Rare Defects: The Silent Profit Killer

Rare defects in manufacturing often go unnoticed but can significantly harm profitability. They lead to hidden costs by disrupting operations, damaging reputations, and reducing financial performance. A survey by Dassault Systèmes highlighted that 20% of manufacturers make poor decisions due to unreliable data, while over 70% saw improvements with accessible data. Addressing these defects ensures operational efficiency and protects profits.

Key Takeaways

Uncommon problems in manufacturing can cause big money losses and hurt reputation. Fix these problems early to save money.

GenX can improve defects detection accuracy by making synthetic defect pictures. This helps companies teach AI tools better and avoid mistakes.

Understanding Rare Defects in Manufacturing

What Defines Rare Defects

Rare defects refer to anomalies in manufacturing that occur infrequently but can have significant consequences. These defects often stem from unique combinations of variables, such as material inconsistencies, equipment malfunctions, or environmental factors. Unlike common defects, rare defects are harder to predict and detect due to their sporadic nature. Their low occurrence rate makes them challenging to study, leaving manufacturers with limited data for analysis. Despite their rarity, these defects pose a substantial risk to product quality and operational efficiency.

Why Rare Defects Are Often Overlooked

Manufacturers frequently overlook rare defects because of their infrequent appearance and the difficulty in identifying them. Traditional inspection systems focus on recurring issues, leaving rare anomalies undetected. Additionally, the scarcity of defect data limits the ability to train AI models effectively. Many manufacturers prioritize addressing common defects, assuming rare defects have minimal impact. However, this assumption can lead to significant risks, including financial losses and reputational damage. The lack of proactive measures to address these anomalies often results in costly consequences.

