What Makes Triggering Essential in Machine Vision

Triggering plays a vital role in ensuring precise timing within a machine vision system. It allows you to capture images at the exact moment needed, enabling accurate analysis and decision-making. Without proper triggering, the system may produce unreliable results or experience delays. A triggering machine vision system achieves higher accuracy and efficiency by synchronizing image capture with real-time events. This synchronization minimizes errors and ensures smooth operations, making triggering an essential component for any application relying on machine vision technology.

Key Takeaways

- Triggering helps cameras take pictures at the right time. This improves accuracy and lowers mistakes in machine vision systems.

- Picking internal or external triggering depends on what you need. Internal is steady, but external works better in changing situations.

- A good trigger sensor improves image quality by timing it right. This reduces motion blur and cuts down on background noise.

- Using triggering systems makes work faster and smoother. It allows nonstop checking in fast production lines.

- Advanced triggering tools can greatly improve how machine vision systems work in many tasks.

Understanding Triggering in a Machine Vision System

What Is Triggering?

Triggering in machine vision refers to the process of signaling a camera to capture an image at a specific moment. This signal ensures that the camera operates in sync with the events happening in its environment. Without triggering, the camera might capture images at random intervals, leading to inaccurate or irrelevant data.

Triggering mechanisms are essential in many machine vision applications. For example:

- A trigger can signal a camera to inspect extruded beadings on a conveyor belt.

- In optical character recognition (OCR), a programmable logic controller (PLC) sends a signal when an object is in position for imaging.

- For cylindrical objects, an encoder triggers a line scan camera as the object rotates on a turntable.

- A photo-sensor can trigger a camera to inspect the internal sections of a refrigerator when it is detected.

These examples highlight how triggering ensures precise image capture, making it a cornerstone of machine vision systems.

The Role of Timing in Machine Vision

Timing plays a critical role in the success of machine vision systems. It determines when the camera captures an image and how that image aligns with the system's processing tasks. Proper timing ensures that the camera captures the right frame at the right moment, avoiding unnecessary or missed images.

Statistical analysis supports the importance of timing in machine vision. For instance, the MV-4 camera system demonstrated superior accuracy in 3D motion analysis compared to a reference system. It achieved a mean merit score difference of 0.4 mm for static calibration and 1.3 mm for dynamic calibration. This level of precision is vital for applications like motion analysis, where even minor errors can lead to significant issues.

By ensuring accurate timing, triggering helps machine vision systems achieve high levels of precision and reliability. This is especially important in industries where even small mistakes can result in costly errors.

Types of Triggering: Internal vs. External

Triggering in machine vision can be classified into two main types: internal and external. Each type serves a specific purpose and is suited for different applications.

-

Internal Triggering: The camera itself generates the trigger signal. This type is useful for applications where the timing of image capture is consistent and predictable. For example, a camera might capture images at regular intervals without relying on external input.

-

External Triggering: An external device, such as a sensor or encoder, sends the trigger signal to the camera. This type is ideal for dynamic environments where image capture depends on external events. For instance, a photo-sensor might trigger a camera when an object passes through a specific point on a conveyor belt.

Choosing the right type of triggering depends on your application's requirements. Internal triggering offers simplicity and consistency, while external triggering provides flexibility and adaptability to real-world conditions.

How Triggering Works in a Machine Vision Camera

The Function of a Trigger Signal

A trigger signal acts as the command that tells a machine vision camera when to capture an image. It ensures that the camera operates in sync with external events, enabling precise and timely image acquisition. You can think of it as the "go" signal for the camera, ensuring that every frame captured aligns with the system's requirements.

Trigger signals can be based on various conditions, such as logic patterns, ranges, or external inputs. For example:

- Words define specific logic patterns in binary or hexadecimal formats.

- Ranges capture events occurring between a low and high value.

- Counters track a user-programmed number of events.

- Signals respond to external inputs like system resets.

- Glitches detect pulses between acquisitions.

- Timers measure elapsed time or event durations.

- Analog triggers respond to analog characteristics and cross-trigger logic analyzers.

