance through machine learning models that forecast failures and optimize schedules. |

| A comprehensive review on artificial intelligence driven predictive maintenance in vehicles | Explores AI advancements in vehicle maintenance, highlighting techniques and future directions. |

These innovations are paving the way for machines to conduct self-maintenance, reducing the need for human intervention and making predictive maintenance systems even more efficient.

Integration with IoT and Smart Factories

The integration of IoT sensors and smart factory technologies is revolutionizing predictive maintenance. IoT sensors collect real-time data on equipment conditions, such as temperature and vibration, while centralized data management systems organize this information for analysis. This combination allows you to transition from reactive to predictive maintenance models, improving accuracy and reliability.

Smart factories leverage predictive maintenance to enhance operational efficiency. By connecting machine vision systems with IoT devices, you can monitor equipment performance continuously and address issues proactively. For example, advanced monitoring techniques analyze equipment conditions in real-time, predicting optimal maintenance timings and reducing unexpected downtime.

Future advancements in AI and data analytics will further refine these systems, making them more precise and effective. As industries adopt smarter solutions, predictive maintenance will become an integral part of modern operations.

Expansion Across Industries

Predictive maintenance machine vision systems are expanding rapidly across diverse industries. The global market for predictive maintenance is projected to grow to USD 80.2 billion by 2034, with a compound annual growth rate (CAGR) of 10.9%. In 2023, the market was valued at USD 8.05 billion and is expected to grow at a CAGR of 35.4% during the forecast period.

Industries like manufacturing, energy, transportation, and healthcare are leading the adoption of these systems. Predictive maintenance reduces unexpected downtime by up to 50%, helping businesses save costs and improve efficiency. For example, manufacturers use machine vision systems to monitor assembly lines, while energy plants rely on IoT sensors to optimize turbine performance.

As predictive maintenance technologies continue to evolve, their applications will expand further, driving innovation and efficiency across sectors. By adopting these systems, you can stay ahead of the curve and ensure your operations remain competitive.

Overcoming Adoption Challenges

Adopting predictive maintenance machine vision systems can transform your operations, but challenges often arise during implementation. Understanding these obstacles and addressing them effectively ensures a smoother transition and maximizes the benefits of these systems.

1. High Initial Costs

The upfront investment for predictive maintenance systems, including hardware, software, and training, can seem overwhelming. Many businesses hesitate due to budget constraints.

Tip: Start small by implementing these systems in high-priority areas. Focus on equipment that frequently breaks down or incurs high maintenance costs. Gradually expand as you see results and savings.

2. Complex Integration with Existing Systems

Integrating machine vision systems with legacy equipment and software can be challenging. Compatibility issues may slow down the process or require additional resources.

- Solution: Work with vendors who offer customizable solutions. Choose systems that support open standards and can adapt to your existing infrastructure.

- Pro Tip: Conduct a pilot program to test integration before scaling up.

3. Lack of Skilled Personnel

Operating and maintaining predictive maintenance systems requires specialized skills. Many businesses struggle to find trained professionals or invest in employee training.

Note: Partner with vendors who provide training programs. Upskill your team through workshops and online courses. This ensures your staff can manage the systems effectively.

4. Resistance to Change

Employees may resist adopting new technologies due to fear of job displacement or unfamiliarity. This resistance can hinder successful implementation.

- Action Plan: Communicate the benefits of predictive maintenance clearly. Highlight how it improves efficiency and reduces workload. Involve employees in the adoption process to build trust and confidence.

5. Data Privacy Concerns

Predictive maintenance systems collect vast amounts of data, raising concerns about security and privacy. Businesses worry about unauthorized access or misuse of sensitive information.

Tip: Choose systems with robust cybersecurity measures. Implement encryption, access controls, and regular audits to protect your data.

By addressing these challenges proactively, you can unlock the full potential of predictive maintenance machine vision systems.

Predictive maintenance machine vision systems have revolutionized how industries manage equipment. These systems reduce downtime by up to 50% and cut maintenance costs by 25%, ensuring smoother operations and greater efficiency. By leveraging technologies like AI and IoT, you can predict failures early and optimize maintenance schedules.

| Measurement Type | Value |

|---|---|

| Reduction in operational downtime | 50% |

| Reduction in maintenance expenditures | 25% |

The transformative potential of predictive maintenance lies in its ability to prevent disruptions and improve productivity. Whether in manufacturing, healthcare, or transportation, these systems offer long-term value and scalability. Explore how predictive maintenance machine vision systems can enhance your industry and unlock new opportunities for growth.

FAQ

What industries benefit the most from predictive maintenance machine vision systems?

Industries like manufacturing, energy, healthcare, and transportation gain the most. These systems reduce downtime, improve safety, and optimize equipment performance. For example, manufacturers use them to monitor assembly lines, while hospitals ensure medical devices operate reliably.

How do predictive maintenance systems differ from preventive maintenance?

Predictive maintenance uses real-time data and AI to predict failures before they happen. Preventive maintenance follows a fixed schedule regardless of equipment condition. Predictive systems save costs by addressing issues only when necessary.

Can small businesses afford predictive maintenance systems?

Yes, small businesses can start with affordable, scalable solutions. Focus on high-priority equipment first. Many vendors offer flexible pricing and cloud-based systems, making it easier to adopt without significant upfront costs.

What kind of data do these systems collect?

These systems collect data like temperature, vibration, pressure, and visual imagery. IoT sensors and cameras gather this information, which AI algorithms analyze to detect patterns and predict failures.

Are predictive maintenance systems difficult to implement?

Implementation can be straightforward with proper planning. Start with a pilot program to test the system on critical equipment. Choose vendors that provide training and support to ensure a smooth transition.

Tip: Begin with a small-scale deployment and expand as you see results. This approach minimizes risks and maximizes ROI.

See Also

Exploring Predictive Maintenance Through Machine Vision Technology

An In-Depth Overview of Machine Vision in Automation

Essential Tips for Equipment Positioning in Vision Systems