The Role of GenX Overcome the Rare Defects Bottlenecks

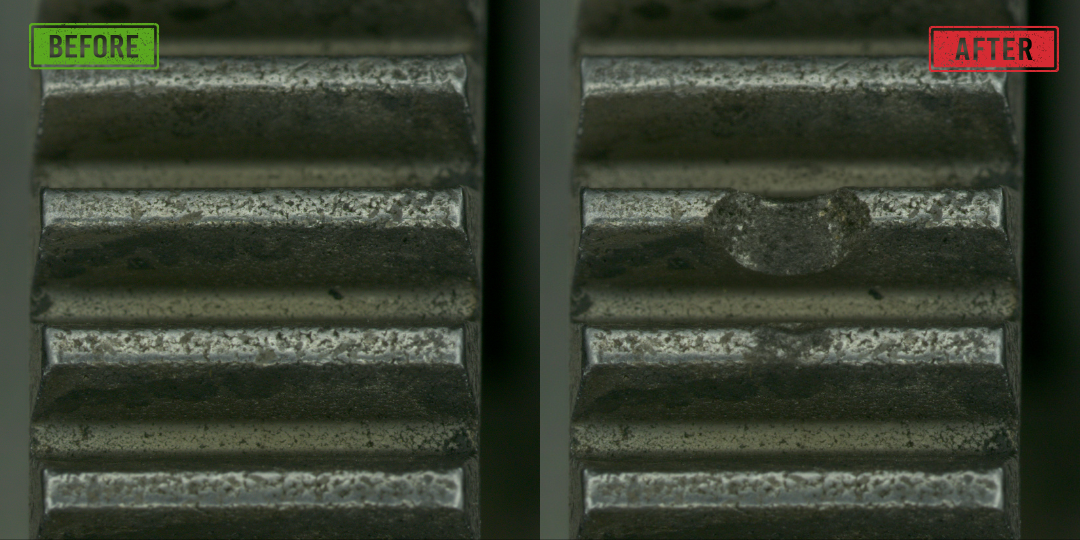

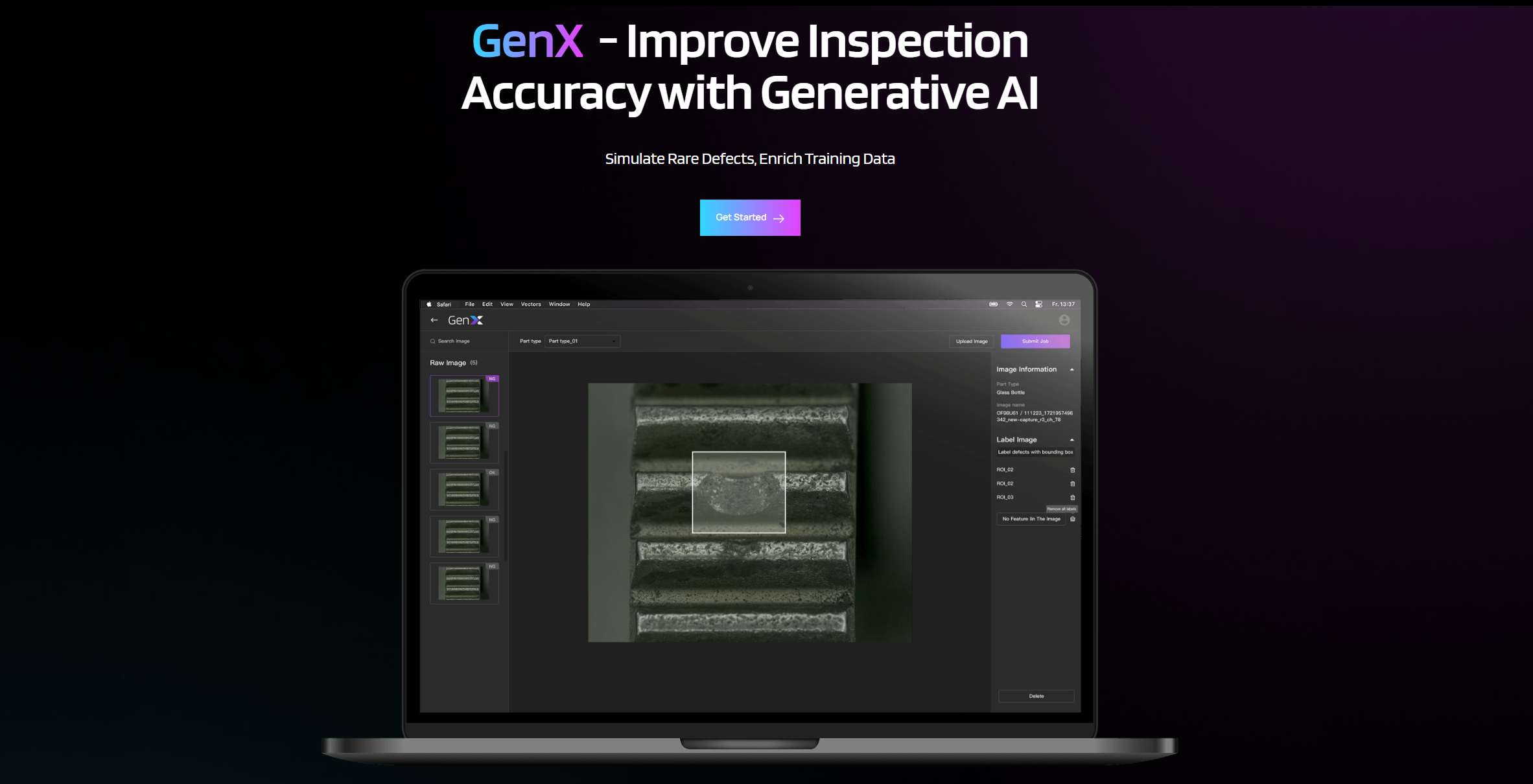

GenX revolutionizes the approach to rare defects in manufacturing by leveraging generative AI to simulate these anomalies. This innovative tool creates synthetic defect images from minimal real-world samples, enabling manufacturers to train AI models with diverse datasets. By generating up to 50 defect images per job, GenX enhances detection accuracy and reduces false positives. Its ability to adapt to high-mix production environments ensures seamless integration with existing systems. GenX empowers manufacturers to mitigate risks associated with rare defects, improving quality control and operational efficiency.

The Hidden Costs of Rare Defects

Financial Losses from Undetected Defects

Rare defects in manufacturing often remain undetected until they cause significant financial damage. These defects can lead to product recalls, warranty claims, and increased production costs. For example, a single defective component in automotive manufacturing can result in millions of dollars in recall expenses. Additionally, undetected defects disrupt supply chains, forcing manufacturers to allocate additional budget to resolve issues. The lack of accurate data on rare defects further complicates cost estimates, making it difficult to predict and manage financial risks effectively.