These conditions allow you to tailor the trigger signal to your application's needs, ensuring optimal performance. For instance, timing measurements on a 'D' flip-flop demonstrated a resolution of 2 ns, emphasizing the importance of high-resolution acquisition for accurate signal event capture.

Synchronization Between the Camera and Trigger Sensor

Synchronization is the backbone of a machine vision camera's triggering mechanism. It ensures that the camera and the trigger sensor work together seamlessly. Without synchronization, the camera might capture images at the wrong moment, leading to errors in data processing.

Recent experiments have shown how synchronization can improve image capture quality. Researchers tested biphasic and triphasic illumination schemes to optimize triggering. In the biphasic scheme, UV illumination occurred during image capture, causing light leakage and reducing signal-to-noise ratios. The triphasic scheme resolved this issue by turning off UV illumination just before image capture. This allowed natural fluorescence to subside while maintaining the dye's fluorescence, resulting in clearer and more accurate images.

By synchronizing the camera with the trigger sensor, you can achieve better image quality and reduce background noise. This is especially important in applications like industrial automation, where precision is critical.

Workflow of Triggered Image Capture

The workflow of triggered image capture involves several steps that ensure the camera captures the right image at the right time. Here's how it typically works:

- Event Detection: A trigger sensor detects an event, such as an object passing a specific point.

- Signal Generation: The sensor sends a trigger signal to the camera.

- Camera Activation: The machine vision camera receives the signal and prepares to capture an image.

- Image Capture: The camera captures the image based on the signal's timing.

- Data Processing: The captured image is sent to the system for analysis and decision-making.

This workflow ensures that every image captured is relevant and useful for the system's tasks. Whether you're using a line scan camera for inspecting cylindrical objects or an area scan camera for broader applications, the workflow remains consistent. A master camera often coordinates multiple cameras in complex systems, ensuring synchronization across all devices.

By following this workflow, you can maximize the efficiency and accuracy of your machine vision system. It minimizes errors and ensures that the system operates smoothly, even in dynamic environments.

Key Components of a Triggering Machine Vision System

The Role of the Trigger Sensor

The trigger sensor is the heart of any triggering machine vision system. It detects events in real time and sends signals to the camera, ensuring precise image capture. You can think of it as the system's eyes, constantly monitoring for changes or movements. Event-based sensors, for instance, excel in high-speed environments. They can process up to 10,000 frames per second while consuming minimal power. Compared to traditional frame-based systems, they offer lower latency and require significantly less data processing. This makes them ideal for applications like high-speed counting or inspections.

| Feature | Event-Based Sensors | Traditional Frame-Based Systems |

|---|---|---|

| Speed | Up to 10,000 fps and more | 24-60 fps |

| Power Consumption | Milli-watt to micro-watt range | Higher power consumption |

| Data Processing Requirements | 10-10,000x less than frame-based systems | Higher data processing needs |

| Latency | Low end-to-end latency | Higher latency due to frame capture |

| Dynamic Range | More than 120 dB | Limited dynamic range |

| Application Suitability | Ideal for high-speed counting, inspection | General applications |

By choosing the right trigger sensor, you can optimize your system for speed, accuracy, and efficiency.

Controllers and Signal Processing

Controllers and signal processors act as the brain of the system. They interpret signals from the trigger sensor and coordinate with the camera. These components ensure that the camera captures images at the exact moment required. Advanced controllers can handle complex logic patterns, such as counting events or measuring time intervals. For example, a controller might use a timer to trigger the camera after a specific delay, ensuring precise synchronization.

Performance metrics play a crucial role here. High-resolution sensors and reliable controllers improve measurement precision and reduce errors. When paired with robust signal processing, these components enhance the overall reliability of your machine vision system.

| Key Component | Description |

|---|---|

| Camera Quality | Essential for capturing high-resolution images necessary for accurate inspection. |

| Lighting | Critical for ensuring consistent image quality; strobed lighting can help mitigate ambient light effects. |

| Sensor Specifications | Sensor resolution is vital for measurement precision and detecting small objects. |

| Optics | The choice of lens affects the working distance and field of view, impacting overall system design. |

| Performance Metrics | Metrics related to image quality and system reliability are crucial for evaluating system effectiveness. |

Integration with Machine Vision Cameras and Lighting

Integrating cameras and lighting with triggering mechanisms ensures optimal performance. High-speed cameras, for example, are essential for monitoring fast-moving production lines. Sensors like photoelectric sensors detect changes in speed and trigger the camera accordingly. This synchronization allows you to capture clear, high-quality images even in dynamic environments.