Reputational Damage and Customer Trust

Rare defects can severely harm a company's reputation. Customers expect high-quality products, and any defect, no matter how rare, can erode trust. Negative reviews and social media backlash amplify the impact, leading to lost sales and reduced customer loyalty. For instance, a cosmetics manufacturer faced lawsuits for failing to disclose harmful chemicals, damaging its brand image. Maintaining customer trust requires robust quality control measures and transparent communication about product safety.

Operational Disruptions and Downtime

Rare defects often cause unexpected operational disruptions. Identifying and addressing these anomalies requires additional resources, delaying production schedules. Downtime not only increases costs but also affects overall manufacturing efficiency. Companies must invest in advanced infrastructure and tools to minimize disruptions. GenX, for instance, helps manufacturers simulate rare defects, enabling proactive measures to reduce downtime and maintain operational continuity.

Regulatory and Legal Risks

Manufacturers face significant regulatory and legal risks due to rare defects. Under strict liability laws, companies are held accountable for defective products, regardless of their quality control efforts. Several legal cases highlight these risks:

Vega v. L’Oreal USA, Inc.: Class action lawsuits for undisclosed harmful chemicals.

Benzene Contamination Cases: Lawsuits for exceeding FDA limits in consumer products.

Goldfarb v. Burt’s Bees, Inc.: Challenges over misleading product labeling.

These cases emphasize the importance of compliance and proactive defect management to avoid costly legal battles.

Real-World Impacts of Rare Defects

Case Study: Product Recalls and Financial Fallout

Rare defects in manufacturing can lead to devastating product recalls, causing significant financial strain. For instance, an automotive company faced a recall due to a rare defect in its braking system. The recall impacted millions of vehicles, resulting in billions of dollars in costs. These expenses included repair services, legal fees, and compensation claims. Additionally, the company had to allocate a larger budget to rebuild its damaged reputation. Such cases highlight the importance of addressing rare defects proactively to avoid unforeseen costs and operational disruptions.

Lessons from Industry Failures

Several industries have experienced failures due to rare defects, offering valuable lessons. A semiconductor manufacturer, for example, improved its yield by 15% after identifying defects using real-time analytics. Similarly, a food processing company optimized its maintenance routines to minimize spoilage and enhance efficiency. These examples underscore the need for robust infrastructure and advanced tools to detect and mitigate risks. Manufacturers must prioritize data-driven approaches to reduce costs and improve operational performance.

How GenX Helps Prevent Costly Mistakes

GenX offers a transformative solution to prevent costly mistakes caused by rare defects. By generating synthetic defect images, it enables manufacturers to train AI models with diverse datasets. This approach reduces defect rates to as low as 3.4 per million opportunities, ensuring near-flawless execution. Its ability to simulate rare defects minimizes risks and enhances quality control, saving costs associated with recalls and downtime.

Strategies to Mitigate Rare Defects

Leveraging GenX for Synthetic Defect Simulation

GenX provides a groundbreaking solution for addressing rare defects in manufacturing. By utilizing generative AI, it creates synthetic defect images from minimal real-world samples. This approach enables manufacturers to train AI models with diverse datasets, improving detection accuracy and reducing false positives. GenX generates up to 50 defect images per job, delivering results within 24 hours. This rapid simulation process minimizes delays and enhances visibility into potential risks. Manufacturers can allocate their budget more effectively by reducing costs associated with defect detection and model training. GenX also integrates seamlessly with existing infrastructure, ensuring smooth adoption without disrupting operations.

Implementing Advanced Quality Control Systems

Advanced quality control systems play a vital role in mitigating rare defects. Statistical Process Control (SPC) tools, such as control charts and root cause analysis, help monitor process variations and identify underlying issues. These tools provide data-driven insights, enabling manufacturers to improve processes and reduce costs. For example, process capability studies assess whether production meets specified limits, while trend analysis identifies patterns over time. Six Sigma, a widely adopted methodology, aims to achieve fewer than 3.4 defects per million opportunities. This approach combines statistical analysis with proactive measures to minimize risks and optimize cost estimates.