Lighting plays an equally important role. LED light heads, optimized for radiant power, provide consistent illumination. Strobe overdriving enhances light output by allowing higher current through LEDs at low duty cycles. Synchronizing strobe flashes with the camera ensures effective inspections. For instance, vibration analysis systems can trigger cameras to capture images during mechanical failures, enabling quick diagnostics.

- High-speed cameras are used for process monitoring in production environments.

- Photoelectric sensors detect changes in production line speed, triggering image capture.

- Vibration analysis systems monitor equipment conditions and trigger cameras based on failures.

- Machine vision cameras integrate with event recorders to capture high-speed images for analysis.

- LED light heads are optimized for maximum radiant power while maintaining stability.

- Strobe overdriving allows for higher current through LEDs at low duty cycles, enhancing light output.

- Synchronization between strobe flashes and the camera is crucial for effective inspections.

By integrating these components, you can create a machine vision system that delivers precision and reliability across various applications.

Benefits of Triggering in Machine Vision Systems

Precision and Accuracy in Image Capture

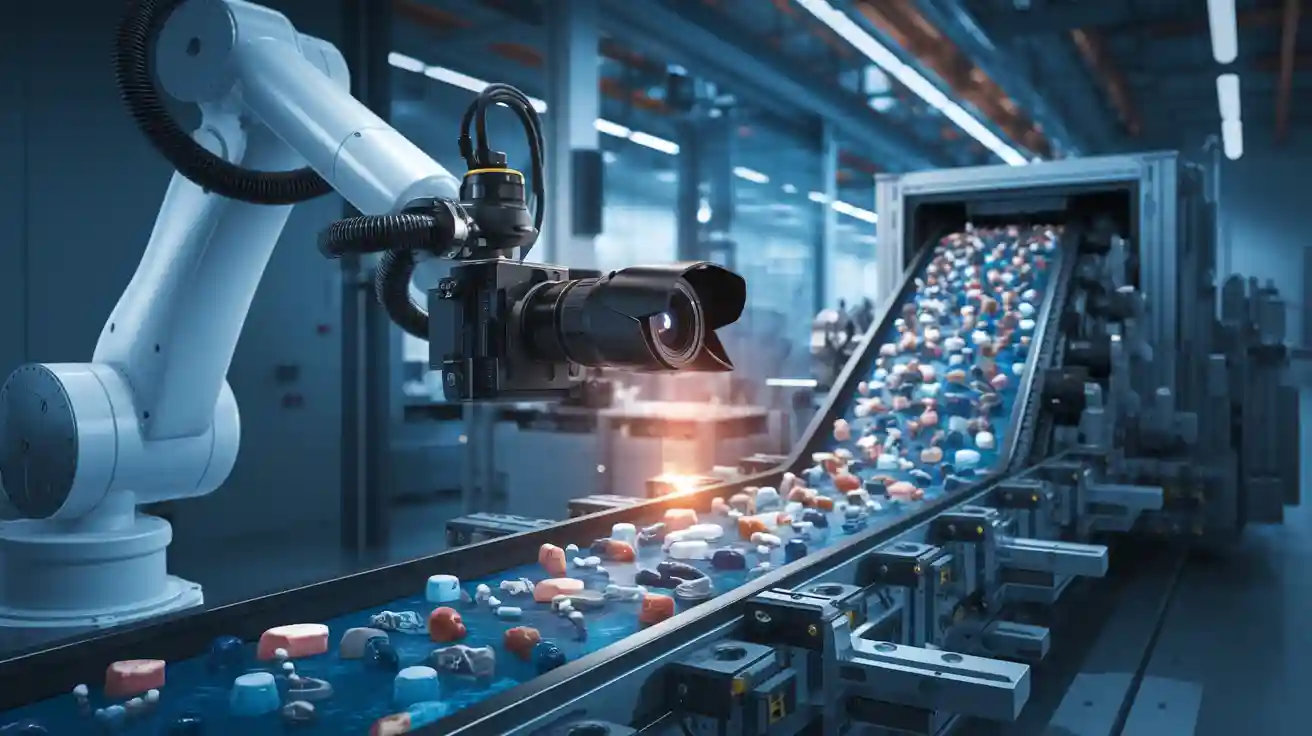

Triggering enhances the precision of image capture by ensuring cameras operate at the exact moment required. This synchronization allows you to capture images that align perfectly with the system's needs, reducing the chances of irrelevant or blurry frames. For example, when inspecting products on a conveyor belt, triggering ensures the camera captures each item as it passes through the inspection zone. This process is vital for applications like flaw detection, where even the smallest defect must be identified.

Research highlights how triggering algorithms improve diagnostic accuracy in clinical settings. Although the focus is on healthcare, the findings emphasize the potential for reducing errors in machine vision systems.

| Findings | Description |

|---|---|

| Diagnostic Errors | Trigger algorithms may reduce delayed diagnosis and improve diagnostic accuracy. |

| Clinical Settings | Evidence primarily focuses on healthcare diagnostics, not specifically on machine vision systems. |

| Recommendations | Future work should establish effectiveness and cost-effectiveness in real-world settings. |

By leveraging triggering mechanisms, you can achieve unparalleled precision in image capture, ensuring reliable results across various applications.

Enhanced Efficiency and Throughput

Triggering plays a key role in improving the efficiency and throughput of machine vision systems. It allows cameras to capture images without delays, enabling continuous inspection of fast-moving objects. For instance, in high-speed production lines, slave cameras synchronized with master cameras ensure seamless operation. This setup minimizes bottlenecks and maximizes productivity.

Case studies demonstrate how triggering enhances system performance. In one scenario, an embedded system used DMA for circular memory transfer and double-buffering to achieve high sampling rates without data loss. Another example involved a microcontroller transmitting image data via SPI, reducing CPU usage by 70% and enabling concurrent tasks.

| Case Study | Scenario | Solution | Outcome |

|---|---|---|---|

| High-Speed Data Acquisition | An embedded system collects data from an ADC at high sampling rates. | Configured DMA for circular memory transfer and double-buffering. | Achieved high sampling rates without data loss, freeing CPU for analysis. |

| Image Transmission via SPI | A microcontroller transmits image data to an external display. | Configured DMA for reading image data and burst mode for throughput. | Reduced CPU usage by 70%, enabling concurrent tasks. |

| Audio Playback System | A portable audio player streams audio data to a DAC. | Used DMA in circular mode for continuous audio feeding. | Seamless playback with minimal power consumption. |

These examples highlight how triggering optimizes system efficiency, allowing you to handle high-speed operations with ease.

Reduction in Errors and Downtime

Triggering minimizes errors and downtime by ensuring cameras capture images at the right moment. This precision reduces the likelihood of missed inspections or incorrect data processing. For example, slave cameras can work in tandem with master cameras to maintain synchronization, even in complex systems. This coordination ensures every frame captured contributes to accurate analysis.

In industrial settings, triggering mechanisms help detect issues early, preventing costly downtime. For instance, vibration analysis systems use triggering to capture images during mechanical failures. This approach allows you to identify problems quickly and take corrective action, reducing the impact on production.

By integrating triggering into your machine vision system, you can achieve higher reliability and lower operational disruptions. This makes it an essential tool for maintaining smooth and efficient workflows.

Real-World Applications of Triggering in Machine Vision

Industrial Automation and Quality Control

Triggering plays a vital role in industrial automation. It ensures that your image acquisition system captures precise frames during production processes. For example, when inspecting products on a conveyor belt, a hardware trigger can synchronize the camera with the movement of items. This coordination allows you to detect defects or inconsistencies without slowing down operations. Sensors, such as photoelectric sensors, act as the trigger source, signaling the camera to capture images at the right moment.