Long-Term Benefits of Proactive Defect Management

Enhanced Profitability with GenX

Proactive defect management directly impacts profitability by reducing costs associated with rare defects. GenX enables manufacturers to simulate defects and train AI models effectively, minimizing the risk of undetected anomalies. This approach reduces quality-related costs, such as recalls and warranty claims, while improving production efficiency. A report by Deloitte highlights a 10-20% decrease in quality costs and a 15-30% reduction in inventory holdings when manufacturers adopt proactive strategies. By leveraging GenX, manufacturers can allocate their budget more efficiently, ensuring better cost estimates and faster return on investment. Predictive maintenance, supported by tools like GenX, also extends equipment lifespan and reduces unplanned downtime, further enhancing profitability.

Trend | Impact | Statistical Insight |

|---|---|---|

Reduces unplanned downtime and extends the life cycle of critical equipment. | Pattern recognition in maintenance data, confirmed via chi-square tests, facilitates timely preventive actions. | |

Emphasis on Continuous Improvement | Drives long-term value creation, making the manufacturing process more agile and resilient. | Regular recalibration of expected values reinforces iterative process refinement. |

Strengthened Customer Trust and Brand Loyalty

Mitigating rare defects fosters customer trust and strengthens brand loyalty. Consumers value quality and reliability, and addressing defects proactively ensures a positive customer experience. A 2023 Deloitte report reveals that brands using real-time sentiment analysis recover customer satisfaction scores 20% faster during crises. Additionally, brands that prioritize customer-first actions see a 20% increase in trust, as noted by PwC. Neglecting defect management, however, leads to higher churn rates and reputational damage. Proactive strategies, supported by tools like GenX, enhance visibility into potential risks, ensuring consistent product quality and customer satisfaction.

A 2023 Deloitte report indicates brands using real-time sentiment analysis during crises achieve a 20% faster recovery in customer satisfaction scores.

Brands that fail to adopt these strategies face a 30% higher churn rate post-crisis.

A PwC study found that 73% of consumers consider customer experience crucial, leading to a 20% increase in trust for customer-first brands.

Improved Operational Efficiency and Compliance

Proactive defect management improves operational efficiency by reducing delays and optimizing processes. GenX enhances data accuracy and visibility, enabling manufacturers to identify inefficiencies and refine operations. Reports from the Manufacturing Institute show a 25% reduction in downtime and a 20% increase in equipment lifespan with proactive strategies. Additionally, compliance with regulatory standards becomes more manageable, reducing legal risks and associated costs. By integrating advanced tools like GenX, manufacturers can build robust infrastructure, streamline workflows, and achieve long-term operational excellence.

Source | Improvement Metrics |

|---|---|

Deloitte (2021) | 10-12% improvement in factory output, 10-20% decrease in quality costs, 15-30% reduction in inventory holdings |

Manufacturing Institute (2022) | 25% reduction in downtime, 20% increase in equipment lifespan |

International Federation of Robotics (2023) | 30% productivity increase, 25% quality improvements |

PwC (2022) | 20-30% increase in throughput, 10-30% decrease in quality-related costs, 20-50% reduction in time to market |

Rare defects in manufacturing silently erode profitability by introducing hidden costs and risks. Proactively addressing these anomalies with tools like GenX ensures financial stability and operational efficiency. Investing in advanced infrastructure and data-driven strategies optimizes cost estimates, protects the budget, and strengthens long-term success. Robust infrastructure minimizes risks and enhances operational resilience.

FAQ

What industries benefit the most from using GenX?

GenX supports industries like automotive, electronics, EV batteries, semiconductors, and packaging. These sectors require high-accuracy visual inspection to detect rare defects efficiently.

How does GenX improve defect detection accuracy?

GenX generates synthetic defect images using generative AI. This process enriches training datasets, enabling AI models to identify rare defects with up to 9X fewer false positives.

Tip: Manufacturers can integrate GenX with existing vision systems for seamless defect detection.

How quickly can GenX deliver results?

GenX generates up to 50 synthetic defect images per job within 24 hours. This rapid turnaround accelerates model development and minimizes production delays.

See Also

Comparing Traditional And Generative AI Techniques For Defect Detection

Evaluating ROI For Automated Visual Inspection Systems By 2025

Expert Techniques For OD Scratch Inspection With Machine Vision

Simplifying Quality Inspection Processes In Semiconductor Manufacturing