In quality control, triggering mechanisms improve accuracy. A rolling shutter camera can capture high-resolution images of fast-moving objects, while a global shutter camera eliminates motion blur for stationary inspections. By adjusting trigger settings, you can tailor the system to meet specific inspection requirements. This flexibility ensures that your acquisition process remains efficient, even in dynamic environments.

Robotics and Autonomous Systems

Robotics relies heavily on triggering for precise image acquisition. Autonomous systems, such as drones or robotic arms, use sensors to detect environmental changes and activate cameras. For instance, a hardware trigger might initiate image capture when a robot identifies an obstacle. This real-time acquisition enables the robot to make quick decisions, enhancing its performance and safety.

Trigger mechanisms also support advanced applications like object recognition and navigation. By using a rolling shutter camera, you can capture detailed images of moving objects, while a global shutter camera provides distortion-free images for static scenes. These cameras work seamlessly with sensors to ensure accurate data acquisition, even in challenging conditions. Trigger delay adjustments further refine the timing, allowing the system to adapt to varying speeds and distances.

Medical Imaging and Diagnostics

Triggering enhances diagnostic accuracy in medical imaging. Your image acquisition system can synchronize with hardware triggers to capture critical moments during procedures. For example, when imaging a patient's heart, sensors detect the heartbeat and trigger the camera to capture images during specific phases. This precision ensures that the images are clear and useful for diagnosis.

Research highlights the importance of calibration in medical imaging. Radiologists often use terms like "possible" or "likely" to describe conditions, which can lead to uncertainty. By treating these phrases as probability distributions, medical systems can quantify diagnostic reliability. This approach improves communication and ensures accurate assessments. Trigger mechanisms play a key role in this process by enabling precise image acquisition during critical moments.

In addition, rolling shutter cameras and global shutter cameras provide flexibility for different imaging needs. Whether capturing dynamic movements or static structures, these cameras ensure high-quality images. Trigger mode adjustments allow you to optimize the system for specific medical applications, enhancing patient outcomes.

Triggering forms the backbone of machine vision systems. It allows you to achieve precise image capture, ensuring your system operates with accuracy and efficiency. By integrating reliable triggering mechanisms, you can enhance productivity and reduce errors in your applications.

Tip: Adopting advanced triggering solutions can unlock the full potential of machine vision technology, helping you stay ahead in competitive industries.

Whether in industrial automation, robotics, or medical imaging, triggering ensures your system delivers consistent and reliable results.

FAQ

What is the purpose of triggering in machine vision systems?

Triggering ensures your camera captures images at the exact moment needed. This synchronization improves accuracy and efficiency, especially in dynamic environments. Without triggering, your system might miss critical events or capture irrelevant data, leading to errors in analysis.

How do external triggers differ from internal triggers?

External triggers rely on sensors or devices to signal the camera, making them ideal for unpredictable events. Internal triggers, generated by the camera itself, work best for consistent, timed image capture. Your choice depends on the application's requirements.

Can triggering improve image quality?

Yes, triggering enhances image quality by aligning the camera's capture with optimal conditions. For example, synchronized lighting and triggering reduce motion blur and improve clarity. This ensures your system produces high-quality images for accurate analysis.

What types of sensors are used for triggering?

Common sensors include photoelectric sensors, encoders, and event-based sensors. Photoelectric sensors detect objects, encoders track motion, and event-based sensors excel in high-speed environments. Choosing the right sensor depends on your system's speed and precision needs.

Is triggering necessary for all machine vision applications?

Not always. Triggering is essential for applications requiring precise timing, such as quality control or robotics. For static or low-speed tasks, continuous image capture without triggering might suffice. Evaluate your system's goals to decide.

Tip: Use triggering when timing and accuracy are critical to avoid errors and maximize efficiency.

See Also

Exploring Thresholding Techniques in Vision Systems

Fundamental Principles of Edge Detection in Vision

An Overview of Image Processing in Vision Systems